Dry Transformer: The Ultimate FAQs Guide – CHBEB

Introduction

It’s hard to know which transformer to choose. If you choose the wrong one, you risk safety, downtime, and higher costs. Dry-type transformers1 fix this by using safer insulation and being easier to maintain. They are perfect for projects in Southeast Asia, Africa, the Middle East, Russia, and Belt & Road countries.

What is a Dry Transformer?

A dry-type transformer is an electrical transformer that uses air or gas as the insulating medium instead of liquid. Unlike oil-immersed transformers, it does not rely on insulating oil for cooling or insulation.

Dry transformers offer several advantages:

- Safety & Reliability – With no liquid to leak or ignite, they significantly reduce fire and environmental risks.

- Low Maintenance – Since there is no oil, there is no need for periodic oil testing, replacement, or leak checks, lowering long-term maintenance costs.

- Compact & Lightweight – For the same power rating, dry-type transformers are usually smaller and lighter because they use efficient coil designs that save space.

- Durability – Their robust insulation structure makes them suitable for indoor use and harsh environments without risk of oil degradation.

These benefits make dry-type transformers a preferred choice in applications such as commercial buildings, hospitals, data centers, and other locations where safety and reliability are critical.

👉 Read more: The Ultimate Guide to Cast Resin Dry Type Transformers

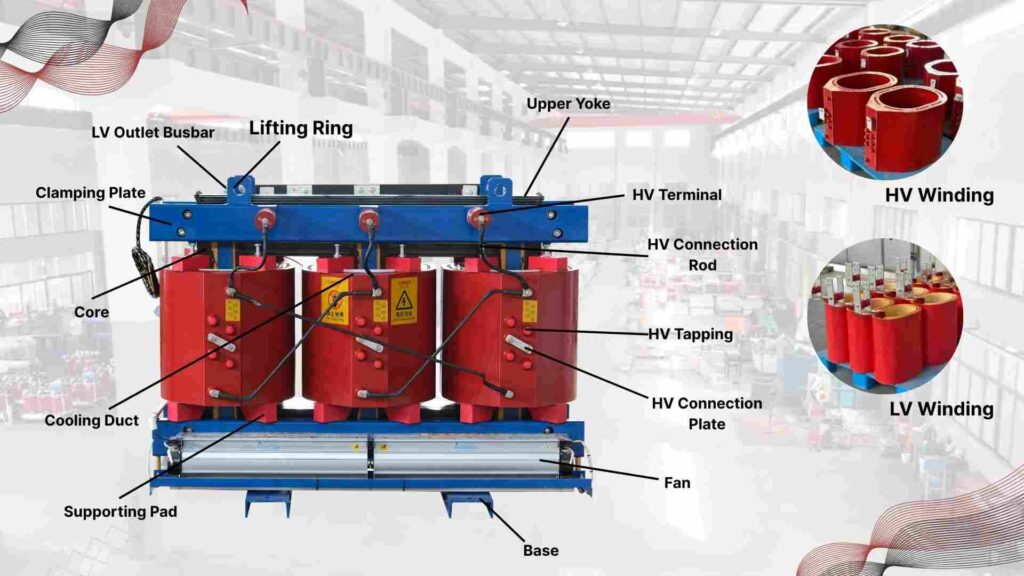

What is a Three-Phase Dry-Type Transformer?

A three-phase dry-type transformer is a self-cooled transformer designed with two windings and available in a wide range of primary and secondary voltage combinations. It is widely used in industrial and commercial applications where large power capacity is required.

Operating on a three-phase power supply, the transformer is built with three sets of windings on both the primary and secondary sides. This design ensures efficient power distribution, reduced conductor material requirements, and stable performance under heavy loads.

What is the Use of a Dry Transformer?

Dry-type transformers are static electrical devices that rely on air circulation and high-temperature insulation materials (such as DuPont Nomex) for cooling. During voltage conversion, heat generated in the windings is effectively dissipated through this air-insulation system, ensuring safe and reliable operation.

These transformers are commonly installed in indoor environments where exposure to water or liquid is minimal. Thanks to their non-flammable insulation system, they are also the preferred choice in fire-sensitive locations such as chemical plants, oil refineries, and high-occupancy buildings.

Dry Type Transformer Standards

Unclear standards create hidden risks. Certified ratings ensure efficiency and compliance. Typical 1.2 kV class benchmarks:

Single-Phase:

- 15 kVA at 97.70

- 50 kVA at 98.30

- 100 kVA at 98.60

- 250 kVA at 98.80

Three-Phase:

- 30 kVA at 98.23

- 112.5 kVA at 98.70

- 300 kVA at 99.02

- 1000 kVA at 99.28

📌 For buyers: higher efficiency = lower long-term energy costs, critical for African utilities and Southeast Asian commercial centers.

👉 Read more: How To Purchase A 1000kVA Transformer

What is a Dry Type Distribution Transformer?

A dry-type distribution transformer is the final stage of an electrical distribution system, stepping down voltage from the secondary side of the main power transformer to the level required by end-user loads.

Unlike oil-filled transformers, it uses air or gas insulation instead of liquid. In some designs, the unit is pressurized with nitrogen gas, which helps prevent moisture absorption, mold growth, and insulation degradation.

Dry-type distribution transformers are suitable for both indoor and outdoor installations. They can be placed in vaults, mounted on poles, or installed underground, providing protection against weather conditions and unauthorized access.

👉 Read more: Oil-Immersed Distribution Transformers Guide

Dry Type VS Oil Type Transformers

| Feature | Dry-Type Transformer | Oil-Immersed Transformer |

|---|---|---|

| Cooling | Air / Epoxy Resin | Mineral Oil |

| Fire Safety | Excellent (no oil) | Risk of oil fire |

| Maintenance | Low | Higher (oil testing, replacement) |

| Capacity | 50–3150 kVA | 50–25,000 kVA |

| Service Life | 20–25 years | 25–30 years |

| Price (2025) | USD 40–90/kVA | USD 20–50/kVA |

Price Comparison: Dry vs Oil Transformers (2025)

| Capacity (kVA) | Dry-Type (USD/kVA) | Oil-Type (USD/kVA) | Example FOB China Price (USD) | Typical Application |

|---|---|---|---|---|

| 500 | 70–85 | 55–65 | Dry: 35,000–42,500 · Oil: 27,500–32,500 | Commercial, small factories |

| 1000 | 65–80 | 45–60 | Dry: 65,000–80,000 · Oil: 45,000–60,000 | Hospitals, industrial parks |

| 2000 | 60–75 | 40–55 | Dry: 120,000–150,000 · Oil: 80,000–110,000 | Data centers, substations |

Prices vary by copper/aluminum windings, loss levels (0.6 vs 1.1), and IEC/UL certification.

What are the Advantages of a Dry Transformer?

- Key Advantages of Dry-Type Transformers

- 1. Better Overload Capacity

- Dry-type transformers can handle overloads more effectively than oil-filled transformers. Their windings are naturally cooled by surrounding air, reducing the risk of overheating during peak loads.

- 2. Low Partial Discharge2

- Partial discharge is a common cause of insulation failure in transformers, typically occurring in tiny voids within the insulation. Dry-type transformers minimize this risk because their windings are embedded in solid insulation material, free from air gaps or voids.

- 3. Outdoor Installation Ready

- Thanks to their oil-free design, dry transformers eliminate the risk of leakage. They can be safely installed outdoors within IP45-rated enclosures, ensuring reliable operation in diverse environments.

- 4. Zero Fire Hazard

- With non-flammable air or resin insulation, dry-type transformers pose virtually no fire risk. This makes them safer than oil-immersed transformers, where flammable insulating oil increases fire hazards.

- 5. Non-Hygroscopic Design

- Dry-type transformers do not absorb moisture from the atmosphere. This resistance to humidity and corrosion makes them highly reliable for outdoor and high-moisture environments.

Can Dry Transformers Be Used Outside?

Yes—if properly enclosed. Use IP-23, IP-45, or IP-54 protection to resist dust, humidity, and water jets.

How Are Dry Transformers Cooled?

- Self-cooling (AN): Air circulation, typical for schools/offices

- Forced cooling (AF): Fans or blowers, needed in data centers and heavy industry

How Do You Protect a Dry Transformer?

- Electrical: Circuit breakers, surge arresters, grounding

- Thermal: Sensors, relays, cooling fans

- Enclosure: IP-rated shells (IP20 for indoor, IP45/IP54 for outdoor, IP65 for harsh sites)

Typical Dry Transformer Prices (2025)

👉 Typical dry transformer prices in 2025: USD 40–90/kVA FOB China.

- Small units (50–500 kVA): USD 40–60/kVA

- Medium units (1000–2500 kVA): USD 60–90/kVA

- Example 1000 kVA (11/0.4 kV): USD 40,000–70,000

Buyers should compare transformer price quotes from different dry transformer suppliers in China to balance quality vs. cost.

CHBEB — Reliable Partner for Distribution Transformers

With over 60 years of transformer manufacturing expertise, CHBEB has become one of China’s most trusted distribution transformer suppliers. The company operates two factories in Wenzhou, one in Nanjing, and an office in Beijing, ensuring both strong production capacity and responsive customer support.

What makes CHBEB stand out:

- Strict Quality Commitment: All raw materials are 100% new and high-grade — no recycled or downgraded components.

- Proven Reliability: A qualified supplier for the State Grid Corporation of China, with a spotless record of zero major accidents.

- 100% Product Testing: Every unit is fully tested before delivery to guarantee safety, efficiency, and long service life.

- Fast-Track Orders: Ability to fulfill urgent orders in as little as one week, helping customers meet tight project deadlines.

- Custom Inventory Planning: Flexible stocking and supply strategies designed to align with customer procurement schedules.

- Global Outlook: Rooted in China and expanding worldwide, CHBEB actively supports local agents and partners, including assistance with market-specific certifications.

- Flexible Customization: Tailored transformer designs for utilities, contractors, and industrial clients, with reliable quality and fast delivery.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

👉 Secure your order early to avoid price increases and shipping delays in 2025.

How Long is Delivery Time in 2025?

- Small units (≤1000 kVA): 1–2 months

- Large units (≥2000 kVA): 2–5 months

- Bulk/custom orders: up to 12 months depending on supplier capacity

How to Choose a Reliable Dry Transformer Supplier in China?

- Check IEC/ISO certifications

- Verify project references in your region

- Request factory test reports before placing an order

- Compare 2–3 dry transformer suppliers China for fair price & quality assurance

Conclusion

In 2025, dry transformers remain the safer and more sustainable choice for critical projects. But the key is not only what you buy, but how you buy it.

✅ Practical steps for buyers:

- Define specs clearly – kVA, enclosure IP, loss class, winding material.

- Verify certifications – IEC/ISO compliance, PD and temperature-rise reports.

- Balance cost vs. lifecycle value – calculate long-term energy savings and service.

- Plan delivery early – standard 1–2 months, custom units up to 6 months.

By following this checklist, buyers can reduce procurement risks, secure reliable delivery, and ensure dry transformers operate safely for 20+ years.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group