Are you having trouble picking the proper oil-immersed transformer for your power distribution needs? These important parts can be very complicated. Don’t worry! This detailed guide will clear up any confusion you may have about oil-immersed transformers, giving you the knowledge you need to make smart choices and improve the operation of your power system.

The Basics: The Main Parts and How Oil-Immersed Transformers Work

Do you just know what oil-immersed transformers are from books? A lot of specialists don’t pay attention to the small things that make these products work so well. Let’s take a closer look at the main parts and how they work. This will provide you more information that will help you comprehend and make better decisions.

The “Blood” That Can’t Be Missed: How Transformer Oil Keeps Things Cool and Insulated

Oil-immersed transformers rely on transformer oil 1to keep them cold and insulated. This fluid made from mineral oil has great dielectric strength, thermal conductivity, and chemical stability. Here’s why it’s important:

- Insulation: The oil fills up the spaces between the windings, which keeps the electricity from breaking down.

- Cooling: It moves heat from the core and windings to the outside of the transformer quickly and easily.

- Diagnostics: Analyzing oil on a regular basis can show problems that could become serious.

Key properties of transformer oil:

| Property | Typical Range | Importance |

|---|---|---|

| Dielectric Strength | 30-50 kV/mm | Prevents electrical breakdown |

| Viscosity | 8-12 cSt at 40°C | Affects cooling efficiency |

| Pour Point | -40°C to -60°C | Ensures fluidity in cold climates |

| Flash Point | >140°C | Safety indicator for fire risk |

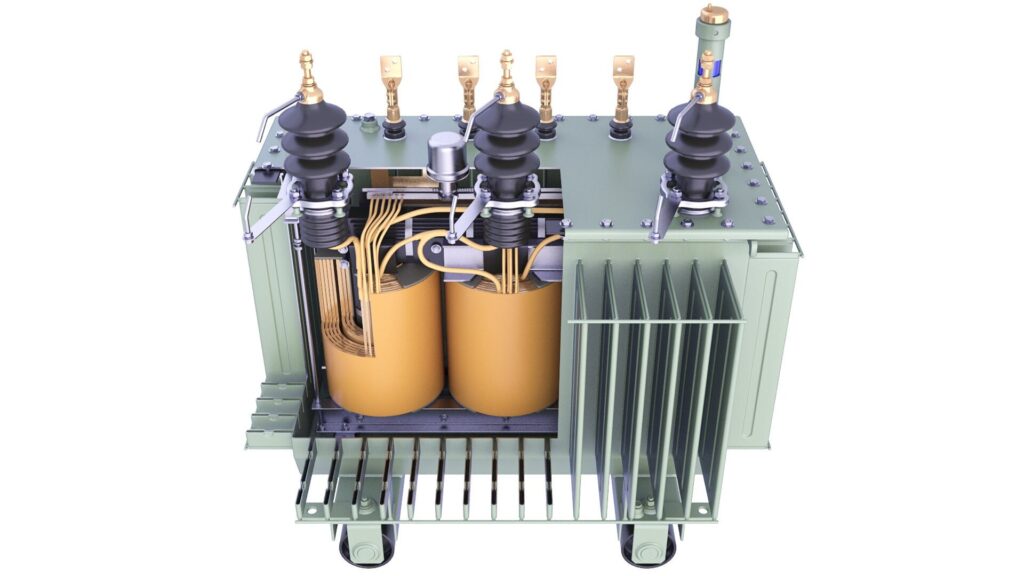

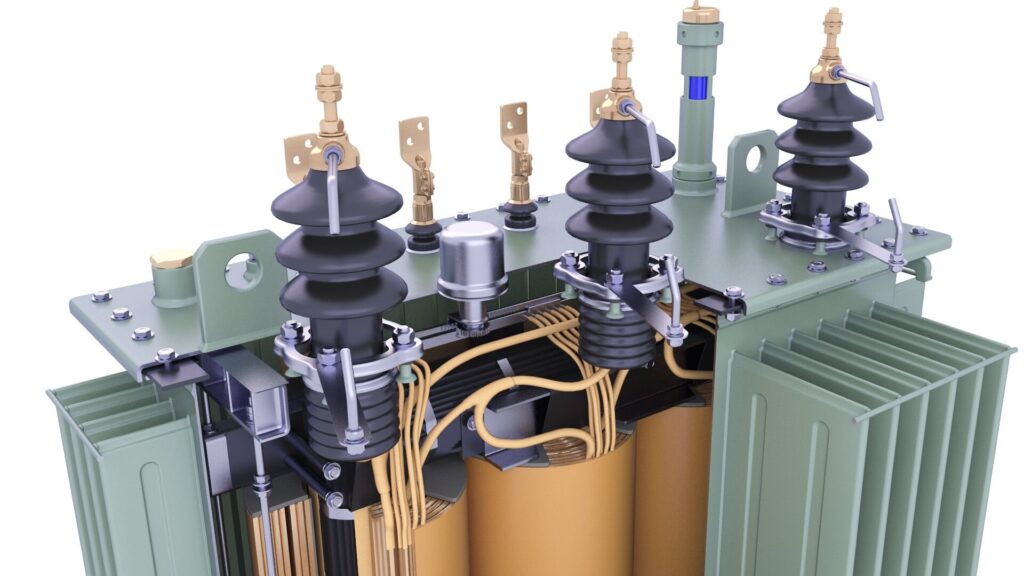

A close look at the technology behind key components, from core to casing

To understand how a transformer works as a whole, you need to know how the basic parts work together:

- Core: The core is usually made of grain-oriented silicon steel2, which lets magnetic flux flow through it easily.

- Windings: Primary and secondary coils, which are commonly made of copper or aluminum, move energy through electromagnetic induction.

- Bushings: These insulated openings let conductors safely leave the transformer tank.

- Tank: The sealed container holds all of the internal parts and the insulating oil.

- Cooling system: Radiators or fans help get rid of heat, which is important for keeping everything running smoothly.

Innovations in core materials, like amorphous metal cores3, can cut down on no-load losses by a lot, which makes the whole system more efficient.

Value is based on performance: Learning about the most important technical aspects of oil-immersed transformers

Are you feeling overwhelmed by all the technical details? You’re not the only one. A lot of buyers only look at the power rating and don’t think about other important factors that affect long-term performance and cost-effectiveness. Let’s look at the most significant things to think about.

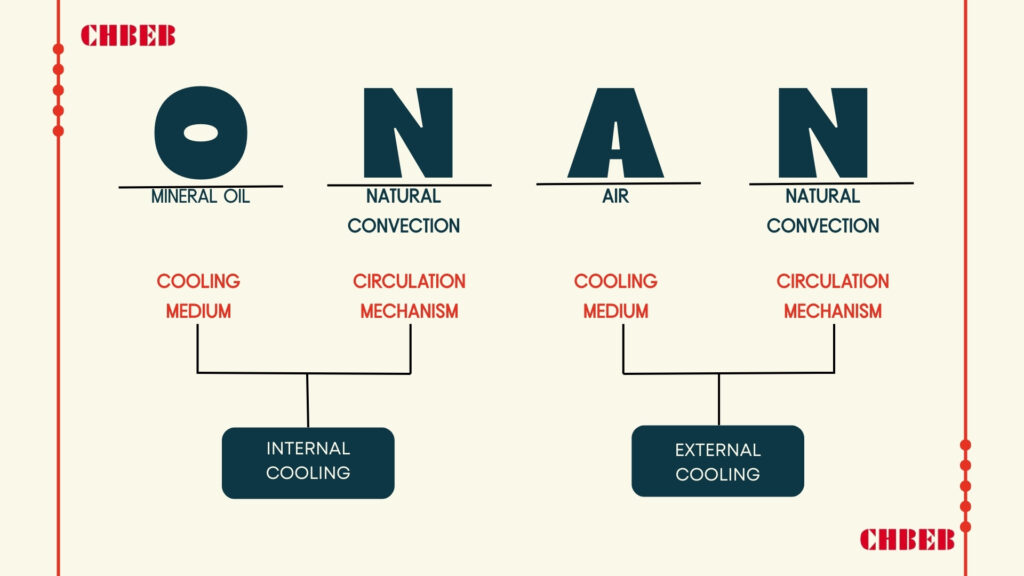

Cooling Methods: The Key to a Transformer’s “Endurance”

For a transformer to last a long time and work well, it needs to be cooled properly. The way a transformer is cooled has a direct effect on how much load it can handle and how long it will last. Some common ways to cool things down are:

- ONAN (Oil Natural Air Natural): Uses natural oil flow and air cooling.

- ONAF (Oil Natural Air Forced): Uses fans to make the air cooler.

- OFAF (Oil Forced Air Forced): Uses fans and oil pumps to make cooling better.

- ODAF (Oil Directed Air Forced): Sends oil through windings to cool things down as much as possible.

Choosing the right way to cool down depends on things like:

- The temperature outside

- Profile of the load

- Setting up the environment

- Ability to do maintenance

Windings and Core: The Best Way to Balance Loss and Impedance

To get the most performance out of a transformer, it’s important to balance losses and impedance:

- No-load losses happen in the core because of hysteresis and eddy currents.

- Load losses happen because of resistance in the windings and stray losses.

- Impedance voltage: affects the current and voltage regulation in a short circuit.

Think about these trade-offs:

- Lower impedance makes voltage regulation better, but it also makes short-circuit current higher.

- Cutting down on losses usually means higher material costs and bigger transformers.

To make a smart choice, think about what you really need:

- Load profile (fixed vs. changing)

- Life expectancy

- Costs of energy

- Limited space

Operation, Maintenance, and Safety: Making Sure Transformers Work Well for a Long Time

Have you thought about how your choice of transformer would affect you in the long run? To get the best performance and longest life out of something, it needs to be used and cared for properly. Let’s look at some important ways to make sure your transformer runs well and safely for a long time.

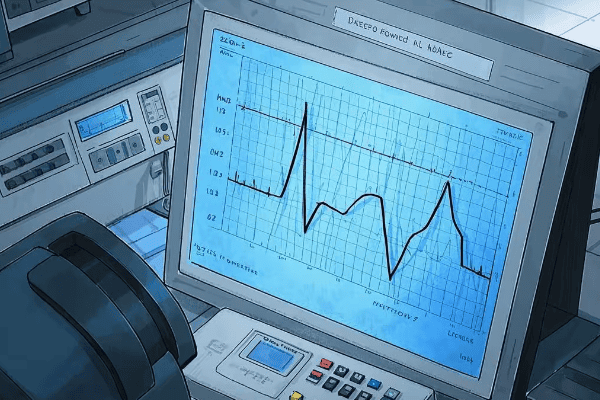

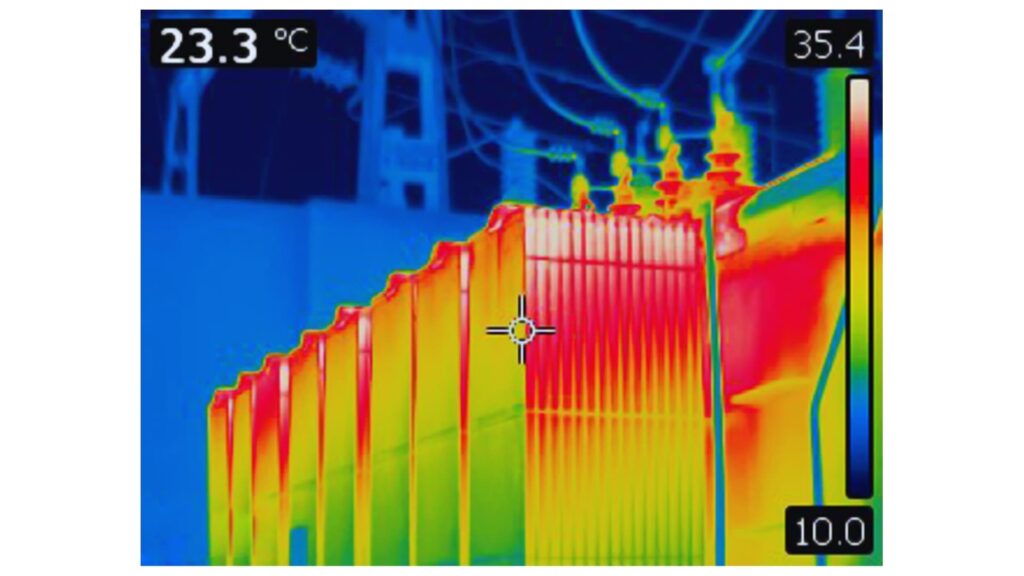

Using oil analysis to check health: finding and fixing common problems

Regularly checking the oil in a transformer is the best way to tell how healthy it is. It can show:

- Moisture content: Too much moisture might damage insulation.

- Acidity: Shows that oil is breaking down and may be corroding.

- Dissolved gas analysis (DGA)4 finds problems inside the system, such as partial discharge or overheating.

Common signs of a problem:

- High hydrogen: Partial discharge

- High acetylene: Arcing

- More carbon monoxide: Paper insulation breaks down

Things you can do to stop it:

- Set up a consistent timetable for taking oil samples

- Use online systems to keep an eye on important transformers.

- When necessary, do oil filtering or regeneration on time.

Fire Protection and Environmental Safety: Keeping Oil-Immersed Transformers Safe

Never put safety off till later. Think about these important things:

- Protection from fire:

- Put up fire barriers and deluge systemss5

- In places where there is a lot of risk, use fluids that don’t catch fire as easily, like silicone or ester-based oils.

- Environmental protections:

- Set up the right systems to hold oil in place

- Use oils that break down in nature when you can

- Things to think about when it comes to earthquakes:

- Make sure the anchors are in the right place in areas that are likely to have earthquakes.

- Think about bushings and accessories that are rated for seismic activity.

Regular safety checks and drills can help find and fix possible problems before they become big ones.

Conclusion

Oil-immersed transformers are complex yet crucial components in power systems. You can make smart choices to improve performance, efficiency, and safety if you know their fundamental technology, important parameters, and maintenance needs. Keep in mind that the appropriate option today will make sure that power is distributed safely for years to come.

- Transformer oil. Wikipedia. Available at: ↩︎

- Grain-oriented electrical steels. ScienceDirect. Available at: ↩︎

- Amorphous metal transformer cores. IEEE Xplore. Available at: ↩︎

- Dissolved Gas Analysis (DGA) for Transformers. All About Circuits. Available at: ↩︎

- Fire protection solutions for transformers. Schneider Electric. Available at: ↩︎

Want to explore detailed specifications and models? You can download our product catalog or browse our website to learn more about CHBEB’s transformer solutions.

A Detailed Look at Oil-Immersed Transformers: From Basic Definition to Key Parts

Intro (PAS): Choosing the wrong transformer can lead to power outages, overheating, and expensive downtime. These hazards are worse when purchasers don’t understand the basics of oil. Find out how they function, which pieces are important, and how to keep them in good shape so you don’t make mistakes and have reliable performance over time.

What Is an Oil-Immersed Transformer? — Idea and How It Works

PAS lead: A lot of teams mix up oil-immersed with other designs, which leads to mis-specification. Not knowing “why oil?” makes decisions worse. Understanding the idea and the principle helps you choose safe, effective tools for tough jobs.

What does it mean and what makes it special? Why does it need “oil”?

An oil-immersed transformer moves energy between circuits using electromagnetic induction1. Its active elements are completely submerged in insulating oil. The oil does three important things:

- Insulation keeps the dielectric strength between high-voltage parts high, which stops flashover.

- Cooling: Takes heat from the windings and core and sends it to the radiators to be released.

- Protection: It keeps moisture and oxygen out, which slows down the aging and oxidation of insulation.

Oil-immersed units are prevalent in heavy industry, utility substations, and high-capacity power plants because they cool and insulate better.

How it works: Using electromagnetic induction in real life

According to Faraday’s Law, AC current in the main winding makes a magnetic flux in the laminated core, which makes voltage in the secondary winding. Oil immersion provides safe insulation and good heat removal, which keeps efficiency stable and extends service life.

- AC in primary → magnetic flux that changes direction in core

- Flux linkage → voltage in the secondary circuit

- Oil and paper system: stable under load in terms of thermal and dielectric properties

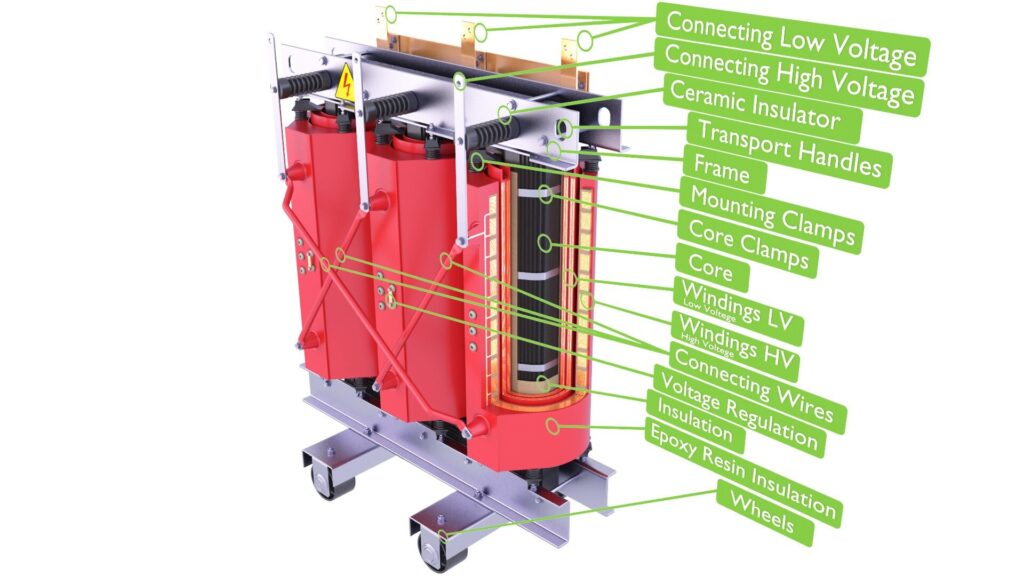

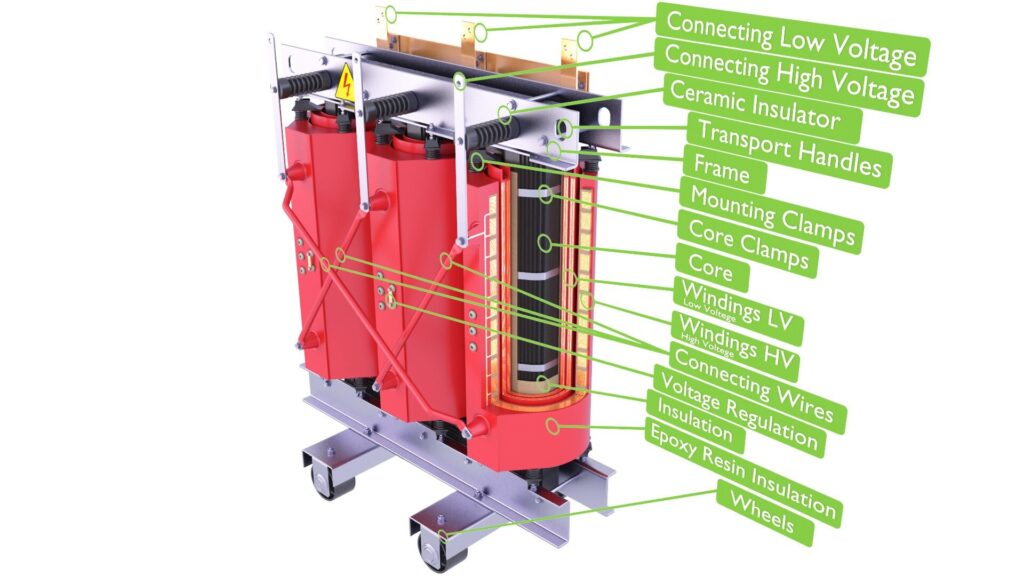

Breaking Down the Main Parts: Oil, Core, Windings, and Other Important Parts

PAS lead: Rating alone doesn’t usually cause underperformance; it’s usually parts that are left out. You can learn how to check, maintain, and specify things for long, reliable service by learning about oil, core, windings, and auxiliaries.

The “Core Medium” of Transformer Oil2

Transformer oil is more than just a coolant; it’s the living substance that keeps the system safe and stable:

- Electrical insulator: Stops electrified items from arcing within.

- Cooling medium: transfers heat to radiators or coolers so it can be released.

- Moisture barrier: Keeps dampness from getting into cellulose (paper) insulation.

- Condition indicator: Dissolved Gas Analysis3 (DGA) and dielectric tests show problems and wear and tear.

Depending on the voltage class, environmental policy, and fire safety needs, the selection ranges from mineral oils to synthetic/ester oils.

The “Heart” of the Transformer: Core and Windings

The laminated steel core reduces eddy currents and directs magnetic flux. The windings, which might be made of copper or aluminum, convey current and move energy through the core’s flux route.

- Primary winding: Connected to the power source; creates magnetic flux.

- Secondary winding: Sends power to the load and gets induced voltage.

- Paper, varnish, spacers, and oil work together to keep the insulation system from breaking down.

Modern systems that use optimized core geometry, the right conductor, and oil immersion usually get efficiencies of above 98%.

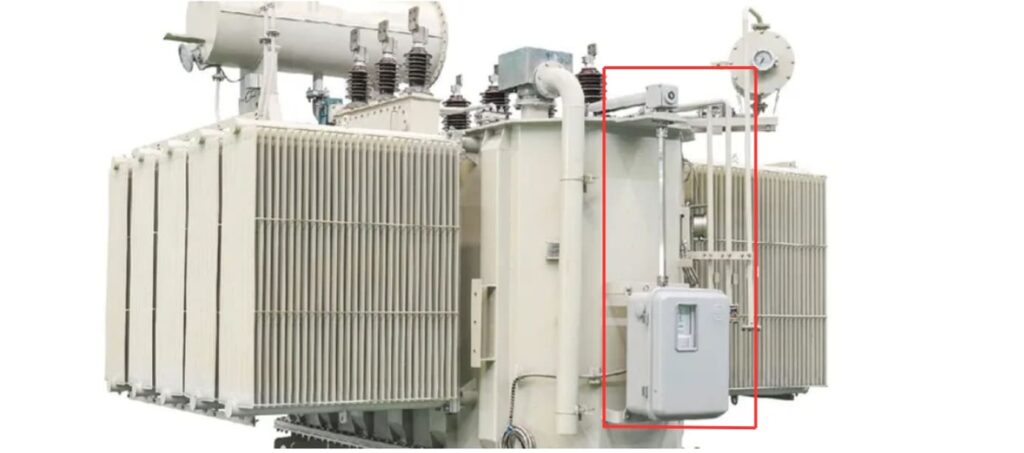

Oil tank, radiator, and other extra parts

- Main tank: An enclosure that can withstand pressure and holds the core, windings, and oil.

- Radiators and fins make the surface area bigger so that hot oil may lose heat more easily.

- The conservator tank keeps the oil from expanding or contracting when the temperature changes.

- Silica-gel breather: It keeps moisture from getting in by drying out the air that comes in.

- Buchholz relay4: Protects early by finding gas buildup from internal problems.

- Temperature gauges and indicators: Keep an eye on the levels and temperatures of the winding and oil.

How to Choose Between Oil-Immersed and Dry-Type Transformers and Important Maintenance Tips

PAS lead: Picking the wrong kind can lead to higher costs, safety issues, and failures that could have been avoided. To choose with confidence and use securely, compare features, match applications, and do the necessary maintenance.

Advantages and Disadvantages Compared: Cooling, Insulation, Cost, and Environmental Impact

| Feature | Oil-Immersed Transformers | Dry-Type Transformers |

|---|---|---|

| Cooling | Excellent; oil circulation + radiators (ONAN/ONAF) | Moderate; air flow or resin encapsulation |

| Insulation | Oil + paper; high dielectric strength | Epoxy resin or air system |

| Initial Cost | Generally lower at high ratings | Often higher |

| Maintenance | Requires oil testing/monitoring | Lower routine maintenance |

| Fire Risk | Higher; oil is flammable | Lower; no oil |

| Environmental | Potential for oil leakage/pollution | Cleaner footprint, indoor-friendly |

For high-voltage, outdoor, or utility-scale uses, use oil-immersed. For indoor, public, or environmentally sensitive settings, use dry-type.

A Guide to Application Scenarios and Choosing

- Oil-Immersed: power plants, mining, steel, petrochemical, rural networks, and transmission/distribution substations.

- Dry-Type: Hospitals, schools, high-rises, shopping complexes, tunnels, and platforms in the ocean.

Checklist for selection:

- Match to the conditions of the place (indoor/outdoor, ambient, fire code).

- Weigh the risks of oil against the benefits of resin for safety and performance.

- Look at the total cost of ownership (TCO) instead of just the capital expenditures (CAPEX).

- Check that you are following the IEC/IEEE/ANSI standards5 for your area.

Maintenance and Questions That Are Often Asked (FAQ)

Things you need to do for maintenance:

- Set up regular oil testing for DGA, acidity, moisture, and dielectric strength.

- Check the silica-gel breather and change it when the color shows it is full.

- Keep an eye on the temperatures of the winding and oil, the loading patterns, and the cooling stage.

- Check the Buchholz relay and protection circuits, and look into any alerts right away.

- Look for leaks, rust, loose bushings, and gaskets that have worn out.

FAQ:

How long will a transformer that is submerged in oil last?

Usually 20 to 30 years, although it can last longer if you load it, cool it, and take care of the oil properly.

When is it time to change the oil in a transformer?

DGA shows problems when dielectric strength is below limits, acidity or moisture levels are too high, or both. This is after checking with trend data.

Which is safer: oil-immersed or dry-type?

Dry-type for inside or public places. Oil-immersed often works better and has more thermal headroom when the voltage is high or the job is tough outside.

What tests do you need to do on a regular basis?

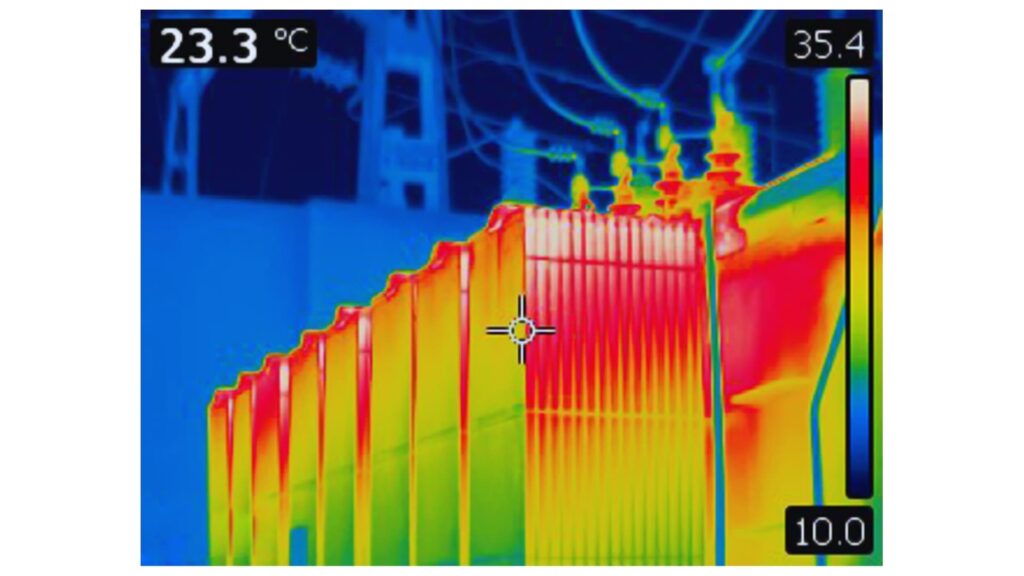

Dielectric testing, DGA, moisture and acidity tests, thermography, protective relay functional checks, and tests of the turns ratio every so often.

Conclusion

In conclusion, PAS: Making bad choices can lead to downtime and safety issues. You may avoid problems by knowing how things work, what they are, and how to take care of them. Choose the proper type, keep the oil system in good shape, and your transformer will work well and safely for decades.

Learn More

Want to explore detailed specifications and models? You can download our product catalog or browse our website to learn more about CHBEB’s transformer solutions.

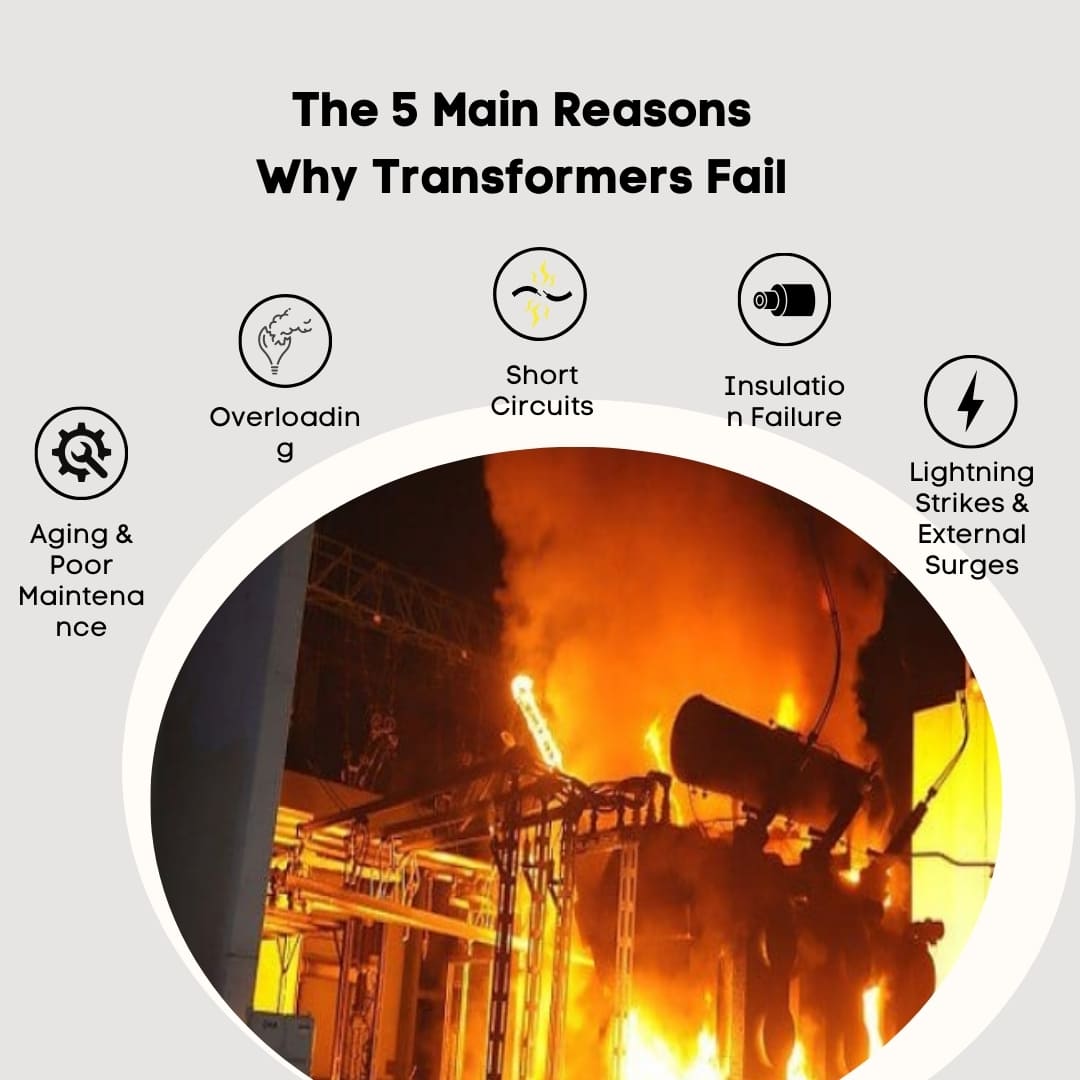

The 5 Main Reasons Why Transformers Fail

Problem: Failures don’t happen by chance. Agitate: When they hit, you have to deal with outages, safety issues, and expensive replacements. Solution: Deal with these five primary problems early on so that “surprise” incidents become regular maintenance tasks.

Overloading: The Quiet Killer

Constant loading above the nameplate rating causes winding hot spots, speeds up the aging of paper, and weakens the dielectric strength. Seasonal peaks, unapproved tie-ins, or growth that is too low might cause a “healthy” unit to go into thermal runaway.

- Make it safer: Plan for capacity growth or install a parallel unit when the trend peak/average load is reached.

- Stay calm: Keep an eye on the temperatures and deaths in hot spots, and turn on the designed fan and pump stages (for example, ONAN → ONAF).

- Plan ahead instead of praying: effective kVA selection and demand control are better than emergency replacements.

Short Circuits: The Quick Rise

Fault currents create enormous electrodynamic forces that change the shape of windings and hardware. Mechanical changes make clearances smaller, which can lead to repeated faults or flashover.

- Your playbook: Set up protection (relays, fuses, and breakers) so that problems clear quickly and only when they need to.

- Look at the skeleton: Torque audits and bracing checks make sure that the insides stay in place.

- After a fault, do a sanity check by running SFRA1 to find any winding movement before you power it back on.

Insulation Failure: The Breakdown Inside

Heat, moisture, and other pollutants break down oil/paper (or resin), which lowers the breakdown voltage. Micro-defects cause partial discharge, which leads to a flashover.

- Stay ahead: Regular testing for DGA2, BDV, moisture (ppm), acidity, and power factor (tan δ).

- Stay dry: Keep breathers, gaskets, and seals in good shape, and patch leaks right away.

- For dry types, keep an eye out for cracks in the resin and dust. You might want to think about doing partial discharge testing.

Lightning Strikes and Outside Surges

Bushings and windings are hit by atmospheric impulses and switching transients that have a steep front. Insulation gets holes in it if there aren’t the right pathways.

- To protect against it, put MOV surge arresters3 next to bushings and check that the grounding is strong.

- Keep it tidy: Check and clean the bushings to stop tracking and surface flashover.

- Use RC snubbers or pre-insertion resistors when you need to to tame switching spikes.

Age and bad upkeep

Oxidation of the oil, sludge, unsecured connections, rusted taps, and worn OLTC contacts all quietly create the stage for disaster. Aging isn’t bad; it’s not taking care of it that is.

- Do the plan: Set clear limits on both time-based and condition-based maintenance.

- Look at the heat: Thermography shows heated joints, and torque audits repair them.

- OLTC4 love: Check contacts, check resistance, and service on time.

Quick Reference: What Causes It, What to Look For, and How to Avoid It

| Cause | The Science | Early Symptoms | How You Stay Safe |

|---|---|---|---|

| Overloading | Thermal aging reduces dielectric strength | High top-oil, frequent fans, thermal alarms | Load studies, uprating/parallel units, cooling upgrades |

| Short Circuits | Electrodynamic forces deform windings | Nuisance trips, abnormal noise, SFRA drift | Protection coordination, bracing checks, post-fault tests |

| Insulation Failure | Moisture/heat/contamination lower BDV | Rising moisture, high tan δ, DGA fault gases | DGA, oil treatment, IR/PI, sealing & breathers |

| Lightning/Surges | Steep impulses puncture insulation | Bushing tracking, arrester operations logged | MOV arresters, earthing, surface cleaning |

| Poor Maintenance/Age | Oxidation, sludge, loose joints | IR hot spots, OLTC arcing, sludge in oil | CBM + TBM, oil care, torque audits, OLTC service |

Beyond the Boom: How to See the Signs and Stay Safe

Problem: Explosions seem to happen right away. Agitate: In real life, clues show up weeks before they should. The greatest way to keep things from happening again is to learn the warning signs and the correct first steps.

Important Signs That a Transformer Is Failing

- Changes in sound: a louder hum, crackling, or random “pops.”

- Heat anomalies: a lot of high top-oil and hot-spot alarms; IR scans showing hot spots that are targeted.

- Electrical signs: tan δ is going up, IR/PI is going down, and SFRA traces are not typical.

- DGA alerts: spikes in hydrogen, acetylene, or ethylene patterns that show arcing or thermal problems.

- Oil/visual signs: Lower BDV, black oil, rising moisture ppm, bushing tracking, and leaks.

- Protection activity: More trips or arrester counter increases.

What Happens After an Explosion? A Quick Guide

- To isolate power, turn it off, lock it up, and make sure the location is safe.

- Set up an exclusion zone: Treat oil fires like Class B fires and execute the emergency plan for the site.

- Tell people and contain the spill: Call the utility or OEM and set up spill kits and environmental barriers.

- Check the PRD, Buchholz5/sudden-pressure relays, bushings, and tank integrity to stop re-energization.

- Record and take samples: pictures, relay logs, arrester counts, and oil/DGA if it’s safe.

- Find the root cause by doing a mechanical check, an SFRA, winding resistance tests, and insulation testing.

If there is a fire or you think there is internal arcing, you should leave the building and allow trained responders put it out.

From Failure to Fix: Real-World Ways to Stop Problems

The problem is that replacing broken units takes a long time and costs a lot of money. Agitate: It’s worse to keep making the same mistake. The answer is to use modern monitoring and preventive maintenance to make things last longer and lower the danger.

The Strength of Preventive Maintenance

Make a condition-based maintenance (CBM) strategy that includes regular testing and specific actions and thresholds. This way, decisions are based on evidence, not gut feelings.

- Routine tests: DGA + furan, moisture (ppm), BDV, acidity; IR/PI and tan δ (winding/bushings).

- SFRA and winding resistance are two things that affect mechanical health. Use published torque settings to tighten hardware.

- Check fans and pumps, clean radiators, replace desiccant, and rectify leaks as soon as you find them.

- OLTC maintenance: verify the contacts, verify the contact resistance, and service them according to the OEM’s schedule.

- Trend it: Use dashboards to look at temperatures, DGA gases, test results, and arrester numbers. Don’t just look at snapshots.

How technology is making transformers safer

- DGA (H2, C2H2), moisture-in-oil, bushing leakage current, hot-spot RTDs, and OLTC motor current are all monitored online all the time.

- IIoT alarms: Tickets are triggered by real-time thresholds, and the event context is saved for speedier response.

- Analytics and AI: Pattern recognition can tell you when insulation is getting old, where hotspots are, and when problems are about to happen.

- Better surge protection: High-energy MOV arresters and clean, low-impedance earth pathways help protect against impulse damage.

- Digital twins: Use thermal profiles and load optimization to reduce loss of life.

Do you need a plan for stopping something? We can map tests, intervals, and thresholds to your fleet and then match surge protection and capacity planning to your risk profile.

Conclusion

Transformers don’t usually “blow” without notice. Overloading, malfunctions, insulation breakdown, surges, and not keeping things up to date leave an obvious trail. To protect people and uptime and lower the entire lifetime cost, pay attention to the signals, act on the data, and engage in proactive monitoring.

FAQ

Q1: What is the most common reason a transformer blows?

Overloading and insulation deterioration are leading causes. Heat accelerates paper aging, lowering dielectric strength until a fault occurs.

Q2: Can a transformer fail without warning?

Rarely. Early signs—abnormal noise, hot spots, rising DGA gases, or repeated protection trips—usually appear weeks or months ahead.

Q3: How often should I test transformer oil?

For critical units, perform quarterly DGA and annual comprehensive oil tests (BDV, moisture, acidity). Adjust frequency based on trends.

Q4: Do surge arresters prevent lightning damage completely?

They greatly reduce risk but require correct rating, placement near bushings, solid earthing, and periodic health checks.

Q5: Is replacement always necessary after an explosion?

Not always. After safe isolation and inspection, repairs may be feasible. A full root cause analysis (SFRA, DGA, mechanical checks) guides the decision.

- Sweep Frequency Response Analysis (SFRA) — ↩︎

- Dissolved Gas Analysis (DGA) — ↩︎

- Lightning arrester (MOV surge arresters) — ↩︎

- Tap changer (On-load tap changer, OLTC) — ↩︎

- Buchholz relay — ↩︎

Want to explore more transformer insights or choose the right model for your project? Visit our homepage for full product details, or download our product catalog to see technical specifications and solutions tailored for you.

Why Do You Want Dry Type Transformers? The best answer for low-voltage uses

A lot of buyers have trouble picking the right type of transformer, which could lead to bad performance or greater prices. Dry type transformers1 overcome these problems by providing safe, efficient, and low-maintenance power solutions that are great for low-voltage uses.

A Comparison of the Main Benefits of Dry Type and Oil-Filled Transformers2

For a long time, oil-filled transformers have been the best way to distribute power, but they need oil management, leak prevention, and regular maintenance. On the other hand, dry type transformers use air or resin insulation, which gets rid of the dangers that come with oil.

- Safety: no oil that can catch fire, hence there are less fire concerns.

- Low Maintenance: No need to change or sample oil

- Good for the environment: little chance of oil leaks or soil pollution

- Compact Installation: Can be put indoors without any particular protection

- Durability: Can handle dust and dampness in tough conditions

This makes them perfect for places like shopping malls, schools, factories, and renewable energy projects where safety and following the rules are very important.

How to Choose the Right Transformer for Your Needs When Shopping Online

If you pick the wrong transformer, it could not work as well, get too hot, or break down too soon. Choosing the appropriate one makes sure it is secure, reliable, and will last a long time, especially when you buy it online and can’t see it in person.

Learn about important specs including kVA, voltage, phase, and winding materials.

For each project, the specifications of the transformer must be exactly right for the load and the environment.

| Specification | Description | Buyer Tip |

|---|---|---|

| kVA Rating3 | Power capacity of the transformer | Choose a kVA that matches or slightly exceeds your maximum load. |

| Primary & Secondary Voltage | Input and output voltages | Ensure compatibility with your local grid and equipment. |

| Phase | Single-phase or three-phase design | Use single-phase for residential/light commercial, three-phase for industrial loads. |

| Winding Material | Copper or aluminum conductors | Copper offers higher efficiency, aluminum is lighter and more cost-effective. |

An expert provider can do load calculations to make sure that what you buy fits your demands.

Customization Services: Making Solutions That Fit Your Specific Projects

Transformers that you may buy off the shelf might not work for specific uses. Customization makes ensuring that your transformer fulfills certain installation, performance, or regulatory needs.

- Unusual voltage combinations for export projects

- Better cooling solutions for hot weather

- Special boxes for putting things inside or outside

- Designs for reducing harmonic interference in sensitive electronics4

If you work with a supplier that offers engineering help, you can receive exactly what your project needs without having to make expensive sacrifices.

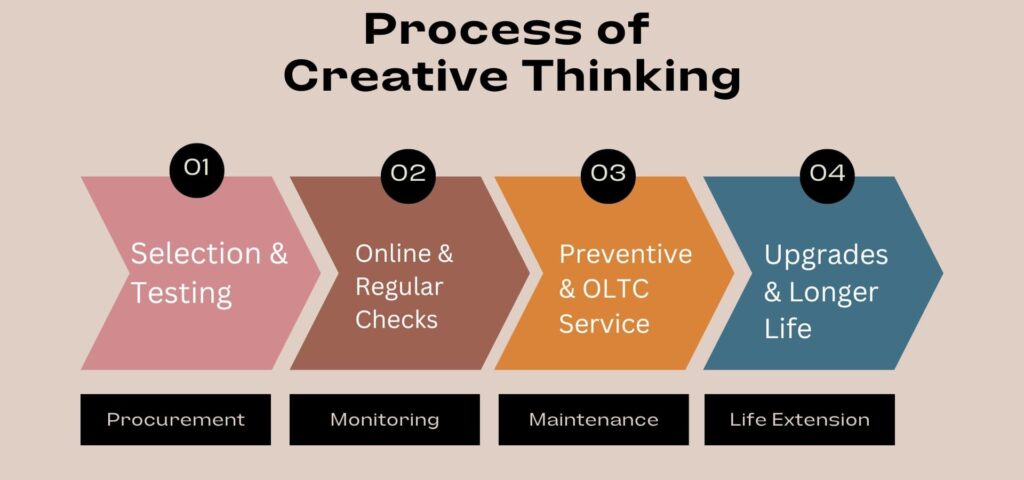

The Buying Process and Long-Term Value: From Asking Questions to Getting Help After the Sale

You shouldn’t have to give up assistance just because you buy online. The top vendors will help you from the first question to after-sales service, making sure you get the most value out of the transformer’s life.

- First, tell us about your load requirements, site circumstances, and compliance criteria.

- Technical Proposal: The supplier gives you specs, drawings, and a price quote.

- Order Confirmation: agreeing on the price, delivery time, and payment terms.

- Making and Testing: The transformer is made and tested to meet standards like IEC, IEEE5, and others.

- Delivery and Installation Help: Logistics are set up with the option of getting help on-site or from a distance.

- Service after the sale includes warranty coverage, spare parts, and technical help.

Frequently Asked Questions (FAQ): A Quick Guide to Common Problems

Q1: Is it okay to use a dry type transformer outside?

Yes, but only if it has a waterproof casing that can handle outdoor circumstances.

Q2: How long does a dry type transformer last?

With the right care, they usually last 20 to 30 years.

Q3: Do dry type transformers cost more than oil-filled ones?

The initial expenditures are a little higher, but the lower maintenance and safety compliance costs usually make up for it.

Q4: How quickly can I acquire a bespoke transformer?

The time it takes to get leads varies, but it’s usually between 2 and 6 weeks, depending on how complicated the project is and when it can be made.

Conclusion

For low-voltage and specialized projects, dry type transformers are a safe, easy-to-maintain, and environmentally responsible choice. You may buy online with confidence and make sure it will work for a long time if you know what you want and work with a trustworthy source.

Ready to Find the Perfect Dry Type Transformer?

Explore our full range of Dry Type Transformers to match your project requirements, or download our Product Catalog for detailed specifications and technical data.

Introduction

Choosing the improper type of dry transformer1 can cause expensive downtime, safety risks, and early failure. A lot of purchasers feel confused by technical specifications and advice that doesn’t agree. This tutorial breaks it down so you can choose the transformer that is safest, most efficient, and least expensive for your needs.

What Dry Type Transformers Are and Why They Are Important

Issue: A lot of people think “dry type” means it’s just a safer transformer, but they don’t know how it works or what it’s good at.

Agitate: If you don’t know this, you might spend too much money or pick a model that doesn’t work well in your area.

Let’s start by explaining what dry type transformers are and why they are becoming more popular around the world.

What does it mean to have a dry type transformer?

A dry type transformer doesn’t utilize mineral oil or other liquids to cool down. Instead, it uses air or solid insulation. Resin or varnish protects its windings and core, and it cools down with natural or forced air. This makes it perfect for places that are indoors or care about the environment.

The Main Benefits of Dry Type and Oil-Filled Transformers

| Feature | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Cooling Medium | Air/Solid Insulation | Mineral/Synthetic Oil |

| Fire Safety | Higher (no flammable liquid) | Lower (oil is combustible) |

| Maintenance | Lower | Higher (oil testing, leak checks) |

| Environmental Impact | Minimal risk of spills | Risk of oil contamination |

| Cost | Higher initial cost | Lower initial cost |

| Applications | Indoor, sensitive sites | Outdoor, high-load grids |

The Most Important Types of Dry Type Transformers and Where They Work Best

Problem: Choosing the wrong type can cause it to not work as well or fail too soon.

Agitate: Not all dry type transformers work the same way in every situation.

Solution: For the best performance and longest life, match the proper type to your use.

Cast Resin Transformers (CRT)

Core Features: Windings are completely covered in epoxy resin, which makes them very resistant to moisture, dust, and chemicals.

Pros: Very durable, needs little upkeep, and is safe for tough or corrosive conditions.

Drawbacks: more expensive and can’t be fixed if the resin splits or burns.

Common Uses: Hospitals, chemical industries, underground mines, and ships.

Vacuum Pressure Impregnated (VPI) Transformers

Main Features: Windings are coated with varnish under vacuum and pressure, and then baked to make them stronger.

Pros: It’s cheaper, it lets heat escape well, and it can be fixed if it breaks.

Limitations: Not as resistant to high humidity or contamination.

Common Uses: Schools, data centers, and commercial structures.

Specialized Dry Type Transformers

K-Factor Rated: Made for data centers or factories with non-linear loads.

Harmonic Mitigation Models: Help sensitive electronics work better by lowering voltage distortion.

High-Temperature Designs: Work in places where the standard ratings are higher.

Decoding Key Specifications and Selection Parameters

Problem: If you don’t know things like the kVA rating or insulation class, you can buy the wrong thing.

Agitate: This can make things less safe, more costly to fix, or less efficient.

Before you buy, be sure you know what each setting implies.

KVA Rating: Choosing the Right Size for Current and Future Loads

kVA tells you how much load the transformer can handle. To get kVA, use this formula: kVA = (Load Voltage × Load Current) ÷ 10002

Always leave room for future growth and environmental derating.

Voltage Class: Meeting the needs of both the primary and secondary systems

To avoid problems with performance, be sure that both the supply and load voltages are compatible.

Class of insulation and rise in temperature

For example, models with 150°C rise survive longer and run cooler than models with 220°C rise.

Longer life and better performance come from a lower temperature rise.

Losses and Efficiency

No-Load Losses: Energy lost while a transformer is turned on but not doing anything.

Load losses happen when energy is lost while under load.

To be in compliance and save money, follow the efficiency criteria set by DOE 2016, NEMA TP-1, or GB 20052-2020.3

IP Rating and Enclosure

IP544: shielded from dust and splashes, therefore it’s suitable for outdoor settings that are sheltered.

NEMA 3R: Weatherproof for outside use.

Pick based on the dangers in the area.

Winding Material: Copper vs. Aluminum

| Property | Copper | Aluminum |

|---|---|---|

| Conductivity | Higher | Lower |

| Cost | Higher | Lower |

| Weight | Heavier | Lighter |

| Mechanical Strength | Higher | Lower |

Impedance

Changes the short-circuit current and the voltage regulation. If it’s too low, there’s a chance of excessive fault currents. If it’s too high, the voltage will drop when it’s loaded.

Cost of maintenance, longevity, and lifetime

Problem: A lot of people think that “dry type” means “no maintenance.”

Agitate: Ignoring things shortens life and makes failure more likely.

Follow a simple maintenance plan and think on the lifetime cost instead of the purchase price.

Common Mistakes and Signs of Trouble

- Overheating

- Insulation cracks

- Unusual humming noise

- Discoloration of windings

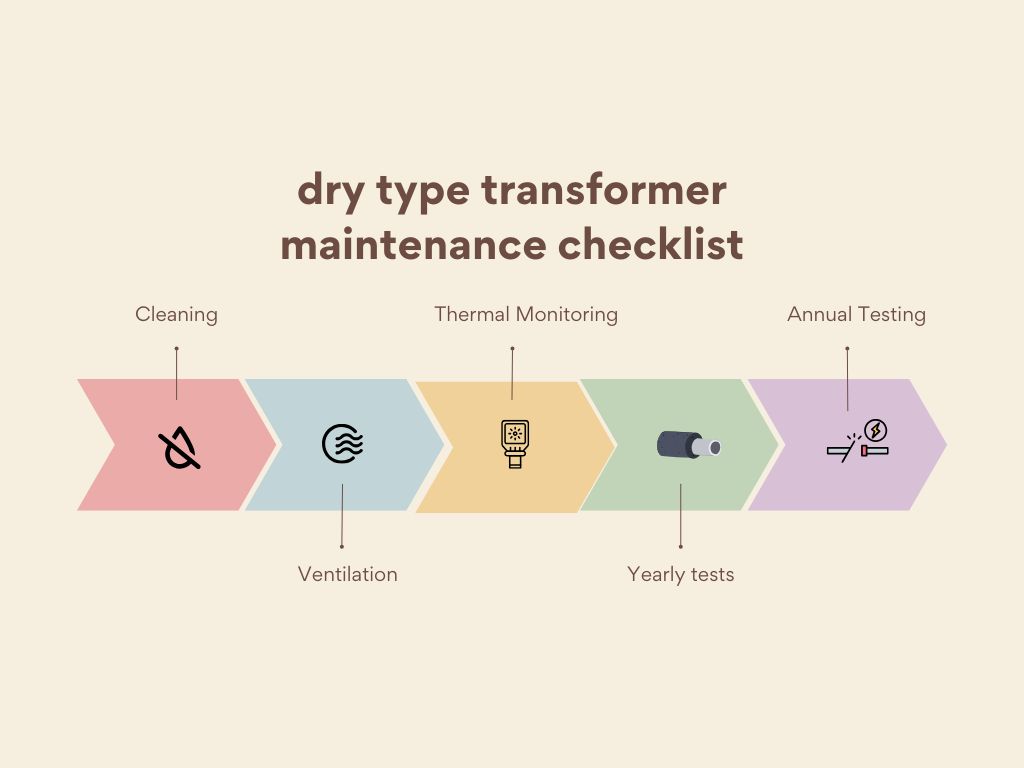

The List of Important Maintenance Tasks

- Visual inspection every 6–12 months

- Cleaning dust and debris

- Tightening connections

- Infrared thermography5 for hot spots

- Insulation resistance tests

Analysis of Lifetime Cost (LCC)

Think about more than simply the purchase price. Think about installation, energy losses, maintenance, and disposal. Models with high efficiency frequently offer a better return on investment.

A process for choosing step by step

Problem: A lot of purchasers only care about price and don’t follow an organized process.

Agitate: This can cause safety problems or units that are too big or too little.

The answer is to use a planned approach..

A Flowchart for Systematic Transformer Selection

- Needs Assessment – Load profile, future expansion

- Environment Evaluation – Indoor/outdoor, humidity, dust

- Parameter Finalization – kVA, voltage, temperature rise, IP rating

- Vendor Comparison – Certifications, track record, support

Picking a Manufacturer You Can Trust

- International certifications (NEMA, IEC, GB/T)

- Proven track record in your industry

- Strong after-sales service

Conclusion

To choose the proper dry type transformer, you need to find a balance between performance, safety, and long-term expenses. Follow a plan, make sure the specs fit your space, and spend money on quality. Your electrical system will be more reliable if you do these things.

- Dry type transformer — Wikipedia ↩︎

- Transformer kVA calculation formula — Electrical Engineering Portal ↩︎

- DOE 2016 Energy Efficiency Standards — U.S. Department of Energy ↩︎

- IP Code — Wikipedia ↩︎

- Infrared thermography in electrical inspections — ScienceDirect ↩︎

Ready to Find the Perfect Dry Type Transformer?

Explore our full range of Dry Type Transformers to match your project requirements, or download our Product Catalog for detailed specifications and technical data.

Dry Type Transformers Explained: A Comprehensive Guide to Their Operation, Advantages, and Applications

What is a transformer that is dry? A Look at the Main Ideas and Benefits

If you pick the wrong type of transformer, it could overheat, catch fire, or cost you a lot of money in downtime. Many engineers and procurement managers have a hard time finding the right balance between performance, safety, and maintenance in power distribution. For modern applications, dry-type transformers are a clean, safe, and efficient choice.

The main idea behind how dry-type transformers work

Oil is used for insulation and cooling in traditional transformers. In dry-type transformers, nevertheless, air and solid insulation materials do the trick. This gets rid of the chance of oil leaks, making them perfect for indoor and delicate settings.

The basic idea behind these transformers is electromagnetic induction1. A primary coil gets electrical energy, which causes voltage to flow through a magnetic core to a secondary coil. They stay cool and safe in different ways: with air ventilation and resin insulation instead of oil.

The main difference between dry-type and oil-immersed transformers is

The difference in insulation is huge. Oil-immersed transformers cool and insulate windings by putting them in oil, although this can be dangerous for the environment and for fires. Dry-type transformers get rid of all of these risks: no oil, no flammability, and no poisonous leaks.

| Feature | Dry-Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Cooling Method | Air/Natural Ventilation or Fan | Oil Circulation |

| Insulation | Epoxy Resin / Varnish | Mineral or Synthetic Oil |

| Fire Risk | Very Low | Medium to High |

| Maintenance | Minimal | Requires Oil Sampling |

| Indoor Use | Excellent | Limited |

Why Are Dry-Type Transformers Safer?

Safety is a must in high-risk areas like hospitals, schools, and businesses. Because they are flame-resistant and self-extinguishing, dry-type transformers are great for use indoors and in crowded locations.

Also, the fact that there is no flammable oil and that fire-resistant epoxy or varnish is used gives you peace of mind, especially in countries like Europe and North America where there are a lot of rules. A lot of models meet the safety criteria set by IEC 60076-112 and IEEE C57.12.91.

A Detailed Look at the Different Types of Dry-Type Transformers, Their Pros and Cons

Not every dry-type transformer is made the same way. Knowing the distinctions can help you pick the best solution for your project demands and the environment. Let’s look at the different types, their benefits, and any possible drawbacks.

VPI and CRT are the two main types.

Dry-type transformers come primarily in two forms: VPI (Vacuum Pressure Impregnated)3 and CRT (Cast Resin Type).

- VPI Transformers: The windings are soaked in varnish while under pressure and vacuum. Air cools them down, and they are commonly employed in industrial and utility situations with lower humidity.

- CRT Transformers: Coils in CRT transformers are made of solid epoxy resin, which makes them more resistant to moisture and stronger mechanically. This makes them perfect for use in coastal or tropical areas.

| Specification | VPI Transformer | CRT (Cast Resin) Transformer |

|---|---|---|

| Insulation | Varnish-impregnated | Solid Epoxy Resin4 |

| Moisture Resistance | Moderate | High |

| Fire Resistance | Good | Excellent |

| Application | General Industrial | High Moisture / Indoor Use |

A Look at Core Benefits: Why They Are Commonly Used in Today’s Apps

- Safety: No chance of oil fires or poisonous leaks

- Good for the environment: no oil discharge, smaller environmental footprint

- Low Maintenance: You don’t have to change the oil or sample the fluid.

- Small size makes it easier to install indoors.

- No noise: Great for business spaces because it doesn’t make noise.

- Ready for Compliance: Meets global safety requirements

An Objective Look: Problems and Limitations of Dry-Type Transformers

- Higher Initial Cost: Cast resin models can cost more at first.

- Size and Weight: CRTs are bigger since they are covered in resin

- Efficiency: A little less energy efficient than oil-immersed when fully loaded

- For Use Outside Protection: When used outside, it must be kept in a protective container.

From Theory to Practice: Important Uses and Upkeep

It’s not only about how dry-type transformers work, but also where and how they do their job. Let’s go from technical details to real-world value and maintenance.

Common Use Cases and Examples

- Commercial Buildings: office towers and shopping complexes

- Hospitals and schools: safe, quiet, and clean inside

- Solar farms and wind substations are examples of renewable energy.

- Industrial Plants: This is especially true in places with a lot of humidity or chemicals.

- Transportation Hubs: Subways, airports, tunnels

For example, in 2024, a Dubai-based solar energy EPC put in 75 dry-type transformers in their PV project in the desert. The transformers didn’t need any maintenance for a whole year, even though they had to deal with high temperature changes and sand exposure. This was all because to cast resin insulation.

A Simple and Efficient Guide to Caring for and Maintaining Dry-Type Transformers

- Check for dust accumulation or signs of overheating once a month by looking at it.

- Cleaning: Don’t get anything wet; use a vacuum or dry cloth.

- Ventilation: Make sure that the cooling ducts are not obstructed.

- Thermal Monitoring: Use sensors that are already in place to keep an eye on temperature fluctuations.

- Yearly tests: IR thermography5 and insulation resistance checksperature changes

- Annual Testing: IR thermography and insulation resistance checks

A dry-type transformer can survive 20 to 30 years with the right maintenance, which is a great return on investment.

Conclusion

Dry-type transformers are safe, reliable, and work well all at the same time. They are a long-term, low-maintenance way to get clean power to people, whether you’re improving city infrastructure or creating renewable systems.

Are you struggling to choose the right dry type transformer for your project? With so many options available, it’s easy to feel overwhelmed. But making the wrong choice could lead to inefficiency, increased costs, or even safety risks.

Dry type transformers come in three main types: cast resin, VPI (Vacuum Pressure Impregnated), and epoxy encapsulated. Cast resin transformers offer excellent moisture resistance and are ideal for indoor use. VPI transformers are cost-effective and suitable for industrial applications. Epoxy encapsulated transformers excel in harsh environments. Each type has unique characteristics, advantages, and ideal use cases, which we’ll explore in detail to help you make an informed decision.

In this comprehensive guide, I’ll break down the key differences between cast resin, VPI, and epoxy encapsulated transformers. We’ll explore their structures, benefits, and ideal applications, helping you make the best choice for your specific needs. Whether you’re an engineer, project manager, or procurement specialist, this information will be invaluable in your decision-making process.

What Are Dry Type Transformers? Basic Definition and Benefits?

Have you ever wondered why some transformers don’t use oil for cooling? Or perhaps you’ve heard about dry type transformers but aren’t sure how they differ from traditional oil-filled units? Let’s dive into the world of dry type transformers and uncover their unique advantages.

Dry type transformers are electrical transformers that use air or solid insulation instead of oil for cooling and insulation. They offer enhanced safety, reduced fire risk, and minimal maintenance compared to oil-filled transformers. Dry type transformers are ideal for indoor installations, environmentally sensitive areas, and applications where oil leakage could be hazardous. They come in various types, including cast resin, VPI, and epoxy encapsulated, each suited for different environments and requirements.

Key Aspects of Dry Type Transformers

Let’s explore the fundamental characteristics and benefits of dry type transformers:

- Basic Structure and Components

- Cooling Methods

- Safety and Environmental Benefits

- Maintenance Requirements

- Common Applications

Basic Structure and Components

The anatomy of a dry type transformer:

- Core (typically made of silicon steel)

- Primary and secondary windings

- Insulation material (air, epoxy resin, or other solid materials)

- Enclosure or housing

I remember the first time I opened a dry type transformer during my early days as an engineer. The absence of oil and the clean, compact design immediately struck me. It was a stark contrast to the oil-filled units I was used to, and it sparked my interest in these innovative designs.

Cooling Methods

How dry type transformers manage heat:

- Natural air cooling (AN)

- Forced air cooling (AF)

- Combination of natural and forced air cooling (ANAF)

During a recent project for a high-rise building, we opted for a dry type transformer with forced air cooling. This choice allowed us to install the transformer in a smaller space while still meeting the building’s power requirements, showcasing the flexibility of dry type cooling methods.

Safety and Environmental Benefits

Advantages over oil-filled transformers:

- Reduced fire risk due to absence of flammable oil

- No risk of oil leaks or spills

- Environmentally friendly, especially in sensitive areas

Here’s a quick comparison of safety aspects:

| Aspect | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Fire Risk | Low | Higher due to oil |

| Environmental Impact | Minimal | Potential oil spills |

| Indoor Use | Suitable | Often restricted |

| Maintenance | Low | Regular oil checks needed |

Maintenance Requirements

Ease of upkeep for dry type transformers:

- No oil to monitor or replace

- Periodic cleaning and inspection of windings

- Checking of connections and ventilation systems

Common Applications

Where dry type transformers excel:

- Indoor installations (office buildings, hospitals, schools)

- Industrial facilities with limited space

- Areas with strict environmental regulations

- Renewable energy projects (wind farms, solar installations)

Key points about dry type transformers:

- They use air or solid materials for insulation instead of oil

- Dry type transformers offer enhanced safety and reduced fire risk

- They are ideal for indoor and environmentally sensitive installations

- Maintenance requirements are generally lower than oil-filled units

- Various types exist, each suited for specific applications

In my experience, the versatility of dry type transformers has made them increasingly popular across various industries. I recall a project for a data center where the client was initially skeptical about using dry type transformers due to concerns about cooling efficiency. After implementing a forced air cooling system and demonstrating the safety benefits, the client was not only satisfied but also decided to standardize dry type transformers across their facilities.

For example, in a recent renewable energy project involving offshore wind turbines, we faced the challenge of installing transformers in a corrosive, space-constrained environment. By selecting epoxy encapsulated dry type transformers, we were able to ensure reliable operation in the harsh marine conditions while minimizing maintenance requirements – a crucial factor for offshore installations.

As we move on to discuss specific types of dry transformers, remember that each type has its unique strengths and ideal applications. Understanding these differences is key to selecting the right transformer for your specific needs.

Cast Resin Transformers: Structure, Use Cases, and Pros & Cons?

Have you ever wondered why some transformers look like they’re encased in solid blocks? Or perhaps you’ve heard about cast resin transformers but aren’t sure how they differ from other dry types? Let’s unravel the mystery of cast resin transformers and discover why they’re a popular choice in many applications.

Cast resin transformers are dry type transformers where the windings are encapsulated in epoxy resin. This design offers excellent protection against moisture, dust, and chemical contaminants. They’re ideal for indoor installations, especially in humid or polluted environments. Cast resin transformers provide high short-circuit strength, good overload capacity, and minimal maintenance requirements. They’re commonly used in commercial buildings, industrial facilities, and areas where fire safety is a primary concern.

Key Aspects of Cast Resin Transformers

Let’s dive deeper into the characteristics and applications of cast resin transformers:

- Structure and Manufacturing Process

- Cooling and Insulation Properties

- Advantages and Limitations

- Typical Applications

- Maintenance Considerations

Structure and Manufacturing Process

How cast resin transformers are made:

- Windings are wound with insulated conductors

- Coils are placed in molds and filled with epoxy resin under vacuum

- Resin is cured to form a solid, void-free insulation

I once visited a manufacturing facility specializing in cast resin transformers. Watching the vacuum casting process was fascinating – seeing how the liquid resin transformed into a solid, protective shell around the windings gave me a new appreciation for the engineering behind these transformers.

Cooling and Insulation Properties

Managing heat and ensuring proper insulation:

- Natural air cooling is most common (AN)

- Forced air cooling can be added for higher capacities (AF)

- Excellent thermal properties of epoxy resin aid in heat dissipation

During a recent project for a chemical plant, we chose cast resin transformers specifically for their superior insulation properties. The epoxy encapsulation provided excellent protection against the corrosive atmosphere, ensuring long-term reliability in a challenging environment.

Advantages and Limitations

Pros and cons of cast resin transformers:

| Advantages | Limitations |

|---|---|

| Excellent moisture resistance | Higher initial cost compared to VPI |

| High short-circuit strength | Heavier than other dry types |

| Fire-resistant (self-extinguishing) | Limited to indoor or protected installations |

| Low maintenance requirements | Potential for cracking under extreme thermal cycling |

| Environmentally friendly |

Typical Applications

Where cast resin transformers shine:

- Commercial buildings (offices, shopping centers)

- Hospitals and healthcare facilities

- Educational institutions

- Industrial plants with humid or polluted environments

- Underground or subway installations

Maintenance Considerations

Keeping cast resin transformers in top shape:

- Regular visual inspections for cracks or damage

- Cleaning of ventilation openings

- Checking of electrical connections

- Monitoring of ambient conditions (temperature, humidity)

Key points about cast resin transformers:

- Windings are fully encapsulated in epoxy resin

- They offer excellent protection against environmental factors

- Cast resin transformers have high short-circuit strength

- They’re ideal for indoor installations in challenging environments

- Maintenance requirements are minimal but regular inspections are crucial

In my experience, cast resin transformers have proven invaluable in projects where reliability and safety are paramount. I recall a hospital expansion project where we needed to install transformers close to sensitive medical equipment. The cast resin units were perfect – their low electromagnetic emissions and fire-resistant properties provided the necessary safety assurances, while their compact design fit well within the space constraints.

For example, in a recent project involving a data center in a coastal area, we faced the challenge of high humidity and salt-laden air. By implementing cast resin transformers, we were able to ensure reliable power distribution without the risk of moisture ingress or corrosion that could have plagued other transformer types. The client was particularly impressed by the low maintenance requirements, which translated to reduced operational costs over time.

As we move on to discuss VPI transformers, keep in mind that while cast resin transformers excel in many applications, each type of dry transformer has its unique strengths. Understanding these differences is key to selecting the right transformer for your specific needs.

VPI (Vacuum Pressure Impregnated) Transformers: How They Work and When to Use Them?

Have you ever wondered how some transformers achieve excellent insulation without the bulk of cast resin? Or perhaps you’re curious about a more cost-effective alternative to cast resin transformers? VPI transformers might be the answer you’re looking for. But what exactly are they, and when should you consider using them?

VPI (Vacuum Pressure Impregnated) transformers are dry type transformers where the windings are impregnated with varnish under vacuum and pressure. This process fills voids and creates a uniform insulation layer. VPI transformers offer good moisture resistance, excellent heat dissipation, and are generally more cost-effective than cast resin types. They’re ideal for industrial applications, indoor substations, and projects where budget constraints are a factor. VPI transformers provide a balance of performance and economy.

Key Aspects of VPI Transformers

Let’s explore the main features and applications of VPI transformers:

- Manufacturing Process

- Insulation and Cooling Characteristics

- Advantages and Limitations

- Typical Use Cases

- Maintenance Requirements

Manufacturing Process

How VPI transformers are made:

- Windings are wound with insulated conductors

- Coils are placed in a vacuum chamber

- Air is removed, and varnish is introduced under pressure

- Varnish is cured to create a solid insulation layer

I remember visiting a factory that produced both cast resin and VPI transformers. The VPI process was particularly intriguing – watching the varnish penetrate every nook and cranny of the windings under vacuum was like seeing the transformer come to life. This experience gave me a deep appreciation for the engineering precision involved in creating these efficient machines.

Insulation and Cooling Characteristics

Managing heat and ensuring proper insulation:

- Natural air cooling is common (AN)

- Forced air cooling can be added for higher capacities (AF)

- Varnish provides good heat dissipation and moisture resistance

During a recent industrial project, we opted for VPI transformers with forced air cooling. This choice allowed us to meet the high power demands of the facility while maintaining a compact footprint. The excellent heat dissipation properties of the VPI insulation system proved crucial in maintaining efficiency under heavy loads.

Advantages and Limitations

Pros and cons of VPI transformers:

| Advantages | Limitations |

|---|---|

| Cost-effective compared to cast resin | Less moisture resistant than cast resin |

| Good heat dissipation | May require more frequent maintenance |

| Lighter weight than cast resin | Not suitable for extremely harsh environments |

| Suitable for most indoor applications | Limited outdoor use without additional protection |

| Can be rewound if damaged |

Typical Use Cases

Where VPI transformers excel:

- Industrial facilities and factories

- Indoor substations

- Commercial buildings with controlled environments

- Renewable energy projects (wind and solar farms)

- Educational institutions

Maintenance Requirements

Keeping VPI transformers in top condition:

- Regular visual inspections for signs of varnish degradation

- Cleaning of ventilation systems

- Checking of electrical connections

- Monitoring of ambient conditions (temperature, humidity)

- Possible re-varnishing after long periods of use

Key points about VPI transformers:

- Windings are impregnated with varnish under vacuum and pressure

- They offer a good balance of performance and cost-effectiveness

- VPI transformers have excellent heat dissipation properties

- They’re ideal for most indoor industrial and commercial applications

- Maintenance is more involved than cast resin but less than oil-filled types

In my experience, VPI transformers have often been the go-to choice for projects where budget constraints are a significant factor, but performance can’t be compromised. I recall a large-scale factory upgrade where the client needed to replace multiple transformers across various production lines. By choosing VPI transformers, we were able to provide reliable power distribution at a cost that fit within the project’s budget constraints. The client was particularly pleased with the balance of performance and economy.

For example, in a recent solar farm project, we faced the challenge of installing multiple transformers in a relatively controlled environment, but with strict budget limitations. VPI transformers proved to be the perfect solution. Their good performance in moderate indoor conditions, combined with their cost-effectiveness, allowed us to optimize the power distribution system without exceeding the project’s financial constraints. The ability to easily maintain and potentially rewind these transformers also appealed to the client’s long-term operational planning.

As we move on to discuss epoxy encapsulated transformers, remember that while VPI transformers offer an excellent balance of performance and cost, each type of dry transformer has its specific strengths and ideal applications. Understanding these nuances is key to making the best choice for your particular needs.

Epoxy Encapsulated Transformers: Best for Harsh Environments?

Have you ever wondered what type of transformer could withstand the most challenging conditions? Or perhaps you’re facing a project where standard dry type transformers just won’t cut it? Epoxy encapsulated transformers might be the solution you’re looking for. But what makes them so special, and are they really the best choice for harsh environments?

Epoxy encapsulated transformers are dry type transformers where the entire core and coil assembly is fully encased in epoxy resin. This design provides superior protection against moisture, dust, and chemical contaminants, making them ideal for harsh environments. They offer excellent resistance to thermal shock, high mechanical strength, and can withstand extreme temperatures. Epoxy encapsulated transformers are commonly used in offshore installations, chemical plants, and other challenging industrial settings where reliability under severe conditions is crucial.

Key Aspects of Epoxy Encapsulated Transformers

Let’s delve into the main features and applications of epoxy encapsulated transformers:

- Design and Manufacturing Process

- Environmental Resistance Properties

- Advantages and Limitations

- Ideal Applications

- Maintenance and Longevity

Design and Manufacturing Process

How epoxy encapsulated transformers are created:

- Core and coil assembly is prepared

- Entire assembly is placed in a mold

- Epoxy resin is injected under vacuum

- Resin is cured to form a solid, void-free encapsulation

I once had the opportunity to witness the manufacturing process of an epoxy encapsulated transformer. The precision required to ensure complete and uniform encapsulation was impressive. Seeing the finished product – a solid, monolithic unit – gave me a new appreciation for the robustness of these transformers.

Environmental Resistance Properties

Withstanding harsh conditions:

- Excellent resistance to moisture and humidity

- High tolerance to chemical exposure

- Ability to withstand extreme temperatures

- Resistance to vibration and mechanical stress

During a recent offshore wind farm project, we specified epoxy encapsulated transformers for the turbine platforms. Their ability to withstand the corrosive sea air, constant vibrations, and temperature fluctuations proved crucial in ensuring reliable power transmission from the turbines to the grid.

Advantages and Limitations

Pros and cons of epoxy encapsulated transformers:

| Advantages | Limitations |

|---|---|

| Superior environmental protection | Higher cost compared to other dry types |

| Excellent mechanical strength | Heavier weight |

| Resistant to thermal shock | Limited ability to dissipate heat in very high ambient temperatures |

| Can be used in outdoor installations | Difficult to repair if damaged |

| Long lifespan in harsh conditions |

Ideal Applications

Where epoxy encapsulated transformers excel:

- Offshore oil and gas platforms

- Chemical and petrochemical plants

- Mining operations

- Coastal and marine environments

- Outdoor installations in extreme climates

- Areas with high pollution or dust levels

Maintenance and Longevity

Ensuring long-term performance:

- Minimal maintenance requirements due to full encapsulation

- Regular visual inspections for any external damage

- Monitoring of electrical parameters

- Cleaning of external surfaces to maintain heat dissipation

Key points about epoxy encapsulated transformers:

- Entire core and coil assembly is fully encased in epoxy resin

- They offer superior protection against harsh environmental factors

- Epoxy encapsulated transformers have excellent mechanical strength

- They’re ideal for extreme environments and outdoor installations

- Maintenance is minimal, but regular monitoring is still important

In my experience, epoxy encapsulated transformers have been lifesavers in some of the most challenging projects I’ve worked on. I recall a project for a chemical plant located in a tropical, coastal area. The combination of high humidity, salt air, and corrosive chemical vapors would have quickly degraded most other transformer types. The epoxy encapsulated units we installed have been running flawlessly for years, with minimal maintenance required.

For example, in a recent mining project in a remote, arid region, we faced the challenge of extreme temperature fluctuations and high dust levels. Epoxy encapsulated transformers were the clear choice. Their robust construction withstood the harsh conditions, and the sealed design prevented dust ingress. The client was particularly impressed by the transformers’ reliability, which significantly reduced downtime and maintenance costs compared to their previous installations.

As we move on to compare these different types of dry transformers, it’s important to remember that while epoxy encapsulated transformers excel in harsh environments, each type has its own strengths and ideal applications. The key is to match the transformer type to your specific environmental and operational requirements.

Comparison Table: Cast Resin vs VPI vs Epoxy Encapsulated

When it comes to choosing the right dry type transformer for your project, understanding the key differences between cast resin, VPI, and epoxy encapsulated transformers is crucial. But with so many factors to consider, how can you easily compare these types side by side? Let’s break it down in a comprehensive comparison table.

Cast resin, VPI, and epoxy encapsulated transformers each have unique characteristics that make them suitable for different applications. Cast resin offers excellent moisture resistance and is ideal for indoor use. VPI transformers are cost-effective and suitable for most industrial applications. Epoxy encapsulated transformers excel in harsh environments. The choice depends on factors like environmental conditions, maintenance requirements, and budget constraints. This comparison will help you identify the best option for your specific needs.

Detailed Comparison of Dry Type Transformers

Let’s dive into a comprehensive comparison of these three transformer types:

| Feature | Cast Resin | VPI | Epoxy Encapsulated |

|---|---|---|---|

| Structure | Windings encapsulated in epoxy | Windings impregnated with varnish | Entire assembly encased in epoxy |

| Moisture Resistance | Excellent | Good | Superior |

| Chemical Resistance | Very Good | Good | Excellent |

| Mechanical Strength | High | Moderate | Very High |

| Heat Dissipation | Good | Very Good | Good |

| Weight | Heavy | Lighter | Heaviest |

| Cost | High | Moderate | Highest |

| Maintenance | Low | Moderate | Very Low |

| Typical Applications | Indoor, moisture-sensitive areas | Industrial, cost-sensitive projects | Harsh, corrosive environments |

| Outdoor Suitability | Limited | Limited | Suitable with proper enclosure |

| Overload Capacity | Good | Good | Excellent |

| Noise Level | Low | Low to Moderate | Low |

| Repairability | Difficult | Possible | Very Difficult |

| Lifespan | Long | Moderate to Long | Very Long |

Key Insights from the Comparison

-

Environmental Protection:

Epoxy encapsulated transformers offer the highest level of protection against environmental factors, making them ideal for the harshest conditions. Cast resin follows closely, while VPI provides good protection for most indoor industrial applications. -

Cost Considerations:

VPI transformers are generally the most cost-effective option, making them attractive for large-scale industrial projects. Cast resin offers a balance of performance and cost, while epoxy encapsulated transformers come at a premium but offer unparalleled durability in extreme conditions. -

Maintenance Requirements:

Epoxy encapsulated transformers require the least maintenance, followed by cast resin. VPI transformers may need more frequent inspections and potential re-varnishing over time. -

Application Flexibility:

Cast resin transformers are versatile for various indoor applications. VPI transformers excel in industrial settings, while epoxy encapsulated units are the go-to choice for harsh environments and outdoor installations. -

Long-term Reliability:

All three types offer good reliability, but epoxy encapsulated transformers typically have the longest lifespan in challenging conditions. Cast resin follows closely, with VPI offering good longevity in appropriate environments.

In my experience, this comparison has been invaluable when consulting with clients on transformer selection. I remember a project where we were upgrading the electrical infrastructure of a large manufacturing complex. Different areas of the facility had varying environmental conditions and budget constraints. By referring to a comparison like this, we were able to strategically deploy a mix of VPI transformers in general industrial areas and cast resin units in more moisture-sensitive locations. This approach optimized both performance and cost-effectiveness across the entire project.

For example, in a recent multi-site renewable energy project, we used this type of comparison to tailor our transformer selections. We chose VPI transformers for the main indoor substations where cost was a significant factor, cast resin units for areas with moderate environmental challenges, and epoxy encapsulated transformers for offshore wind turbine platforms exposed to extreme marine conditions. This strategic mix ensured optimal performance and reliability across all sites while managing the overall project budget effectively.

As we move on to discuss how to choose the right dry type transformer for your application, keep this comparison in mind. It serves as a valuable reference point, but remember that each project has unique requirements that may influence your final decision.

How to Choose the Right Dry Type Transformer for Your Application?

Are you feeling overwhelmed by the options available in dry type transformers? With cast resin, VPI, and epoxy encapsulated transformers each offering unique benefits, how do you determine which one is best suited for your specific application? Let’s break down the decision-making process to help you make an informed choice.

Choosing the right dry type transformer involves considering several key factors: environmental conditions, load requirements, budget constraints, and maintenance capabilities. For indoor applications with moderate environmental challenges, cast resin transformers often provide an excellent balance. VPI transformers are ideal for cost-sensitive industrial projects with controlled environments. Epoxy encapsulated transformers are best for harsh outdoor or highly corrosive conditions. Always consider future expansion needs and long-term operational costs in your decision.

Key Considerations for Selecting the Right Transformer

Let’s explore the main factors to consider when choosing a dry type transformer:

- Environmental Conditions

- Load Requirements and Capacity

- Installation Location and Space Constraints

- Budget Considerations

- Maintenance Capabilities and Long-term Costs

Environmental Conditions

Assessing the operating environment:

- Indoor vs. outdoor installation

- Humidity and moisture levels

- Presence of corrosive chemicals or salt air

- Temperature extremes and fluctuations

- Dust and pollution levels

I once consulted on a project for a coastal industrial facility where the client initially considered VPI transformers to save on costs. After a thorough environmental assessment revealing high humidity and salt content in the air, we recommended cast resin transformers instead. This decision, while more expensive upfront, prevented premature failure and costly replacements down the line.

Load Requirements and Capacity

Matching transformer capacity to your needs:

- Current and future power requirements

- Peak load considerations

- Overload capacity needs

- Voltage regulation requirements

During a recent data center expansion project, we had to carefully consider both current needs and future growth. By selecting cast resin transformers with slightly higher capacity than immediately required, we provided room for the planned expansion without needing to replace the units in the near future.

Installation Location and Space Constraints

Considering physical limitations:

- Available floor space

- Height restrictions

- Ventilation and cooling requirements

- Accessibility for maintenance and replacement

Here’s a quick guide for space considerations:

| Transformer Type | Space Efficiency | Cooling Needs | Installation Flexibility |

|---|---|---|---|

| Cast Resin | Moderate | Good | Indoor, some outdoor with enclosure |

| VPI | Good | Very Good | Primarily indoor |

| Epoxy Encapsulated | Low | Moderate | Indoor and outdoor |

Budget Considerations

Balancing cost and performance:

- Initial purchase cost

- Installation expenses

- Long-term operational costs

- Expected lifespan and replacement costs

Maintenance Capabilities and Long-term Costs

Assessing ongoing care requirements:

- Frequency of required inspections

- Complexity of maintenance procedures

- Availability of skilled maintenance personnel

- Potential for repairs or rewinding

Key points for selecting the right transformer:

- Carefully assess your environmental conditions

- Consider both current and future load requirements

- Evaluate installation location and space constraints

- Balance initial costs with long-term operational expenses

- Assess your maintenance capabilities and resources

In my experience, the most successful transformer selections come from a holistic evaluation of all these factors. I recall a project for a pharmaceutical manufacturing facility where we initially leaned towards VPI transformers due to budget constraints. However, after a comprehensive analysis of the clean room environments, potential for chemical exposure, and the critical nature of the processes, we opted for cast resin transformers. This decision, while more expensive initially, provided the necessary reliability and reduced the risk of contamination, aligning perfectly with the facility’s stringent requirements.

For example, in a recent renewable energy project involving both solar and wind installations, we faced diverse environmental conditions across multiple sites. We implemented a mixed approach: VPI transformers for the main substation where conditions were controlled and cost was a factor, cast resin units for the solar inverter stations exposed to varying weather, and epoxy encapsulated transformers for the offshore wind turbines. This tailored selection ensured optimal performance and reliability across all aspects of the project while managing costs effectively.

As you make your decision, remember that choosing the right dry type transformer is not just about meeting immediate needs—it’s about ensuring long-term reliability, efficiency, and cost-effectiveness for your specific application.

Conclusion

Selecting the right dry type transformer—whether cast resin, VPI, or epoxy encapsulated—depends on a careful assessment of environmental conditions, load requirements, installation constraints, budget, and maintenance capabilities. Each type offers unique advantages for specific applications. By understanding these differences and considering your long-term needs, you can make an informed decision that ensures optimal performance, reliability, and cost-effectiveness for your electrical system.

Thank you for joining me in this exploration of dry type transformers. Stay curious, stay informed, and let’s keep pushing the boundaries of what’s possible in power distribution and electrical engineering.

When planning an electrical system—whether for a residential building, factory, or control panel—one question almost always comes up:

"Should we use a fuse or a circuit breaker for protection?"

This decision, though often underestimated, can have major implications for safety, cost, reliability, and future maintenance.

Fuses and circuit breakers are both overcurrent protection devices, but they operate differently. Fuses are single-use devices that melt when overloaded, while circuit breakers can be reset after tripping. Fuses generally respond faster and are more compact, making them ideal for sensitive electronics and space-constrained applications. Circuit breakers offer easier resetting and are better for circuits requiring frequent switching. The choice depends on factors like response time needs, maintenance preferences, and installation requirements.

In this article, I’ll break down the real differences between fuses and circuit breakers, helping you make the right choice for your application. We’ll explore their working principles, compare key features, and provide practical guidelines for selection. Whether you’re a procurement specialist, an electrical engineer, or a project manager, this guide will equip you with the knowledge to make informed decisions about electrical protection in your systems.

What Is a Fuse and How Does It Work?

Have you ever wondered what happens inside that small glass tube or plastic housing when an electrical fault occurs? Fuses are often the unsung heroes of electrical safety, but how exactly do they protect our circuits and equipment?