Are you struggling with power limitations in your facility? Maybe you’re wondering how to upgrade from single-phase to three-phase power without breaking the bank. You’re not alone in this challenge.

Converting from single-phase to three-phase power can significantly improve energy efficiency and equipment performance. This guide will walk you through the entire process, from understanding basic concepts to implementing the conversion, helping you make an informed decision for your power needs.

As an electrical engineer with over 20 years of experience, I’ve helped countless clients tackle this exact problem. In this comprehensive guide, I’ll share practical insights to help you understand and implement this conversion safely and efficiently. Whether you’re a seasoned pro or new to electrical systems, you’ll find valuable information here to power up your knowledge and your facility.

Understanding the Basics: Single-Phase vs Three-Phase Power Systems?

Have you ever wondered why your home uses a different electrical system than a factory? The answer lies in the fundamental difference between single-phase and three-phase power. But what exactly sets these two systems apart?

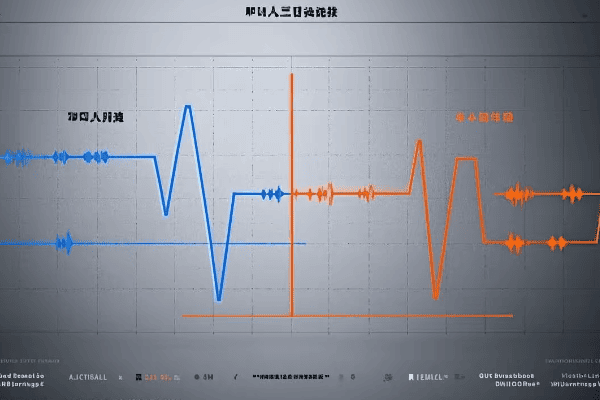

Single-phase power uses one alternating current, while three-phase uses three currents offset by 120 degrees. Three-phase is more efficient for large loads, delivering about 1.73 times more power with the same current and providing smoother operation for motors.

Let’s dive deeper into the world of power systems and explore the key differences between single-phase and three-phase:

Power Basics: Unraveling Single-Phase and Three-Phase Systems

-

Power Delivery:

- Single-Phase: One alternating current, two wires

- Three-Phase: Three alternating currents, three or four wires

-

Efficiency:

- Single-Phase: Less efficient for large loads (typically 70-80% efficient)

- Three-Phase: More efficient, especially for industrial applications (up to 95% efficient)

-

Applications:

- Single-Phase: Residential, small commercial (common in homes and small offices)

- Three-Phase: Industrial, large commercial, data centers (standard in factories and large buildings)

I remember a project where we were upgrading a small manufacturing plant’s power system. The owner was amazed to learn that switching to three-phase could reduce their energy costs by 15% and improve equipment performance. It was a lightbulb moment for both of us, highlighting the real-world impact of understanding these power systems.

Here’s a simple comparison table to illustrate the key differences:

| Characteristic | Single-Phase | Three-Phase |

|---|---|---|

| Number of wires | 2 (1 hot, 1 neutral) | 3 or 4 (3 hot, optional neutral) |

| Voltage waveform | One sine wave | Three sine waves, 120° apart |

| Power consistency | Pulsating | Constant |

| Typical voltage (US) | 120/240V | 208/240V or 480V |

| Load capacity | Lower | Higher (1.732 times more) |

| Motor starting | Less efficient | More efficient (30% better starting torque) |

| Typical applications | Homes, small offices | Factories, large buildings |

| Energy efficiency | Lower | Higher (up to 15% more efficient) |

Understanding these differences is crucial when planning your conversion from single-phase to three-phase power. It helps you appreciate the benefits you’ll gain and sets the foundation for the transformation process.

Assessing Your Needs: When and Why to Convert to Three-Phase Power?

Now that we understand the basics, you might be wondering: "Is converting to three-phase power right for my situation?" It’s a critical question that can significantly impact your operations and bottom line.

Converting to three-phase power is beneficial when you need to run heavy machinery, improve energy efficiency, or expand your power capacity. It’s ideal for industrial settings, large commercial buildings, and facilities with high power demands or motor-driven equipment.

Let’s explore the scenarios where converting to three-phase power makes sense:

When Three is Better Than One: Scenarios for Three-Phase Conversion

-

Heavy Machinery Operation:

- Three-phase power is ideal for running large motors and heavy equipment

- It provides smoother operation and reduces wear on machinery

-

Energy Efficiency Improvement:

- Three-phase systems are more efficient, especially for large loads

- Can lead to significant energy cost savings over time

-

Power Capacity Expansion:

- Three-phase allows for higher power capacity without increasing wire size

- Essential for growing businesses or facilities adding new equipment

-

Voltage Stability:

- Three-phase power provides more stable voltage

- Critical for sensitive equipment or processes requiring consistent power

-

Future-Proofing:

- Many modern industrial and commercial equipment require three-phase power

- Converting now can prepare your facility for future upgrades

I once worked with a small printing company that was struggling with frequent equipment breakdowns and high energy bills. After assessing their needs, we determined that converting to three-phase power would solve their issues. Post-conversion, they saw a 20% reduction in energy costs and significantly reduced maintenance needs for their printing presses.

Here’s a decision matrix to help you assess if three-phase conversion is right for you:

| Factor | Consider Three-Phase If… | Stay with Single-Phase If… |

|---|---|---|

| Power Demand | Over 15 kW | Under 15 kW |

| Equipment | Large motors, industrial machinery | Small appliances, residential equipment |

| Facility Type | Factory, large office, data center | Small office, residential |

| Energy Costs | High, looking to reduce | Low, not a major concern |

| Future Plans | Expansion, adding heavy equipment | No major changes planned |

| Voltage Needs | Require higher or more stable voltage | Current voltage is sufficient |

| Budget | Can invest for long-term savings | Limited budget for upgrades |

Remember, converting to three-phase power is a significant decision. It requires careful consideration of your current needs, future plans, and budget. If you’re unsure, it’s always best to consult with a professional electrical engineer who can assess your specific situation.

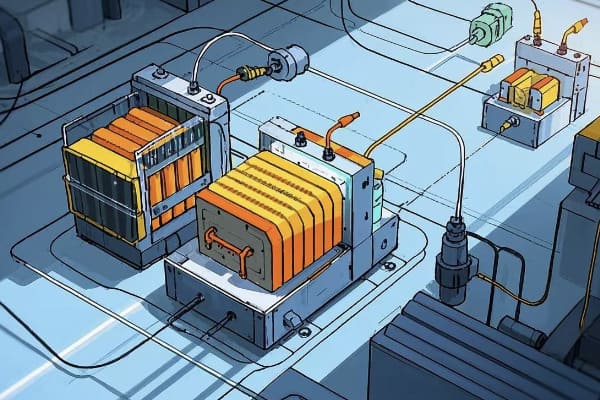

The Conversion Arsenal: Tools and Equipment for Successful Transformation?

You’ve decided that three-phase power is right for your needs. Great! But what tools and equipment will you need to make this conversion a reality? Let’s gear up for success.

Converting to three-phase power requires specific tools and equipment, including phase converters or VFDs, three-phase panels, appropriate wiring, and safety gear. Proper selection and use of these tools are crucial for a safe and effective conversion.

Let’s break down the essential components of your conversion toolkit:

Equipping for Success: Your Three-Phase Conversion Toolkit

-

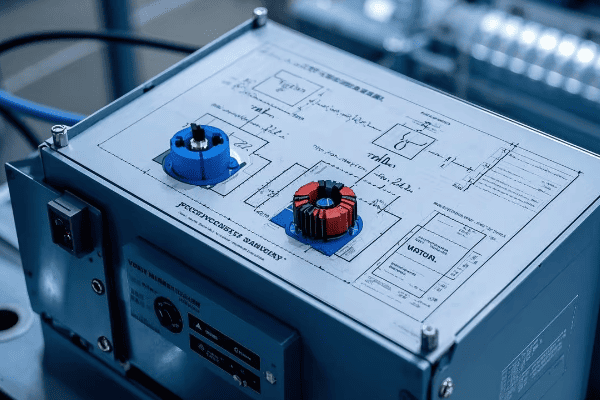

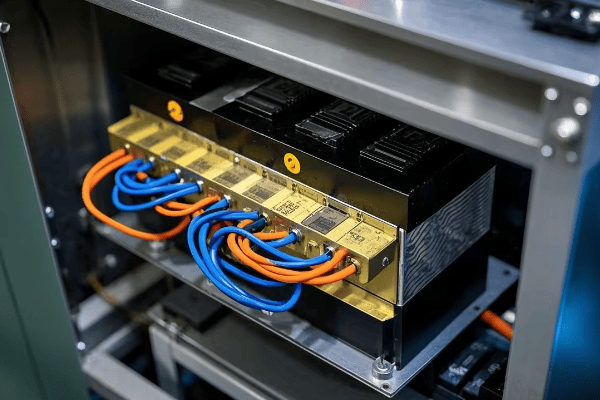

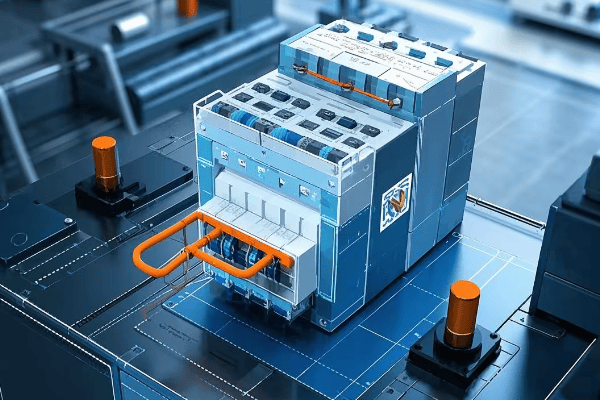

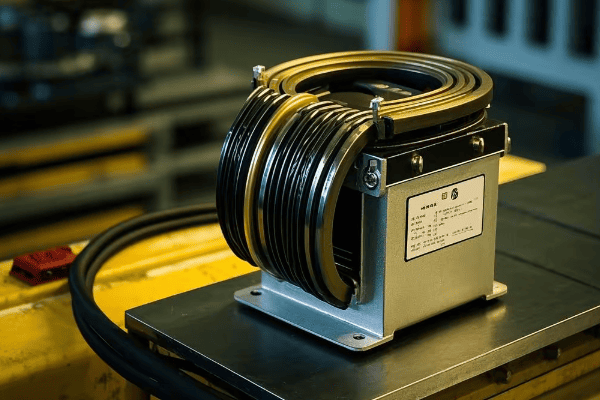

Phase Converters:

- Static Phase Converters: Simple, cost-effective for motor loads

- Rotary Phase Converters: More versatile, good for mixed loads

- Variable Frequency Drives (VFDs): Offer speed control and soft start

-

Three-Phase Panels:

- Main Distribution Panel: Distributes power to sub-panels or equipment

- Sub-Panels: For specific areas or equipment groups

-

Wiring and Connectors:

- Three-Phase Cable: Properly rated for voltage and amperage

- Connectors and Lugs: For secure and safe connections

-

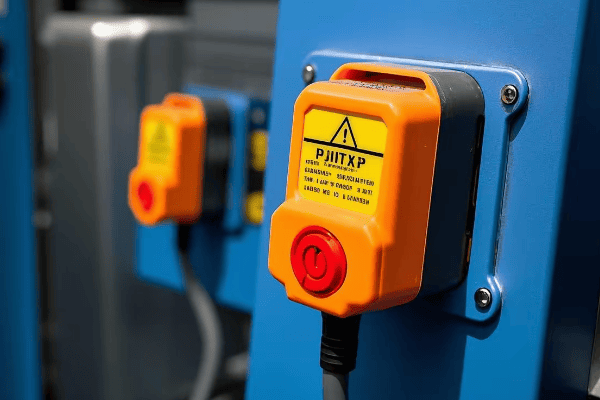

Safety Equipment:

- Voltage Tester: To ensure power is off before working

- Insulated Tools: Screwdrivers, wire strippers, pliers

- Personal Protective Equipment (PPE): Insulated gloves, safety glasses

-

Measurement Tools:

- Multimeter: For voltage and current measurements

- Clamp Meter: For measuring current without breaking the circuit

- Phase Rotation Meter: To ensure correct phase sequence

I recall a project where a client tried to cut costs by using inadequate wiring for their three-phase conversion. The result was overheating and a near fire. It taught me the importance of using the right tools and materials for the job, no matter what.

Here’s a checklist of essential tools and their uses:

| Tool/Equipment | Purpose | Importance |

|---|---|---|

| Phase Converter | Creates three-phase power from single-phase | Essential for conversion |

| Three-Phase Panel | Distributes three-phase power | Critical for power management |

| Three-Phase Cable | Carries three-phase current | Must be properly rated |

| Voltage Tester | Ensures power is off | Critical for safety |

| Multimeter | Measures voltage, current, resistance | Essential for testing |

| Insulated Tools | Protect against electrical shock | Important for safety |

| PPE | Personal protection | Crucial for worker safety |

| Phase Rotation Meter | Checks phase sequence | Important for proper motor operation |

Remember, the quality of your tools can significantly impact the success and safety of your conversion project. Invest in reliable, properly rated equipment, and don’t hesitate to consult with experts or rent specialized tools if needed. Your safety and the longevity of your new three-phase system depend on it.

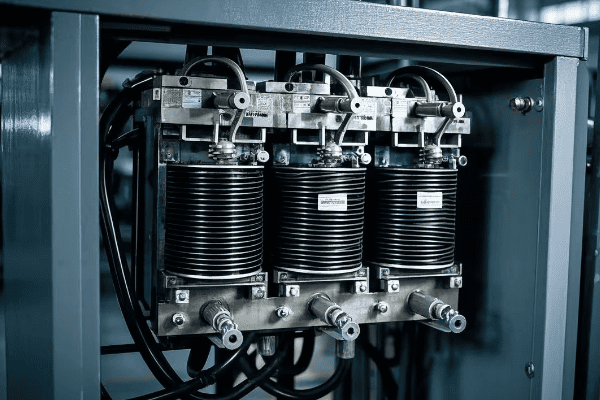

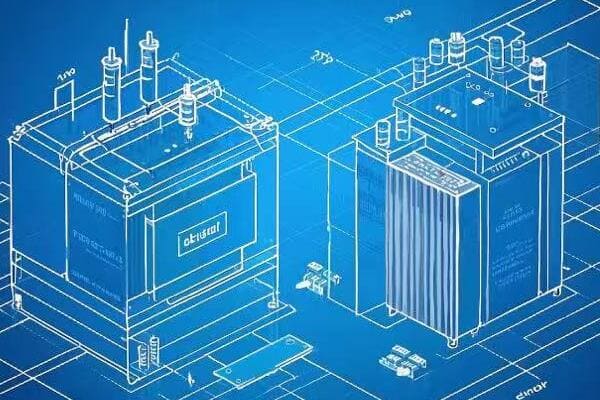

Wiring Wizardry: Mastering Delta and Wye Connections?

Now that we have our toolkit ready, it’s time to dive into the heart of three-phase systems: Delta and Wye connections. But what are they, and how do they affect our conversion process?

Delta and Wye are two fundamental ways to connect three-phase systems. Delta forms a triangle, while Wye forms a star with a neutral point. The choice between them affects voltage relationships, current flow, and system grounding. Understanding these connections is crucial for a successful conversion.

Let’s unravel the mystery of Delta and Wye connections:

Decoding Delta and Wye: The Core of Three-Phase Power

-

Delta Connection:

- Shape: Triangular configuration

- Voltage: Line voltage = Phase voltage

- Current: Line current = √3 × Phase current

- Uses: Often used on the primary (high voltage) side

- Advantages: Good for balancing loads, no neutral needed

-

Wye (Star) Connection:

- Shape: Star configuration with a neutral point

- Voltage: Line voltage = √3 × Phase voltage

- Current: Line current = Phase current

- Uses: Common on the secondary (low voltage) side

- Advantages: Provides a neutral for single-phase loads, good for unbalanced loads

I once worked on a project where we needed to power both heavy machinery and office equipment from the same three-phase system. By using a Delta-Wye transformer configuration, we were able to provide the high voltage needed for the machinery on the Delta side while having a neutral available for office equipment on the Wye side. It was a perfect balance of power distribution.

Here’s a comparison table to help you understand the key differences:

| Characteristic | Delta Connection | Wye Connection |

|---|---|---|

| Symbol | Δ | Y |

| Neutral point | No | Yes |

| Voltage relationship | VLine = VPhase | VLine = √3 × VPhase |

| Current relationship | ILine = √3 × IPhase | ILine = IPhase |

| Typical use | Primary side, high voltage | Secondary side, low voltage |

| Load balancing | Excellent | Good |

| Harmonic handling | Blocks 3rd harmonics | Allows 3rd harmonics |

| Ground fault detection | More challenging | Easier |

When converting from single-phase to three-phase, you’ll often encounter these connections:

- Delta-Wye Transformer: Common in distribution systems

- Delta-Delta: Used in some industrial applications

- Wye-Wye: Less common, but used in some specific scenarios

The choice between Delta and Wye connections depends on your specific needs, including voltage requirements, load characteristics, and grounding needs. It’s crucial to consult with an experienced electrical engineer to determine the best configuration for your conversion project.

Remember, proper connection is not just about getting power from point A to point B. It’s about ensuring efficiency, safety, and compatibility with your equipment. Take the time to understand these connections, and you’ll be well on your way to mastering the art of three-phase power distribution.

Safety First: Critical Precautions for High-Voltage Conversions?

As we gear up for the actual conversion process, we must address the elephant in the room: safety. Working with high-voltage systems is inherently dangerous, but how can we minimize risks and ensure a safe conversion process?

High-voltage conversions pose serious risks including electric shock, arc flash, and fire. Essential safety measures include proper personal protective equipment (PPE), lockout/tagout procedures, grounding, and adherence to electrical codes. Prioritizing safety can prevent accidents and save lives.

Let’s explore the critical safety precautions you should take during your conversion project:

Safeguarding Your Project: A Comprehensive Safety Approach

-

Personal Protective Equipment (PPE):

- Insulated gloves rated for the voltage level

- Arc-flash rated face shield and clothing

- Safety glasses and steel-toed boots

-

Lockout/Tagout Procedures:

- Identify all power sources

- Disconnect and lock out all electrical supplies

- Use "Do Not Operate" tags to prevent accidental energization

-

Grounding and Bonding:

- Properly ground all equipment

- Use temporary grounding cables during work

- Verify integrity of grounding connections

-

Workspace Safety:

- Ensure adequate lighting and ventilation

- Keep work area clean and free of obstacles

- Have a fire extinguisher rated for electrical fires nearby

-

Training and Certification:

- Ensure all workers are properly trained in electrical safety

- Verify certifications for high-voltage work

- Conduct regular safety briefings throughout the project

I once witnessed a near-miss incident where a technician, accustomed to different color codes, misidentified a live wire. This experience reinforced the importance of understanding and adhering to local standards, even for experienced professionals.

Here’s a comprehensive safety checklist for your conversion project:

| Safety Aspect | Key Actions | Why It’s Critical |

|---|---|---|

| Risk Assessment | Identify potential hazards | Prevents unforeseen dangers |

| PPE | Wear appropriate gear | Protects against shock and arc flash |

| Lockout/Tagout | Secure all power sources | Prevents accidental energization |

| Grounding | Properly ground all equipment | Protects against stray voltages |

| Insulation Testing | Check insulation integrity | Prevents insulation failures |

| Voltage Testing | Verify de-energized state | Ensures safe working conditions |

| Workspace | Keep area clean and organized | Reduces accidents and improves focus |

| Communication | Inform all team members of procedures | Ensures everyone is on the same page |

| Emergency Procedures | Know what to do in case of accident | Speeds up response in critical situations |

| Documentation | Record all safety steps taken | Provides accountability and learning opportunities |

Remember, no project is worth risking safety. Always prioritize safety measures and create a culture of safety awareness among all team members. It’s better to take extra time to ensure safety than to rush and risk an accident. If you’re not comfortable with any aspect of the conversion process, don’t hesitate to bring in professional help. Your life and the lives of your team members are far more valuable than any potential savings from DIY work.

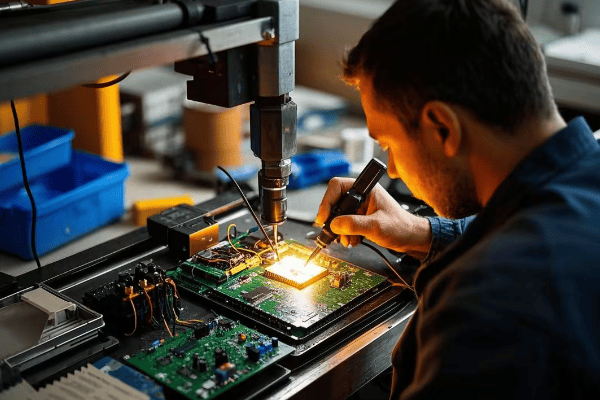

Step-by-Step Guide: Implementing Your Single to Three-Phase Conversion?

Now that we’ve covered the essentials of planning and safety, it’s time to roll up our sleeves and dive into the actual conversion process. But how exactly do we transform our single-phase system into a functioning three-phase powerhouse?

Converting from single-phase to three-phase involves several key steps: installing a phase converter or VFD, upgrading the main panel, rewiring for three-phase distribution, and connecting three-phase equipment. Each step requires careful planning, precise execution, and thorough testing to ensure a safe and effective conversion.

Let’s break down the conversion process into manageable steps:

From One to Three: Your Conversion Roadmap

-

Preparation:

- Conduct a thorough power audit

- Obtain necessary permits and approvals

- Gather all required tools and equipment

-

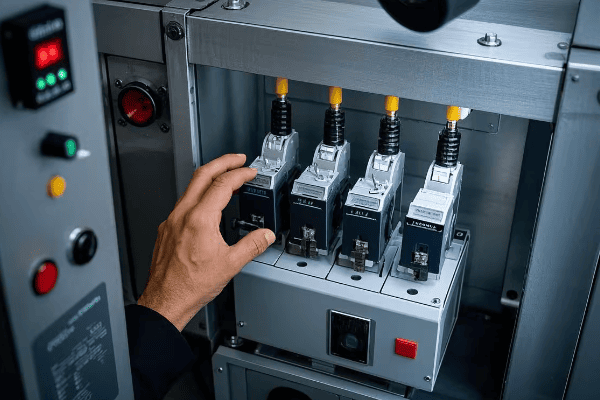

Install Phase Converter or VFD:

- Choose the right type and size for your needs

- Mount securely in a well-ventilated area

- Connect input and output wiring according to manufacturer’s instructions

-

Upgrade Main Panel: – Install new three-phase main breaker

- Add three-phase bus bars

- Ensure proper grounding and bonding

-

Rewire for Three-Phase Distribution:

- Run new three-phase wiring to sub-panels and equipment

- Use properly rated cables and connectors

- Label all new wiring clearly

-

Connect Three-Phase Equipment:

- Rewire or replace single-phase equipment as needed

- Ensure proper phase rotation for motors

- Install any necessary protective devices (e.g., overload protection)

-

Testing and Verification:

- Check all connections for tightness

- Measure voltages between phases and to ground

- Verify phase rotation and balance

-

Final Inspection and Power-Up:

- Conduct a thorough visual inspection

- Gradually power up the system, starting with main breaker

- Monitor for any issues during initial operation

I remember a challenging conversion project for a small factory in a remote area. We had limited resources, so precision was key. By meticulously following these steps and double-checking each connection, we successfully created a stable three-phase system that significantly improved their production efficiency.

Here’s a detailed checklist for the conversion process:

| Step | Action | Key Considerations | Potential Issues |

|---|---|---|---|

| 1. Preparation | Conduct power audit, obtain permits | Accurate load calculation | Underestimating power needs |

| 2. Install Converter | Mount and wire phase converter | Proper sizing and ventilation | Overheating, inadequate capacity |

| 3. Upgrade Panel | Install three-phase breaker and bus bars | Correct ampacity rating | Overloading, improper grounding |

| 4. Rewiring | Run new three-phase wiring | Proper cable sizing and routing | Voltage drop, overheating |

| 5. Equipment Connection | Connect and test each piece of equipment | Correct phase rotation | Motor burnout, equipment malfunction |

| 6. Testing | Measure voltages, check balance | Use calibrated instruments | Imbalanced loads, incorrect readings |

| 7. Final Inspection | Visual check, gradual power-up | Systematic approach | Overlooked issues, sudden failures |

Remember, this process involves working with high voltages and currents. If you’re not comfortable or experienced with electrical work, it’s crucial to consult or hire a professional electrician. Safety should always be your top priority throughout the conversion process.

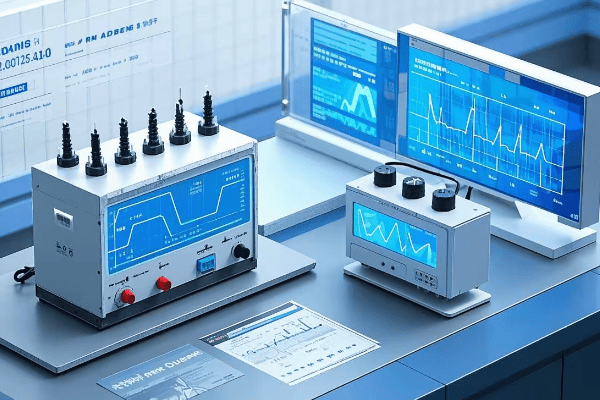

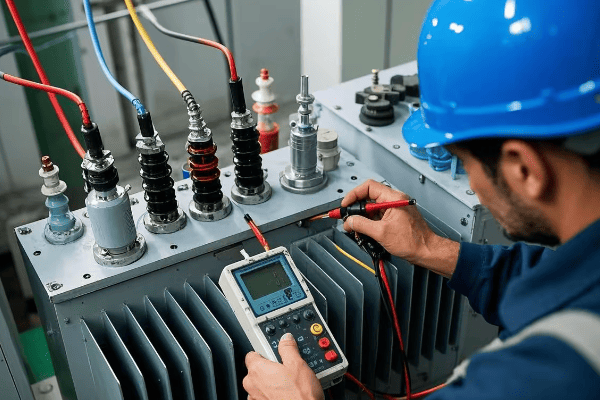

Testing and Troubleshooting: Ensuring Your New Three-Phase System Performs Flawlessly?

With our three-phase system now assembled, it’s time to put it to the test. But what checks should we perform, and how do we troubleshoot any issues that arise?

Testing a newly converted three-phase system involves checking voltage levels, phase balance, rotation, and load performance. Key tests include no-load tests, load tests, and insulation resistance tests. Proper testing and troubleshooting ensure system safety, efficiency, and longevity.

Let’s dive into the essential testing procedures and troubleshooting tips:

From Theory to Practice: Testing and Fine-Tuning Your Three-Phase System

-

No-Load Testing:

- Measure voltages between phases and phase-to-neutral

- Check for balanced voltages (should be within 1% of each other)

- Verify correct phase rotation

-

Load Testing:

- Gradually apply balanced load to the system

- Monitor voltage regulation under load

- Check for any unusual heating or noise

-

Insulation Resistance Testing:

- Use a megohmmeter to test insulation integrity

- Perform tests between windings and from windings to ground

- Compare results to manufacturer’s specifications

-

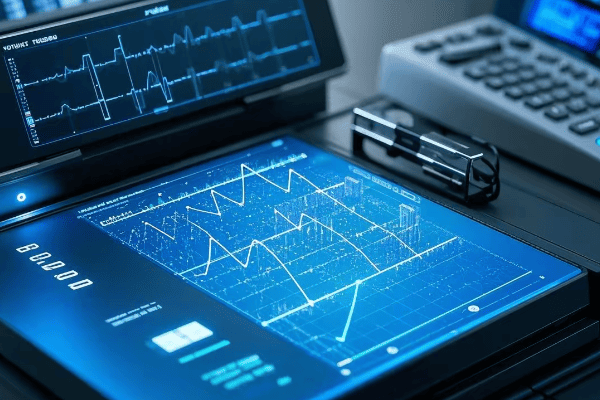

Power Quality Analysis:

- Use a power quality analyzer to check for harmonics

- Measure power factor under various load conditions

- Identify any voltage or current imbalances

-

Thermal Imaging:

- Use an infrared camera to check for hot spots

- Inspect connections and windings for abnormal heating

- Compare temperatures across all three phases

I once worked on a project where initial testing revealed a significant voltage imbalance. After careful troubleshooting, we discovered a loose connection in one of the main panel’s bus bars. Fixing this issue before putting the system into full operation prevented potential equipment damage and downtime.

Here’s a troubleshooting guide for common issues:

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Voltage Imbalance | Loose connections, uneven loads | Check all connections, redistribute loads |

| Incorrect Phase Rotation | Wiring errors | Swap any two phase connections |

| Overheating | Overloading, poor ventilation | Reduce load, improve cooling |

| Low Insulation Resistance | Moisture, contamination | Dry out equipment, clean connections |

| Harmonics | Non-linear loads | Install harmonic filters, redistribute loads |

| Power Factor Issues | Inductive loads | Add power factor correction capacitors |

| Noise or Vibration | Loose components, resonance | Tighten connections, check for mechanical issues |

Remember, thorough testing and prompt troubleshooting are key to ensuring the reliability and efficiency of your newly converted three-phase system. If you encounter issues you can’t resolve or if you’re unsure about any test results, don’t hesitate to consult with a professional. It’s always better to address potential problems early rather than risk system failure down the line.

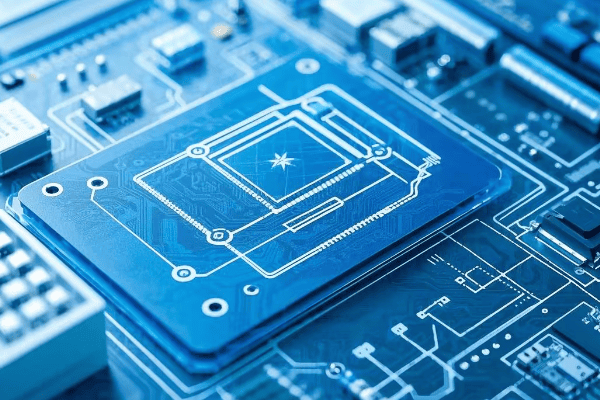

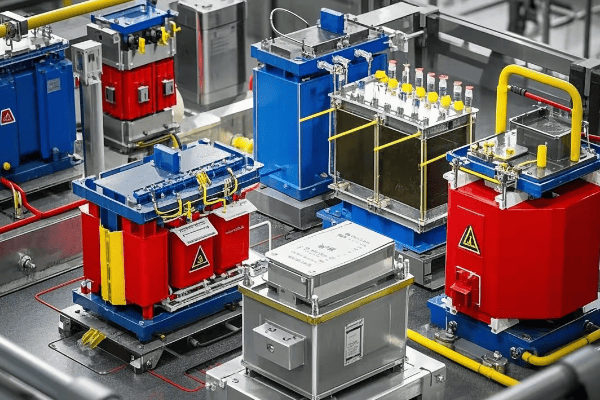

Future-Proofing Your Setup: Adapting to Emerging Power Distribution Technologies?

As we wrap up our three-phase conversion project, it’s important to look ahead. How can we ensure our newly converted system remains relevant and efficient in the face of rapidly evolving power technologies?

Future-proofing your three-phase system involves considering smart grid integration, renewable energy compatibility, and evolving efficiency standards. Implementing flexible designs, incorporating digital monitoring systems, and staying informed about global trends can help your system remain efficient and compliant for years to come.

Let’s explore key strategies for keeping your system ahead of the curve:

Embracing the Future: Keeping Your Three-Phase System Cutting-Edge

-

Smart Grid Integration:

- Implement digital monitoring and control systems

- Consider compatibility with demand response programs

- Prepare for bi-directional power flow capabilities

-

Renewable Energy Compatibility:

- Design for integration with solar and wind power systems

- Consider energy storage integration for load balancing

- Implement inverter-friendly protection schemes

-

Efficiency Standards Evolution:

- Stay informed about upcoming efficiency regulations

- Plan for potential retrofits or replacements to meet future standards

- Consider ultra-high efficiency transformers for long-term savings

-

Advanced Materials and Designs:

- Explore amorphous core transformers for reduced losses

- Consider solid-state transformers for improved control and efficiency

- Investigate high-temperature superconducting transformers for specialized applications

-

Cybersecurity Considerations:

- Implement robust security measures for digital control systems

- Plan for regular security audits and updates

- Consider physical security measures for critical infrastructure

I recently worked on a project upgrading a manufacturing plant’s power system. We incorporated a flexible design that allowed for easy integration of planned solar installations and future energy storage systems. By thinking ahead, we created a system that not only met current needs but was also ready for the company’s future sustainability goals.

Here’s a table summarizing key future-proofing strategies and their implications:

| Strategy | Description | Benefits | Global Trends |

|---|---|---|---|

| Smart Grid Readiness | Implementing digital monitoring and control | Improved efficiency and grid stability | Rapid adoption in developed countries |

| Renewable Integration | Designing for solar and wind power compatibility | Reduced carbon footprint, potential cost savings | Growing worldwide, led by EU and China |

| Efficiency Standard Compliance | Planning for future efficiency requirements | Long-term cost savings, regulatory compliance | Increasingly stringent globally |

| Advanced Materials Adoption | Using new core materials and designs | Reduced losses, improved performance | Growing interest, especially in high-cost energy markets |

| Cybersecurity Implementation | Securing digital systems against threats | Protected operations, compliance with security standards | Critical focus in all regions |

| Modular Design | Creating systems that can be easily upgraded | Flexibility for future needs, reduced replacement costs | Gaining popularity in fast-evolving industries |

| Energy Storage Readiness | Preparing for battery or other storage integration | Improved reliability, peak shaving capabilities | Rapid growth, especially in areas with unstable grids |

| Power Quality Enhancement | Implementing harmonic mitigation and voltage stabilization | Improved equipment life, reduced downtime | Critical in sensitive industrial and data center applications |

Remember, the power industry is constantly evolving. By staying informed about emerging technologies and trends, and designing your system with flexibility in mind, you can ensure that your three-phase conversion investment continues to pay dividends well into the future.

Conclusion

Transforming your power distribution from single-phase to three-phase is a complex but rewarding process. By understanding the basics, carefully planning, prioritizing safety, and implementing best practices in conversion and testing, you can successfully unlock the power of three-phase electricity for your facility. Remember to consider future trends and technologies to ensure your system remains efficient and relevant for years to come.

Are you struggling with power limitations in your facility? Maybe you’re wondering how to upgrade from single-phase to three-phase power without breaking the bank. You’re not alone in this challenge.

Converting single-phase transformers into a three-phase system is a cost-effective solution for many businesses. This guide will walk you through the entire process, from understanding basic concepts to implementing the conversion, helping you make an informed decision for your power needs.

As an electrical engineer with over 20 years of experience, I’ve helped countless clients tackle this exact problem. In this comprehensive guide, I’ll share practical insights to help you understand and implement this conversion safely and efficiently. Whether you’re a seasoned pro or new to electrical systems, you’ll find valuable information here to power up your knowledge and your facility.

Power Basics: Unraveling Single-Phase and Three-Phase Systems?

Have you ever wondered why your home uses a different electrical system than a factory? The answer lies in the fundamental difference between single-phase and three-phase power. But what exactly sets these two systems apart?

Single-phase power uses one alternating current, while three-phase uses three currents offset by 120 degrees. Three-phase is more efficient for large loads, delivering about 1.73 times more power with the same current and providing smoother operation for motors.

Let’s dive deeper into the world of power systems and explore the key differences between single-phase and three-phase:

Understanding the Power Flow: Single-Phase vs Three-Phase

-

Power Delivery:

- Single-Phase: One alternating current, two wires

- Three-Phase: Three alternating currents, three or four wires

-

Efficiency:

- Single-Phase: Less efficient for large loads (typically 70-80% efficient)

- Three-Phase: More efficient, especially for industrial applications (up to 95% efficient)

-

Applications:

- Single-Phase: Residential, small commercial (common in homes and small offices)

- Three-Phase: Industrial, large commercial, data centers (standard in factories and large buildings)

I remember a project where we were upgrading a small manufacturing plant’s power system. The owner was amazed to learn that switching to three-phase could reduce their energy costs by 15% and improve equipment performance. It was a lightbulb moment for both of us, highlighting the real-world impact of understanding these power systems.

Here’s a simple comparison table to illustrate the key differences:

| Characteristic | Single-Phase | Three-Phase |

|---|---|---|

| Number of wires | 2 (1 hot, 1 neutral) | 3 or 4 (3 hot, optional neutral) |

| Voltage waveform | One sine wave | Three sine waves, 120° apart |

| Power consistency | Pulsating | Constant |

| Typical voltage (US) | 120/240V | 208/240V or 480V |

| Load capacity | Lower | Higher (1.732 times more) |

| Motor starting | Less efficient | More efficient (30% better starting torque) |

| Typical applications | Homes, small offices | Factories, large buildings |

| Energy efficiency | Lower | Higher (up to 15% more efficient) |

Understanding these differences is crucial when planning your conversion from single-phase to three-phase power. It helps you appreciate the benefits you’ll gain and sets the foundation for the transformation process.

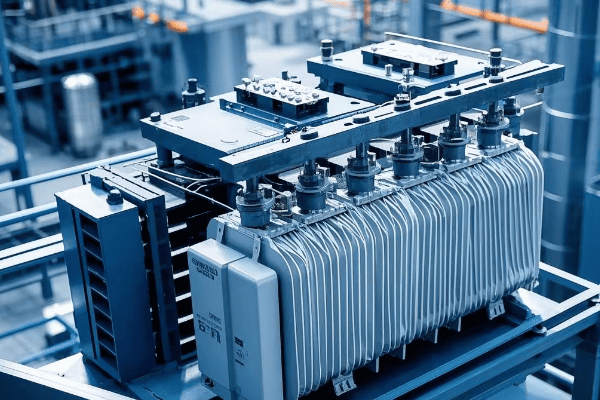

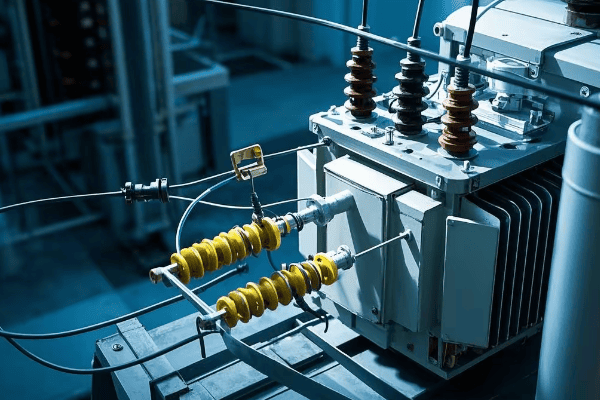

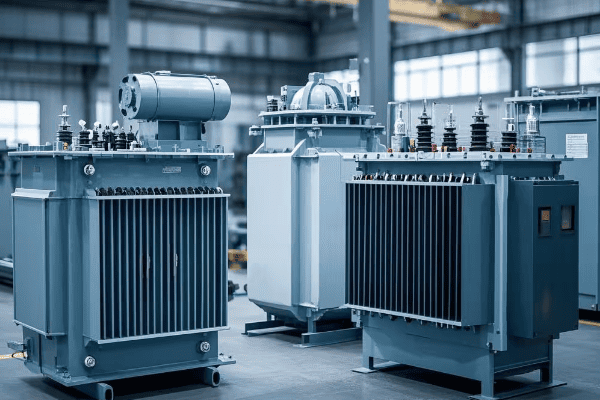

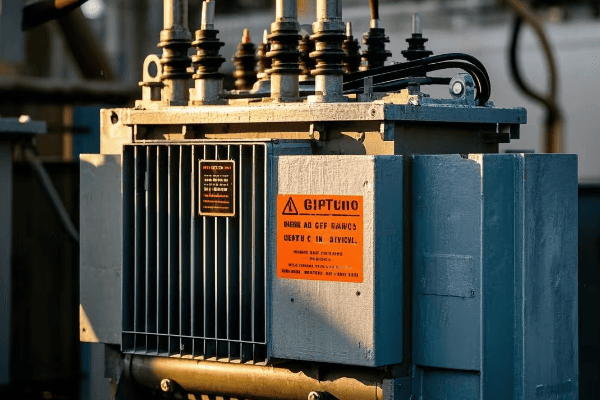

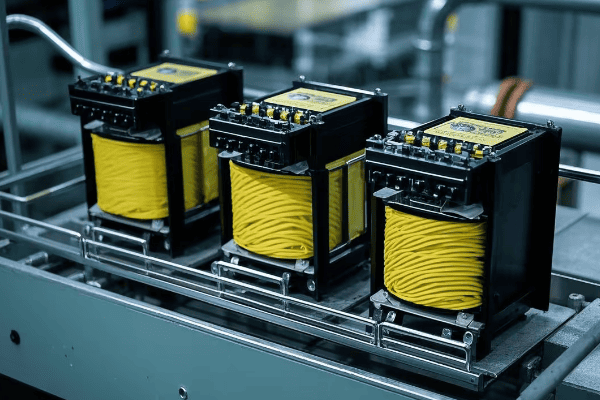

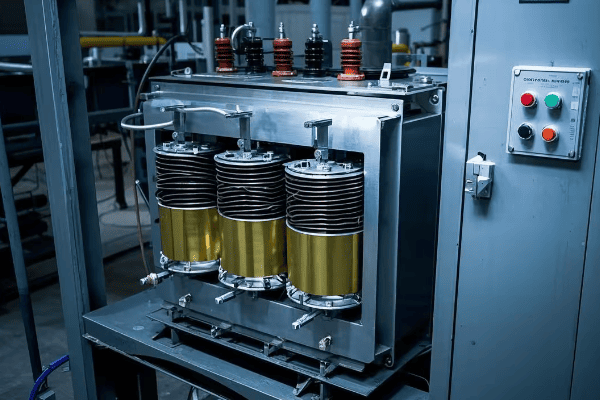

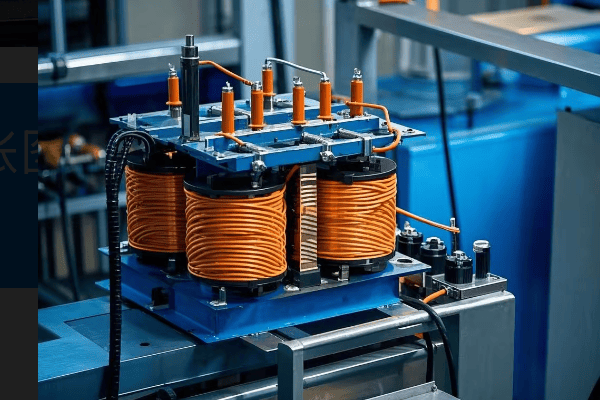

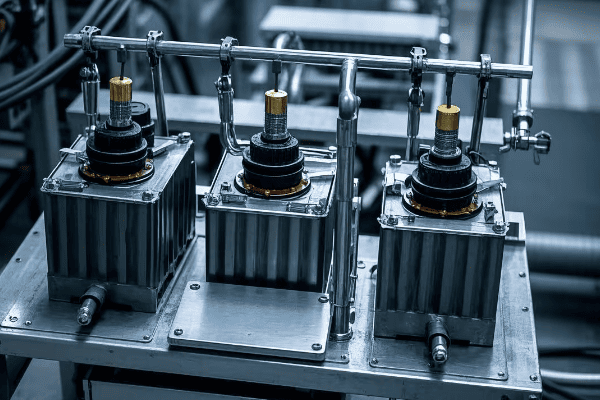

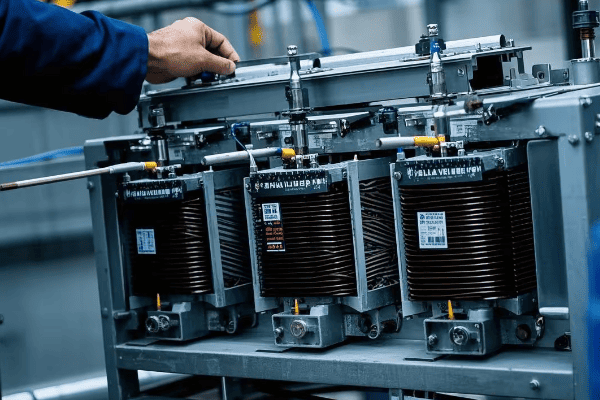

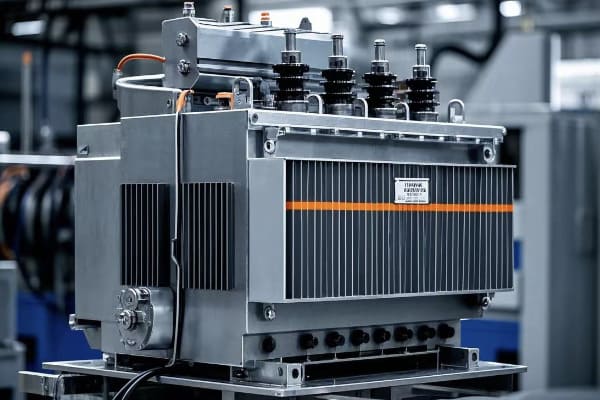

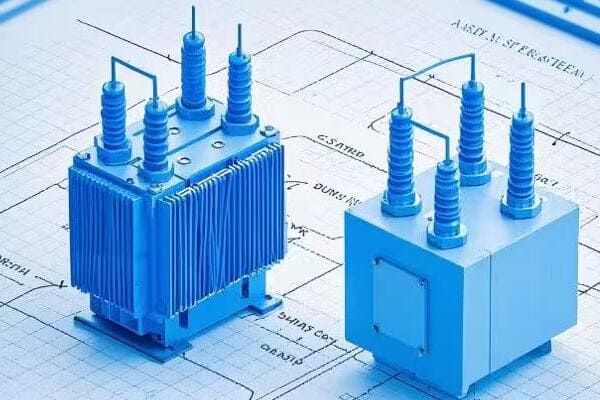

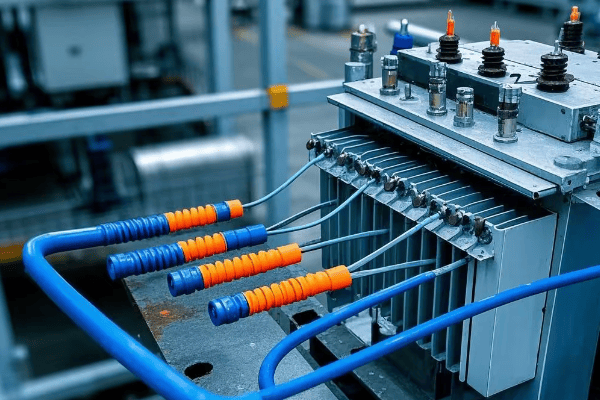

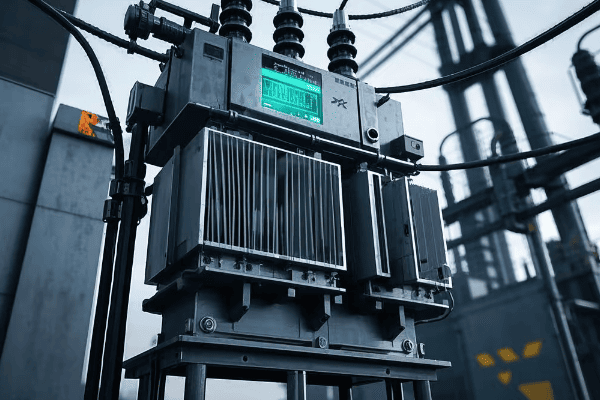

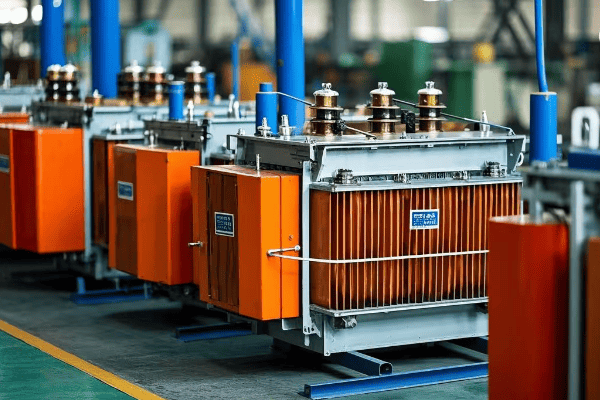

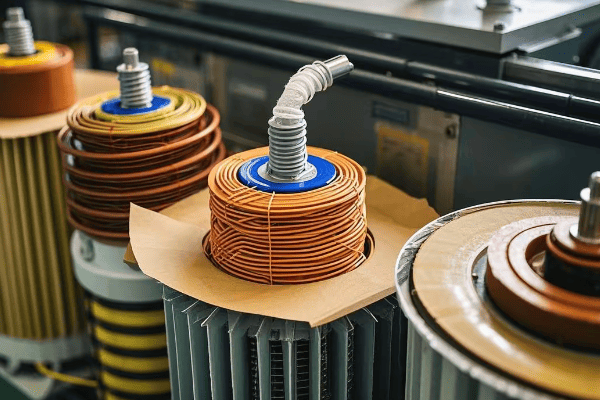

The Transformer Trio: Selecting Compatible Single-Phase Units?

Now that we understand the basics of single-phase and three-phase power, let’s focus on the heart of our conversion project: the transformers. But how do you choose the right single-phase transformers for a successful three-phase conversion?

Selecting compatible single-phase transformers is crucial for a successful three-phase conversion. Key factors include matching voltage ratings, power capacity, impedance, and efficiency. All three units must have identical specifications to ensure balanced operation and optimal performance of the converted system.

Let’s explore the critical aspects of transformer selection for your conversion project:

The Perfect Match: Choosing Your Transformer Trio

-

Voltage Ratings:

- Primary voltage: Must match your input supply (e.g., 480V in US, 400V in EU)

- Secondary voltage: Determine based on load requirements

- Tap settings: Consider transformers with multiple taps for flexibility

-

Power Capacity:

- Calculate total load requirements

- Each transformer should handle 1/3 of the total load

- Allow for future expansion (typically 20-30% extra capacity)

-

Impedance Matching:

- All three transformers should have the same impedance (within 0.3% tolerance)

- Typical range: 2-5% for distribution transformers

- Matching impedance ensures balanced current flow and minimizes circulating currents

-

Efficiency Considerations:

- Look for high-efficiency models to reduce losses

- Consider total cost of ownership, not just initial price

- Check for compliance with energy efficiency standards (e.g., DOE 2016 in US, IE3 in EU)

I once consulted on a project for a multinational corporation setting up a factory in Mexico. They initially planned to use transformers from their US supplier, but we quickly realized these wouldn’t meet local voltage standards or efficiency requirements. By selecting locally manufactured transformers that met both IEC and NOM (Mexican) standards, we ensured compliance and optimal performance.

Here’s a detailed comparison table to guide your transformer selection:

| Specification | Why It’s Important | What to Look For | Potential Issues if Mismatched |

|---|---|---|---|

| Voltage Rating | Ensures compatibility with system | Exact match to system voltage | Overvoltage or undervoltage conditions |

| kVA Rating | Determines power handling capacity | Sum of three should exceed total load | Overloading, reduced efficiency |

| Impedance | Affects fault currents and voltage regulation | Must be identical for all three (±0.3%) | Unbalanced currents, overheating |

| Efficiency | Impacts operating costs | Look for high efficiency models (>98%) | Higher energy costs, increased heat generation |

| Temperature Rise | Indicates cooling effectiveness | 65°C rise common (80°C in hot climates) | Reduced lifespan, potential failure |

| BIL (Basic Impulse Level) | Protects against voltage surges | Should match or exceed system requirements | Vulnerability to transient overvoltages |

| Taps | Allows for voltage adjustment | 5-position taps offer good flexibility | Inability to fine-tune voltage |

| Vector Group | Affects phase relationships | Typically Dyn11 for distribution transformers | Phase shift issues, potential system instability |

| Cooling Method | Determines installation requirements | ONAN is most common for smaller sizes | Inadequate cooling, reduced capacity |

Remember, the cheapest option isn’t always the most cost-effective in the long run. Consider the total cost of ownership, including energy costs and maintenance, when making your selection. It’s often worth investing in higher quality, more efficient transformers to ensure the longevity and reliability of your three-phase system.

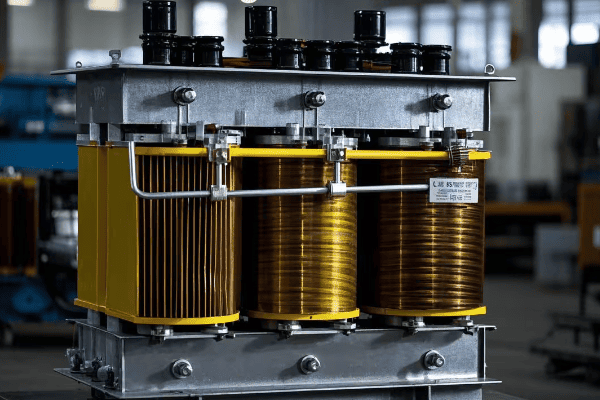

Wiring Wizardry: Mastering Delta and Wye Connections?

Now that we’ve selected our transformer trio, it’s time to connect them. But how exactly do we wire these single-phase units to create a three-phase system? This is where Delta and Wye connections come into play.

Delta and Wye are two fundamental ways to connect three-phase transformers. Delta forms a triangle, while Wye forms a star with a neutral point. The choice between them affects voltage relationships, current flow, and system grounding. Most three-phase conversions use a Delta-Wye configuration for optimal performance.

Let’s dive into the details of these connections and understand their roles in our three-phase system:

Decoding Delta and Wye: The Heart of Three-Phase Power

-

Delta Connection:

- Shape: Triangular configuration

- Voltage: Line voltage = Phase voltage

- Current: Line current = √3 × Phase current

- Uses: Often used on the primary (high voltage) side

- Advantages: Good for balancing loads, no neutral needed

-

Wye (Star) Connection:

- Shape: Star configuration with a neutral point

- Voltage: Line voltage = √3 × Phase voltage

- Current: Line current = Phase current

- Uses: Common on the secondary (low voltage) side

- Advantages: Provides a neutral for single-phase loads, good for unbalanced loads

In a recent project for a manufacturing plant, we used a Delta-Wye configuration. We connected the primary side in Delta to handle load balancing efficiently, and the secondary side in Wye to provide a neutral for office equipment. This combination offered the best of both worlds, showcasing how understanding these connections can lead to optimal system design.

Here’s a detailed comparison of Delta and Wye connections:

| Characteristic | Delta Connection | Wye Connection |

|---|---|---|

| Symbol | Δ | Y |

| Neutral point | No | Yes |

| Voltage relationship | VLine = VPhase | VLine = √3 × VPhase |

| Current relationship | ILine = √3 × IPhase | ILine = IPhase |

| Harmonic handling | Blocks 3rd harmonics | Allows 3rd harmonics |

| Ground fault detection | More challenging | Easier |

| Typical use | Primary side | Secondary side |

| Balanced load handling | Excellent | Good |

| Unbalanced load handling | Good | Excellent |

When converting single-phase transformers to a three-phase system, we typically connect the primary windings in Delta and the secondary windings in Wye. This Delta-Wye configuration offers several advantages:

- It provides a neutral point on the secondary side, which is useful for powering single-phase loads.

- It helps in suppressing harmonics, improving power quality.

- It allows for easier ground fault detection on the secondary side.

Remember, the choice between Delta and Wye can significantly impact your system’s performance, efficiency, and safety. As you plan your conversion, consider your specific needs and consult with an expert if you’re unsure about the best configuration for your application.

Blueprint for Success: Planning Your Three-Phase Conversion Project?

With our transformers selected and our connection strategy in place, it’s time to plan the conversion project. But where do you start, and what factors should you consider to ensure a smooth transition?

Planning a three-phase conversion involves assessing power needs, evaluating existing infrastructure, understanding local regulations, and preparing for potential challenges. A well-planned project can save time, money, and prevent safety issues during the conversion process.

Let’s break down the key steps in planning your conversion project:

Crafting Your Conversion Roadmap: From Concept to Completion

-

Assess Your Power Needs:

- Calculate your total power requirements

- Consider future expansion plans

- Identify any specific voltage or current needs

-

Evaluate Existing Infrastructure:

- Check the capacity of your electrical service

- Assess the condition of your electrical panels and wiring

- Determine if any equipment upgrades are necessary

-

Understand Regulations:

- Research local electrical codes and standards

- Determine if permits are required for the conversion

- Consider hiring a licensed electrician if required by law

-

Create a Detailed Project Plan:

- Outline each step of the conversion process

- Assign responsibilities to team members or contractors

- Set realistic timelines for each phase of the project

-

Budget and Financial Planning:

- Estimate costs for equipment, labor, and potential downtime

- Consider energy savings and ROI in your financial analysis

- Explore financing options if needed

I once worked with a client who skipped the planning phase and jumped straight into conversion. Halfway through, we discovered their existing wiring couldn’t handle the new load, leading to costly delays and rewiring. This experience taught me the invaluable lesson of thorough planning.

Here’s a checklist to guide your planning process:

| Planning Step | Key Considerations | Potential Pitfalls |

|---|---|---|

| Power Assessment | Total load, future growth | Underestimating power needs |

| Infrastructure Evaluation | Service capacity, wiring condition | Inadequate infrastructure |

| Regulatory Compliance | Local codes, permits | Legal issues, failed inspections |

| Project Planning | Step-by-step process, timelines | Overlooked tasks, delays |

| Budgeting | Equipment costs, labor, downtime | Unexpected expenses |

| ROI Analysis | Energy savings, productivity gains | Overestimating benefits |

| Team Assembly | Skills needed, roles assignment | Lack of expertise |

| Risk Assessment | Potential challenges, mitigation strategies | Unforeseen problems |

Remember, proper planning is the foundation of a successful conversion project. Take the time to thoroughly assess your needs, understand the requirements, and prepare for potential challenges. This upfront investment will pay off in smoother execution, fewer surprises, and a more efficient three-phase system in the end.

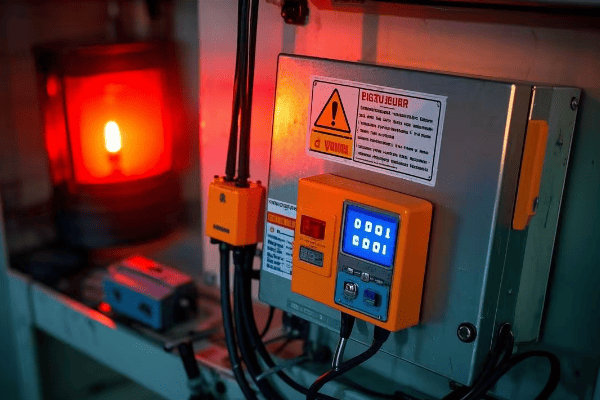

Safety First: Essential Precautions for High-Voltage Transformations?

As we gear up for the actual conversion process, it’s crucial to address the elephant in the room: safety. Working with high-voltage systems is inherently dangerous, but how can we minimize risks and ensure a safe conversion process?

High-voltage transformer conversions pose serious risks including electric shock, arc flash, and fire. Essential safety measures include proper personal protective equipment (PPE), lockout/tagout procedures, grounding, and adherence to electrical codes. Prioritizing safety can prevent accidents and save lives.

Let’s explore the critical safety precautions you should take during your conversion project:

Safeguarding Your Project: A Comprehensive Safety Approach

-

Personal Protective Equipment (PPE):

- Insulated gloves rated for the voltage level

- Arc-flash rated face shield and clothing

- Safety glasses and steel-toed boots

-

Lockout/Tagout Procedures:

- Identify all power sources

- Disconnect and lock out all electrical supplies

- Use "Do Not Operate" tags to prevent accidental energization

-

Grounding and Bonding:

- Properly ground all transformer cases

- Use temporary grounding cables during work

- Verify integrity of grounding connections

-

Workspace Safety:

- Ensure adequate lighting and ventilation

- Keep work area clean and free of obstacles

- Have a fire extinguisher rated for electrical fires nearby

-

Training and Certification:

- Ensure all workers are properly trained in electrical safety

- Verify certifications for high-voltage work

- Conduct regular safety briefings throughout the project

I once witnessed a near-miss incident where a technician, accustomed to different color codes, misidentified a live wire. This experience reinforced the importance of understanding and adhering to local standards, even for experienced professionals.

Here’s a comprehensive safety checklist for your conversion project:

| Safety Aspect | Key Actions | Why It’s Critical |

|---|---|---|

| Risk Assessment | Identify potential hazards | Prevents unforeseen dangers |

| PPE | Wear appropriate gear | Protects against shock and arc flash |

| Lockout/Tagout | Secure all power sources | Prevents accidental energization |

| Grounding | Properly ground all equipment | Protects against stray voltages |

| Insulation Testing | Check insulation integrity | Prevents insulation failures |

| Voltage Testing | Verify de-energized state | Ensures safe working conditions |

| Workspace | Keep area clean and organized | Reduces accidents and improves focus |

| Communication | Inform all team members of procedures | Ensures everyone is on the same page |

| Emergency Procedures | Know what to do in case of accident | Speeds up response in critical situations |

| Documentation | Record all safety steps taken | Provides accountability and learning opportunities |

Remember, no project is worth risking safety. Always prioritize safety measures and create a culture of safety awareness among all team members. It’s better to take extra time to ensure safety than to rush and risk an accident.

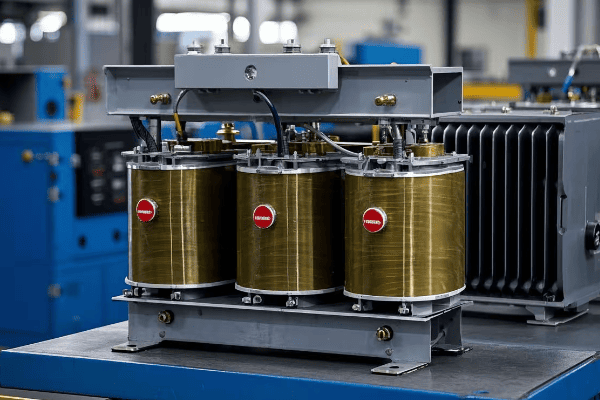

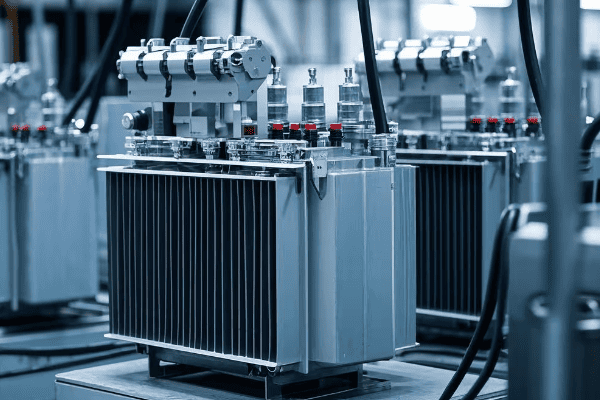

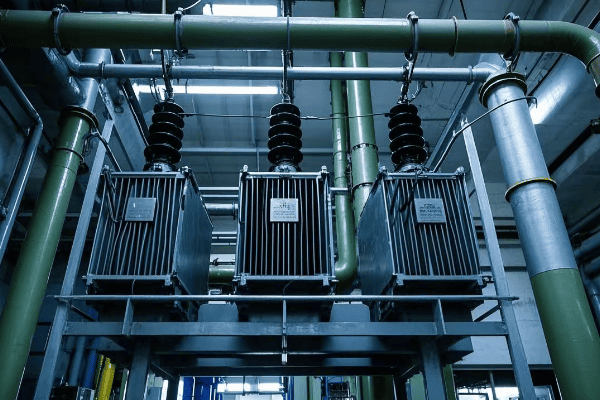

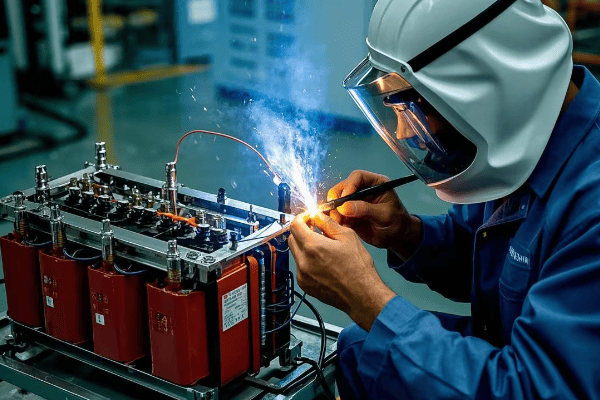

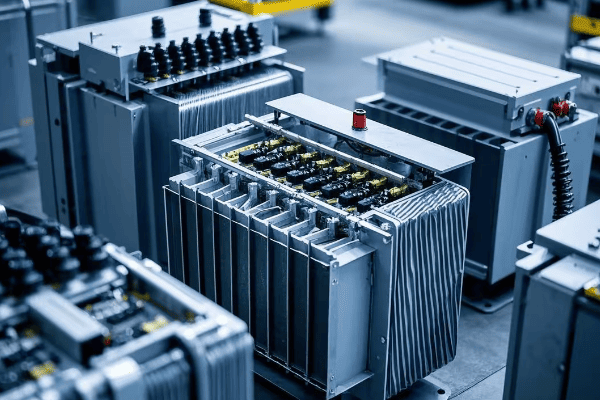

The Conversion Process: Step-by-Step Guide to Three-Phase Integration?

Now that we’ve covered the essentials of planning and safety, it’s time to roll up our sleeves and dive into the actual conversion process. But how exactly do we transform our single-phase transformers into a functioning three-phase system?

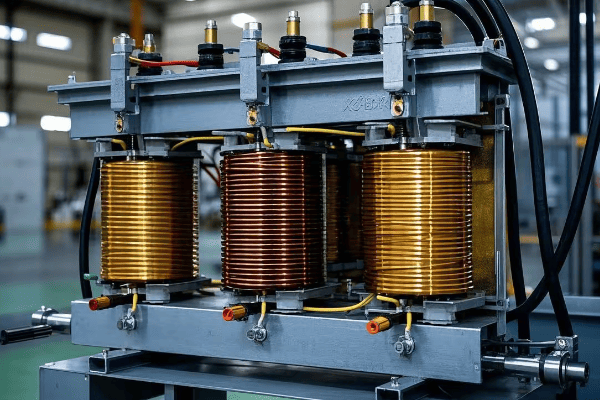

Converting single-phase transformers to a three-phase system involves carefully connecting the primary and secondary windings in specific configurations, typically Delta for the primary and Wye for the secondary. This process requires precise measurements, proper insulation, and attention to phase relationships to ensure a balanced and efficient three-phase output.

Let’s break down the conversion process into manageable steps:

From Single to Three: A Step-by-Step Transformation Guide

-

Preparation:

- Gather three identical single-phase transformers

- Ensure all transformers have the same voltage ratings and capacity

- Collect necessary tools: multimeter, insulation tester, phase rotation meter

-

Primary Winding Connection (Delta):

- Identify the primary terminals of each transformer

- Connect the end of the first transformer to the start of the second

- Connect the end of the second to the start of the third

- Connect the end of the third to the start of the first

-

Secondary Winding Connection (Wye):

- Identify the secondary terminals of each transformer

- Connect one end of each transformer’s secondary to a common point (neutral)

- The other ends become the three phases of your output

-

Insulation and Protection:

- Apply appropriate insulation to all connections

- Install overcurrent protection devices for each phase

-

Testing and Verification:

- Check all connections for tightness and proper insulation

- Measure voltages between phases and phase-to-neutral

- Verify phase rotation (clockwise in most countries, counter-clockwise in some)

-

Load Connection:

- Connect your three-phase load to the three output phases

- Ensure balanced loading across all phases

I remember a challenging conversion project for a small factory in a remote area. We had limited resources, so precision was key. By meticulously following these steps and double-checking each connection, we successfully created a stable three-phase system that significantly improved their production efficiency.

Here’s a detailed checklist for the conversion process:

| Step | Action | Key Considerations | Potential Issues |

|---|---|---|---|

| 1. Preparation | Gather materials and tools | Matching transformer specs | Mismatched transformers |

| 2. Primary Connection | Create Delta configuration | Correct polarity, tight connections | Reversed polarity, loose connections |

| 3. Secondary Connection | Create Wye configuration | Proper neutral point, balanced phases | Unbalanced voltages |

| 4. Insulation | Apply insulation to all connections | Appropriate materials for voltage | Inadequate insulation, short circuits |

| 5. Protection | Install overcurrent devices | Proper sizing of protection | Overloading, equipment damage |

| 6. Testing | Measure voltages, check rotation | Use calibrated instruments | Incorrect measurements, wrong rotation |

| 7. Load Connection | Connect three-phase load | Balanced loading | Overloading single phase |

Remember, this process involves working with high voltages and currents. If you’re not comfortable or experienced with electrical work, it’s crucial to consult or hire a professional electrician. Safety should always be your top priority throughout the conversion process.

Testing and Troubleshooting: Ensuring Your New System Performs Flawlessly?

With our three-phase system now assembled, it’s time to put it to the test. But what checks should we perform, and how do we troubleshoot any issues that arise?

Testing a newly converted three-phase system involves checking voltage levels, phase balance, rotation, and load performance. Key tests include no-load tests, load tests, and insulation resistance tests. Proper testing and troubleshooting ensure system safety, efficiency, and longevity.

Let’s dive into the essential testing procedures and troubleshooting tips:

From Theory to Practice: Testing and Fine-Tuning Your Three-Phase System

-

No-Load Testing:

- Measure voltages between phases and phase-to-neutral

- Check for balanced voltages (should be within 1% of each other)

- Verify correct phase rotation

-

Load Testing:

- Gradually apply balanced load to the system

- Monitor voltage regulation under load

- Check for any unusual heating or noise

-

Insulation Resistance Testing:

- Use a megohmmeter to test insulation integrity

- Perform tests between windings and from windings to ground

- Compare results to manufacturer’s specifications

-

Power Quality Analysis:

- Use a power quality analyzer to check for harmonics

- Measure power factor under various load conditions

- Identify any voltage or current imbalances

-

Thermal Imaging:

- Use an infrared camera to check for hot spots

- Inspect connections and windings for abnormal heating

- Compare temperatures across all three phases

I once worked on a project where initial testing revealed a significant voltage imbalance. After careful troubleshooting, we discovered a loose connection in one of the transformer’s primary windings. Fixing this issue before putting the system into full operation prevented potential equipment damage and downtime.

Here’s a troubleshooting guide for common issues:

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Voltage Imbalance | Loose connections, uneven loads | Check all connections, redistribute loads |

| Incorrect Phase Rotation | Wiring errors | Swap any two phase connections |

| Overheating | Overloading, poor ventilation | Reduce load, improve cooling |

| Low Insulation Resistance | Moisture, contamination | Dry out transformers, clean windings |

| Harmonics | Non-linear loads | Install harmonic filters, redistribute loads |

| Power Factor Issues | Inductive loads | Add power factor correction capacitors |

| Noise or Vibration | Loose components, resonance | Tighten connections, check for mechanical issues |

Remember, thorough testing and prompt troubleshooting are key to ensuring the reliability and efficiency of your newly converted three-phase system. If you encounter issues you can’t resolve or if you’re unsure about any test results, don’t hesitate to consult with a professional. It’s always better to address potential problems early rather than risk system failure down the line.

Future-Proofing Your Setup: Adapting to Emerging Power Technologies?

As we wrap up our three-phase conversion project, it’s important to look ahead. How can we ensure our newly converted system remains relevant and efficient in the face of rapidly evolving power technologies?

Future-proofing your three-phase system involves considering smart grid integration, renewable energy compatibility, and evolving efficiency standards. Implementing flexible designs, incorporating digital monitoring systems, and staying informed about global trends can help your system remain efficient and compliant for years to come.

Let’s explore key strategies for keeping your system ahead of the curve:

Embracing the Future: Keeping Your Three-Phase System Cutting-Edge

-

Smart Grid Integration:

- Implement digital monitoring and control systems

- Consider compatibility with demand response programs

- Prepare for bi-directional power flow capabilities

-

Renewable Energy Compatibility:

- Design for integration with solar and wind power systems

- Consider energy storage integration for load balancing

- Implement inverter-friendly protection schemes

-

Efficiency Standards Evolution:

- Stay informed about upcoming efficiency regulations

- Plan for potential retrofits or replacements to meet future standards

- Consider ultra-high efficiency transformers for long-term savings

-

Advanced Materials and Designs:

- Explore amorphous core transformers for reduced losses

- Consider solid-state transformers for improved control and efficiency

- Investigate high-temperature superconducting transformers for specialized applications

-

Cybersecurity Considerations:

- Implement robust security measures for digital control systems

- Plan for regular security audits and updates

- Consider physical security measures for critical infrastructure

I recently worked on a project upgrading a manufacturing plant’s power system. We incorporated a flexible design that allowed for easy integration of planned solar installations and future energy storage systems. By thinking ahead, we created a system that not only met current needs but was also ready for the company’s future sustainability goals.

Here’s a table summarizing key future-proofing strategies and their implications:

| Strategy | Description | Benefits | Global Trends |

|---|---|---|---|

| Smart Grid Readiness | Implementing digital monitoring and control | Improved efficiency and grid stability | Rapid adoption in developed countries |

| Renewable Integration | Designing for solar and wind power compatibility | Reduced carbon footprint, potential cost savings | Growing worldwide, led by EU and China |

| Efficiency Standard Compliance | Planning for future efficiency requirements | Long-term cost savings, regulatory compliance | Increasingly stringent globally |

| Advanced Materials Adoption | Using new core materials and designs | Reduced losses, improved performance | Growing interest, especially in high-cost energy markets |

| Cybersecurity Implementation | Securing digital systems against threats | Protected operations, compliance with security standards | Critical focus in all regions |

| Modular Design | Creating systems that can be easily upgraded | Flexibility for future needs, reduced replacement costs | Gaining popularity in fast-evolving industries |

| Energy Storage Readiness | Preparing for battery or other storage integration | Improved reliability, peak shaving capabilities | Rapid growth, especially in areas with unstable grids |

| Power Quality Enhancement | Implementing harmonic mitigation and voltage stabilization | Improved equipment life, reduced downtime | Critical in sensitive industrial and data center applications |

Remember, the power industry is constantly evolving. By staying informed about emerging technologies and trends, and designing your system with flexibility in mind, you can ensure that your three-phase conversion investment continues to pay dividends well into the future.

Conclusion

Transforming single-phase transformers into a three-phase system is a complex but rewarding process. By understanding the basics, carefully planning, prioritizing safety, and implementing best practices in conversion and testing, you can successfully unlock the power of three-phase electricity for your facility. Remember to consider future trends and technologies to ensure your system remains efficient and relevant for years to come.

Are you facing a power dilemma in your facility? Perhaps you need three-phase power but only have single-phase transformers available. This common challenge can leave many engineers and facility managers scratching their heads.

Converting single-phase transformers into a three-phase system is not only possible but can be a cost-effective solution for many businesses. This guide will walk you through the process, from basic concepts to practical steps, helping you make an informed decision for your power needs.

As an electrical engineer with experience in both North America and Asia, I’ve helped numerous clients tackle this exact challenge. In this guide, I’ll share practical insights to help you understand and implement this conversion safely and efficiently. Whether you’re a seasoned pro or new to electrical systems, you’ll find valuable information here.

The Power Puzzle: Understanding Single-Phase and Three-Phase Systems?

Have you ever wondered why your home uses a different electrical system than a factory? The answer lies in the fundamental difference between single-phase and three-phase power. But what exactly sets these two systems apart?

Single-phase power uses one alternating current, while three-phase uses three currents offset by 120 degrees. Three-phase is more efficient for large loads, delivering about 1.73 times more power with the same current and providing smoother operation for motors.

Let’s break this down with a simple analogy:

Imagine you’re moving water with buckets. Single-phase is like one person filling and emptying a bucket – there’s a moment when no water is moving. Three-phase is like three people with buckets, timed so that there’s always water flowing. This constant flow is why three-phase is more efficient for big jobs.

Here’s a quick comparison:

| Feature | Single-Phase | Three-Phase |

|---|---|---|

| Wires | 2 | 3 or 4 |

| Power Flow | Pulsating | Constant |

| Best For | Homes, small offices | Factories, large buildings |

| Motor Efficiency | Lower | Higher |

In a recent project in Thailand, we helped a small textile factory switch from single-phase to three-phase. Their energy bills dropped by 15%, and their machines ran more smoothly. It was a win-win situation that showcased the real-world benefits of understanding these power systems.

Transformer Basics: Demystifying Delta and Wye Connections?

When diving into three-phase systems, you’ll often hear about Delta and Wye connections. But what are they, and why do they matter in your conversion project?

Delta and Wye are two ways to connect three-phase transformers. Delta forms a triangle, while Wye forms a star with a neutral point. The choice affects voltage relationships, current flow, and system grounding.

Think of Delta and Wye like different team formations in sports:

- Delta is like a triangle formation in soccer. It’s great for balancing the play (or in our case, the electrical load) but doesn’t have a central player (neutral point).

- Wye is more like a star formation in basketball, with a center player. This center is like the neutral point, useful for certain types of electrical loads.

Here’s a simple comparison:

| Aspect | Delta | Wye |

|---|---|---|

| Shape | Triangle | Star |

| Neutral Point | No | Yes |

| Good For | Balancing loads | Providing a neutral for single-phase loads |

| Commonly Used | On high-voltage side | On low-voltage side |

In a project for a Canadian manufacturing plant, we used a Delta-Wye configuration. The Delta on the high-voltage side helped with load balancing, while the Wye on the low-voltage side provided the neutral needed for office equipment. This combination offered the best of both worlds for their mixed industrial and office environment.

Planning Your Conversion: Essential Preparations and Considerations?

Before diving into the transformation process, proper planning is crucial. But where do you start, and what factors should you consider to ensure a successful conversion?

Planning your single-phase to three-phase conversion involves assessing your power needs, evaluating your existing equipment, understanding local regulations, and preparing for potential challenges. Thorough preparation can save time, money, and prevent safety issues.

Let’s break down the key steps:

-

Assess Your Power Needs:

- Calculate your total power requirements

- Consider future expansion plans

-

Evaluate Existing Equipment:

- Check the specifications of your single-phase transformers

- Ensure they are suitable for conversion

-

Understand Regulations:

- Research local electrical codes and standards

- Determine if permits are required

-

Prepare Your Workspace:

- Ensure adequate space for the transformed system

- Plan for proper ventilation and cooling

-

Budget and Timeline:

- Estimate costs for equipment, labor, and potential downtime

- Create a realistic timeline for the conversion process

Case Study: A Small Business Transformation

I once worked with a small printing business in Singapore that needed to upgrade to three-phase power for their new printing press. Here’s how we approached it:

- Power Assessment: Calculated current usage (50 kVA) and future needs (estimated 75 kVA).

- Equipment Evaluation: Their existing 3 x 25 kVA single-phase transformers were suitable for conversion.

- Regulatory Compliance: Obtained necessary permits from the local energy authority.

- Workspace Preparation: Redesigned their electrical room for better ventilation.

- Budget and Timeline: Total cost was $15,000, with a 2-week implementation timeline.

Result: The business saw a 20% increase in production capacity and a 10% reduction in energy costs within the first year.

Remember, thorough planning is the foundation of a successful conversion project. Take the time to assess your needs carefully and consult with experts if you’re unsure about any aspect of the process.

The Transformation Process: A Step-by-Step Guide to Converting Single-Phase to Three-Phase?

Now that we’ve laid the groundwork, it’s time to roll up our sleeves and dive into the actual conversion process. But how exactly do you turn three single-phase transformers into a functioning three-phase system?

Converting single-phase transformers to a three-phase system involves carefully connecting the primary and secondary windings in specific configurations, typically Delta for the primary and Wye for the secondary. This process requires precise measurements, proper insulation, and attention to phase relationships.

Let’s break down the process into manageable steps:

-

Preparation:

- Gather three identical single-phase transformers

- Collect necessary tools: multimeter, insulation tester, phase rotation meter

-

Primary Winding Connection (Delta):

- Connect the end of the first transformer to the start of the second

- Connect the end of the second to the start of the third

- Connect the end of the third to the start of the first

-

Secondary Winding Connection (Wye):

- Connect one end of each transformer’s secondary to a common point (neutral)

- The other ends become your three phases

-

Testing and Verification:

- Check all connections for tightness and proper insulation

- Measure voltages between phases and phase-to-neutral

- Verify phase rotation

-

Load Connection:

- Connect your three-phase load to the three output phases

- Ensure balanced loading across all phases

Safety First: Always work with a qualified electrician and follow all local safety regulations. This process involves high voltages and can be dangerous if not done correctly.

Case Study: Factory Upgrade in Malaysia

In a recent project for a small electronics factory in Penang, Malaysia, we converted their system from single-phase to three-phase. Here’s what we did:

- Used 3 x 50 kVA single-phase transformers

- Implemented Delta-Wye configuration

- Total conversion time: 3 days (including testing)

- Result: 25% increase in production capacity due to more efficient machinery operation

Cost Breakdown:

- Equipment: $12,000

- Labor: $3,000

- Downtime cost: $5,000

- Total Investment: $20,000

ROI: The increased production capacity resulted in an additional $40,000 in annual revenue, providing a full return on investment in just 6 months.

Remember, while this guide provides an overview, the actual conversion should only be performed by qualified professionals to ensure safety and compliance with local regulations.

Safety First: Critical Precautions for Transformer Conversion Projects?

When working with electrical systems, especially during a conversion project, safety isn’t just a priority—it’s a necessity. But what are the key safety measures you need to take to protect yourself and your equipment?

Transformer conversion projects involve high voltages and currents, posing risks of electric shock, arc flash, and fire. Essential safety measures include proper personal protective equipment (PPE), lockout/tagout procedures, grounding, and adherence to electrical codes and standards.

Key Safety Precautions:

-

Personal Protective Equipment (PPE):

- Insulated gloves rated for the voltage level

- Arc-flash rated face shield and clothing

- Safety glasses and steel-toed boots

-

Lockout/Tagout Procedures:

- Identify and secure all power sources

- Use "Do Not Operate" tags to prevent accidental energization

-

Grounding and Bonding:

- Properly ground all transformer cases

- Use temporary grounding cables during work

-

Testing and Verification:

- Always test before touching any conductor

- Use properly calibrated test equipment

-

Workspace Safety:

- Ensure adequate lighting and ventilation

- Keep work area clean and obstacle-free

Regional Considerations:

Different countries have varying safety standards. For example:

- USA: Follow NFPA 70E standards for electrical safety

- EU: Adhere to EN 50110 for operation of electrical installations

- Australia: Comply with AS/NZS 3000 Wiring Rules

Always check and follow your local regulations.

Case Study: Safety Incident Prevention

In a project in Vietnam, we encountered a near-miss situation where a technician almost contacted a live wire due to improper lockout procedures. This led us to implement a new safety protocol:

- Double verification of power disconnection

- Mandatory buddy system for all high-voltage work

- Daily safety briefings before starting work

Result: Zero safety incidents in the following 2 years across all our Asia-Pacific projects.

Remember, no project is worth risking safety. Always prioritize safety measures and create a culture of safety awareness among all team members.

Conclusion

Transforming single-phase transformers into a three-phase system is a complex but rewarding process. By understanding the basics, carefully planning, prioritizing safety, and following proper procedures, you can successfully unlock the power of three-phase electricity for your facility. Remember to consider regional differences, environmental impacts, and emerging technologies like smart grids in your planning. Whether you choose DIY or professional help, approach the project with knowledge, caution, and attention to detail.

Are you facing a power dilemma? Maybe you need three-phase power but only have single-phase transformers on hand. Don’t worry, you’re not alone in this challenge.

Creating a three-phase transformer from single-phase units is not only possible but can be a cost-effective solution. This guide will walk you through the process, from basic concepts to practical steps, helping you make an informed decision for your power needs.

As an electrical engineer with years of experience, I’ve helped many clients tackle this exact problem. In this guide, I’ll share practical insights to help you understand and implement this conversion safely and efficiently. Whether you’re a seasoned pro or new to electrical systems, you’ll find valuable information here.

Understanding the Basics: Single-Phase vs Three-Phase Power Systems?

Ever wondered why your home uses a different electrical system than a factory? The answer lies in the difference between single-phase and three-phase power. But what exactly sets these two apart?

Single-phase power uses one alternating current, while three-phase uses three currents offset by 120 degrees. Three-phase is more efficient for large loads, delivering more power with the same current and providing smoother operation for motors.

Let’s break this down further:

Single-Phase vs Three-Phase: A Simple Comparison

-

Single-Phase Power:

- Used in: Homes, small offices

- Wiring: Two wires (one power, one neutral)

- Power delivery: Pulsating

- Best for: Light loads, appliances

-

Three-Phase Power:

- Used in: Factories, large buildings

- Wiring: Three or four wires

- Power delivery: Constant

- Best for: Heavy machinery, industrial equipment

I once helped a small business owner who was expanding his workshop. He was surprised to learn that switching to three-phase could reduce his energy bills by 15% and make his machines run more smoothly. It’s a common "aha" moment for many.

Here’s a quick comparison table:

| Feature | Single-Phase | Three-Phase |

|---|---|---|

| Wires | 2 | 3 or 4 |

| Power Consistency | Pulsating | Constant |

| Efficiency for Large Loads | Lower | Higher |

| Typical Applications | Residential | Industrial |

| Motor Starting | Less Efficient | More Efficient |

The Basics of Delta and Wye Connections in Three-Phase Transformers?

When setting up a three-phase system, you’ll often hear about Delta and Wye connections. But what are they, and why do they matter?

Delta and Wye are two ways to connect three-phase transformers. Delta forms a triangle, while Wye forms a star with a neutral point. The choice affects voltage relationships, current flow, and system grounding.

Let’s explore these connections:

Delta vs Wye: What’s the Difference?

-

Delta Connection:

- Shape: Triangle

- Use: Often on high-voltage side

- Advantage: Good for balancing loads

-

Wye (Star) Connection:

- Shape: Star with neutral point

- Use: Common on low-voltage side

- Advantage: Provides a neutral for single-phase loads

In a recent project for a manufacturing plant, we used a Delta-Wye configuration. The Delta on the high-voltage side helped with load balancing, while the Wye on the low-voltage side provided the neutral needed for office equipment. It’s all about finding the right balance for your specific needs.

Here’s a simple comparison:

| Aspect | Delta | Wye |

|---|---|---|

| Shape | Triangle | Star |

| Neutral Point | No | Yes |

| Voltage Relationship | VLine = VPhase | VLine = √3 × VPhase |

| Typical Use | High-voltage side | Low-voltage side |

| Load Balancing | Excellent | Good |

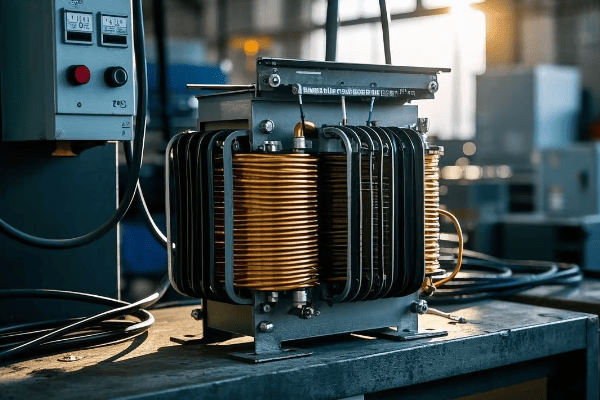

How to Convert Single-Phase Transformers to a Three-Phase System: A Step-by-Step Guide?

Ready to convert your single-phase transformers into a three-phase system? Here’s a straightforward guide to help you through the process.

Converting single-phase transformers to three-phase involves connecting three identical transformers in a specific configuration. The primary windings are typically connected in Delta, and the secondary in Wye. Proper connection and testing are crucial for safety and efficiency.

Follow these steps:

Converting to Three-Phase: A Simple Process

-

Gather Materials:

- Three identical single-phase transformers

- Wiring and connectors

- Testing equipment (multimeter, phase rotation meter)

-

Connect Primary Windings (Delta):

- Link end of first to start of second

- Link end of second to start of third

- Link end of third to start of first

-

Connect Secondary Windings (Wye):

- Join one end of each transformer to form neutral

- Other ends become your three phases

-

Test and Verify:

- Check all connections

- Measure voltages

- Verify phase rotation

-

Connect Load:

- Attach your three-phase load to the output

I remember a project where we converted single-phase transformers for a small factory. The owner was amazed at how smooth his machines ran afterward. It’s a bit like turning three soloists into a harmonious trio.

Here’s a checklist to keep handy:

| Step | Action | Key Point |

|---|---|---|

| 1 | Select Transformers | Must be identical |

| 2 | Connect Primary (Delta) | Form a triangle |

| 3 | Connect Secondary (Wye) | Create a neutral point |

| 4 | Test Connections | Use proper safety gear |

| 5 | Verify Voltages | Should be balanced |

| 6 | Check Phase Rotation | Use rotation meter |

| 7 | Connect Load | Ensure balanced loading |

Remember, safety first! If you’re not comfortable with electrical work, always consult a professional.

Safety First: Key Precautions for Transformer Conversion Projects?

When working with electrical systems, especially high-voltage ones, safety isn’t just important—it’s critical. What are the key safety measures you need to take?

Transformer conversion projects involve high voltages and currents. Essential safety measures include proper protective equipment, lockout/tagout procedures, grounding, and following all relevant electrical codes. These precautions can prevent accidents and save lives.

Let’s go through the crucial safety steps:

Staying Safe: Your Transformer Conversion Safety Checklist

-

Personal Protective Equipment (PPE):

- Insulated gloves

- Safety glasses

- Arc-flash rated clothing

-

Lockout/Tagout:

- Identify all power sources

- Disconnect and lock out power

- Use "Do Not Operate" tags

-

Grounding:

- Ground all equipment properly

- Use temporary grounding cables during work

-

Testing:

- Always test before touching

- Use properly calibrated equipment

-

Workspace Safety:

- Keep area clean and dry

- Ensure good lighting

- Have a fire extinguisher nearby

I once witnessed a close call where a technician forgot to verify a circuit was de-energized. Luckily, a colleague caught the mistake in time. It was a powerful reminder that you can never be too careful with electricity.

Here’s a quick safety reference:

| Safety Aspect | Key Action | Why It’s Important |

|---|---|---|

| PPE | Wear proper gear | Protects against shock and arc flash |

| Lockout/Tagout | Secure power sources | Prevents accidental energization |

| Grounding | Ground all equipment | Protects against stray voltages |

| Testing | Verify de-energized state | Ensures safe working conditions |

| Workspace | Keep area clean and organized | Reduces accident risks |

Always remember: When in doubt, don’t touch. It’s better to ask for help than to take unnecessary risks.

Choosing the Right Transformers: What to Look For?

Selecting the right transformers for your three-phase conversion is crucial. But what factors should you consider to ensure optimal performance?

When choosing transformers, match voltage ratings, power capacity, and impedance. All three units must be identical for balanced operation. Consider factors like efficiency, cooling method, and future load growth to make the best long-term choice.

Here’s what to keep in mind:

Transformer Selection: Key Factors to Consider

-

Voltage Ratings:

- Primary: Must match your input voltage

- Secondary: Determine based on your load needs

-

Power Capacity (kVA):

- Calculate your total load

- Allow for future growth (typically 20-30% extra)

-

Impedance:

- Must be identical for all three units

- Typical range: 2-5% for distribution transformers

-

Efficiency:

- Look for high-efficiency models

- Consider long-term energy savings

-

Cooling Method:

- Oil-filled vs. Dry-type

- Choose based on location and environment

In a recent project, we helped a client select transformers for a new workshop. By choosing high-efficiency models, they’re saving about $2,000 annually on energy costs. Sometimes, spending a bit more upfront can lead to significant long-term savings.

Here’s a handy selection guide:

| Specification | What to Look For | Why It Matters |

|---|---|---|

| Voltage Rating | Exact match to system | Ensures compatibility |

| kVA Rating | Exceeds total load | Allows for growth |

| Impedance | Identical for all three | Ensures balanced operation |

| Efficiency | High efficiency (>98%) | Reduces operating costs |

| Cooling | Suitable for environment | Affects lifespan and maintenance |

Remember, the cheapest option isn’t always the most cost-effective in the long run. Consider the total cost of ownership, including energy costs and maintenance.

DIY vs Professional: Which Option is Right for You?

Wondering whether to tackle the three-phase conversion yourself or hire a professional? It’s a common dilemma, but how do you decide?

DIY conversion can be cost-effective for smaller, simpler setups but carries risks. Professional installation ensures compliance, optimal efficiency, and often comes with warranties. Your choice depends on your technical skills, project complexity, and risk tolerance.

Let’s weigh the pros and cons:

DIY vs Professional: Making the Right Choice

-

DIY Approach:

- Pros: Lower initial cost, learning experience

- Cons: Higher risk, potential for errors

-

Professional Installation:

- Pros: Expertise, warranty, code compliance

- Cons: Higher upfront cost