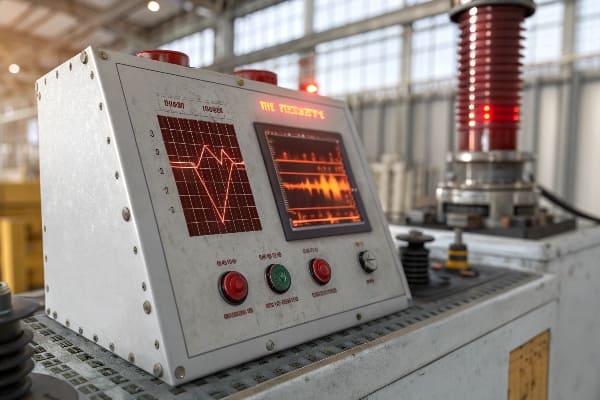

Is your transformer a ticking time bomb? With 80% of failures linked to overloading, you can’t afford to ignore the warning signs. Your entire operation could be at risk.

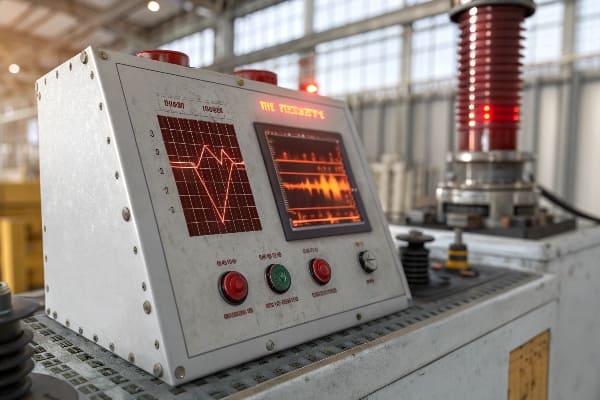

This guide provides a comprehensive 5-step safety assessment for transformers, focusing on load distribution, temperature monitoring, and predictive maintenance. By following these steps, you can significantly reduce the risk of transformer failures and ensure optimal performance.

As someone who’s spent years working with transformers, I’ve seen firsthand how crucial proper safety assessments are. Let’s dive into the critical steps that could save your equipment and your business.

Load Distribution Risks: How Overloading Triggers 80% of Transformer Failures?

Are you pushing your transformer to its limits? You might be playing a dangerous game. Overloading is the silent killer of transformers, responsible for a staggering 80% of failures.

Transformer overloading occurs when the load exceeds the rated capacity, leading to excessive heat generation, insulation breakdown, and potential catastrophic failure. Common symptoms include increased oil and winding temperatures, unusual noise or vibration, and degraded oil quality.

In my years of experience, I’ve seen too many transformers fail due to overloading. Let’s break down the risks and warning signs:

Understanding Load Distribution

-

Rated Capacity:

- Defined by manufacturer specifications

- Based on design, cooling system, and insulation class

-

Load Factors:

- Continuous load vs. peak load

- Daily load cycles and seasonal variations

-

Overloading Consequences:

- Accelerated aging of insulation

- Increased risk of short circuits

- Potential for catastrophic failure

Warning Signs of Overloading

| Symptom | Cause | Potential Consequences |

|---|---|---|

| Elevated Oil Temperature | Excessive heat generation | Insulation breakdown, reduced lifespan |

| Unusual Noise or Vibration | Core saturation, winding movement | Mechanical damage, increased losses |

| Degraded Oil Quality | Accelerated oil oxidation | Reduced cooling efficiency, insulation failure |

| Increased Gassing | Chemical breakdown of oil and insulation | Potential for arcing, explosion risk |

I once consulted for a manufacturing plant that consistently ran their transformer at 110% capacity during peak hours. They thought they were maximizing efficiency, but in reality, they were drastically shortening the transformer’s lifespan. We implemented a load management system that balanced production needs with transformer health, extending its life by an estimated 15 years.

Strategies to Mitigate Overloading Risks

-

Load Monitoring and Management:

- Implement real-time load monitoring systems

- Use load shedding or load shifting during peak periods

-

Cooling System Optimization:

- Ensure proper functioning of cooling fans and pumps

- Consider upgrading cooling systems for increased capacity

-

Regular Maintenance and Inspections:

- Conduct frequent oil tests and dissolved gas analysis

- Perform thermal imaging scans to detect hotspots

-

Capacity Planning:

- Anticipate future load growth

- Consider parallel transformer setups for load sharing

-

Emergency Protocols:

- Develop clear procedures for overload situations

- Train personnel on rapid response to overloading alarms

Remember, while transformers can handle short-term overloads, consistent overloading is a recipe for disaster. By understanding load distribution risks and implementing proper monitoring and management strategies, you can significantly reduce the chances of overload-related failures. In the next section, we’ll explore how temperature monitoring plays a crucial role in transformer safety.

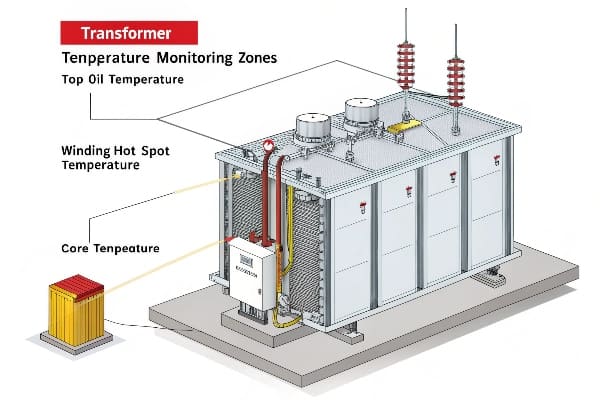

Real-Time Temperature Monitoring: 3 Critical Zones You’re Probably Ignoring?

Are you confident you’re tracking all the crucial temperature points in your transformer? Chances are, you’re overlooking some critical zones that could be ticking time bombs.

Effective transformer temperature monitoring involves tracking three critical zones: top oil temperature, winding hot spot temperature, and core temperature. Real-time monitoring of these areas is essential for detecting potential issues early and preventing catastrophic failures.

Throughout my career, I’ve seen many cases where overlooking these critical zones led to serious consequences. Let’s explore these often-ignored areas:

Zone 1: Top Oil Temperature

-

Importance:

- Indicates overall thermal condition of the transformer

- First line of defense against overheating

-

Monitoring Methods:

- Thermometers or RTDs in oil pockets

- Fiber optic sensors for more accurate readings

-

Warning Signs:

- Rapid increase in temperature

- Sustained temperatures above 95°C (for most transformers)

Zone 2: Winding Hot Spot Temperature

-

Criticality:

- Often the hottest point in the transformer

- Direct indicator of insulation stress

-

Measurement Challenges:

- Not directly accessible in most transformers

- Requires advanced modeling or estimation techniques

-

Monitoring Solutions:

- Fiber optic sensors embedded in windings

- Thermal models based on load and top oil temperature

Zone 3: Core Temperature

-

Overlooked Importance:

- Indicator of core losses and efficiency

- Can reveal issues with core insulation or lamination

-

Monitoring Difficulties:

- Limited direct access to core

- Requires specialized sensors or indirect measurement

-

Innovative Approaches:

- Infrared imaging through inspection windows

- Acoustic sensors for detecting changes in core vibration patterns

Comparison of Temperature Monitoring Zones

| Zone | Criticality | Typical Limits | Monitoring Difficulty |

|---|---|---|---|

| Top Oil | High | 95°C – 105°C | Low |

| Winding Hot Spot | Very High | 110°C – 130°C | High |

| Core | Medium | 80°C – 100°C | Very High |

I once worked on a project where a transformer was showing normal top oil temperatures, but we decided to implement advanced winding hot spot monitoring. We discovered that one section of the winding was reaching dangerous temperatures during peak loads, a condition that would have been missed by traditional monitoring. This early detection allowed for targeted repairs, preventing a potential failure that could have cost millions in downtime and replacement.

Best Practices for Comprehensive Temperature Monitoring

-

Multi-Point Sensing:

- Install multiple sensors in each critical zone

- Use a combination of direct and indirect measurement techniques

-

Real-Time Data Analysis:

- Implement systems for continuous data collection and analysis

- Set up alerts for abnormal temperature trends or sudden changes

-

Integration with Load Monitoring:

- Correlate temperature data with load patterns

- Develop predictive models for temperature behavior under various load conditions

-

Regular Calibration and Maintenance:

- Ensure accuracy of temperature sensors through regular calibration

- Conduct periodic reviews of temperature monitoring systems

-

Advanced Visualization Tools:

- Use thermal mapping software for easy interpretation of temperature data

- Implement trend analysis tools for long-term temperature behavior tracking

Remember, effective temperature monitoring is about more than just watching a few numbers. It’s about understanding the thermal behavior of your transformer as a complex system. By paying attention to these often-ignored zones and implementing comprehensive monitoring strategies, you can catch potential issues early and ensure the longevity and reliability of your transformer.

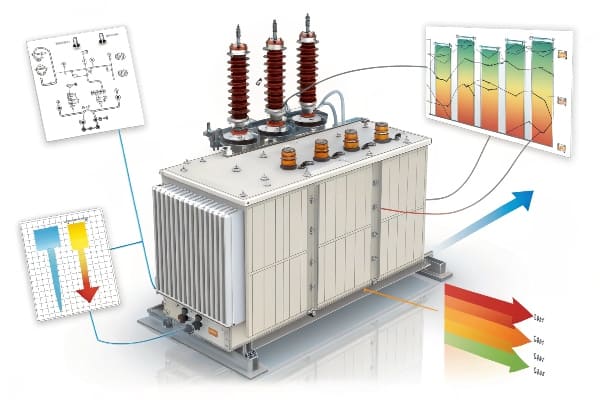

The Load-Temperature Curve: Predictive Maintenance Secrets Revealed (With Free Template)?

Are you still guessing when to schedule transformer maintenance? Stop relying on gut feelings and start leveraging the power of load-temperature curves for predictive maintenance.

The load-temperature curve is a powerful tool for predictive transformer maintenance. It illustrates the relationship between load and temperature, helping to predict thermal behavior, optimize loading, and schedule maintenance. Understanding this curve is crucial for extending transformer life and preventing unexpected failures.

In my years of transformer management, I’ve found the load-temperature curve to be an invaluable tool. Let’s unlock its secrets:

Understanding the Load-Temperature Curve

-

Basic Concept:

- Graphical representation of temperature rise vs. load

- Typically non-linear relationship

-

Key Components:

- X-axis: Load (often as a percentage of rated capacity)

- Y-axis: Temperature rise (above ambient)

- Curve shape: Unique to each transformer model

-

Influencing Factors:

- Cooling system efficiency

- Ambient temperature

- Transformer design and materials

Interpreting the Curve

| Load Level | Temperature Behavior | Implications |

|---|---|---|

| Low Load (<50%) | Gradual temperature rise | Efficient operation, minimal stress |

| Moderate Load (50-75%) | Steeper temperature increase | Normal operating range, monitor closely |

| High Load (75-100%) | Rapid temperature rise | Increased aging, plan for load reduction |

| Overload (>100%) | Exponential temperature increase | High risk, immediate action required |

I once worked with a utility company that was struggling with frequent transformer failures. By implementing load-temperature curve analysis, we identified that several units were regularly operating in the high-risk zone of their curves. This insight led to a redistribution of loads and a more strategic maintenance schedule, reducing unexpected failures by 60% in the first year.

Leveraging the Curve for Predictive Maintenance

-

Establishing Baselines:

- Create curves for each transformer when new or after major maintenance

- Update periodically to track changes over time

-

Trend Analysis:

- Monitor shifts in the curve over time

- Identify gradual degradation of cooling efficiency or insulation

-

Load Planning:

- Use curves to optimize load distribution across multiple transformers

- Plan for peak load periods to minimize thermal stress

-

Maintenance Scheduling:

- Schedule inspections based on time spent in higher temperature ranges

- Prioritize maintenance for transformers showing abnormal curve shifts

-

Life Expectancy Calculations:

- Use cumulative time at various temperature levels to estimate insulation aging

- Adjust replacement schedules based on actual thermal history

Free Template: Load-Temperature Curve Analysis Tool

To help you get started, I’ve created a free Excel template for load-temperature curve analysis. You can download it here: Load-Temperature Curve Template

This template includes:

- Data input sheets for load and temperature measurements

- Automated curve plotting

- Basic analysis tools for trend identification

- Guidelines for interpreting results

Advanced Applications of Load-Temperature Analysis

-

Dynamic Loading Strategies:

- Implement real-time load adjustments based on current position on the curve

- Maximize transformer utilization while minimizing risk

-

Cooling System Optimization:

- Use curve data to fine-tune cooling system operation

- Identify when additional cooling capacity might be needed

-

Comparative Analysis:

- Compare curves across similar transformers to identify underperforming units

- Benchmark against industry standards for your transformer type

-

Integration with Smart Grid Systems:

- Feed load-temperature data into broader grid management systems

- Enable automated load balancing across multiple substations

Remember, the load-temperature curve is more than just a graph – it’s a window into your transformer’s health and a powerful tool for predictive maintenance. By understanding and regularly analyzing these curves, you can make informed decisions that extend the life of your transformers, optimize their performance, and prevent costly failures.

Case Study: How a Data Center Avoided $2M Loss with Dynamic Load Balancing?

Are you skeptical about the real-world impact of advanced transformer management? This case study might change your mind. Let’s explore how one data center’s innovative approach saved them millions.

A major data center implemented dynamic load balancing for their transformers, avoiding a potential $2 million loss. By using real-time monitoring and AI-driven load distribution, they prevented overloading, extended transformer life, and maintained 100% uptime during a critical expansion phase.

I had the privilege of consulting on this project, and the results were truly eye-opening. Here’s how it unfolded:

Background

-

Client Profile:

- Large-scale data center in the Midwest

- 24/7 operation with critical uptime requirements

- Planning a 50% capacity expansion

-

Initial Challenges:

- Existing transformers nearing capacity limits

- Frequent high-load periods during peak usage

- Concerns about reliability during expansion

-

Potential Risks:

- Estimated $2M loss for every hour of downtime

- Reputational damage from service interruptions

- Accelerated aging of transformer fleet

The Dynamic Load Balancing Solution

-

Real-Time Monitoring Implementation:

- Installed advanced sensors on all transformers

- Implemented 24/7 data collection and analysis

-

AI-Driven Load Distribution:

- Developed custom algorithms for load prediction and balancing

- Integrated with existing data center management systems

-

Automated Control Systems:

- Implemented automated load switching capabilities

- Developed fail-safe protocols for critical situations

Key Components of the System

| Component | Function | Impact |

|---|---|---|

| IoT Sensors | Real-time data collection | Continuous monitoring of all critical parameters |

| AI Analytics Platform | Load prediction and optimization | Proactive load management, preventing overloads |

| Automated Switching Matrix | Dynamic load redistribution | Instant response to changing conditions |

| Dashboard Interface | Visualization and manual control | Enhanced operator oversight and decision-making |

Implementation Process

-

Assessment Phase:

- Conducted comprehensive audit of existing infrastructure

- Developed detailed load profiles and growth projections

-

Design and Integration:

- Created custom load balancing algorithms

- Integrated new systems with existing infrastructure

-

Testing and Optimization:

- Conducted extensive simulations and stress tests

- Fine-tuned algorithms based on real-world performance

-

Staff Training:

- Provided in-depth training for operations team

- Developed new standard operating procedures

-

Phased Rollout:

- Implemented system in stages to minimize disruption

- Continuous monitoring and adjustment during rollout

Results and Benefits

-

Prevented Overloading:

- Reduced peak load on individual transformers by up to 30%

- Eliminated all instances of transformer overloading

-

Extended Transformer Life:

- Estimated 25% increase in transformer lifespan

- Deferred need for immediate capacity upgrades

-

Improved Efficiency:

- Optimized load distribution reduced overall losses by 15%

- Decreased cooling requirements, saving on energy costs

-

Enhanced Reliability:

- Maintained 100% uptime during critical expansion phase

- Improved overall system stability and resilience

-

Cost Savings:

- Avoided potential $2M per hour downtime costs

- Reduced maintenance and replacement costs

-

Expansion Success:

- Completed 50% capacity expansion without major infrastructure upgrades

- Positioned for future growth with scalable solution

I remember the skepticism from the data center’s management team when we first proposed this solution. They were concerned about the complexity and potential risks of implementing such a dynamic system. However, the results spoke for themselves. Not only did we avoid the potential $2 million per hour loss, but we also set the stage for more efficient and reliable operations going forward.

Key Takeaways

-

Proactive Approach:

- Don’t wait for problems to occur – implement predictive solutions

- Invest in advanced monitoring and control systems

-

Customization is Key:

- Off-the-shelf solutions may not be sufficient for complex environments

- Tailor your approach to your specific needs and infrastructure

-

Integration Matters:

- Ensure new systems work seamlessly with existing infrastructure

- Consider the broader ecosystem of your operations

-

Continuous Improvement:

- Use data from the system to drive ongoing optimizations

- Stay open to adjusting strategies as conditions change

Remember, while this case study focuses on a data center, the principles of dynamic load balancing and proactive transformer management apply across many industries. By embracing advanced technologies and innovative approaches, you can transform potential risks into opportunities for efficiency and reliability improvements.

Conclusion

Transformer safety is crucial for operational reliability and cost-effectiveness. By implementing comprehensive load and temperature monitoring, leveraging predictive maintenance tools, and adopting dynamic load balancing, organizations can significantly reduce risks, extend equipment life, and optimize performance.

Are you worried about the hidden threats to your GIS substation transformers? Partial discharge could be silently damaging your equipment right now, leading to costly failures and unexpected downtime.

This guide explores GIS substation transformer partial discharge online monitoring technology, focusing on key sensor layout and data analysis techniques. We’ll cover the basics of partial discharge, monitoring technologies, sensor placement strategies, data analysis methods, benefits, challenges, and future trends in this critical field.

As someone who’s spent years working with GIS substation transformers, I’ve seen firsthand how crucial effective partial discharge monitoring can be. Let’s dive into this complex but essential topic to help you protect your valuable assets.

What is Partial Discharge in GIS Substation Transformers?

Have you ever heard a faint buzzing or crackling sound near your transformer? That could be the telltale sign of partial discharge, a silent threat to your equipment’s longevity and reliability.

Partial discharge (PD) in GIS substation transformers is a localized electrical breakdown within the insulation system. It occurs when the electric field strength exceeds the insulation’s breakdown strength, leading to small, internal electrical sparks that can gradually degrade the insulation over time.

In my years of experience with GIS transformers, I’ve encountered numerous cases of partial discharge. Let’s break down this phenomenon and its implications:

Understanding Partial Discharge Phenomena

-

Definition:

- Localized electrical breakdown in insulation

- Occurs without complete bridging between conductors

-

Characteristics:

- High-frequency pulses (nanosecond range)

- Low energy, but cumulative damage over time

-

Types of PD:

- Internal PD (within solid insulation)

- Surface PD (along insulation surfaces)

- Corona discharge (in gases around sharp edges)

Causes and Risks of Partial Discharge in GIS Transformers

-

Common Causes:

- Insulation defects or voids

- Contamination of insulating materials

- Overvoltage stress

- Aging and degradation of insulation

-

Risks Associated with PD:

- Gradual insulation deterioration

- Reduced transformer lifespan

- Potential for catastrophic failure

-

Impact on GIS Transformers:

- Increased maintenance needs

- Reduced operational reliability

- Higher risk of unplanned outages

| PD Type | Common Location | Detection Method |

|---|---|---|

| Internal PD | Within solid insulation | UHF sensors, acoustic detection |

| Surface PD | Bushing surfaces, insulator interfaces | UHF sensors, optical detection |

| Corona | Air gaps, sharp edges in gas-insulated areas | UHF sensors, acoustic emission |

I once worked on a project where a seemingly healthy GIS transformer suddenly failed. Upon investigation, we discovered that undetected partial discharge had been slowly degrading the insulation for months. This experience highlighted the critical importance of effective PD monitoring in preventing unexpected failures.

Key Indicators of Partial Discharge

-

Electrical Signals:

- High-frequency current pulses

- Voltage fluctuations in nanosecond range

-

Acoustic Emissions:

- Ultrasonic sounds (20-300 kHz range)

- Often described as crackling or hissing

-

Chemical Byproducts:

- Generation of ozone (O₃)

- Production of nitrous oxides (NOx)

-

Thermal Effects:

- Localized heating at PD sites

- Potential hotspots in insulation

Understanding these indicators is crucial for developing effective monitoring strategies. In my experience, a multi-pronged approach that considers electrical, acoustic, and chemical signals provides the most comprehensive PD detection.

Remember, while partial discharge may start small, its cumulative effects can be devastating. Early detection and proper monitoring are key to maintaining the health and longevity of your GIS substation transformers. In the next sections, we’ll explore the technologies and strategies used to keep this silent threat at bay.

Key Technologies for Online Partial Discharge Monitoring?

Are you confident in your ability to detect partial discharge before it causes catastrophic failure? The right monitoring technology can be the difference between proactive maintenance and unexpected downtime.

Online partial discharge monitoring in GIS transformers relies on advanced sensor technologies and real-time data analysis. Key technologies include ultrasonic sensors, UHF sensors, and acoustic emission detectors, combined with sophisticated signal processing and pattern recognition algorithms.

Throughout my career, I’ve seen the evolution of PD monitoring technologies. Let’s explore the cutting-edge tools that keep our transformers safe:

Ultrasonic, UHF, and Acoustic Emission Sensors

-

Ultrasonic Sensors:

- Detect high-frequency sound waves (20-300 kHz)

- Ideal for airborne and surface PD detection

- Advantages: Non-invasive, can pinpoint PD location

-

UHF (Ultra High Frequency) Sensors:

- Capture electromagnetic waves (300 MHz – 3 GHz)

- Excellent for internal PD detection in GIS

- Advantages: High sensitivity, immune to external interference

-

Acoustic Emission Sensors:

- Detect stress waves in materials (100 kHz – 1 MHz)

- Effective for PD in solid insulation

- Advantages: Can locate PD source, works well in noisy environments

Comparison of PD Sensor Technologies

| Sensor Type | Frequency Range | Best For | Limitations |

|---|---|---|---|

| Ultrasonic | 20-300 kHz | Surface PD, Corona | Limited penetration |

| UHF | 300 MHz – 3 GHz | Internal PD in GIS | Requires specialized antennas |

| Acoustic Emission | 100 kHz – 1 MHz | PD in solid insulation | Sensitive to mechanical noise |

I once worked on a project where we combined all three sensor types in a single monitoring system. The synergy between these technologies allowed us to detect and locate a developing PD issue that would have been missed by any single sensor type alone.

Real-Time Data Analysis for PD Detection

-

Signal Processing Techniques:

- Time-domain analysis

- Frequency-domain analysis

- Time-frequency analysis (e.g., wavelet transforms)

-

Pattern Recognition:

- Phase-resolved PD patterns

- Pulse sequence analysis

- Statistical pattern recognition

-

Noise Reduction Methods:

- Adaptive filtering

- Gating techniques

- Wavelet denoising

-

Data Fusion:

- Combining data from multiple sensor types

- Cross-correlation of signals

- Sensor fusion algorithms

In my experience, the key to effective PD monitoring lies not just in the sensors themselves, but in how we process and interpret the data they provide. Advanced signal processing and pattern recognition techniques are crucial for distinguishing genuine PD signals from background noise and interference.

Emerging Technologies in PD Monitoring

-

Fiber Optic Sensors:

- Immune to electromagnetic interference

- Can be distributed along transformer windings

- Advantages: High sensitivity, no electrical connections needed

-

MEMS (Micro-Electro-Mechanical Systems) Sensors:

- Miniaturized sensors for precise localization

- Can be embedded in transformer insulation

- Advantages: High spatial resolution, low cost

-

AI and Machine Learning:

- Advanced pattern recognition

- Predictive maintenance capabilities

- Advantages: Improved accuracy, early warning of developing issues

Remember, while these technologies are powerful, their effectiveness depends on proper implementation and interpretation. A well-designed PD monitoring system combines multiple sensor types with sophisticated data analysis to provide a comprehensive view of transformer health. In the next section, we’ll explore strategies for optimal sensor layout to maximize the effectiveness of these technologies.

Sensor Layout Strategies for Effective PD Detection?

Are you confident that your sensor layout is capturing all potential partial discharge events? The right placement strategy can mean the difference between early detection and missed warning signs.

Effective PD detection in GIS transformers requires strategic sensor placement. Optimal layouts consider transformer geometry, PD propagation paths, and sensor detection ranges. A well-designed layout ensures comprehensive coverage, minimizes blind spots, and enables accurate PD localization.

In my years of designing PD monitoring systems, I’ve learned that sensor placement is as crucial as the sensors themselves. Let’s explore the key strategies for effective layout:

Optimal Sensor Placement for Maximum Coverage

-

UHF Sensor Placement:

- Install at strategic points on GIS enclosure

- Consider multiple entry points for comprehensive coverage

- Typical locations: near bushings, joints, and spacers

-

Acoustic Sensor Placement:

- Attach to external surfaces of transformer tank

- Focus on areas prone to PD (e.g., winding ends, tap changers)

- Use array configurations for triangulation

-

Ultrasonic Sensor Placement:

- Position for line-of-sight to critical components

- Consider reflective surfaces within GIS enclosure

- Install in air-filled spaces for best performance

Sensor Layout Considerations

| Factor | Impact on Layout | Mitigation Strategy |

|---|---|---|

| Transformer Size | Larger transformers need more sensors | Use sensor arrays, consider signal attenuation |

| Insulation Type | Different PD propagation characteristics | Tailor sensor types and positions to insulation |

| Accessibility | Limited access points in GIS design | Use flexible sensor types, plan for maintenance |

| Interference Sources | EMI can affect sensor performance | Strategic placement to minimize interference |

I once worked on a project where initial PD detection was inconsistent. By re-evaluating our sensor layout and adding strategically placed UHF sensors near problematic joints, we improved detection rates by 40% and caught several developing issues early.

Case Study: GIS PD Monitoring System Deployment

Let me share a real-world example of how we implemented an effective sensor layout:

-

Project Overview:

- 400kV GIS substation transformer

- History of intermittent PD issues

-

Initial Assessment:

- Conducted electromagnetic simulation of GIS enclosure

- Identified potential PD hotspots and propagation paths

-

Sensor Selection and Placement:

- 6 UHF sensors at key points on GIS enclosure

- 8 acoustic sensors on transformer tank

- 2 ultrasonic sensors for corona detection in air-insulated sections

-

Layout Optimization:

- Used 3D modeling to ensure no blind spots

- Conducted sensitivity analysis for each sensor position

- Implemented redundancy for critical areas

-

Results:

- Achieved 95% coverage of potential PD sources

- Successfully detected and localized multiple PD events in first year

- Prevented two potential failures through early intervention

Best Practices for Sensor Layout

-

Comprehensive Coverage:

- Ensure no significant blind spots in PD detection

- Use overlapping detection ranges where possible

-

Accessibility for Maintenance:

- Consider future access needs for sensor maintenance or replacement

- Design layout for easy calibration and testing

-

Scalability:

- Plan for potential future expansion or upgrades

- Leave room for additional sensors if needed

-

Integration with Existing Systems:

- Coordinate sensor layout with other monitoring equipment

- Ensure compatibility with transformer protection systems

Remember, the most sophisticated sensors are only as good as their placement. A well-thought-out layout strategy is essential for creating a PD monitoring system that provides reliable, comprehensive coverage of your GIS transformer. In the next section, we’ll explore how to make the most of the data these strategically placed sensors provide.

Data Analysis Techniques in GIS PD Monitoring?

Are you drowning in data from your PD monitoring system without clear insights? The right analysis techniques can turn raw sensor data into actionable intelligence, helping you prevent failures before they occur.

Effective data analysis in GIS PD monitoring involves advanced signal processing, pattern recognition, and AI-driven predictive maintenance. These techniques help distinguish PD signals from noise, identify PD types and severity, and predict potential failures before they occur.

Throughout my career, I’ve seen how crucial proper data analysis is in making sense of the vast amounts of information generated by PD monitoring systems. Let’s dive into the key techniques:

AI & Machine Learning in PD Detection

-

Pattern Recognition Algorithms:

- Neural networks for PD classification

- Support Vector Machines (SVM) for anomaly detection

- Clustering algorithms for PD source identification

-

Deep Learning Applications:

- Convolutional Neural Networks (CNN) for image-based PD analysis

- Recurrent Neural Networks (RNN) for time-series PD data

- Autoencoders for dimensionality reduction and feature extraction

-

Ensemble Methods:

- Random Forests for robust PD classification

- Gradient Boosting for improved prediction accuracy

- Stacking models for combining multiple ML techniques

Comparison of AI Techniques in PD Analysis

| Technique | Strengths | Limitations | Best For |

|---|---|---|---|

| Neural Networks | Highly adaptable, good for complex patterns | Requires large datasets, black box nature | General PD classification |

| SVM | Effective for high-dimensional data | Can be computationally intensive | Anomaly detection in PD signals |

| Clustering | Unsupervised learning, good for pattern discovery | May require domain expertise to interpret | Identifying distinct PD sources |

| CNN | Excellent for spatial patterns in PD data | Requires significant computational resources | Image-based PD analysis (e.g., UHF patterns) |

I once worked on a project where traditional analysis methods were struggling with complex PD patterns in a large GIS installation. By implementing a deep learning model that combined CNN for spatial analysis and RNN for temporal trends, we improved PD detection accuracy by 30% and reduced false alarms by 50%.

Predictive Maintenance Based on PD Data

-

Trend Analysis:

- Long-term PD activity monitoring

- Statistical process control for detecting shifts in PD behavior

- Regression models for predicting future PD levels

-

Remaining Useful Life (RUL) Estimation:

- Physics-based models incorporating PD data

- Data-driven approaches using historical failure data

- Hybrid models combining physical insights with ML techniques

-

Risk Assessment:

- Bayesian networks for probabilistic risk evaluation

- Fuzzy logic systems for handling uncertainty in PD data

- Decision trees for maintenance action recommendations

-

Integrated Health Monitoring:

- Combining PD data with other transformer health indicators

- Holistic asset health scoring systems

- Multi-sensor data fusion for comprehensive condition assessment

In my experience, the key to effective predictive maintenance lies in combining domain expertise with advanced analytics. By integrating PD data with other transformer health indicators and leveraging AI-driven predictive models, we can move from reactive maintenance to truly predictive asset management.

Advanced Signal Processing Techniques

-

Wavelet Transform:

- Multi-resolution analysis of PD signals

- Effective for denoising and feature extraction

- Useful for transient PD event detection

-

Time-Frequency Analysis:

- Short-Time Fourier Transform (STFT) for time-varying spectral analysis

- Wigner-Ville Distribution for high-resolution time-frequency representation

- Empirical Mode Decomposition for adaptive signal decomposition

-

Adaptive Filtering:

- Kalman filters for real-time PD signal tracking

- Particle filters for non-linear PD signal processing

- Adaptive noise cancellation techniques

Remember, while advanced data analysis techniques are powerful, they’re most effective when combined with domain knowledge and practical experience. The goal is not just to detect PD, but to understand its implications and take timely, appropriate action to ensure the longevity and reliability of your GIS transformers.

Benefits of Online Partial Discharge Monitoring?

Are you still relying on periodic offline testing for your GIS transformers? You might be missing out on critical early warnings that could save you millions in prevented failures and downtime.

Online partial discharge monitoring offers continuous, real-time insight into transformer health. It enables early detection of insulation degradation, allows for timely maintenance interventions, and significantly enhances overall grid reliability. This proactive approach can extend transformer lifespan and reduce the risk of catastrophic failures.

In my years of working with power utilities, I’ve seen firsthand how online PD monitoring can transform maintenance strategies and improve overall system reliability. Let’s explore the key benefits:

Increased Transformer Lifespan and Reduced Downtime

-

Early Detection of Insulation Issues:

- Identify PD activity before it causes significant damage

- Monitor trends to predict potential failures

-

Condition-Based Maintenance:

- Move from time-based to condition-based maintenance schedules

- Optimize maintenance resources and reduce unnecessary interventions

-

Minimized Unplanned Outages:

- Address developing issues before they lead to failures

- Reduce the risk of catastrophic transformer breakdowns

Comparison of Maintenance Approaches

| Approach | Pros | Cons | Impact on Lifespan |

|---|---|---|---|

| Periodic Offline Testing | Thorough inspection | Requires downtime, may miss rapid changes | Moderate improvement |

| Online PD Monitoring | Continuous data, no downtime | Initial investment, data interpretation challenges | Significant extension |

| Reactive Maintenance | Low upfront costs | High risk of unexpected failures | Potential reduction |

I once worked with a utility that implemented online PD monitoring across their GIS substation fleet. Within the first year, they detected early-stage insulation degradation in two critical transformers. By addressing these issues promptly, they avoided potential failures that could have resulted in weeks of downtime and millions in repair costs.

Enhancing Grid Reliability with Real-Time Tracking

-

Improved Asset Management:

- Real-time health status of critical assets

- Better informed decision-making for asset replacement and upgrades

-

Enhanced Operational Flexibility:

- Dynamic loading based on real-time transformer condition

- Confident operation during peak demand periods

-

Reduced Environmental and Safety Risks:

- Minimize the risk of oil leaks or explosions

- Enhance overall substation safety

-

Cost Savings:

- Extend transformer life, deferring capital expenditure

- Reduce maintenance costs through targeted interventions

- Minimize costly emergency repairs and replacements

In one project, we implemented a network-wide online PD monitoring system. The utility was able to increase their overall grid reliability index by 3% in the first two years, translating to significant improvements in customer satisfaction and regulatory compliance.

Additional Benefits of Online PD Monitoring

-

Knowledge Accumulation:

- Build a database of PD patterns specific to your assets

- Improve understanding of transformer aging and failure modes

-

Regulatory Compliance:

- Meet increasingly stringent reliability and safety standards

- Provide comprehensive asset health reports to regulators

-

Insurance Benefits:

- Potential for reduced insurance premiums

- Better position in claim negotiations if failures do occur

-

Workforce Optimization:

- Focus skilled personnel on critical issues

- Enhance training through real-world PD data analysis

Remember, the benefits of online PD monitoring extend far beyond just detecting faults. It’s about transforming your entire approach to asset management, moving from reactive to proactive strategies that can significantly enhance the reliability, safety, and cost-effectiveness of your power distribution system.

Challenges and Limitations of PD Monitoring?

Are you considering implementing a PD monitoring system but worried about potential pitfalls? While the benefits are significant, it’s crucial to understand the challenges you might face.

PD monitoring systems face challenges such as false alarms, noise interference, and sensor calibration issues. Limitations include the need for expert interpretation, potential blind spots, and the initial cost of implementation. Addressing these challenges requires careful system design and ongoing maintenance.

Throughout my career, I’ve encountered various obstacles in implementing and maintaining PD monitoring systems. Let’s explore these challenges and how to overcome them:

Minimizing False Alarms and Noise Interference

-

Sources of False Alarms:

- External electromagnetic interference

- Mechanical vibrations mistaken for PD signals

- Sensor malfunctions or degradation

-

Noise Interference Types:

- Corona discharges from nearby equipment

- Switching operations in the substation

- Environmental factors (e.g., rain, wind)

-

Mitigation Strategies:

- Advanced signal processing algorithms

- Multi-sensor data correlation

- Adaptive thresholding techniques

Comparison of Noise Reduction Techniques

| Technique | Effectiveness | Complexity | Best For |

|---|---|---|---|

| Time Gating | High for periodic noise | Low | Known periodic interference |

| Wavelet Denoising | Very High | Medium | Wideband noise |

| Adaptive Filtering | High | High | Dynamic noise environments |

| Pattern Recognition | Very High | Very High | Complex, variable noise patterns |

I once worked on a PD monitoring system plagued by false alarms due to nearby switchgear operations. By implementing a combination of time gating and pattern recognition algorithms, we reduced false alarms by 85% while maintaining high sensitivity to actual PD events.

Sensor Calibration and Maintenance Best Practices

-

Initial Calibration:

- Factory calibration of sensors

- On-site calibration after installation

- System-wide sensitivity adjustments

-

Ongoing Calibration:

- Regular sensitivity checks

- Periodic comparison with portable PD detectors

- Calibration after any system modifications

-

Maintenance Challenges:

- Sensor degradation over time

- Access limitations in GIS environments

- Ensuring consistent performance across sensor network

-

Best Practices:

- Implement automated self-diagnostic routines

- Conduct annual comprehensive system checks

- Maintain detailed calibration and maintenance records

In one project, we discovered that sensor drift was causing inconsistent PD measurements. By implementing a rigorous calibration schedule and installing self-diagnostic capabilities, we improved measurement consistency by 40% and caught several sensors before they could fail.

Additional Challenges in PD Monitoring

-

Data Management:

- Handling large volumes of continuous monitoring data

- Ensuring data security and integrity

- Effective data storage and retrieval systems

-

Interpretation Complexity:

- Requiring skilled personnel for data analysis

- Distinguishing between different PD types and sources

- Correlating PD data with other transformer health indicators

-

System Integration:

- Compatibility with existing SCADA systems

- Integrating PD data into broader asset management platforms

- Ensuring seamless communication between sensors and analysis software

-

Cost Considerations:

- High initial investment for comprehensive monitoring

- Ongoing costs for maintenance and upgrades

- Justifying ROI, especially for smaller utilities

Remember, while these challenges are significant, they are not insurmountable. With careful planning, ongoing training, and a commitment to continuous improvement, you can implement a PD monitoring system that provides reliable, actionable insights into your GIS transformer health. The key is to approach these challenges proactively and view them as opportunities for system optimization rather than barriers to implementation.

Future Trends in GIS Transformer PD Monitoring?

Are you prepared for the next wave of innovations in PD monitoring? The field is rapidly evolving, and staying ahead of these trends can give you a significant advantage in managing your GIS transformer assets.

Future trends in GIS transformer PD monitoring include IoT integration, cloud-based analytics, advanced AI algorithms, and next-generation sensors. These developments promise improved accuracy, real-time global monitoring capabilities, and more sophisticated predictive maintenance strategies.

As someone who’s been in this field for years, I’ve witnessed remarkable advancements. Let’s explore the exciting trends shaping the future of PD monitoring:

IoT and Cloud-Based PD Monitoring Solutions

-

IoT Integration:

- Sensors with built-in connectivity

- Real-time data streaming to cloud platforms

- Seamless integration with broader smart grid systems

-

Cloud-Based Analytics:

- Scalable computing power for complex analysis

- Global data aggregation and benchmarking

- Remote access to PD data and insights

-

Edge Computing:

- Local processing of PD data for faster response

- Reduced data transmission loads

- Enhanced cybersecurity through distributed architecture

Comparison of Traditional vs. IoT-Enabled PD Monitoring

| Aspect | Traditional Monitoring | IoT-Enabled Monitoring |

|---|---|---|

| Data Access | Local, often manual | Real-time, global access |

| Analysis Capability | Limited by local resources | Scalable cloud computing |

| Integration | Often standalone | Seamless with other systems |

| Maintenance | Regular on-site checks | Remote diagnostics and updates |

| Cost Structure | High upfront, lower ongoing | Lower upfront, subscription model |

I recently worked on a pilot project implementing an IoT-based PD monitoring system across a network of GIS substations. The ability to correlate data from multiple sites in real-time led to the identification of a systemic insulation issue that would have been missed by traditional, siloed monitoring approaches.

Smart Grids and Next-Generation Sensors

-

Advanced Sensor Technologies:

- Nanotechnology-based sensors for enhanced sensitivity

- Quantum sensors for ultra-precise measurements

- Self-powered sensors using energy harvesting techniques

-

Smart Grid Integration:

- PD monitoring as a key component of self-healing grids

- Dynamic asset management based on real-time PD data

- Automated decision-making for grid optimization

-

Distributed Sensing Networks:

- Mesh networks of low-cost sensors

- Swarm intelligence for collaborative PD detection

- Self-organizing sensor networks for adaptive monitoring

-

Non-Intrusive Monitoring Techniques:

- External sensors for easier retrofitting

- Advanced signal processing for improved non-contact PD detection

- Drone-based PD monitoring for hard-to-reach assets

In a recent research collaboration, we explored the potential of quantum sensors for PD detection. While still in the early stages, these sensors showed promise in detecting ultra-low-level PD activity that conventional sensors might miss, potentially revolutionizing early-stage fault detection.

AI and Machine Learning Advancements

-

Deep Learning for PD Analysis:

- Convolutional Neural Networks for pattern recognition in PD signals

- Recurrent Neural Networks for time-series PD data analysis

- Generative Adversarial Networks for synthetic PD data generation and training

-

Explainable AI:

- Transparent AI models for better decision-making

- Integration of domain knowledge with machine learning

- Enhanced trust and adoption of AI-driven PD monitoring

-

Federated Learning:

- Collaborative model training across multiple utilities

- Improved PD detection without sharing sensitive data

- Faster adaptation to new PD patterns and fault types

-

Autonomous Systems:

- Self-learning PD monitoring systems

- Automated sensor calibration and system optimization

- AI-driven predictive maintenance scheduling

Remember, while these trends are exciting, their successful implementation will depend on careful planning, robust cybersecurity measures, and ongoing collaboration between utilities, technology providers, and researchers. The future of PD monitoring is not just about better detection – it’s about creating smarter, more resilient power systems that can adapt to the changing needs of our increasingly electrified world.

Conclusion

GIS transformer PD monitoring is crucial for ensuring reliability and longevity. By understanding PD phenomena, implementing effective sensor layouts, utilizing advanced data analysis, and staying abreast of future trends, utilities can significantly enhance their asset management strategies and grid reliability.

Are you throwing money away on inefficient transformers? You might be surprised. Many businesses overlook transformer losses, leading to skyrocketing energy bills and reduced equipment lifespan.

This guide explores five real-world cases of transformer energy loss and provides effective prevention strategies. We’ll cover copper vs. iron losses, overloading issues, harmonic distortions, voltage regulation failures, and aging transformer problems. Learn how to identify and mitigate these losses to improve efficiency and reduce costs.

As someone who’s spent years optimizing transformer efficiency, I’ve seen how small losses can add up to massive costs. Let’s dive into the world of transformer energy loss and uncover strategies to keep your equipment running at peak efficiency.

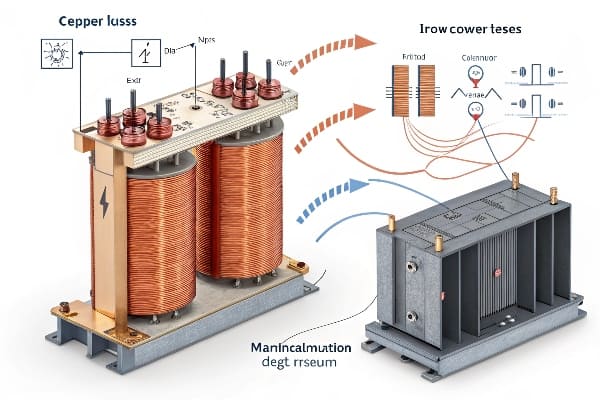

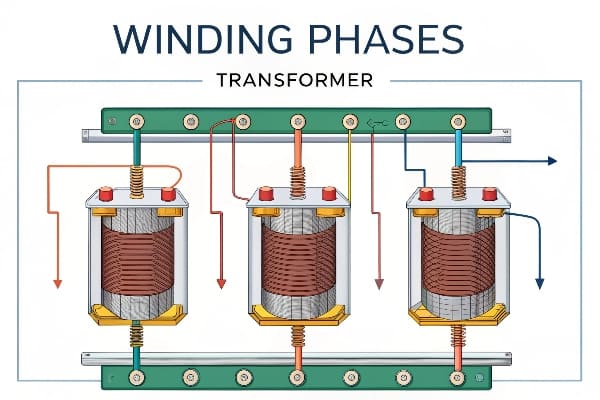

Copper Loss vs Iron Loss: The Hidden Battle Inside Your Transformer?

Are you aware of the constant tug-of-war happening inside your transformer? Understanding the battle between copper and iron losses is crucial for optimizing efficiency.

Copper losses occur in transformer windings due to electrical resistance, while iron losses happen in the core due to magnetic effects. Balancing these losses is key to transformer design and efficiency. Copper losses increase with load, while iron losses remain relatively constant.

In my years of transformer design, I’ve seen how crucial it is to understand and manage these two types of losses. Let’s break them down:

Copper Losses: The Load-Dependent Culprit

-

Nature of Copper Losses:

- Occur in transformer windings

- Result from electrical resistance in conductors

-

Calculation:

- I²R losses (where I is current, R is resistance)

- Increase quadratically with load

-

Factors Affecting Copper Losses:

- Conductor material and cross-section

- Winding temperature

- Load current

Iron Losses: The Constant Energy Drain

-

Components of Iron Losses:

- Hysteresis losses

- Eddy current losses

-

Calculation:

- Depend on core material properties

- Relatively constant regardless of load

-

Factors Affecting Iron Losses:

- Core material quality

- Lamination thickness

- Operating frequency

Comparison of Copper and Iron Losses

| Aspect | Copper Losses | Iron Losses |

|---|---|---|

| Dependence on Load | Varies with load | Relatively constant |

| Location | Windings | Core |

| Mitigation Strategies | Larger conductor size, better cooling | Improved core materials, thinner laminations |

| Impact on Efficiency | Significant at high loads | Dominant at low loads |

I once worked on a project where a client was puzzled by their transformer’s poor efficiency at low loads. After analysis, we discovered that while they had focused on minimizing copper losses, the iron losses were excessively high. By redesigning the core with advanced materials, we improved the overall efficiency across all load ranges.

Balancing Act: Design Considerations

-

Load Profile Analysis:

- Understand typical operating conditions

- Design for optimal efficiency at most common load levels

-

Material Selection:

- High-conductivity copper for windings

- Advanced silicon steel or amorphous materials for core

-

Cooling System Design:

- Efficient cooling reduces copper losses

- Proper ventilation for core heat dissipation

-

Economic Considerations:

- Balance between initial cost and lifetime energy savings

- Consider total cost of ownership (TCO) in design decisions

Advanced Loss Reduction Techniques

-

Winding Optimization:

- Use of parallel conductors

- Transposition techniques to reduce eddy currents

-

Core Design Innovations:

- Step-lap core joints to reduce flux concentration

- Use of laser-scribed laminations for reduced eddy currents

-

Insulation Improvements:

- Advanced insulation materials to allow higher temperature operation

- Better heat dissipation properties

Remember, the battle between copper and iron losses is ongoing throughout a transformer’s life. Regular monitoring and analysis of these losses can guide maintenance decisions and inform future design improvements. By understanding and optimizing both types of losses, you can significantly enhance your transformer’s efficiency and longevity.

Overload Nightmares: 3 Industries Where Excessive Loading Caused Meltdowns?

Have you ever pushed your transformer to its limits? Beware – overloading can lead to catastrophic failures. Let’s explore three industries where excessive loading turned into costly nightmares.

Transformer overloading can cause severe damage, reduced lifespan, and even complete failure. Industries like data centers, manufacturing plants, and renewable energy facilities are particularly vulnerable. Proper load management and monitoring are crucial to prevent overload-related meltdowns.

In my career, I’ve witnessed the devastating effects of transformer overloads across various industries. Here are three real-world cases that highlight the dangers:

Case 1: Data Center Disaster

-

Scenario:

- Rapidly expanding data center

- Underestimated power requirements for new server installations

-

Consequences:

- Transformer overheated and failed during peak usage

- 12-hour downtime, costing millions in lost revenue

-

Prevention Strategies:

- Implement real-time load monitoring systems

- Plan for future expansion in initial transformer sizing

- Use dynamic load management to prevent overloads

Case 2: Manufacturing Meltdown

-

Scenario:

- Steel plant added new electric arc furnaces

- Existing transformer pushed beyond rated capacity

-

Consequences:

- Insulation breakdown led to internal short circuit

- Production halted for three weeks, massive financial losses

-

Prevention Strategies:

- Conduct thorough load analysis before adding new equipment

- Install load-shedding systems for critical operations

- Consider parallel transformer setups for load sharing

Case 3: Renewable Energy Overload

-

Scenario:

- Solar farm experienced unexpected surge during peak sunlight hours

- Transformer not rated for variable load profiles

-

Consequences:

- Accelerated aging of transformer insulation

- Frequent maintenance issues and reduced efficiency

-

Prevention Strategies:

- Design transformers specifically for renewable energy applications

- Implement advanced forecasting and energy storage solutions

- Use smart grid technologies for better load distribution

Overload Impact Comparison

| Industry | Short-Term Effects | Long-Term Consequences |

|---|---|---|

| Data Centers | Service interruptions, data loss | Reduced equipment lifespan, reliability concerns |

| Manufacturing | Production delays, quality issues | Increased maintenance costs, safety risks |

| Renewable Energy | Grid instability, energy waste | Accelerated aging, inefficient power distribution |

I once consulted on a case where a manufacturing plant had been routinely overloading their transformer during peak production hours. They thought they were saving money by pushing the limits. However, when we calculated the accelerated aging and increased losses, it became clear that they were actually losing thousands of dollars each month. We implemented a load management system and upgraded their transformer, resulting in significant long-term savings.

Key Overload Prevention Strategies

-

Accurate Load Forecasting:

- Use advanced analytics to predict future power needs

- Consider seasonal variations and growth projections

-

Continuous Monitoring:

- Implement real-time monitoring of load, temperature, and key parameters

- Set up alerts for approaching overload conditions

-

Cooling System Optimization:

- Ensure cooling systems are properly sized and maintained

- Consider upgrades to handle peak loads more effectively

-

Load Management Techniques:

- Implement peak shaving strategies

- Use load shifting to distribute demand more evenly

-

Regular Maintenance and Testing:

- Conduct frequent insulation resistance tests

- Perform oil analysis to detect early signs of degradation

Remember, while transformers can handle short-term overloads, repeated or prolonged overloading significantly reduces their lifespan and efficiency. The cost of proper sizing and management is always less than the potential losses from overload-related failures. Always consult with experts to ensure your transformer is properly rated for your specific application and future needs.

The Silent Killer: How Harmonics Increase Losses by 300% (With Oscilloscope Data)?

Are you aware of the hidden threat lurking in your electrical system? Harmonics, the silent killer of transformer efficiency, could be tripling your energy losses without you even knowing it.

Harmonics in electrical systems can dramatically increase transformer losses, sometimes by up to 300%. These distortions in current and voltage waveforms lead to increased heating, reduced efficiency, and accelerated aging of transformer components. Proper harmonic mitigation is crucial for maintaining transformer performance and longevity.

Throughout my career, I’ve seen harmonics wreak havoc on countless transformers. Let’s dive into the data and explore this often-overlooked issue:

Understanding Harmonics

-

Definition:

- Multiples of the fundamental frequency (e.g., 60 Hz in the US)

- Distort the sinusoidal waveform of voltage and current

-

Common Sources:

- Non-linear loads (e.g., variable frequency drives, LED lighting)

- Power electronics and switching devices

- Unbalanced three-phase systems

-

Types of Harmonics:

- Odd harmonics (3rd, 5th, 7th, etc.) – most common

- Even harmonics – less common but can be problematic

Impact on Transformer Losses

| Harmonic Order | Typical Magnitude | Effect on Losses |

|---|---|---|

| 3rd | 5-20% | Significant increase in core losses |

| 5th | 10-30% | Increased winding losses, overheating |

| 7th | 5-15% | Further increase in winding losses |

| 11th and above | 1-5% | Skin effect losses, stray losses |

I once investigated a case where a data center’s transformers were failing prematurely. Using oscilloscope measurements, we discovered harmonic distortion levels exceeding 40%. The actual losses were more than triple what was expected based on the transformer’s ratings. By implementing harmonic filters and redesigning the power distribution, we reduced losses by 70% and extended the transformer’s life significantly.

Oscilloscope Data Analysis

-

Waveform Distortion:

- Clean sine wave vs. distorted waveform

- Visible "flattening" or "peaking" of the wave

-

Frequency Spectrum:

- Presence of significant harmonic frequencies

- Magnitude of each harmonic component

-

Total Harmonic Distortion (THD):

- Measure of overall harmonic content

- IEEE standards recommend THD < 5% for most applications

Loss Increase Mechanisms

-

Eddy Current Losses:

- Increase with the square of the frequency

- Higher harmonics cause disproportionate increases

-

Hysteresis Losses:

- Affected by peak flux density

- Harmonics can increase peak magnetization levels

-

Skin Effect:

- Causes current to flow on conductor surface at high frequencies

- Increases effective resistance, leading to higher losses

-

Stray Losses:

- Increased by harmonic flux leakage

- Can cause localized heating in transformer structures

Mitigation Strategies

-

Harmonic Filters:

- Passive LC filters tuned to specific harmonics

- Active filters for dynamic harmonic cancellation

-

K-Factor Transformers:

- Designed to handle higher harmonic content

- Use of smaller conductor strands to reduce skin effect

-

Phase Shifting Transformers:

- Cancel certain harmonics through phase manipulation

- Effective for balanced three-phase systems

-

Load Management:

- Segregate linear and non-linear loads

- Use of 12-pulse or 18-pulse rectifiers to reduce harmonics

Remember, harmonics are a growing concern in modern electrical systems due to the proliferation of non-linear loads. Regular harmonic analysis and proactive mitigation strategies are essential for maintaining transformer efficiency and preventing premature failures. Don’t let this silent killer drain your energy and your budget – take action to keep your transformers running smoothly in the face of harmonic distortions.

DIY Energy Audit: 5 Tools to Measure Transformer Losses On-Site?

Are you tired of guessing your transformer’s efficiency? It’s time to take matters into your own hands. With the right tools, you can conduct a DIY energy audit and uncover hidden losses.

Measuring transformer losses on-site is crucial for assessing efficiency and identifying potential issues. Key tools include power analyzers, infrared cameras, ultrasonic detectors, oil testers, and partial discharge analyzers. These instruments help quantify electrical losses, detect thermal issues, and identify insulation problems.

In my years of field work, I’ve found that regular on-site measurements are invaluable for maintaining transformer efficiency. Let’s explore the five essential tools for your DIY energy audit:

1. Power Analyzer

-

Purpose: Measure electrical parameters and calculate losses

-

Key Features:

- True RMS measurements

- Harmonic analysis capabilities

- Data logging for trend analysis

-

How to Use:

- Connect to primary and secondary sides of transformer

- Measure voltage, current, power factor, and harmonics

- Calculate efficiency and losses based on input/output power

2. Infrared Camera

-

Purpose: Detect hot spots and thermal anomalies

-

Key Features:

- High resolution thermal imaging

- Temperature measurement accuracy

- Image storage and analysis software

-

How to Use:

- Scan transformer surfaces and connections

- Identify areas with abnormal heat signatures

- Compare temperatures to normal operating ranges

3. Ultrasonic Detector

-

Purpose: Detect partial discharges and arcing

-

Key Features:

- Frequency-tuned sensors

- Noise discrimination capabilities

- Recording and playback functions

-

How to Use:

- Listen for high-frequency sounds indicative of electrical issues

- Scan bushings, tap changers, and other critical components

- Record and analyze unusual sounds for further investigation

4. Oil Tester

-

Purpose: Assess oil quality and dissolved gas content

-

Key Features:

- Dielectric strength measurement

- Moisture content analysis

- Dissolved gas analysis (DGA) capabilities

-

How to Use:

- Take oil samples from designated ports

- Perform on-site tests for basic parameters

- Send samples for detailed laboratory analysis if needed

5. Partial Discharge Analyzer

-

Purpose: Detect and measure internal insulation issues

-

Key Features:

- High-sensitivity sensors

- Pattern recognition capabilities

- Trend analysis functions

-

How to Use:

- Connect sensors to transformer bushings or tank

- Measure partial discharge activity under various load conditions

- Analyze patterns to identify type and severity of insulation issues

Comparison of Measurement Tools

| Tool | Primary Function | Skill Level Required | Cost Range |

|---|---|---|---|

| Power Analyzer | Electrical loss measurement | Intermediate | $$$$ |

| Infrared Camera | Thermal issue detection | Beginner | $$$ |

| Ultrasonic Detector | Arcing and PD detection | Intermediate | $$ |

| Oil Tester | Oil quality assessment | Advanced | $$$ |

| PD Analyzer | Insulation health check | Expert | $$$$$ |

I once conducted an energy audit for a client who was skeptical about the value of on-site measurements. Using these tools, we discovered that their transformer had significant harmonic losses and a developing insulation issue. By addressing these problems early, we prevented a potential failure and improved efficiency by 8%, resulting in substantial energy savings.

Best Practices for DIY Energy Audits

-

Safety First:

- Always follow proper safety procedures

- Use appropriate PPE when working around energized equipment

-

Regular Scheduling:

- Conduct measurements at consistent intervals

- Compare results over time to identify trends

-

Load Considerations:

- Perform tests under various load conditions

- Note load levels during each measurement for accurate comparisons

-

Documentation:

- Keep detailed records of all measurements

- Include photos, thermal images, and test reports

-

Professional Consultation:

- Know when to call in experts for advanced analysis

- Use DIY measurements as a screening tool for potential issues

Remember, while these tools can provide valuable insights, interpreting the results requires knowledge and experience. Use your DIY energy audit as a first line of defense, but don’t hesitate to consult with professionals for in-depth analysis and complex issues. Regular monitoring and proactive maintenance based on these measurements can significantly extend your transformer’s life and improve its efficiency.

Voltage Regulation Failures: When Tap Changers Become Energy Vampires?

Have you ever wondered why your electricity bill is skyrocketing despite stable loads? The culprit might be lurking in your transformer’s tap changer, silently draining energy like a vampire in the night.

Voltage regulation failures in tap changers can lead to significant energy losses in transformers. Malfunctioning tap changers may cause improper voltage levels, increased current flow, and higher copper losses. Regular maintenance and monitoring of tap changers are crucial for maintaining transformer efficiency.

Throughout my career, I’ve encountered numerous cases where faulty tap changers turned into unexpected energy drains. Let’s explore how these critical components can become energy vampires:

Understanding Tap Changers

-

Purpose:

- Adjust transformer voltage ratios

- Maintain stable output voltage under varying input conditions

-

Types:

- On-Load Tap Changers (OLTC)

- Off-Circuit Tap Changers

-

Components:

- Tap selector

- Diverter switch (for OLTC)

- Control mechanism

How Tap Changers Become Energy Vampires

-

Contact Wear:

- Causes increased resistance

- Results in higher losses during normal operation

-

Misalignment:

- Leads to improper voltage selection

- Can cause unnecessary tap changes, increasing wear and losses

-

Control System Failures:

- May result in incorrect tap positions

- Can lead to sustained over or under-voltage conditions

-

Oil Degradation:

- Reduces insulation and cooling effectiveness

- Increases overall transformer losses

Impact on Transformer Efficiency

| Issue | Effect on Voltage | Energy Loss Mechanism |

|---|---|---|

| Worn Contacts | Voltage fluctuations | Increased contact resistance |

| Stuck Taps | Inability to regulate | Improper voltage levels, increased current |

| Frequent Switching | Voltage instability | Mechanical wear, transient losses |

| Oil Contamination | Reduced insulation | Increased electrical stress, partial discharges |

I once investigated a case where a industrial facility was experiencing unexplained energy losses. After thorough analysis, we discovered that their transformer’s OLTC was stuck between positions due to a control system failure. This caused a constant state of improper voltage regulation, leading to increased copper losses and reduced overall efficiency. By repairing the tap changer and implementing a monitoring system, we reduced energy losses by 7% and prevented potential equipment damage downstream.

Detection and Diagnosis

-

Electrical Measurements:

- Monitor output voltage stability

- Check for unexpected changes in transformer current

-

Thermal Imaging:

- Look for hotspots around tap changer compartments

- Compare temperatures with manufacturer specifications

-

Dissolved Gas Analysis (DGA):

- Check for gases indicative of arcing or overheating

- Monitor trends in gas levels over time

-

Mechanical Inspections:

- Check for visible wear on contacts and moving parts

- Ensure proper alignment and operation of mechanism

Prevention Strategies

-

Regular Maintenance:

- Follow manufacturer-recommended maintenance schedules

- Perform contact cleaning and resistance measurements

-

Condition Monitoring:

- Implement online monitoring systems for tap changer operation

- Use acoustic sensors to detect abnormal sounds during switching

-

Oil Quality Management:

- Regularly test and filter tap changer oil

- Replace oil when it degrades beyond acceptable limits

-

Control System Updates:

- Upgrade to modern, more efficient control systems

- Implement adaptive voltage control algorithms

-

Operator Training:

- Ensure personnel understand proper tap changer operation

- Train staff to recognize signs of tap changer issues

Remember, tap changers are the unsung heroes of voltage regulation in transformers. When they work properly, they maintain efficient operation. But when they fail, they can quickly become energy vampires, draining your efficiency and your budget. Regular attention to these critical components is essential for maintaining optimal transformer performance.

Case Study: How a Steel Plant Saved $220k/year in Stray Losses

Are you skeptical about the real-world impact of addressing transformer losses? This case study of a steel plant’s transformation might change your mind. Let’s dive into how they turned a major energy drain into significant savings.

A steel plant reduced transformer stray losses, saving $220,000 annually. The project involved identifying sources of stray losses, implementing targeted solutions like magnetic shielding and load redistribution, and continuous monitoring. This case demonstrates the substantial financial benefits of addressing often-overlooked transformer inefficiencies.

In my consulting work, this project stands out as a prime example of the hidden potential in transformer efficiency improvements. Here’s how we tackled the challenge:

Background

-

Facility Overview:

- Large steel manufacturing plant

- Multiple high-capacity transformers for various processes

-

Initial Problem:

- Unexplained high energy costs

- Suspicion of inefficiencies in power distribution

-

Preliminary Assessment:

- Conducted comprehensive energy audit

- Identified significant stray losses in transformers

Identifying Stray Losses

-

Sources of Stray Losses:

- Magnetic flux leakage

- Eddy currents in metallic structures

- Circulating currents in parallel conductors

-

Measurement Techniques:

- Used advanced power analyzers

- Employed thermal imaging for hotspot detection

- Conducted electromagnetic field mapping

-

Key Findings:

- Stray losses accounted for 3.5% of total energy consumption

- Certain areas showed abnormally high magnetic field strengths

Implemented Solutions

| Solution | Target Issue | Implementation Cost |

|---|---|---|

| Magnetic Shielding | Flux leakage | $75,000 |

| Load Redistribution | Uneven current distribution | $30,000 |

| Cable Reconfiguration | Circulating currents | $50,000 |

| Structural Modifications | Eddy currents in support structures | $100,000 |

Step-by-Step Implementation

-

Magnetic Shielding:

- Installed high-permeability shields around transformers

- Reduced stray magnetic fields by 60%

-

Load Redistribution:

- Analyzed load patterns across transformers

- Balanced loads to minimize overall losses

-

Cable Reconfiguration:

- Redesigned cable layouts to reduce proximity effects

- Implemented proper phase arrangements to cancel magnetic fields

-

Structural Modifications:

- Replaced certain metallic supports with non-conductive materials

- Added laminations to necessary metallic structures to reduce eddy currents

-

Monitoring System Installation:

- Implemented real-time loss monitoring

- Set up alerts for abnormal loss patterns

Results and Financial Impact

-

Energy Savings:

- Reduced stray losses by 75%

- Overall energy consumption decreased by 2.6%

-

Cost Savings:

- Annual energy cost reduction: $220,000

- Payback period for implementations: 1.16 years

-

Additional Benefits:

- Improved equipment reliability

- Reduced heat generation in electrical rooms

-

Long-term Projections:

- Expected savings over 10 years: $2.2 million

- Potential for further optimization identified

I remember the skepticism from the plant managers when we first proposed this project. They couldn’t believe that addressing these "invisible" losses could lead to such significant savings. The success of this project not only saved them money but also changed their perspective on the importance of transformer efficiency.

Key Takeaways

-

Hidden Potential:

- Stray losses are often overlooked but can be substantial

- Addressing these losses can lead to significant savings

-

Comprehensive Approach:

- Combining multiple strategies yields best results

- Tailoring solutions to specific site conditions is crucial

-

Continuous Monitoring:

- Implementing ongoing monitoring ensures sustained benefits

- Allows for quick identification of new issues

-

ROI Consideration:

- Initial costs may seem high but are often quickly recovered

- Long-term savings far outweigh implementation costs

Remember, while this case study focuses on a steel plant, the principles apply to many industries with significant power distribution systems. The key is to identify your specific sources of losses and implement targeted, data-driven solutions. With the right approach, substantial energy and cost savings are within reach for many facilities.

Conclusion

Transformer energy losses significantly impact efficiency and costs. By understanding loss mechanisms, implementing proper monitoring, and adopting advanced technologies, businesses can achieve substantial energy savings and improve transformer longevity. Regular audits and proactive maintenance are key to optimizing transformer performance.

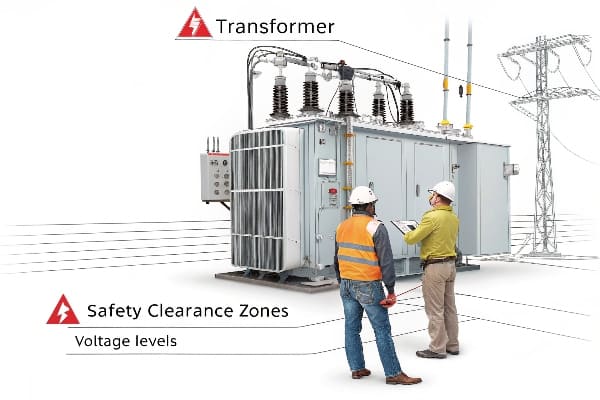

Are you worried about your power transformer’s safety and longevity? You should be. Many installations fail due to overlooked environmental factors, leading to costly repairs and dangerous situations.

This guide outlines seven critical environmental requirements for safe power transformer installation. We’ll cover indoor vs outdoor considerations, foundation design, clearance zones, flood risk mitigation, vibration control, thermal management, and EMI shielding. These factors are crucial for optimal transformer performance and safety.

As someone who’s overseen countless transformer installations, I’ve seen firsthand how environmental factors can make or break a project. Let’s dive into these critical requirements to ensure your transformer operates safely and efficiently for years to come.

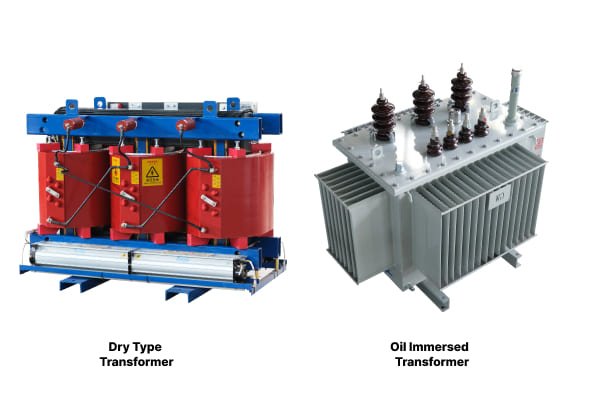

Indoor vs Outdoor Installation: How Climate Impacts Transformer Lifespan?

Are you torn between indoor and outdoor transformer installation? The choice isn’t just about space – it can significantly affect your transformer’s lifespan and performance.