What is the difference between an oil-immersed transformer and a dry-type transformer?

Choosing the wrong transformer causes project failures and high costs. Understanding their core differences is key to making the right choice for your power system’s safety and reliability.

The main difference is their cooling method and where they are used. Oil-immersed transformers use special oil to cool down, making them ideal for outdoor, high-power applications. Dry-type transformers use air for cooling, making them safer for indoor spaces like buildings and data centers.

On the surface, they both transform voltage. But if you look closer, their construction, manufacturing process1, and best use cases are completely different. Getting this choice right is fundamental to building a reliable and safe electrical system. Let’s dive into what really sets them apart, so you can choose the right one for your next project without any guesswork.

What is the core difference between them?

Are you confused about which transformer2 to specify for your project? Making the wrong choice leads to wasted money, project delays, and serious safety risks down the line. Let’s simplify it.

Oil-immersed transformers use oil for cooling and are built for outdoor, high-power jobs. Think of them as the heavy-duty workhorses. Dry-type transformers use air for cooling, so they are smaller, cleaner, and perfect for indoor locations where fire safety is the top priority.

To make it even clearer, I often compare them to an “outdoor giant” versus an “indoor specialist.” Each is designed for a specific environment, and using one where the other belongs is asking for trouble.

Oil-Immersed: The Outdoor Workhorse

This type is a big, heavy unit filled with transformer oil. The oil serves two purposes: it acts as an insulator and, more importantly, it transfers heat away from the core and coils. This makes them great at handling large power loads and temporary overloads. You will see them everywhere outdoors—in substations powering a neighborhood, at large industrial plants, or in open-air power distribution yards. Their main drawback is the oil itself. It can leak, it is flammable, and it needs to be maintained.

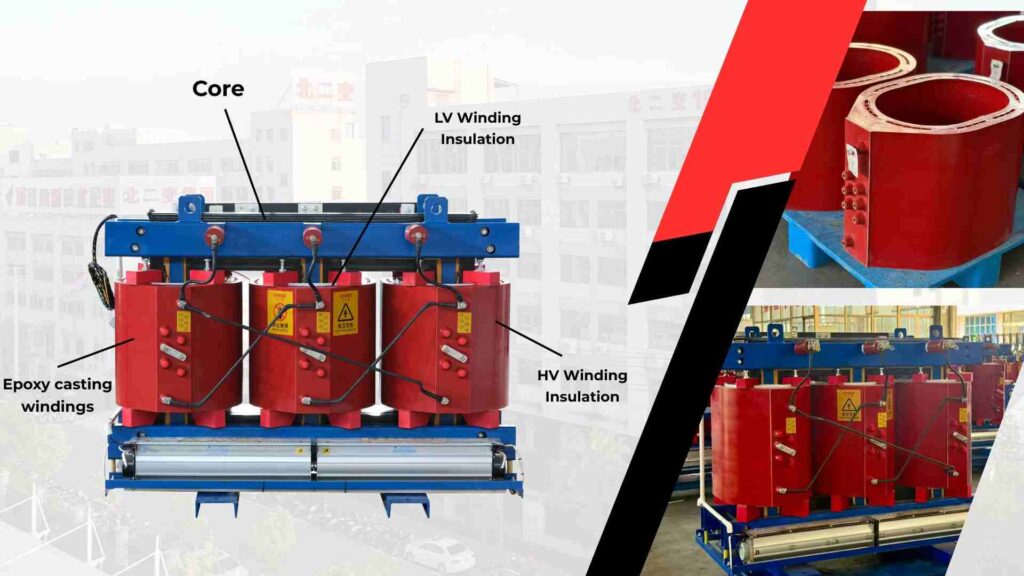

Dry-Type: The Indoor Specialist

This transformer looks more like a clean, metal cabinet. It has no oil. Instead, its coils are sealed in epoxy resin and it cools itself with the surrounding air, sometimes with the help of fans. This design makes it much safer for indoor use. There is no risk of oil leaks3 or fires. That is why they are the standard choice for commercial buildings, hospitals, data centers, and factory floors. Their downside is that they are more sensitive to moisture and don’t handle overloads as well as their oil-filled counterparts.

Here is a simple table to summarize the key differences:

| Feature | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling Medium | Transformer Oil | Air (Natural or Forced) |

| Typical Location | Outdoor (substations, factory yards) | Indoor (buildings, data centers) |

| Size & Weight | Large and heavy | Smaller and lighter |

| Key Advantage | Excellent heat dissipation, high overload capacity | High safety (no oil), low maintenance |

| Key Disadvantage | Fire/leak risk, needs oil maintenance | Sensitive to moisture, lower overload capacity |

Are they equally difficult to manufacture?

Do you think all transformers are just a core with some wires wrapped around it? This simple view leads many to source from cheap factories, resulting in equipment that fails prematurely. Let’s look at the real manufacturing challenges.

No, their manufacturing is completely different and requires specialized skills. Oil-immersed transformers need perfect sealing to prevent oil leaks and fires. Dry-type transformers need advanced epoxy casting without any air bubbles to prevent electrical failure. Only experienced manufacturers can produce high-quality versions of either.

When you look inside our factory, you see that the production lines for these two types have very different critical control points. A small factory might be able to make a basic version of one, but they will not have the technology or quality control to make a reliable, high-performance model.

The Challenge of Oil-Immersed: Sealing and Purity

For an oil-immersed transformer, everything comes down to containing the oil. The steel tank must be welded perfectly, with no pinholes. A tiny leak can lead to a short circuit, fire, or environmental contamination. The oil itself is just as important. We filter our transformer oil at least three times to get the impurity content below 0.01%. Any more than that, and the oil could fail to insulate properly. Finally, the silicon steel sheets that make up the core must be stacked with less than 0.1mm of error. Any more, and the transformer will overheat and waste energy.

The Challenge of Dry-Type: Insulation and Casting

With a dry-type transformer, the difficulty is in the insulation. We use a high-temperature epoxy resin4 to completely encapsulate the coils. This process, called vacuum casting5, is extremely precise. It must be done in a vacuum to ensure there are absolutely no air bubbles trapped in the resin. A single bubble creates a weak spot in the insulation that can cause the coil to burn out under load. The surface of the coil also needs a special treatment to protect it from moisture. Without it, the transformer would be unreliable in humid environments.

What are their biggest weaknesses?

Every piece of equipment has a weakness. Ignoring a transformer’s “fatal flaw” can lead to unexpected downtime, expensive repairs, and dangerous situations for your personnel. Knowing these weaknesses helps you prepare and choose wisely.

The biggest fear for an oil-immersed transformer is an oil leak or oil aging, which requires costly maintenance. The biggest fear for a dry-type transformer is high heat, moisture, and dust. These conditions can destroy its insulation and cause it to fail unexpectedly.

Understanding these vulnerabilities is not about avoiding these transformers. It is about matching them to the right environment and planning the right maintenance schedule. A good plan turns a potential weakness into a manageable characteristic.

The “Achilles’ Heel” of Oil-Immersed Transformers

The main problem is, and always will be, the oil. After years of exposure to outdoor weather, the rubber seals on the tank can become brittle and crack, causing oil leaks. This is not just a maintenance headache; it is an environmental hazard that can require a full shutdown for repairs. Second, the oil itself degrades over time. After 2-3 years, it oxidizes and loses its insulating properties. It must be tested and eventually replaced, which adds to the lifetime operating cost of the transformer.

The “Achilles’ Heel” of Dry-Type Transformers

Dry-type transformers are sensitive to their operating environment. Their number one enemy is heat. If the indoor space has poor ventilation or if summer temperatures get too high, the coil temperature can exceed 155°C. This will rapidly age the epoxy insulation and drastically shorten the transformer’s life. Their other enemies are moisture and dust. In a humid or dusty place like a textile mill, moisture and dust can build up on the coils. This lowers the insulation resistance and can lead to frequent tripping or even a complete short circuit.

| Transformer Type | Primary Weakness 1 | Primary Weakness 2 |

|---|---|---|

| Oil-Immersed | Oil Leaks (from aging seals) | Oil Aging (requires replacement) |

| Dry-Type | Overheating (in poor ventilation) | Moisture & Dust Contamination |

What are the most critical manufacturing steps?

How can you tell a high-quality transformer from a low-quality one just by looking at a spec sheet? A single shortcut in the manufacturing process can cause a catastrophic failure years later. You need to know what to ask a supplier.

For oil-immersed units, the most vital step is vacuum oil filling to remove all air. For dry-type units, it is the bubble-free vacuum casting of the epoxy resin. These two steps are the most difficult to master and are what separates a world-class manufacturer from the rest.

Over my years in this business, I have seen failures that all trace back to one of these critical steps being done poorly. That is why we invest so heavily in the machinery and quality control for these specific processes. They are not negotiable.

Three Hurdles for Oil-Immersed Transformers

- Core Stacking (Foundation): The process starts with precisely stacking silicon steel sheets. If the alignment is off by more than 0.1mm, magnetic losses increase, causing the transformer to run hot and inefficiently. We scrap any core that does not meet this tolerance.

- Vacuum Oil Filling (Most Difficult!): This is the make-or-break step. We place the assembled transformer in a large vacuum chamber and inject the purified oil. The vacuum pulls every last air bubble out of the windings and insulation. Air bubbles in the oil will lead to electrical discharge and eventual failure.

- Seal Testing (Crucial): After filling, we pressurize the tank to 0.3 MPa with air and submerge it in water for 24 hours. We watch for any bubbles, no matter how small. Any unit that shows even the slightest leak is rejected and disassembled.

Three Hurdles for Dry-Type Transformers

- Coil Winding (Foundation): The copper wire must be wound tightly and evenly. Any gaps or unevenness will create hot spots on the coil when the transformer is under load, which can lead to insulation failure.

- Epoxy Resin Casting (Most Difficult!): This is our most controlled process. The mold is heated to 60-80°C, and the epoxy resin is injected very slowly under vacuum. We monitor the process in real-time to ensure the bubble rate is below 0.1%. Any higher is a safety risk.

- Insulation & Temperature Rise Test (Crucial): Every single dry-type transformer we make goes through a final test. We run it at full load until its temperature stabilizes at 155°C and keep it there for 48 hours. We monitor its insulation resistance and performance to ensure it can handle real-world stress without degrading.

Where can I find reliable transformer manufacturers?

Do you believe all manufacturers are the same? Sourcing from the wrong region can mean you get a product that is not built for your standards, uses substandard materials, and fails prematurely. Location matters.

For top-tier dry-type transformers[^6], focus on manufacturers in the Suzhou and Shanghai area, which is a hub for precision electronics. For robust oil-immersed transformers[^7], look to the industrial clusters in Taizhou and Liaocheng. Be careful with low-cost factories in other regions.

In China, different regions have developed different specialties over decades. Knowing where to look gives you a huge advantage in finding a partner who truly understands the technology you need.

The Hub for High-End Dry-Type: Jiangsu & Shanghai

This region is the heart of China’s electronics industry. Manufacturers here have access to the best epoxy resin materials and the most advanced precision casting equipment. They have deep experience meeting the demanding quality standards for data centers, high-rise buildings, and international projects. If you need a high-performance dry-type transformer for a critical application, this is where you should look.

The Hub for Robust Oil-Immersed: Jiangsu & Shandong

Manufacturers in cities like Taizhou (where one of our bases is) and Liaocheng have a long history of making heavy electrical equipment. They have perfected the processes of oil purification, tank welding, and sealing. Many top factories here, including us, use imported sealing gaskets that last three times longer than standard ones. This is the best region for sourcing large, reliable oil-immersed transformers for utility and industrial projects.

What to Watch Out For: Low-End Production

In other regions, like parts of Hebei and Henan, you will find many smaller factories focused on producing low-cost transformers. To cut costs, they often use cheaper seals, do not purify their oil thoroughly, and have bubbles in their dry-type casting. These products might work for temporary power or very low-demand situations, but they are prone to leaks and insulation failure. For any serious project, it is a risk not worth taking.

How does choosing the right transformer solve real-world problems?

Is all this technical detail just theory? A project in a harsh environment with the wrong equipment is a recipe for constant problems and budget overruns. Here is a real story of how we helped a client succeed.

We helped an Uzbekistan client by providing a custom solution for their textile park. We supplied a high-temperature-rated oil-immersed unit for outdoors and a special dust-proof dry-type unit for indoors. This solved their environmental challenges, met local standards, and cut their maintenance costs by 60%.

I remember this project clearly because the client flew to our factory with samples from their previous supplier. They were frustrated with constant failures and wanted to see our process firsthand.

The client was building a large textile park in Tashkent. They had two big challenges. First, their outdoor substation needed a 2000kVA transformer that could handle summer heat up to 44°C and frequent salt-dust storms. They were worried a standard oil-immersed unit would leak. Second, their indoor workshops needed 1000kVA transformers, but the air was filled with textile dust. They feared a standard dry-type unit would clog up and fail. On top of that, all equipment had to be UZCERT certified.

During their visit, we focused on their pain points. We showed them our oil-immersed production line, highlighting the imported high-temperature seals and our vacuum oil-filling process that gets impurity levels down to 0.005%. We even ran a 48-hour test for them in a 45°C environmental chamber, and the transformer showed zero leaks. For the dry-type unit, we demonstrated our bubble-free casting and a special anti-dust coating we apply to the coils. We did a live dust-spray test, and the insulation resistance remained perfect.

The client was convinced. They saw our UZCERT documents and that our product labels and manuals were already in Uzbek. They signed a three-year supply contract on the spot. Two years later, they told me, “The outdoor transformer hasn’t leaked a drop of oil, and the indoor one has never tripped. Your products are perfectly adapted to our environment, and our maintenance costs are down 60%.”

Conclusion

Choosing between oil-immersed and dry-type transformers is about matching the product to the application. Understanding their differences in cooling, manufacturing, and weaknesses ensures you select a reliable and cost-effective solution.

⚙️ CHBEB — Reliable Partner for Dry Type Distribution Transformers

When it comes to dry type transformer manufacturing, CHBEB stands among China’s most experienced and trusted suppliers. With over 60 years of transformer production expertise, the company has mastered both technical precision and global reliability — serving utilities, EPC contractors, and industrial buyers worldwide.

Our Manufacturing Network

CHBEB operates two factories in Wenzhou, one in Nanjing, and a Beijing office, ensuring large-scale production capacity and fast global delivery. Each factory is equipped with advanced VPI and Cast Resin production lines that comply with IEC 600762, ISO9001, and CE standards.

Why CHBEB for Dry Type Transformers:

- High-End Materials: Every unit uses 100% new copper, Class F/H insulation, and premium silicon steel for maximum efficiency.

- Full Testing Assurance: All dry type transformers undergo strict routine and type tests — including insulation resistance, partial discharge, and temperature rise.

- Proven Reliability: CHBEB is a qualified supplier for the State Grid Corporation of China, maintaining a zero-accident record in global projects.

- Fast OEM/ODM Service: From prototype to batch delivery, customized orders can be completed in as little as one week for urgent projects.

- Global Focus: With exports to Russia, Southeast Asia, Africa, and Belt & Road countries, CHBEB supports local distributors and contractors with on-site service and certification assistance.

- Green Manufacturing: Our dry type transformers are designed for fire safety, low noise, and eco-compliance, ideal for hospitals, schools, and renewable energy systems.

💡 Looking for a reliable dry type transformer manufacturer that combines Chinese manufacturing strength with international quality?

👉 Contact CHBEB today at [email protected] or visit www.chbeb-ele.com to get your customized solution or download our full dry type transformer catalog.

- Understanding the manufacturing process can help you identify quality transformers. ↩︎

- Understanding the various type of transformer can help you choose the right one for your project. ↩︎

- Explore the causes of oil leaks to better maintain and choose oil-immersed transformers. ↩︎

- Learn about epoxy resin’s importance in ensuring the reliability of dry-type transformers. ↩︎

- Understand the vacuum casting process to appreciate its role in transformer quality. ↩︎

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group