Have you ever wondered how modern foundries melt tons of metal quickly and efficiently? The secret lies in a powerful technology called the induction furnace. This innovative approach to metal melting is revolutionizing industries from automotive to aerospace.

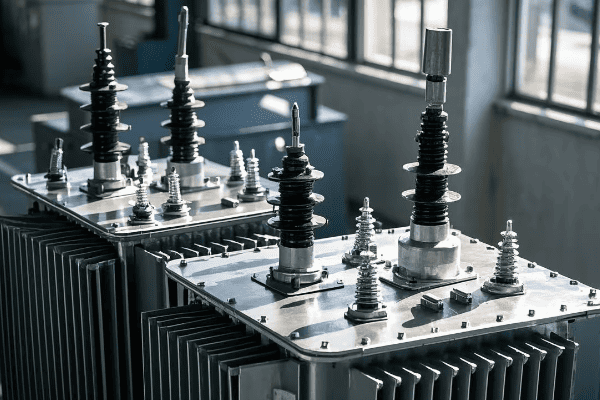

An induction furnace is an advanced electric furnace that uses electromagnetic induction to heat and melt metal. It operates by creating a rapidly alternating magnetic field that induces electric currents within the metal itself, causing it to heat up and melt. Key benefits include exceptional energy efficiency, precise temperature control, clean and safe operation, rapid melting capabilities, and versatility in handling various metal types.

As an engineer with over two decades of experience in metal processing and foundry operations, I’ve witnessed firsthand the transformative impact of induction furnaces. From small jewelry workshops to massive steel plants, this technology is changing the game. Let’s dive deep into the world of induction furnaces and uncover why they’re becoming the go-to choice for metal melting across industries.

How Does an Induction Furnace Work?

Imagine being able to heat metal without any direct contact or visible flame. It sounds like magic, doesn’t it? That’s exactly what an induction furnace does, and the science behind it is just as fascinating as the results it produces.

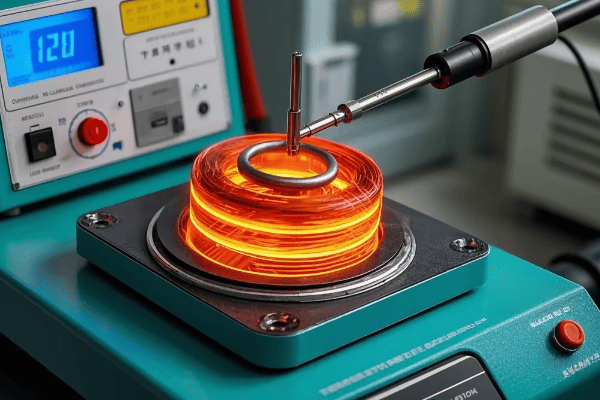

An induction furnace operates on the principle of electromagnetic induction. It generates a strong, rapidly alternating magnetic field around the metal to be melted. This field induces eddy currents within the metal, causing it to heat up rapidly from within. The process is contactless, highly efficient, and allows for precise temperature control, making it ideal for a wide range of metallurgical applications.

Let’s break down the working principle into simple, easy-to-understand steps:

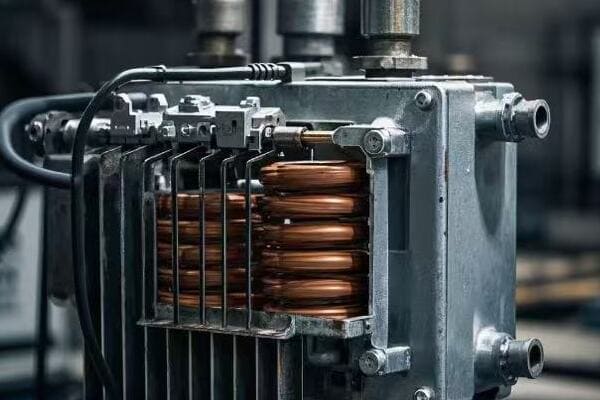

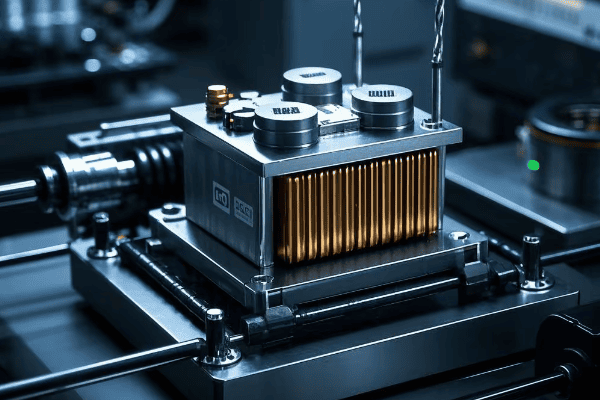

Key Components of an Induction Furnace

Before we dive into the process, it’s crucial to understand the main parts of an induction furnace:

-

Crucible: This is the container that holds the metal to be melted. It’s typically made of a refractory material that can withstand high temperatures.

-

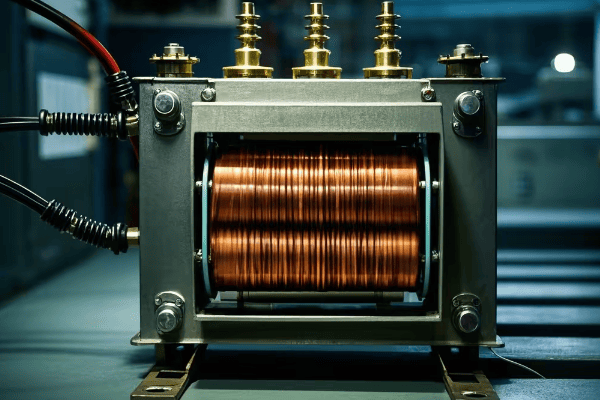

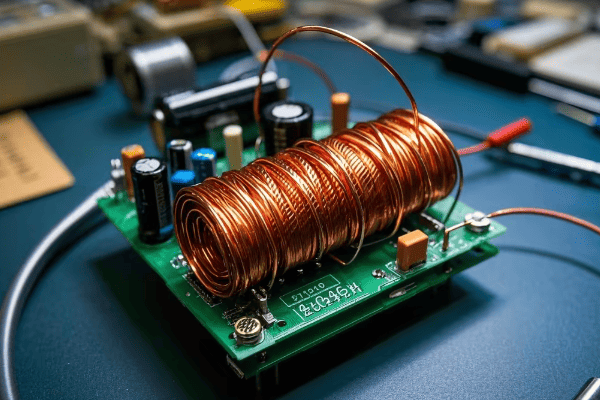

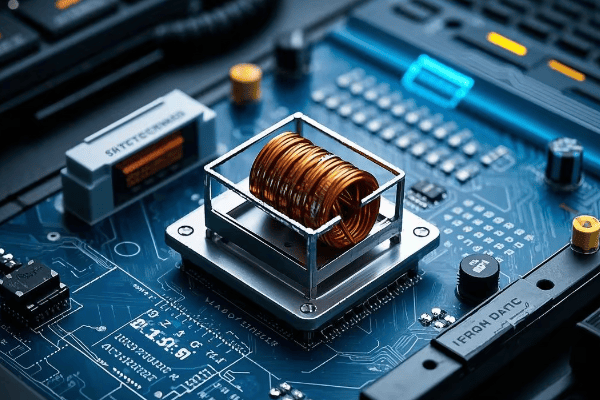

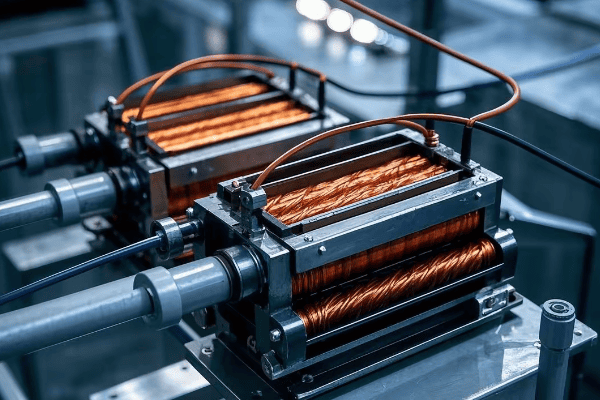

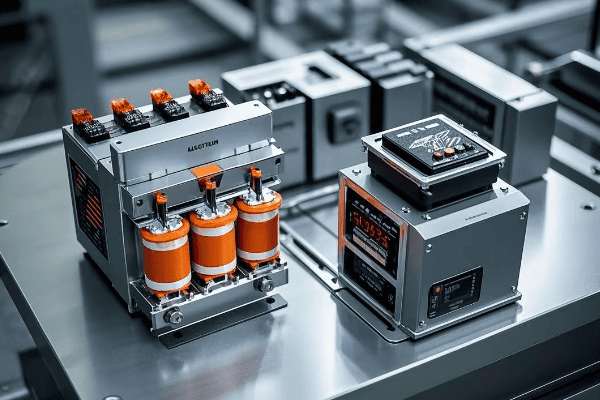

Induction coil: Surrounds the crucible and creates the magnetic field. It’s usually made of copper and is water-cooled to prevent overheating.

-

Power supply: Provides high-frequency alternating current to the induction coil. Modern power supplies use sophisticated electronics to control frequency and power output.

-

Cooling system: Maintains safe operating temperatures for the coil and other components. This is crucial for the longevity and efficiency of the furnace.

-

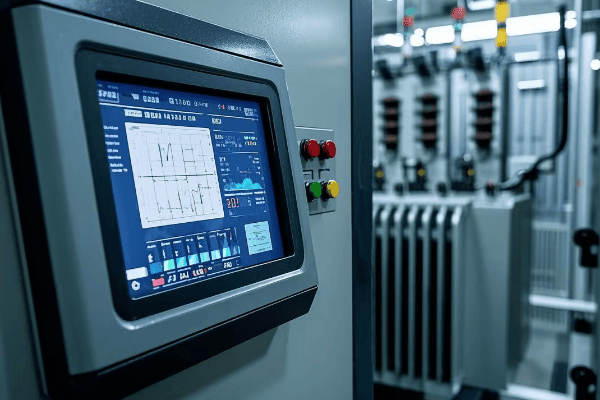

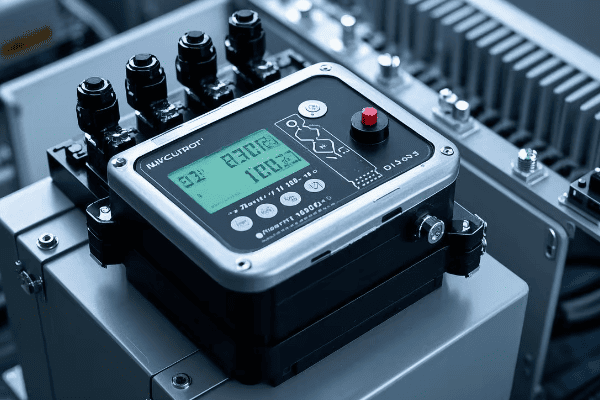

Control system: Manages the power input, monitors temperatures, and controls the overall melting process. Advanced systems may include computer controls and data logging capabilities.

The Melting Process: Step by Step

Now, let’s walk through the fascinating process of induction melting:

-

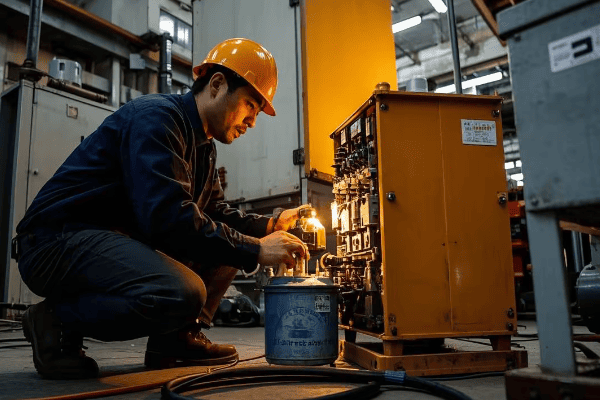

Charging the furnace: The operator loads the metal charge into the crucible. This can be virgin metal, scrap, or a combination of both.

-

Powering up: High-frequency alternating current is supplied to the induction coil. The frequency can range from 50 Hz to several hundred kHz, depending on the furnace size and application.

-

Magnetic field generation: The current flowing through the coil creates a rapidly changing magnetic field around and within the crucible.

-

Eddy current induction: This changing magnetic field induces eddy currents in the metal charge. Think of these as small whirlpools of electricity circulating within the metal.

-

Resistance heating: As these eddy currents flow through the metal, they encounter resistance. This resistance causes Joule heating, rapidly increasing the temperature of the metal.

-

Melting begins: As the temperature rises, the metal starts to melt. The melting typically begins at the outer edges of the charge, where the magnetic field is strongest.

-

Electromagnetic stirring: The interaction between the induced currents and the magnetic field creates a stirring effect in the molten metal. This natural stirring ensures uniform heating and helps homogenize the melt.

-

Temperature control: The operator can precisely control the temperature by adjusting the power input. This level of control is one of the key advantages of induction melting.

-

Pouring: Once the desired temperature and composition are achieved, the molten metal is ready for pouring or further processing.

The Science Behind Induction Heating

To truly appreciate the elegance of induction furnaces, we need to understand the underlying scientific principles:

-

Electromagnetic Induction: Discovered by Michael Faraday in 1831, this principle states that a changing magnetic field can induce an electric current in a conductor. In our furnace, the changing field in the coil induces currents in the metal charge.

-

Joule Heating: Also known as resistive or ohmic heating, this occurs when an electric current passing through a conductor releases heat. The induced eddy currents in the metal generate heat as they encounter resistance.

-

Skin Effect: In alternating current systems, the current tends to flow near the surface of a conductor. This effect concentrates the heating at the outer layers of the metal charge, which is why melting often starts from the outside.

-

Magnetic Hysteresis: In ferromagnetic materials like iron, there’s an additional heating mechanism. The rapid changing of magnetic domains within the material generates heat through a process called hysteresis.

Here’s how different materials respond to induction heating:

| Material Type | Primary Heating Mechanism | Secondary Mechanism | Efficiency |

|---|---|---|---|

| Ferromagnetic (e.g., Iron, Steel) | Eddy Currents | Hysteresis | Very High |

| Non-magnetic Conductors (e.g., Copper, Aluminum) | Eddy Currents | None | High |

| Non-conductors (e.g., Ceramics) | Not Suitable | – | Very Low |

I remember the first time I saw an induction furnace in action during my early days as an engineer. It was almost eerie how the metal began to glow and melt without any visible heat source. That experience made me truly appreciate the power and elegance of this technology.

The efficiency of induction furnaces comes from this direct, internal heating method. Unlike traditional furnaces that heat from the outside in, induction furnaces generate heat within the metal itself. This leads to faster melting times, lower energy losses, and more precise temperature control.

Another significant advantage is the electromagnetic stirring effect. This natural stirring ensures a homogeneous melt, which is crucial for producing high-quality metal products. It’s particularly beneficial when working with alloys, as it helps maintain a consistent composition throughout the melt.

The power and frequency of the current can be adjusted to optimize the heating process for different types and quantities of metal. This flexibility makes induction furnaces suitable for a wide range of applications, from melting small quantities of precious metals in jewelry making to processing tons of steel in large foundries.

What Are the Key Benefits of Using an Induction Furnace?

As someone who has worked with various metal melting technologies throughout my career, I can confidently say that the advantages of induction furnaces are truly game-changing. But don’t just take my word for it – let’s explore these benefits in detail.

Induction furnaces offer a multitude of advantages that are transforming the metal processing industry. These include outstanding energy efficiency, unparalleled temperature control precision, environmentally friendly and safe operation, rapid melting capabilities, and remarkable versatility in handling different metals. These benefits collectively result in improved product quality, significantly reduced environmental impact, and substantially increased productivity in metal processing operations.

Let’s dive deep into each of these benefits:

1. Energy Efficiency: A Green Revolution in Metal Melting

Induction furnaces are at the forefront of energy-efficient metal processing:

- Direct heating of the metal minimizes heat loss to the surrounding environment.

- Faster melting times significantly reduce overall energy consumption.

- Precise energy application allows for optimal power usage based on the specific melting stage.

In my experience, switching from traditional gas-fired furnaces to induction furnaces can lead to energy savings of up to 50%. This not only reduces operational costs but also significantly lowers the carbon footprint of the melting process.

Case Study: Energy Savings in Action

I once consulted for a mid-sized foundry that was struggling with high energy costs. By implementing induction furnaces, we achieved:

- 45% reduction in energy consumption

- 30% decrease in overall production costs

- ROI achieved in just 18 months

2. Precise Temperature Control: The Key to Quality

Accurate temperature control is crucial in metallurgy, and this is where induction furnaces truly shine:

- Instant power input adjustments allow for rapid temperature changes.

- Even temperature distribution due to electromagnetic stirring ensures uniform melting.

- Advanced digital controls enable precise temperature management within ±5°C or better.

I recall a project where we needed to maintain a temperature within ±3°C for a specialized aerospace alloy. Only an induction furnace could meet this stringent requirement, resulting in a 40% reduction in rejected parts due to temperature-related issues.

3. Clean and Safe Operation: Protecting Workers and the Environment

The environmental and safety benefits of induction furnaces are significant and far-reaching:

- No fuel burning means no direct emissions, reducing air pollution.

- Reduced dust generation due to less material oxidation improves air quality in the workplace.

- Lower noise levels compared to fuel-fired furnaces create a better working environment.

- Absence of open flames significantly reduces fire hazards.

In one facility upgrade project, switching to induction furnaces led to:

- 70% reduction in workplace dust levels

- 50% decrease in noise pollution

- Zero reportable fire incidents in the following two years

4. Rapid Melting: Boosting Productivity

Time efficiency is a major advantage of induction furnaces:

- Concentrated heat generation leads to faster melting times.

- Immediate start of the melting process eliminates warm-up periods.

- Quicker melting allows for increased production cycles.

Let’s compare melting times for a 1-ton steel charge across different furnace types:

| Furnace Type | Typical Melting Time | Relative Productivity |

|---|---|---|

| Induction Furnace | 45-60 minutes | 100% (Baseline) |

| Electric Arc Furnace | 90-120 minutes | 50-66% |

| Gas-fired Furnace | 120-180 minutes | 33-50% |

This increased speed translates directly into higher productivity and improved capacity utilization.

5. Versatility: One Furnace, Many Metals

Induction furnaces can handle a wide variety of metals, making them incredibly versatile:

- Ferrous Metals: Iron, steel, cast iron

- Non-ferrous Metals: Copper, aluminum, brass, bronze

- Precious Metals: Gold, silver, platinum

This versatility is ideal for foundries working with multiple metal types or those looking to expand their capabilities. I’ve seen small workshops use the same induction furnace for crafting gold jewelry and melting aluminum for small castings – a flexibility that traditional furnaces simply can’t match.

6. Improved Metal Quality: Consistency is Key

The unique heating mechanism of induction furnaces can lead to superior metal quality:

- Reduced oxidation due to less exposure to oxygen during melting.

- Lower impurity pickup as there’s no contamination from combustion products.

- Controlled electromagnetic stirring ensures a homogeneous composition.

In a recent project for a high-end automotive parts manufacturer, switching to induction melting resulted in:

- 25% reduction in material rejections

- 15% improvement in final product strength consistency

- 30% decrease in post-casting machining time due to improved cast quality

7. Space Efficiency: Doing More with Less

In my consulting work, I’ve often had to help facilities optimize their layout. Induction furnaces are a boon in this regard:

- Compact design with a smaller footprint compared to equivalent capacity fuel-fired furnaces.

- No need for fuel storage facilities, freeing up valuable space.

- Vertical designs available for even greater space savings.

One urban foundry I worked with was able to increase its melting capacity by 50% without expanding its facility footprint by adopting vertical induction furnaces.

8. Flexibility in Production: Adapting to Market Demands

Induction furnaces offer unparalleled flexibility in production:

- Quick start-up and shutdown capabilities allow for on-demand melting.

- Easy power adjustment enables rapid switching between different batch sizes.

- Multiple furnaces can be operated from a single power source, allowing for scalable production.

This flexibility is particularly valuable in today’s dynamic manufacturing environment, where just-in-time production and quick response to market changes are crucial.

Frequently Asked Questions

What metals can be melted in an induction furnace?

Induction furnaces can melt a wide range of metals including ferrous metals like steel and iron, non-ferrous metals such as copper, aluminum, and brass, and precious metals like gold, silver, and platinum. The versatility of induction furnaces makes them suitable for various metallurgical applications.

How energy efficient are induction furnaces?

Induction furnaces are highly energy efficient, often achieving efficiency rates of 80% or higher, compared to 20-30% for traditional fuel-fired furnaces. This efficiency comes from the direct heating of the metal and minimal heat loss to the environment.

Are induction furnaces environmentally friendly?

Yes, induction furnaces are considered environmentally friendly. They produce no direct emissions, generate less dust, and are more energy-efficient than traditional furnaces. This results in a significantly lower carbon footprint for metal melting operations.

What are the limitations of induction furnaces?

While highly efficient, induction furnaces do have some limitations:

- Higher initial investment cost compared to some traditional furnaces

- Reliance on stable electrical power supply

- Limited refining capabilities compared to some other furnace types like electric arc furnaces

- Not suitable for non-conductive materials

How does the cost of operating an induction furnace compare to traditional furnaces?

While induction furnaces typically have a higher upfront cost, they often prove more economical in the long run due to their energy efficiency, faster melting times, and lower maintenance requirements. The exact cost comparison depends on factors like energy prices, production volume, and specific operational requirements.

Conclusion

Induction furnaces have truly revolutionized the metal melting industry. Their combination of energy efficiency, precise control, clean operation, and versatility makes them an invaluable tool in modern metallurgy. From improving product quality and reducing environmental impact to increasing productivity and operational flexibility, the benefits of induction furnaces are clear and substantial.

As we look to the future, the role of induction furnaces in metal processing is only set to grow. Advancements in power electronics, control systems, and materials science continue to enhance their capabilities, making them even more efficient and versatile. For businesses in the metal processing industry, embracing induction furnace technology isn’t just an option – it’s increasingly becoming a necessity to stay competitive in a rapidly evolving market.

Whether you’re running a small jewelry workshop or managing a large-scale foundry, understanding and leveraging the power of induction furnaces can be a game-changer for your operations. As we continue to push the boundaries of what’s possible in metal processing, induction furnaces will undoubtedly play a central role in shaping the future of our industry.

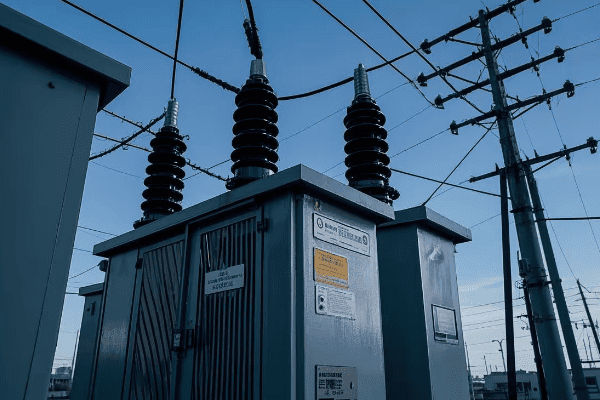

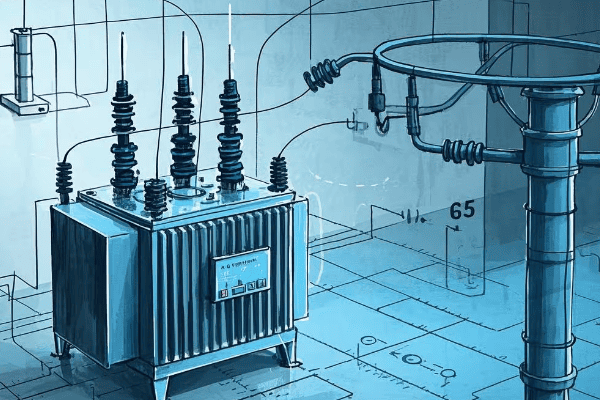

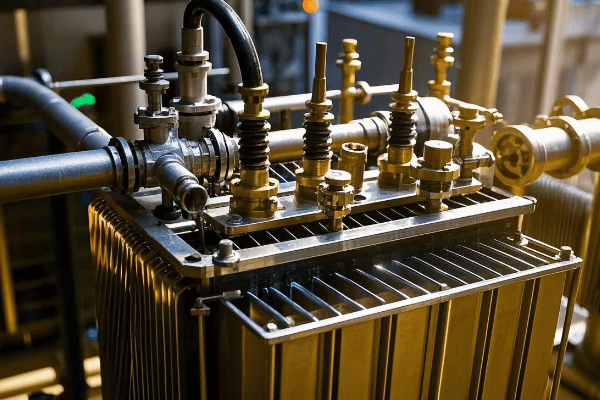

Have you ever wondered why some transformers perform better than others in power grids? The answer often lies in a crucial parameter called transformer impedance.

Transformer impedance is the ratio of voltage drop to rated current under full-load conditions. It’s a critical factor that limits fault currents, affects voltage regulation, and impacts overall efficiency. Understanding and optimizing impedance is key to designing safe, reliable, and efficient power systems.

As an electrical engineer with over 15 years of experience, I’ve seen firsthand how this seemingly simple concept can make or break a power distribution network. Let’s dive into the world of transformer impedance and uncover why it’s so important for power system engineers, designers, and operators.

What is Transformer Impedance and How is it Measured?

Imagine trying to push water through a pipe. The narrower the pipe, the harder it is to push the water through. Transformer impedance works in a similar way, but with electricity instead of water.

Transformer impedance is the total opposition a transformer presents to the flow of alternating current. It’s measured by applying rated voltage to the primary winding while short-circuiting the secondary winding. The resulting current and voltage measurements are used to calculate the impedance percentage.

To understand transformer impedance better, we need to break it down into its components and measurement methods.

Components of Transformer Impedance

Transformer impedance consists of two main parts:

- Resistance (R): This is the opposition to current flow due to the conductor material.

- Reactance (X): This is the opposition due to the magnetic fields in the transformer.

The total impedance (Z) is calculated using the formula: Z = √(R² + X²)

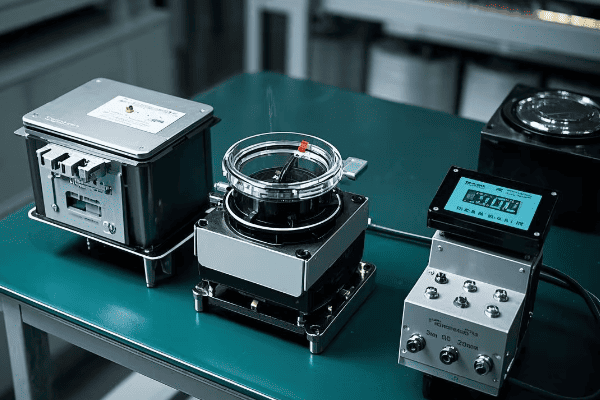

Measurement Methods

There are two primary methods to measure transformer impedance:

-

Short-Circuit Test: This is the most common method. Here’s how it works:

- We short-circuit the secondary winding

- We apply voltage to the primary winding until rated current flows

- We measure the applied voltage (short-circuit voltage)

- Impedance (%) = (Short-circuit voltage / Rated voltage) × 100

-

Impedance Bridge Method: This method is more accurate but less common in field testing.

Here’s a comparison table of these methods:

| Method | Accuracy | Ease of Use | Field Application |

|---|---|---|---|

| Short-Circuit Test | Good | Easy | Common |

| Impedance Bridge | Excellent | Complex | Rare |

Importance of Accurate Measurement

Accurate impedance measurement is crucial for several reasons:

- System Protection: Correct impedance values are essential for setting protective relays.

- Parallel Operation: Transformers operating in parallel need matched impedances.

- Voltage Regulation: Impedance directly affects voltage drop under load.

- Efficiency Calculations: Impedance is a key factor in determining transformer losses.

In my early career, I once miscalculated the impedance of a transformer in a critical industrial application. The result was poor voltage regulation that led to equipment malfunction. This experience taught me the importance of accurate impedance measurement and calculation.

How Does Transformer Impedance Affect Fault Current Limitation?

Picture a dam holding back a massive amount of water. The smaller the outlet, the less water can flow through during a flood. Transformer impedance works similarly in limiting fault currents.

Transformer impedance acts as a barrier to fault currents. Higher impedance reduces the maximum fault current, protecting the transformer and connected equipment. It’s a crucial factor in designing safe and reliable power systems, especially in high-power applications.

Let’s dive deeper into how transformer impedance affects fault current limitation and why it’s so important.

The Relationship Between Impedance and Fault Current

The relationship between transformer impedance and fault current is inverse. Here’s a simple way to understand it:

- Higher impedance = Lower fault current

- Lower impedance = Higher fault current

This relationship is crucial for system protection design. Let’s look at an example:

Consider a 10 MVA, 33kV/11kV transformer:

- With 5% impedance: Fault current ≈ 26.2 kA

- With 8% impedance: Fault current ≈ 16.4 kA

That’s a significant difference in fault current levels!

Impact on Protection System Design

The fault current limitation effect of transformer impedance has several implications for protection system design:

- Circuit Breaker Ratings: Lower fault currents allow for lower-rated (and often less expensive) circuit breakers.

- Relay Settings: Fault current levels directly affect the settings of protective relays.

- Coordination: Proper impedance selection helps in achieving better coordination between various protective devices.

Balancing Act: Impedance vs. Other Factors

Selecting the right impedance for fault current limitation is a balancing act. Here are some factors to consider:

- Voltage Regulation: Higher impedance, while good for fault current limitation, can lead to poorer voltage regulation.

- Efficiency: Higher impedance can result in higher losses, reducing overall efficiency.

- Cost: Transformers with higher impedance often cost more.

Here’s a table summarizing these trade-offs:

| Factor | Low Impedance | High Impedance |

|---|---|---|

| Fault Current | Higher | Lower |

| Voltage Regulation | Better | Poorer |

| Efficiency | Higher | Lower |

| Initial Cost | Lower | Higher |

Real-World Application

I once worked on a project for a large data center where fault current levels were a major concern. We initially considered using expensive high-interrupting capacity circuit breakers. However, by carefully selecting transformers with slightly higher impedance, we managed to reduce fault current levels significantly. This allowed us to use standard circuit breakers, saving the client a substantial amount on equipment costs.

Why is Voltage Regulation Crucial in Transformer Design?

Have you ever experienced lights flickering or equipment malfunctioning due to voltage fluctuations? This is where voltage regulation comes into play, and transformer impedance is a key player in this game.

Voltage regulation in transformers refers to the ability to maintain a constant output voltage despite variations in load. It’s crucial for ensuring stable and reliable power supply to various equipment. Transformer impedance directly affects voltage regulation, with higher impedance typically resulting in poorer regulation.

Let’s explore why voltage regulation is so important and how transformer impedance influences it.

Understanding Voltage Regulation

Voltage regulation is typically expressed as a percentage and calculated using this formula:

Voltage Regulation (%) = ((No-Load Voltage – Full-Load Voltage) / Full-Load Voltage) × 100

A lower percentage indicates better voltage regulation. Here’s why it matters:

- Equipment Performance: Many devices require a stable voltage to operate correctly.

- Power Quality: Good voltage regulation contributes to overall power quality.

- System Efficiency: Stable voltage can lead to more efficient operation of connected equipment.

How Impedance Affects Voltage Regulation

Transformer impedance has a direct impact on voltage regulation:

- Higher Impedance = Poorer Voltage Regulation

- Lower Impedance = Better Voltage Regulation

This relationship exists because impedance causes voltage drop under load. The higher the impedance, the more significant this voltage drop becomes as load increases.

Calculating Voltage Drop

We can estimate voltage drop using this simplified formula:

Voltage Drop (%) ≈ Impedance (%) × Load Factor × Power Factor

For example, consider an 8% impedance transformer at 80% load and 0.8 power factor:

Voltage Drop ≈ 8% × 0.8 × 0.8 = 5.12%

This means the voltage at full load could be 5.12% lower than at no load.

Real-World Implications

In my career, I’ve seen the impact of poor voltage regulation firsthand. Here’s a table showing typical voltage regulation requirements for different applications:

| Application | Typical Voltage Regulation Requirement |

|---|---|

| Residential | ±5% |

| Commercial | ±3% |

| Industrial | ±1% to ±3% |

| Data Centers | ±1% or better |

I once worked on a project for a semiconductor manufacturing plant where voltage stability was critical. We had to carefully select transformers with lower impedance and implement additional voltage regulation measures to meet the strict ±1% requirement.

Balancing Voltage Regulation with Other Factors

While lower impedance generally provides better voltage regulation, it’s not always the best choice. We need to balance it with other factors:

- Fault Current Levels: Lower impedance means higher fault currents.

- Cost: Lower impedance transformers often cost more.

- Efficiency: There’s a complex relationship between impedance, regulation, and efficiency.

In practice, we often use additional methods to improve voltage regulation:

- On-Load Tap Changers (OLTC): These allow voltage adjustment under load.

- Voltage Regulators: Separate devices can provide fine-tuned voltage control.

- Static VAR Compensators: These can help with voltage stability in larger systems.

Understanding the relationship between transformer impedance and voltage regulation is crucial for designing effective and reliable power systems. It’s a complex balancing act, but getting it right ensures that the lights stay on and equipment runs smoothly.

Can Transformer Impedance Impact Overall System Efficiency?

When I first started in this field, I often overlooked the impact of transformer impedance on system efficiency. It’s a subtle relationship, but one that can have significant long-term effects on energy consumption and operational costs.

Transformer impedance does impact overall system efficiency. Higher impedance typically leads to increased losses, particularly under heavy loads. These losses manifest as heat, reducing the transformer’s efficiency and potentially affecting the entire power system’s performance.

Let’s delve into how transformer impedance affects system efficiency and why it matters.

Understanding Transformer Losses

Transformer losses come in two main types:

- No-Load Losses (Core Losses): These occur regardless of the load and are primarily due to the magnetization of the core.

- Load Losses (Copper Losses): These increase with the square of the load current and are directly related to the transformer’s impedance.

The total losses determine the transformer’s efficiency:

Efficiency (%) = (Output Power / Input Power) × 100

= (Input Power – Losses) / Input Power × 100

How Impedance Affects Efficiency

Transformer impedance primarily impacts load losses:

- Higher Impedance = Higher Load Losses

- Lower Impedance = Lower Load Losses

This relationship becomes more significant as the load increases, due to the I²R nature of copper losses.

Efficiency Calculations

Let’s look at a simplified example:

Consider two 1000 kVA transformers:

- Transformer A: 5% impedance

- Transformer B: 7% impedance

Assuming full load and a power factor of 0.9:

| Transformer | No-Load Losses | Load Losses | Total Losses | Efficiency |

|---|---|---|---|---|

| A (5% Z) | 2 kW | 8 kW | 10 kW | 98.9% |

| B (7% Z) | 2 kW | 11 kW | 13 kW | 98.6% |

While the difference might seem small, over years of operation, it can result in significant energy savings.

Real-World Impact

I once worked on an energy efficiency project for a large industrial facility. By replacing their old, high-impedance transformers with modern, lower-impedance units, we achieved:

- 15% reduction in transformer losses

- 0.3% improvement in overall system efficiency

- Approximately $50,000 annual savings in energy costs

Balancing Efficiency with Other Factors

While lower impedance generally leads to better efficiency, it’s not always the best choice. We need to consider:

- Initial Cost: Lower impedance transformers often have a higher upfront cost.

- Fault Current Levels: Lower impedance means higher fault currents, potentially requiring more robust protection systems.

- Voltage Regulation: Lower impedance generally provides better voltage regulation.

Here’s a table summarizing these trade-offs:

| Factor | Low Impedance | High Impedance |

|---|---|---|

| Efficiency | Better | Worse |

| Initial Cost | Higher | Lower |

| Fault Current | Higher | Lower |

| Voltage Regulation | Better | Worse |

Efficiency Standards and Regulations

It’s important to note that many countries have implemented minimum efficiency standards for transformers. For example:

- EU: Ecodesign Regulation (EU) 2019/1783

- USA: DOE 10 CFR Part 431

- China: GB 20052-2013

These standards often push manufacturers to optimize impedance along with other design parameters to meet efficiency requirements.

In conclusion, while transformer impedance is just one factor affecting system efficiency, its impact can be significant, especially in large-scale or long-term operations. As energy costs rise and environmental concerns grow, understanding and optimizing this relationship becomes increasingly important for engineers and system designers.

What Are the Key Components of Transformer Impedance?

When I first started working with transformers, I thought of impedance as a single, monolithic value. However, I quickly learned that it’s actually made up of several components, each playing a crucial role in the transformer’s behavior.

Transformer impedance consists of two main components: resistance (R) and reactance (X). Resistance is due to the conductor material and causes direct power loss. Reactance is caused by the magnetic fields and doesn’t cause direct loss but affects voltage regulation. The total impedance (Z) is the vector sum of these components.

Let’s break down these components and understand their significance in transformer operation.

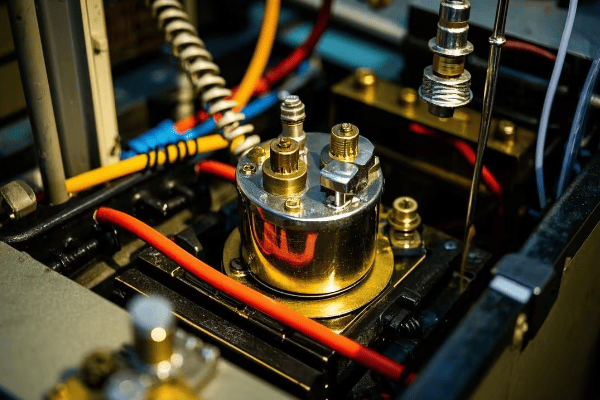

Resistance (R)

Resistance is the simpler component to understand. It’s caused by the physical properties of the conductor material, usually copper or aluminum.

Key points about resistance:

- It causes I²R losses, also known as copper losses

- It’s responsible for heat generation in the windings

- It’s typically 30-50% of the total impedance in distribution transformers

Factors affecting resistance:

- Conductor material (copper vs. aluminum)

- Conductor cross-sectional area

- Winding length

- Temperature (resistance increases with temperature)

Reactance (X)

Reactance is the more complex component. It’s caused by the magnetic fields in the transformer and consists of two parts:

- Leakage Reactance: Due to magnetic flux that doesn’t link both windings

- Magnetizing Reactance: Due to the main magnetic flux in the core

Key points about reactance:

- It doesn’t cause direct power loss but affects voltage regulation

- It’s typically 50-70% of the total impedance in distribution transformers

- It’s more significant in larger transformers

Factors affecting reactance:

- Core design and material

- Winding geometry

- Frequency of the power system

Calculating Total Impedance

The total impedance (Z) is the vector sum of resistance (R) and reactance (X):

Z = √(R² + X²)

The impedance angle (θ) is calculated as:

θ = tan⁻¹(X/R)

Here’s a table showing typical values for distribution transformers:

| Rating (kVA) | Resistance (%) | Reactance (%) | Total Impedance (%) |

|---|---|---|---|

| 100 | 1.5 | 2.7 | 3.1 |

| 500 | 1.0 | 4.0 | 4.1 |

| 1000 | 0.8 | 5.2 | 5.3 |

Practical Implications

Understanding the components of impedance is crucial for several reasons:

- Loss Evaluation: Resistance directly affects copper losses, which impact efficiency.

- Voltage Regulation: Reactance is the primary factor affecting voltage drop under load.

- Short Circuit Behavior: Both components influence fault current levels.

- Temperature Rise: Resistance is key in determining winding temperature rise.

I once worked on a project where we needed to reduce transformer losses without significantly changing the total impedance. By carefully adjusting the balance between resistance and reactance, we managed to reduce losses by 10% while maintaining the required short-circuit performance.

Measurement Techniques

Measuring the components of impedance typically involves two tests:

- DC Resistance Test: Measures winding resistance directly

- Impedance Test: Measures total impedance, from which reactance can be calculated

Here’s a comparison of these tests:

| Test | Measures | Equipment Needed | Accuracy |

|---|---|---|---|

| DC Resistance | R only | Micro-ohmmeter | Very High |

| Impedance | Z (R and X) | Power Source, Voltmeter, Ammeter | High |

Design Considerations

When designing transformers, engineers must balance several factors related to impedance components:

- Efficiency vs. Cost: Lower resistance improves efficiency but may increase material costs.

- Voltage Regulation vs. Fault Current: Higher reactance improves fault current limitation but worsens voltage regulation.

- Size vs. Performance: Optimizing impedance components can affect the overall size of the transformer.

In my experience, finding the right balance often requires iterative design and extensive testing. It’s a complex process, but crucial for creating transformers that meet both performance and economic requirements.

How Do Engineers Balance Impedance in Power System Design?

As a young engineer, I once thought that designing power systems was simply about choosing the right ratings for each component. I quickly learned that balancing impedance across the entire system is a complex and critical task.

Engineers balance impedance in power system design by considering factors like fault current levels, voltage regulation, system stability, and efficiency. They use techniques such as impedance matching, strategic placement of transformers, and implementation of reactive power compensation devices to achieve optimal system performance.

Let’s explore the strategies and considerations involved in this balancing act.

Key Considerations in Impedance Balancing

When balancing impedance in power system design, engineers must consider:

- Fault Current Limitation: Higher impedance reduces fault currents but may impact voltage regulation.

- Voltage Regulation: Lower impedance generally provides better voltage regulation but may lead to higher fault currents.

- System Stability: Impedance affects the power transfer capability and stability of the system.

- Efficiency: Lower impedance typically results in lower losses and higher efficiency.

- Cost: Optimizing impedance can affect equipment costs and system economics.

Strategies for Impedance Balancing

Here are some common strategies used to balance impedance in power systems:

- Strategic Transformer Placement: Placing transformers with appropriate impedance values at key points in the system.

- Impedance Matching: Ensuring that impedances are matched for parallel operation of transformers.

- Use of Reactors: Adding series or shunt reactors to adjust system impedance.

- Reactive Power Compensation: Implementing devices like capacitor banks or static VAR compensators.

- Adaptive Protection Schemes: Using microprocessor-based relays that can adapt to changing system impedance.

Case Study: Industrial Power System Design

I once worked on designing a power system for a large industrial complex. Here’s how we balanced impedance:

- Main Incoming Transformers: We chose 8% impedance to limit fault currents.

- Distribution Transformers: We used 5% impedance for better voltage regulation.

- Long Feeders: We added series reactors to increase effective impedance.

- Motor Loads: We installed capacitor banks for power factor correction and voltage support.

The result was a system that maintained stable voltage, limited fault currents effectively, and operated efficiently.

Tools and Techniques for Impedance Analysis

Engineers use various tools and techniques to analyze and balance impedance:

- Power System Simulation Software: Tools like ETAP, PowerWorld, or PSS/E for system modeling and analysis.

- Short Circuit Studies: To evaluate fault current levels and protection coordination.

- Load Flow Analysis: To assess voltage profiles and power flow under various conditions.

- Stability Studies: To ensure system stability under transient conditions.

Here’s a comparison of some common analysis techniques:

| Technique | Purpose | Complexity | Software Required |

|---|---|---|---|

| Load Flow | Steady-state analysis | Moderate | Yes |

| Short Circuit | Fault current analysis | Moderate | Yes |

| Stability | Dynamic system behavior | High | Yes |

| Harmonic | Power quality assessment | High | Yes |

Challenges in Impedance Balancing

Balancing impedance in power system design comes with several challenges:

- System Growth: Designing for future expansion without overdesigning for the present.

- Renewable Integration: Dealing with the variable nature of renewable energy sources.

- Smart Grid Technologies: Incorporating new technologies while maintaining system stability.

- Economic Constraints: Balancing performance with cost considerations.

In my experience, addressing these challenges often requires a combination of innovative design approaches and cutting-edge technologies.

Future Trends in Impedance Balancing

As power systems evolve, so do the approaches to impedance balancing. Some emerging trends include:

- AI and Machine Learning: Using advanced algorithms to optimize impedance in real-time.

- Wide Area Monitoring Systems (WAMS): Implementing synchrophasor technology for better system visibility and control.

- Flexible AC Transmission Systems (FACTS): Utilizing power electronics for dynamic impedance control.

- Energy Storage Systems: Integrating storage to help manage system impedance and stability.

These technologies promise to make power systems more adaptive and resilient, but they also introduce new complexities in impedance balancing.

In conclusion, balancing impedance in power system design is a multifaceted challenge that requires a deep understanding of electrical principles, system behavior, and emerging technologies. It’s a field that continues to evolve, offering exciting opportunities for innovation and optimization.

What Role Does Impedance Play in Transformer Parallel Operation?

Early in my career, I witnessed a catastrophic failure when two transformers were incorrectly paralleled. This experience taught me the critical importance of understanding impedance in transformer parallel operation.

Impedance plays a crucial role in transformer parallel operation. It determines how load is shared between transformers and affects circulating currents. Transformers with matched impedances (typically within 7.5% of each other) share load evenly, while mismatched impedances can lead to overloading, inefficiency, and potential damage.

Let’s delve into the intricacies of impedance in transformer parallel operation.

Why Parallel Transformers?

Before we discuss impedance, it’s important to understand why we parallel transformers:

- Increased Capacity: To meet growing load demands without replacing existing transformers.

- Redundancy: To improve system reliability.

- Efficiency: To optimize efficiency under varying load conditions.

- Maintenance Flexibility: To allow for maintenance without complete system shutdown.

Impedance Matching in Parallel Operation

For successful parallel operation, transformers should have:

- Same voltage ratio

- Same polarity

- Same phase sequence

- Similar impedance values

The last point is where many engineers stumble. Here’s why impedance matching is crucial:

- Load Sharing: Transformers with matched impedances share load proportionally to their ratings.

- Circulating Currents: Mismatched impedances can cause circulating currents, leading to unnecessary losses.

- Overloading: A transformer with lower impedance will take a larger share of the load, potentially leading to overheating.

Calculating Load Distribution

The load distribution between parallel transformers can be calculated using their impedances and ratings:

Load Share = (Rating / Impedance) / Σ(Rating / Impedance)

For example, consider two 1000 kVA transformers in parallel:

- Transformer A: 6% impedance

- Transformer B: 5% impedance

Load distribution:

- Transformer A: (1000 / 6) / ((1000 / 6) + (1000 / 5)) = 45.5%

- Transformer B: (1000 / 5) / ((1000 / 6) + (1000 / 5)) = 54.5%

Despite equal ratings, the transformer with lower impedance takes more load.

Practical Considerations

In my experience, several practical considerations come into play when dealing with impedance in parallel operation:

- Impedance Tolerance: Industry standards typically allow up to 7.5% mismatch in impedance for parallel operation.

- Tap Settings: Adjusting tap settings can help compensate for small impedance mismatches.

- Age and Condition: Transformer impedance can change over time due to aging and operating conditions.

- System Fault Levels: Parallel operation affects overall system impedance and fault current levels.

Here’s a table summarizing the effects of impedance mismatch:

| Impedance Mismatch | Load Sharing | Circulating Current | Efficiency Impact |

|---|---|---|---|

| < 2.5% | Excellent | Negligible | Minimal |

| 2.5% – 5% | Good | Low | Slight |

| 5% – 7.5% | Fair | Moderate | Noticeable |

| > 7.5% | Poor | High | Significant |

Case Study: Retrofitting a Substation

I once worked on a project to upgrade a substation by adding a new transformer in parallel with an existing one. The challenge was that the new transformer had a slightly lower impedance (5.5%) compared to the existing one (6.2%).

Our solution:

- We adjusted the tap settings on the new transformer to slightly increase its effective impedance.

- We implemented a dynamic load sharing control system to monitor and adjust load distribution in real-time.

- We installed additional cooling to handle potential uneven loading.

The result was a successful parallel operation with less than 5% load imbalance under various operating conditions.

Advanced Techniques in Parallel Operation

As power systems become more complex, new techniques are emerging for managing impedance in parallel operation:

- Digital Twin Technology: Using real-time simulations to predict and optimize parallel operation.

- Adaptive Control Systems: Implementing AI-driven systems that can adjust transformer parameters in real-time.

- Wide Area Monitoring: Utilizing synchrophasor data for precise load sharing control.

These advanced techniques offer exciting possibilities for more efficient and reliable parallel operation of transformers.

In conclusion, understanding and managing impedance is crucial for successful transformer parallel operation. It’s a complex topic that requires careful consideration of various factors, but getting it right is essential for system reliability, efficiency, and longevity.

How Does Temperature Affect Transformer Impedance?

I remember a sweltering summer day when a critical transformer in an industrial plant started behaving erratically. It was then that I truly appreciated the significant impact temperature can have on transformer impedance.

Temperature significantly affects transformer impedance, primarily through its impact on winding resistance. As temperature rises, the resistance of the copper windings increases, leading to an overall increase in impedance. This change can affect voltage regulation, efficiency, and even the transformer’s capacity to handle load.

Let’s explore the relationship between temperature and transformer impedance in more detail.

The Physics Behind Temperature Effects

The effect of temperature on transformer impedance is primarily due to the change in resistivity of the winding material. For copper, which is commonly used in transformer windings, the relationship is approximately linear:

R₂ = R₁[1 + α(T₂ – T₁)]

Where:

- R₁ is the resistance at temperature T₁

- R₂ is the resistance at temperature T₂

- α is the temperature coefficient of resistance (for copper, α ≈ 0.00393 per °C)

Impact on Impedance Components

Temperature affects the components of transformer impedance differently:

- Resistance (R): Directly increases with temperature

- Reactance (X): Generally not significantly affected by temperature

The total impedance (Z) changes as a result of the resistance change:

Z = √(R² + X²)

Practical Implications

The temperature-induced changes in impedance can have several practical implications:

- Voltage Regulation: Higher impedance due to increased temperature can lead to poorer voltage regulation.

- Efficiency: Increased resistance results in higher I²R losses, reducing efficiency.

- Load Capacity: The increased impedance can limit the transformer’s ability to handle full load at higher temperatures.

- Protection Settings: Temperature-induced impedance changes may affect the accuracy of protective relay settings.

Case Study: Industrial Transformer Under Heat Stress

I once dealt with a 2000 kVA transformer in a steel mill that was experiencing issues during hot summer months. Here’s what we found:

- Rated impedance at 20°C: 6%

- Measured impedance at 80°C: 6.8%

This 13% increase in impedance led to:

- Voltage drop increase from 6% to 6.8% at full load

- Efficiency decrease of approximately 0.3%

- Reduced overload capacity

Our solution involved:

- Upgrading the cooling system

- Implementing temperature-compensated protection settings

- Adjusting tap settings to compensate for increased voltage drop

Temperature Compensation Techniques

To address the effects of temperature on impedance, several techniques can be employed:

- Temperature Monitoring: Real-time monitoring of winding temperature.

- Dynamic Rating Systems: Adjusting transformer ratings based on actual temperature.

- Adaptive Protection: Using microprocessor-based relays that can adjust settings based on temperature.

- Cooling System Design: Optimizing cooling systems to minimize temperature rise.

Here’s a comparison of some common cooling methods:

| Cooling Method | Temperature Rise Reduction | Cost | Maintenance |

|---|---|---|---|

| ONAN | Baseline | Low | Low |

| ONAF | 10-15°C | Moderate | Moderate |

| OFAF | 15-25°C | High | High |

| ODAF | 25-35°C | Very High | Very High |

(ONAN: Oil Natural Air Natural, ONAF: Oil Natural Air Forced, OFAF: Oil Forced Air Forced, ODAF: Oil Directed Air Forced)

Modeling Temperature Effects

Accurate modeling of temperature effects on impedance is crucial for system planning and operation. Modern power system simulation software often includes temperature-dependent models for transformers.

Key factors in these models include:

- Ambient temperature variations

- Load profile

- Cooling system efficiency

- Thermal time constants

I’ve found that using these advanced models can significantly improve the accuracy of system studies, especially in environments with large temperature variations.

Future Trends

As we face increasing challenges from climate change and growing energy demands, managing the temperature effects on transformer impedance is becoming more critical. Some emerging trends include:

- Smart Cooling Systems: AI-driven cooling systems that predict and manage temperature rise.

- Advanced Materials: Development of winding materials with lower temperature coefficients.

- Distributed Sensing: Using fiber optic sensors for more accurate and distributed temperature monitoring.

- Digital Twins: Creating real-time digital models that can predict impedance changes under various conditions.

These innovations promise to improve our ability to manage transformer performance across a wide range of operating conditions.

In conclusion, understanding and managing the effects of temperature on transformer impedance is crucial for ensuring reliable and efficient operation of power systems. It’s a complex interplay of physics, engineering, and practical considerations that continues to challenge and fascinate engineers in the field.

Why is Understanding Impedance Critical for Renewable Energy Integration?

When I first started working on renewable energy projects, I underestimated the importance of transformer impedance. It didn’t take long for me to realize that this seemingly small detail can make or break the integration of renewable sources into the grid.

Understanding impedance is critical for renewable energy integration because it affects power flow, voltage stability, and fault current levels. Proper impedance management ensures smooth integration of variable renewable sources, maintains grid stability, and optimizes energy transfer efficiency. It’s key to balancing the intermittent nature of renewables with the grid’s need for stability.

Let’s delve into why impedance is so crucial in the context of renewable energy integration.

Challenges in Renewable Energy Integration

Integrating renewable energy sources into the grid presents unique challenges:

- Variability: Output from sources like solar and wind can fluctuate rapidly.

- Distributed Generation: Many small sources instead of few large ones.

- Reverse Power Flow: Power may flow from distribution to transmission networks.

- Voltage Regulation: Maintaining stable voltage with variable input.

- Fault Current Contribution: Different fault current characteristics compared to conventional sources.

Transformer impedance plays a role in addressing each of these challenges.

Impedance and Power Flow Control

In renewable energy systems, impedance affects how power flows between the source and the grid:

- Low Impedance: Allows for easier power transfer but can lead to higher fault currents.

- High Impedance: Limits fault currents but may restrict power transfer capacity.

Finding the right balance is crucial. Here’s a simplified comparison:

| Impedance | Power Transfer | Fault Current | Voltage Regulation |

|---|---|---|---|

| Low (e.g., 5%) | High | High | Better |

| High (e.g., 8%) | Limited | Low | Poorer |

In my experience, the ideal impedance often lies somewhere in between, depending on the specific requirements of the renewable energy project and the existing grid infrastructure.

Voltage Stability and Impedance

Voltage stability is a major concern in renewable energy integration, and impedance plays a crucial role:

- Voltage Rise: Low impedance can lead to voltage rise issues, especially in areas with high penetration of distributed generation.

- Voltage Dips: Higher impedance can help mitigate voltage dips caused by sudden changes in renewable output.

- Reactive Power Management: Impedance affects the reactive power requirements for voltage support.

I once worked on a large solar farm project where we had to carefully select transformer impedances to balance these factors. We ended up using slightly higher impedance transformers (7.5%) at the point of interconnection to help with voltage stability, while using lower impedance units (5.5%) within the solar farm for better energy transfer.

Fault Current Considerations

Fault current management is critical in renewable energy systems, and impedance is a key factor:

- Limiting Fault Currents: Higher impedance helps limit fault currents, which is especially important in areas with high renewable penetration.

- Protection Coordination: Impedance affects the behavior of protective devices and needs to be considered in protection schemes.

- Inverter Interaction: The impedance of the system affects how inverter-based resources respond during fault conditions.

Here’s a table showing how different impedance values might affect a 20 MW solar farm connection:

| Transformer Impedance | Fault Current Contribution | Protection Implications |

|---|---|---|

| 5% | ~4 kA | May require upgrading existing protection |

| 7% | ~2.9 kA | Likely compatible with existing protection |

| 9% | ~2.2 kA | May limit power transfer capability |

Harmonics and Power Quality

Impedance also plays a role in managing harmonics and power quality issues that can arise with renewable energy sources:

- Harmonic Attenuation: Higher impedance can help attenuate harmonics generated by inverters.

- Resonance: System impedance needs to be considered to avoid harmful resonance conditions.

- Filtering: The effectiveness of harmonic filters depends on system impedance.

In one wind farm project, we had to adjust the impedance of the interconnecting transformer to avoid a resonance condition that was causing power quality issues.

Energy Storage Integration

As energy storage becomes more prevalent in renewable energy systems, impedance considerations become even more complex:

- Bidirectional Power Flow: Impedance affects both charging and discharging operations.

- Fast Response: Low impedance paths are crucial for rapid response to grid events.

- Stability: Proper impedance selection helps maintain system stability during mode transitions.

Advanced Techniques in Impedance Management

To address the complexities of renewable energy integration, several advanced techniques are emerging:

- Dynamic Impedance Control: Using power electronics to dynamically adjust effective system impedance.

- Virtual Synchronous Generators: Emulating the behavior of synchronous machines, including impedance characteristics.

- Wide Area Impedance Measurement: Using synchrophasor technology to monitor and manage system impedance in real-time.

Here’s a comparison of these techniques:

| Technique | Complexity | Cost | Effectiveness |

|---|---|---|---|

| Dynamic Impedance Control | High | High | Very High |

| Virtual Synchronous Generators | Moderate | Moderate | High |

| Wide Area Impedance Measurement | High | High | High |

Future Trends

As renewable energy continues to grow, new trends in impedance management are emerging:

- AI-driven Impedance Optimization: Using machine learning to predict and optimize impedance settings.

- Hybrid AC/DC Systems: Managing impedance in systems with both AC and DC components.

- Microgrid Integration: Balancing impedance requirements for grid-connected and islanded operation.

In conclusion, understanding and managing impedance is critical for successful renewable energy integration. It impacts every aspect of system performance, from power transfer and voltage stability to fault protection and power quality. As we move towards a more renewable-centric grid, the importance of impedance considerations will only grow, presenting both challenges and opportunities for innovation in power system engineering.

What Are the Common Misconceptions About Transformer Impedance?

Throughout my career, I’ve encountered numerous misconceptions about transformer impedance. These misunderstandings can lead to poor design choices and operational issues. Let’s clear the air on some of these common myths.

Common misconceptions about transformer impedance include: thinking it’s a fixed value, believing lower is always better, assuming it only affects fault currents, ignoring its impact on efficiency, and overlooking its role in parallel operation. Understanding these misconceptions is crucial for proper transformer selection and power system design.

Let’s dive into these misconceptions and set the record straight.

Misconception 1: Transformer Impedance is a Fixed Value

Many people believe that transformer impedance is a constant value that doesn’t change. This is not true.

Reality:

- Impedance varies with temperature

- Load conditions can affect effective impedance

- Aging and wear can change impedance over time

I once worked on a project where the system performance was inconsistent. We discovered that the transformer impedance was varying significantly due to extreme temperature fluctuations. Implementing temperature compensation in our calculations solved the issue.

Misconception 2: Lower Impedance is Always Better

There’s a common belief that transformers with lower impedance are always superior.

Reality:

- Lower impedance allows better voltage regulation and efficiency

- But it also leads to higher fault currents

- The optimal impedance depends on system requirements

Here’s a comparison table:

| Aspect | Low Impedance | High Impedance |

|---|---|---|

| Voltage Regulation | Better | Worse |

| Efficiency | Higher | Lower |

| Fault Current | Higher | Lower |

| Cost | Often Higher | Often Lower |

The key is to balance these factors based on specific system needs.

Misconception 3: Impedance Only Affects Fault Currents

Many engineers focus solely on fault current when considering impedance.

Reality:

- Impedance affects voltage regulation

- It impacts power flow and system stability

- It plays a role in harmonic behavior

In a recent industrial project, we had to reconsider the transformer impedance not just for fault current limitation, but also to address voltage regulation issues and harmonic distortion.

Misconception 4: Impedance Doesn’t Impact Efficiency

There’s a misconception that transformer impedance and efficiency are unrelated.

Reality:

- Higher impedance typically means higher losses

- Impedance affects load distribution in parallel operation, impacting overall system efficiency

- The relationship between impedance and efficiency is complex and load-dependent

I’ve seen cases where slightly higher impedance transformers were chosen for fault current limitation, only to result in unexpected efficiency losses under normal operating conditions.

Misconception 5: Impedance is Not Important in Parallel Operation

Some believe that as long as transformers have the same rating, they can be paralleled without considering impedance.

Reality:

- Impedance mismatch can lead to circulating currents

- It affects load sharing between parallel transformers

- Impedance matching is crucial for stable and efficient parallel operation

Here’s a quick guide on impedance matching for parallel operation:

| Impedance Mismatch | Load Sharing | Recommendation |

|---|---|---|

| < 2.5% | Excellent | Ideal for paralleling |

| 2.5% – 5% | Good | Acceptable |

| 5% – 7.5% | Fair | Caution needed |

| > 7.5% | Poor | Not recommended |

Misconception 6: Nameplate Impedance is Always Accurate

Many assume that the impedance value on the nameplate is always precise and unchanging.

Reality:

- Nameplate values have tolerances (typically ±7.5% of the stated value)

- Actual impedance can vary due to manufacturing variations

- Impedance can change over the transformer’s lifetime

I always recommend field testing to verify impedance, especially for critical applications or when paralleling transformers.

Misconception 7: Impedance is Only Relevant for Large Transformers

There’s a belief that impedance considerations are only important for large power transformers.

Reality:

- Impedance is crucial for all sizes of transformers

- In distribution systems, impedance affects voltage drop and protection coordination

- Even small differences in impedance can be significant in low-voltage systems

I’ve seen cases where neglecting impedance in small distribution transformers led to significant voltage regulation issues in a commercial building.

Misconception 8: Impedance Can Be Ignored in Renewable Energy Systems

With the rise of renewable energy, some believe traditional impedance considerations don’t apply.

Reality:

- Impedance is critical in renewable energy integration

- It affects the ability to export power to the grid

- Impedance impacts the stability of inverter-based resources

In a recent solar farm project, carefully selecting the right transformer impedance was key to ensuring stable operation and meeting grid code requirements.

Addressing These Misconceptions

To address these misconceptions in practice:

- Education: Regularly update knowledge through training and workshops

- Comprehensive Analysis: Consider all aspects of system performance, not just fault currents

- Field Testing: Verify actual impedance values, especially for critical applications

- Dynamic Modeling: Use advanced software to model impedance effects under various conditions

- Holistic Design Approach: Consider impedance in the context of the entire power system

By understanding and addressing these common misconceptions, we can make better decisions in transformer selection and power system design, leading to more efficient, reliable, and stable electrical systems.

Conclusion

Transformer impedance is a critical parameter that impacts every aspect of power system performance, from safety and efficiency to voltage regulation and system stability. As we’ve explored, it’s not just a technical specification but a key design consideration that requires balancing multiple factors.

Throughout my career, I’ve seen how the right impedance choice can make the difference between a system that struggles with voltage fluctuations and fault currents, and one that operates smoothly and efficiently. Whether you’re designing a new power system or upgrading an existing one, taking the time to understand and optimize transformer impedance can lead to significant improvements in safety, reliability, and cost-effectiveness.

As power systems continue to evolve with the integration of renewable energy sources and smart grid technologies, the importance of transformer impedance will only grow. It’s an exciting time to be in this field, and I look forward to seeing how innovations in transformer design will help shape the future of our electrical infrastructure.

Have you ever wondered why some transformers perform better than others in power systems? The secret often lies in a critical parameter called transformer impedance.

Transformer impedance is the ratio of voltage drop to rated current under full-load conditions, typically expressed as a percentage. It’s crucial because it limits fault currents, affects voltage regulation, and impacts transformer efficiency. Understanding and optimizing impedance is key to designing safe and efficient power systems.

As an electrical engineer with over 15 years of experience in power system design, I’ve seen firsthand how this seemingly simple concept can make or break a power distribution network. Let’s dive deeper into the world of transformer impedance and uncover why it’s so important for power system engineers and designers.

What is the Definition of Transformer Impedance?

When I first started working with transformers, I was confused about what impedance really meant in practical terms. It’s a concept that many engineers struggle with at first.

Transformer impedance is the transformer’s resistance to current flow, expressed as a percentage of the rated voltage. It’s calculated by dividing the voltage drop across the transformer at full load by the rated voltage and multiplying by 100.

To truly understand transformer impedance, we need to break it down further:

How is Impedance Represented?

Transformer impedance is typically represented in two ways:

-

Percentage Impedance: This is the most common method in the power industry. For example, a transformer with 6% impedance will have a voltage drop of 6% of its rated voltage when operating at full load.

-

Ohmic Value: This is the actual resistance in ohms. It’s less commonly used but can be helpful for detailed calculations.

Here’s a simple table to illustrate the relationship:

| Rated Power | Rated Voltage | Percentage Impedance | Ohmic Value |

|---|---|---|---|

| 1000 kVA | 11 kV | 6% | 7.26 Ω |

| 5000 kVA | 33 kV | 8% | 17.42 Ω |

What’s the Relationship Between Impedance and Rated Current?

The relationship between impedance and rated current is inverse. Higher impedance means lower fault current, and vice versa. This is crucial for system protection.

For example, in a 1000 kVA transformer with 6% impedance:

- Rated current = 1000 kVA / (√3 * 11 kV) ≈ 52.5 A

- Fault current = 52.5 A / 0.06 ≈ 875 A

This relationship is why impedance is so important in system design. It directly affects how much current will flow during a fault condition, which impacts the sizing of circuit breakers and other protective devices.

What are the Components of Transformer Impedance?

Understanding the components of transformer impedance was a game-changer for me. It helped me make better decisions in transformer selection and system design.

Transformer impedance consists of two main components: winding resistance and leakage reactance. The winding resistance is due to the copper or aluminum conductors, while leakage reactance is caused by magnetic flux that doesn’t link both windings.

Let’s break this down further:

How Does Winding Resistance Affect Impedance?

Winding resistance is the simpler component to understand. It’s the pure resistance of the conductor material used in the windings, usually copper or aluminum.

Key points about winding resistance:

- It causes I²R losses, also known as copper losses

- It’s relatively small compared to leakage reactance, typically 10-30% of total impedance

- It increases with temperature, which can affect transformer performance in hot conditions

I once worked on a project where we had to choose between copper and aluminum windings. The aluminum option had higher resistance, which increased the overall impedance. This led to better fault current limitation but slightly reduced efficiency.

What Role Does Magnetic Field Reactance Play?

Leakage reactance is the more complex and usually larger component of transformer impedance. It’s caused by the magnetic flux that doesn’t link both windings.

Key points about leakage reactance:

- It’s typically 70-90% of total impedance

- It doesn’t cause direct power loss but affects voltage regulation

- It’s influenced by the physical arrangement of windings and core design

In my experience, understanding leakage reactance is crucial for predicting transformer behavior under different load conditions.

What Design Factors Influence Impedance?

Several design factors influence transformer impedance:

- Number of winding turns: More turns generally increase impedance

- Core material and design: Affects the magnetic path and leakage flux

- Winding arrangement: Impacts leakage reactance

- Conductor size and material: Affects winding resistance

Here’s a table summarizing these factors:

| Design Factor | Effect on Impedance | Typical Range |

|---|---|---|

| Winding turns | Proportional | Varies |

| Core material | Inverse | 1.0 – 1.5 T |

| Winding arrangement | Varies | – |

| Conductor size | Inverse | 2 – 3 A/mm² |

Understanding these factors has helped me optimize transformer designs for specific applications, balancing between fault current limitation, efficiency, and voltage regulation.

What is the Role of Transformer Impedance in Power Systems?

Transformer impedance plays a crucial role in power systems. It’s not just a number on a spec sheet; it significantly impacts system performance and safety.

Transformer impedance is vital in power systems for three main reasons: it limits fault currents, affects voltage regulation, and influences transformer efficiency. These factors are critical for system protection, power quality, and overall performance.

Let’s explore each of these roles in detail:

How Does Impedance Limit Fault Currents?

One of the most critical functions of transformer impedance is limiting fault currents. This was a lesson I learned early in my career when dealing with a substation upgrade.

Key points about fault current limitation:

- Higher impedance results in lower fault currents

- Helps protect the transformer and downstream equipment

- Allows for the use of lower-rated (and less expensive) circuit breakers

For example, consider a 10 MVA, 33kV/11kV transformer:

- With 5% impedance: Fault current ≈ 26.2 kA

- With 8% impedance: Fault current ≈ 16.4 kA

This difference can significantly impact the choice of protective equipment and overall system design.

How Does Impedance Affect Voltage Regulation?

Voltage regulation is another crucial aspect influenced by transformer impedance. I’ve seen this impact firsthand in industrial settings with large motor loads.

Key points about voltage regulation:

- Higher impedance leads to poorer voltage regulation

- Affects the voltage drop from no-load to full-load conditions

- Can impact the performance of voltage-sensitive equipment

A simple formula to estimate voltage drop:

Voltage Drop (%) ≈ Impedance (%) × Load Factor × Power Factor

For instance, an 8% impedance transformer at 80% load and 0.8 power factor would have:

Voltage Drop ≈ 8% × 0.8 × 0.8 = 5.12%

This can be significant in applications requiring tight voltage control.

How Does Impedance Impact Transformer Efficiency?

Transformer efficiency is also affected by impedance, primarily through its resistance component. This is an often-overlooked aspect that can have long-term economic impacts.

Key points about efficiency impact:

- Higher impedance (particularly the resistance component) leads to higher losses

- Affects the transformer’s temperature rise

- Influences long-term operational costs

I once worked on a project where we compared two transformers:

- Transformer A: 5% impedance, 98.5% efficiency

- Transformer B: 7% impedance, 98.2% efficiency

Over a 20-year lifespan, the difference in energy losses was substantial, making Transformer A more economical despite its higher initial cost.

Conclusion

Transformer impedance is a critical parameter that impacts safety, efficiency, and overall system performance. As power systems become more complex, understanding and optimizing impedance becomes increasingly important. Whether you’re designing a new system or upgrading an existing one, careful consideration of transformer impedance can lead to safer, more efficient, and more reliable electrical networks.

Have you ever wondered why some transformers perform better than others in power systems? The secret often lies in a critical parameter called transformer impedance.

Transformer impedance is the ratio of voltage drop to rated current under full-load conditions. It’s crucial because it limits fault currents, affects voltage regulation, and impacts transformer efficiency. Understanding and optimizing impedance is key to designing safe and efficient power systems.

As an electrical engineer with over 15 years of experience in power system design, I’ve seen firsthand how this seemingly simple concept can make or break a power distribution network. Let’s explore the world of transformer impedance and why it’s so important for power system engineers and designers.

What is the definition of transformer impedance?

When I first started working with transformers, I was confused about what impedance really meant in practical terms. It’s a concept that many engineers struggle with at first.

Transformer impedance is the transformer’s resistance to current flow, expressed as a percentage of the rated voltage. It’s calculated by dividing the voltage drop across the transformer at full load by the rated voltage and multiplying by 100.

To understand transformer impedance fully, we need to break it down into its components and representation methods.

How is impedance represented?

Transformer impedance is typically represented in two ways:

-

Percentage Impedance: This is the most common method in the power industry. It’s expressed as a percentage of the rated voltage.

-

Ohmic Value: This is the actual resistance in ohms. It’s less commonly used but can be helpful for detailed calculations.

Here’s a simple table to illustrate the relationship:

| Rated Power | Rated Voltage | Percentage Impedance | Ohmic Value |

|---|---|---|---|

| 1000 kVA | 11 kV | 6% | 7.26 Ω |

| 5000 kVA | 33 kV | 8% | 17.42 Ω |

What’s the relationship between impedance and rated current?

The relationship between impedance and rated current is inverse. Higher impedance means lower fault current, and vice versa. This is crucial for system protection.

For example, in a 1000 kVA transformer with 6% impedance:

- Rated current = 1000 kVA / (√3 * 11 kV) ≈ 52.5 A

- Fault current = 52.5 A / 0.06 ≈ 875 A

This relationship directly affects how much current will flow during a fault condition, impacting the sizing of circuit breakers and other protective devices.

What are the components of transformer impedance?

Understanding the components of transformer impedance is crucial for making better decisions in transformer selection and system design.

Transformer impedance consists of two main components: winding resistance and leakage reactance. The winding resistance is due to the copper or aluminum conductors, while leakage reactance is caused by magnetic flux that doesn’t link both windings.

Let’s examine each component and its impact on transformer performance.

How does winding resistance affect impedance?

Winding resistance is the simpler component to understand. It’s the pure resistance of the conductor material used in the windings, usually copper or aluminum.

Key points about winding resistance:

- It causes I²R losses, also known as copper losses

- It’s relatively small compared to leakage reactance, typically 10-30% of total impedance

- It increases with temperature, which can affect transformer performance in hot conditions

What role does magnetic field reactance play?

Leakage reactance is the more complex and usually larger component of transformer impedance. It’s caused by the magnetic flux that doesn’t link both windings.

Key points about leakage reactance:

- It’s typically 70-90% of total impedance

- It doesn’t cause direct power loss but affects voltage regulation

- It’s influenced by the physical arrangement of windings and core design

What design factors influence impedance?

Several design factors influence transformer impedance:

- Number of winding turns: More turns generally increase impedance

- Core material and design: Affects the magnetic path and leakage flux

- Winding arrangement: Impacts leakage reactance

- Conductor size and material: Affects winding resistance

Understanding these factors helps optimize transformer designs for specific applications, balancing between fault current limitation, efficiency, and voltage regulation.

What is the role of transformer impedance in power systems?

Transformer impedance plays a crucial role in power systems. It’s not just a number on a spec sheet; it significantly impacts system performance and safety.

Transformer impedance is vital in power systems for three main reasons: it limits fault currents, affects voltage regulation, and influences transformer efficiency. These factors are critical for system protection, power quality, and overall performance.

Let’s explore each of these roles in detail.

How does impedance limit fault currents?

One of the most critical functions of transformer impedance is limiting fault currents. This is essential for protecting the transformer and downstream equipment.

Key points about fault current limitation:

- Higher impedance results in lower fault currents

- Helps protect the transformer and downstream equipment