5 Critical Functions of Tank Transformers in High-Voltage Power Systems?

Have you ever wondered how electricity travels safely from power plants to your home? The answer lies in the unsung heroes of our power grid: tank transformers. These massive machines play a crucial role in our daily lives, yet few understand their importance.

Tank transformers perform five critical functions in high-voltage power systems: voltage transformation, insulation and cooling, protection against electrical faults, efficient power distribution, and load regulation. These functions ensure safe, reliable, and efficient electricity transmission across vast distances.

As an electrical engineer with years of experience in power systems, I’ve seen firsthand how tank transformers keep our lights on and our cities running. Let’s dive into the fascinating world of these electrical giants and explore their vital functions.

What Are Tank Transformers? Understanding Their Role in Power Systems?

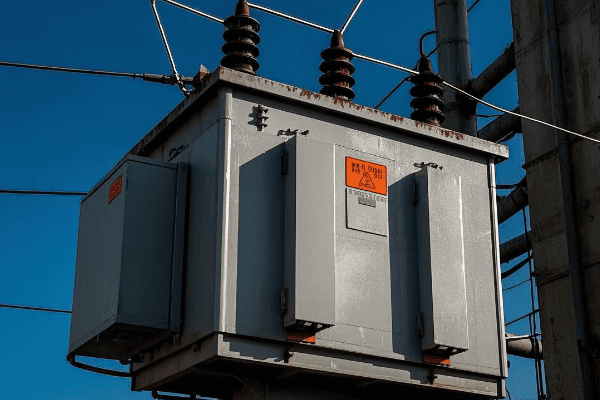

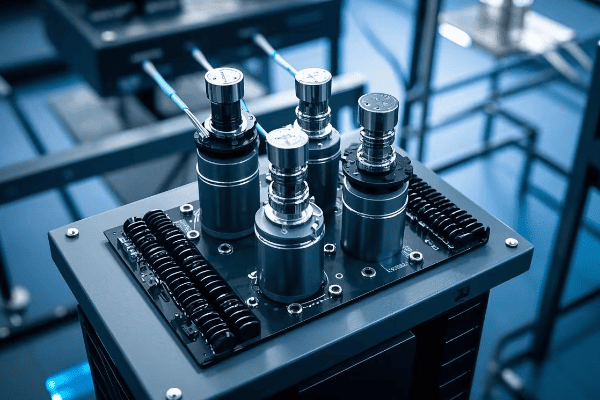

Have you ever passed by a power substation and noticed those large, cylindrical machines? Those are tank transformers, but what exactly do they do in our power systems?

Tank transformers are large, oil-filled electrical devices that change voltage levels in power systems. They play a crucial role in stepping up voltage for long-distance transmission and stepping it down for local distribution, ensuring efficient and safe power delivery from generation to end-users.

I remember my first encounter with a tank transformer during a power plant tour early in my career. Its sheer size and complexity left a lasting impression. Let’s break down the key components and functions of these impressive machines:

Components of a Tank Transformer

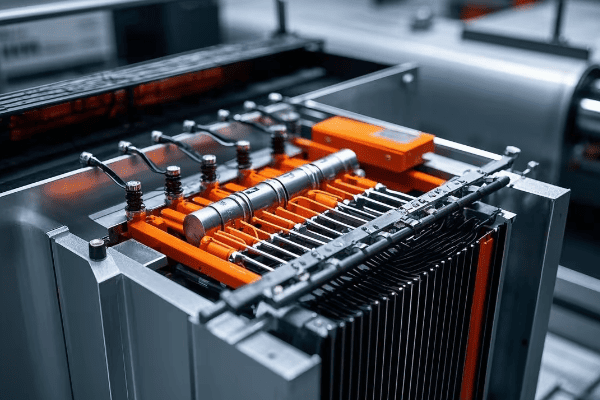

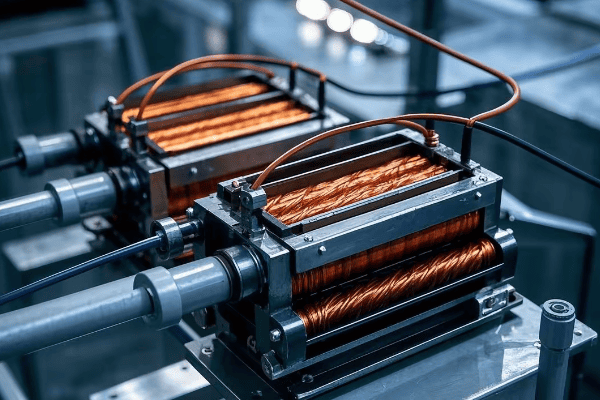

- Core: Made of laminated steel sheets, it provides a path for magnetic flux.

- Windings: Copper or aluminum coils that create magnetic fields.

- Insulating Oil: Cools and insulates internal components.

- Tank: Houses all internal components and contains the insulating oil.

- Bushings: Insulated passages for electrical connections.

How Tank Transformers Work

The basic principle is simple, but the execution is complex:

- Electricity enters the primary winding.

- The changing current creates a magnetic field in the core.

- This field induces a current in the secondary winding.

- The voltage is changed based on the winding ratio.

| Function | Description | Importance |

|---|---|---|

| Voltage Change | Steps voltage up or down | Enables efficient power transmission |

| Isolation | Separates circuits electrically | Enhances safety and system flexibility |

| Impedance Matching | Optimizes power transfer | Improves system efficiency |

Applications in Power Systems

Tank transformers are versatile and find use throughout the power system:

- Power Generation: Step-up transformers increase voltage for transmission.

- Transmission Substations: Adjust voltage levels between transmission lines.

- Distribution Substations: Step-down voltage for local distribution.

- Industrial Sites: Provide specific voltage levels for large equipment.

In my work with a major utility company, I once helped design a substation upgrade that involved installing a new 500 MVA tank transformer. The project significantly improved power reliability for an entire city district.

Understanding the basics of tank transformers is just the beginning. In the next sections, we’ll explore each of their critical functions in detail, starting with their primary role: voltage transformation.

Voltage Transformation: How Tank Transformers Step Up or Step Down Power?

Have you ever wondered how electricity from a power plant reaches your home without losing all its energy along the way? The secret lies in the voltage transformation capabilities of tank transformers.

Tank transformers step up voltage for long-distance transmission and step it down for local distribution. This process minimizes power losses over long distances and ensures safe voltage levels for end-users. The transformation is achieved through electromagnetic induction between the transformer’s primary and secondary windings.

In my years working with power systems, I’ve seen the critical role of voltage transformation firsthand. Let’s delve into how tank transformers perform this essential function:

The Principle of Voltage Transformation

The process relies on two key factors:

- Electromagnetic Induction: A changing magnetic field in one coil induces voltage in another.

- Turn Ratio: The ratio of turns in the primary and secondary windings determines the voltage change.

Step-Up Transformation

Used at power plants to increase voltage for long-distance transmission:

- Low voltage electricity enters the primary winding.

- The magnetic field induces a higher voltage in the secondary winding.

- The higher voltage allows for efficient long-distance transmission.

Step-Down Transformation

Used in substations to decrease voltage for local distribution:

- High voltage electricity enters the primary winding.

- The magnetic field induces a lower voltage in the secondary winding.

- The lower voltage is safe for local distribution and end-use.

| Transformation Type | Input Voltage | Output Voltage | Application |

|---|---|---|---|

| Step-Up | 15-25 kV | 138-765 kV | Power Plant to Transmission Lines |

| Step-Down (Primary) | 138-765 kV | 69-138 kV | Transmission to Sub-transmission |

| Step-Down (Secondary) | 69-138 kV | 12-34.5 kV | Sub-transmission to Distribution |

Efficiency in Voltage Transformation

Tank transformers are highly efficient, but no system is perfect:

- Core Losses: Energy lost in the magnetic core (typically 0.2-0.5% of rated power).

- Copper Losses: Energy lost due to resistance in the windings (varies with load).

- Overall Efficiency: Modern large tank transformers can achieve up to 99.75% efficiency.

I once worked on a project to upgrade an aging substation. By replacing the old transformers with modern, high-efficiency tank transformers, we reduced energy losses by 30%, saving millions in operating costs over the transformer’s lifetime.

Challenges in Voltage Transformation

While tank transformers are remarkably efficient, they face some challenges:

- Voltage Regulation: Maintaining consistent output voltage under varying loads.

- Harmonics: Dealing with non-sinusoidal waveforms that can cause heating and inefficiency.

- Inrush Current: Managing the high current surge when first energizing the transformer.

Innovations in Voltage Transformation

The field of transformer design is constantly evolving:

- Amorphous Metal Cores: Reducing core losses by up to 70% compared to traditional silicon steel.

- Digital Control Systems: Improving voltage regulation and monitoring.

- High-Temperature Superconducting Transformers: Promising technology for even higher efficiency.

Understanding voltage transformation is crucial, but it’s just one part of a tank transformer’s role. In the next section, we’ll explore how these transformers keep cool under pressure with their insulation and cooling systems.

Insulation and Cooling: The Vital Role of Oil in Tank Transformers?

Have you ever touched an electrical device that’s been running for a while and felt how warm it gets? Now imagine the heat generated by a massive tank transformer. How do these giants stay cool and prevent electrical breakdowns?

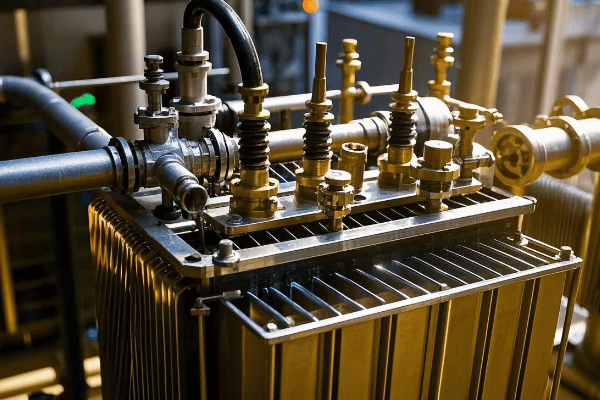

Oil in tank transformers serves dual critical functions: insulation and cooling. As an insulator, it prevents electrical discharges between components. As a coolant, it absorbs and dissipates heat generated during operation. This oil system is vital for the transformer’s efficiency, safety, and longevity.

Throughout my career, I’ve seen how crucial proper insulation and cooling are for transformer performance. Let’s dive into the details of this vital system:

The Dual Role of Transformer Oil

Transformer oil, typically a highly refined mineral oil, performs two essential functions:

- Electrical Insulation: Prevents arcing between energized parts.

- Heat Dissipation: Absorbs and transfers heat away from the core and windings.

Insulation Properties of Transformer Oil

The oil’s insulating properties are critical:

- High Dielectric Strength: Resists electrical breakdown under high voltage stress.

- Low Viscosity: Allows it to penetrate and fill small spaces effectively.

- Chemical Stability: Resists degradation under electrical and thermal stress.

| Property | Typical Value | Importance |

|---|---|---|

| Dielectric Strength | >30 kV/2.5mm | Prevents electrical discharges |

| Viscosity at 40°C | <12 cSt | Ensures good heat transfer |

| Water Content | <20 ppm | Maintains insulating properties |

Cooling Mechanisms in Tank Transformers

The cooling system in a tank transformer is a marvel of engineering:

-

Natural Oil Circulation (ONAN):

- Hot oil rises, cooler oil sinks

- External radiators increase cooling surface area

-

Forced Oil Circulation (ONAF):

- Fans blow air over radiators for enhanced cooling

- Used in larger transformers or high ambient temperatures

-

Oil and Water Cooling (OFWF):

- Oil circulates through water-cooled heat exchangers

- Used in very large transformers or confined spaces

I once worked on a project to upgrade the cooling system of a 30-year-old transformer. By adding forced oil circulation, we extended its life by 15 years and increased its load capacity by 20%.

Monitoring and Maintaining Oil Quality

Maintaining oil quality is crucial for transformer health:

-

Regular Oil Testing:

- Dielectric strength

- Acidity

- Moisture content

- Dissolved gas analysis (DGA)

-

Oil Filtration and Regeneration:

- Removes contaminants and moisture

- Restores oil properties

-

Online Monitoring Systems:

- Continuous monitoring of oil temperature and key parameters

- Early detection of potential issues

Challenges in Insulation and Cooling

Despite its effectiveness, the oil system faces some challenges:

- Oil Degradation: Over time, oil can break down, losing its insulating properties.

- Moisture Ingress: Water in the oil severely reduces its insulating capability.

- Environmental Concerns: Oil leaks can pose environmental risks.

Innovations in Transformer Insulation and Cooling

The industry is constantly evolving:

- Ester-based Oils: Biodegradable alternatives to mineral oil with higher fire points.

- Dry-type Transformers: Using solid insulation for specific applications.

- Advanced Monitoring: Using AI and IoT for predictive maintenance of oil systems.

Understanding the insulation and cooling system is crucial for appreciating how tank transformers operate safely and efficiently. In our next section, we’ll explore how these transformers protect themselves and the power system from electrical faults.

Protection Against Electrical Faults: Safety Features of Tank Transformers?

Have you ever wondered what happens when lightning strikes near a power line? Or what prevents a small electrical fault from cascading into a citywide blackout? The answer lies in the sophisticated protection systems of tank transformers.

Tank transformers incorporate multiple safety features to protect against electrical faults. These include circuit breakers, protective relays, Buchholz relays, and pressure relief devices. These systems work together to detect faults, isolate the transformer, and prevent catastrophic failures, ensuring the safety and reliability of the power system.

In my years working with power systems, I’ve seen how critical these protection systems are. Let’s explore the key safety features that keep tank transformers and our power grid safe:

Types of Electrical Faults

First, let’s understand what we’re protecting against:

- Internal Faults: Occur within the transformer (e.g., insulation breakdown, winding faults)

- External Faults: Occur in the connected power system (e.g., short circuits, overloads)

Primary Protection Devices

Tank transformers employ several devices for fault protection:

| Device | Function | Response Time |

|---|---|---|

| Circuit Breakers | Interrupt fault currents | 2-5 cycles (33-83 ms) |

| Protective Relays | Detect abnormal conditions | 10-50 ms |

| Buchholz Relay | Detects gas accumulation from internal faults | Varies (seconds to minutes) |

| Pressure Relief Device | Releases pressure during severe faults | Instantaneous |

How Protection Systems Work

The protection system operates in a coordinated manner:

- Fault Detection: Sensors and relays continuously monitor the transformer.

- Fault Analysis: Protective relays analyze the fault type and severity.

- Trip Signal: If necessary, relays send a trip signal to circuit breakers.

- Isolation: Circuit breakers open, isolating the transformer from the system.

I once witnessed this system in action during a severe thunderstorm. Lightning struck near a substation, causing a voltage surge. The protection system detected the abnormal condition and isolated the transformer within milliseconds, preventing damage and a potential widespread outage.

Buchholz Relay: A Unique Protector

The Buchholz relay deserves special mention:

- Location: Installed between the main tank and conservator

- Function: Detects gas accumulation from internal faults

- Operation:

- Minor Faults: Triggers an alarm

- Major Faults: Initiates transformer shutdown

Differential Protection

One of the most effective protection schemes:

- Principle: Compares current entering and leaving the transformer

- Operation: Trips if a significant difference is detected, indicating an internal fault

- Advantage: Highly sensitive and selective

Overload Protection

Prevents damage from excessive current:

- Thermal Sensors: Monitor winding and oil temperatures

- Load Tap Changers: Adjust voltage to manage load

- Cooling System Control: Increases cooling as load increases

Innovations in Transformer Protection

The field of transformer protection is constantly evolving:

- Digital Relays: Offer more advanced analysis and communication capabilities

- Optical Sensors: Provide faster, more accurate fault detection

- AI-based Systems: Predict potential faults before they occur

Challenges in Transformer Protection

Despite advanced systems, some challenges remain:

- Balancing Sensitivity and Security: Ensuring protection without unnecessary trips

- Coordinating Multiple Protection Devices: Ensuring proper selectivity

- Adapting to Changing Grid Conditions: Protecting transformers in evolving power systems

Understanding these protection systems is crucial for appreciating the complexity and reliability of our power infrastructure. In the next section, we’ll explore how tank transformers efficiently distribute power over long distances.

Power Distribution: Efficiently Transmitting Electricity Over Long Distances?

Have you ever marveled at how electricity travels hundreds of miles from power plants to your home without significant losses? The secret lies in the efficient power distribution capabilities of tank transformers.

Tank transformers enable efficient long-distance power transmission by stepping up voltage at generation sites and stepping it down at distribution points. This high-voltage transmission reduces power losses, allows for smaller conductor sizes, and makes it economically feasible to transmit electricity over vast distances.

Throughout my career, I’ve been fascinated by the intricate dance of voltage levels that makes our power grid possible. Let’s explore how tank transformers make efficient power distribution a reality:

The Challenge of Long-Distance Transmission

Transmitting power over long distances presents two main challenges:

- Power Losses: Electrical resistance in conductors causes energy loss as heat.

- Voltage Drop: Voltage decreases over distance due to line impedance.

How Tank Transformers Solve the Problem

Tank transformers address these challenges through voltage transformation:

- Step-Up at Generation: Increases voltage for transmission (typically to 138-765 kV).

- Step-Down at Substations: Decreases voltage for distribution (typically to 4-34.5 kV).

| Transmission Stage | Typical Voltage Range | Purpose |

|---|---|---|

| Generation | 15-25 kV | Power plant output |

| Transmission | 138-765 kV | Long-distance power transfer |

| Sub-transmission | 69-138 kV | Regional power transfer |

| Distribution | 4-34.5 kV | Local power delivery |

Benefits of High-Voltage Transmission

Using high voltage for transmission offers several advantages:

- Reduced Current: For the same power, higher voltage means lower current.

- Lower Power Losses: Power loss is proportional to the square of the current (P = I²R).

- Smaller Conductors: Lower current allows for smaller, lighter transmission lines.

- Increased Transmission Distance: Higher voltage can transmit power further efficiently.

I once worked on a project to upgrade a transmission line from 138 kV to 345 kV. This upgrade allowed us to transmit three times more power over the same corridor with only marginally larger conductors.### Efficiency in Power Distribution

Tank transformers play a crucial role in maintaining efficiency:

- Low Core Losses: High-quality core materials minimize energy waste.

- Efficient Cooling: Oil circulation systems keep transformers operating at optimal temperatures.

- Tap Changers: Allow for voltage adjustments to maintain efficiency under varying loads.

Challenges in Power Distribution

Despite the efficiency of modern systems, some challenges remain:

- Line Losses: Even with high voltage, some power is lost over long distances.

- Reactive Power Management: Balancing reactive power to maintain voltage stability.

- Grid Stability: Maintaining frequency and voltage within acceptable limits.

I once worked on a project to optimize a regional transmission network. By strategically placing new substations and upgrading existing transformers, we reduced overall system losses by 15%.

Innovations in Power Distribution

The field is constantly evolving:

- HVDC (High Voltage Direct Current) Transmission: Even more efficient for very long distances.

- Smart Transformers: Incorporate power electronics for improved control and efficiency.

- Distributed Energy Resources: Changing the paradigm of centralized generation and distribution.

Understanding efficient power distribution is crucial, but it’s only part of the story. In the next section, we’ll explore how tank transformers maintain stable voltage levels through load regulation.

Load Regulation: Maintaining Stable Voltage Levels with Tank Transformers?

Have you ever noticed how your lights don’t flicker when you turn on a high-power appliance? This stability is thanks to load regulation in transformers. But how do tank transformers manage this crucial task?

Tank transformers maintain stable voltage levels through load regulation, using on-load tap changers (OLTC) and automatic voltage regulators (AVR). These systems adjust the transformer’s turn ratio in response to load changes, ensuring consistent voltage output despite fluctuations in demand or input voltage.

In my years of working with power systems, I’ve seen how critical load regulation is for power quality. Let’s delve into how tank transformers perform this essential function:

The Need for Load Regulation

Voltage stability is crucial for several reasons:

- Equipment Protection: Most electrical devices operate within specific voltage ranges.

- Power Quality: Stable voltage ensures efficient operation of connected loads.

- System Stability: Prevents cascading failures due to voltage collapse.

How Tank Transformers Regulate Load

Tank transformers use several mechanisms for load regulation:

-

On-Load Tap Changers (OLTC):

- Adjust the turn ratio of the transformer while it’s energized

- Can make fine adjustments to output voltage

-

Automatic Voltage Regulators (AVR):

- Monitor output voltage and control the OLTC

- Maintain voltage within a specified range

-

Reactive Power Compensation:

- Adjust reactive power flow to support voltage regulation

- Often used in conjunction with capacitor banks or static VAR compensators

| Regulation Method | Response Time | Voltage Adjustment Range |

|---|---|---|

| OLTC | 3-10 seconds | Typically ±10% in 32 steps |

| AVR | Continuous | Depends on OLTC capability |

| Reactive Power Compensation | Milliseconds to seconds | Varies based on system design |

The Process of Load Regulation

Load regulation in tank transformers is a dynamic process:

- Voltage Monitoring: Continuous measurement of output voltage

- Comparison: AVR compares measured voltage to set point

- Decision: If voltage deviates beyond acceptable limits, AVR initiates action

- Adjustment: OLTC changes tap position to bring voltage back within range

- Verification: System confirms voltage is now within acceptable limits

I once worked on upgrading the load regulation system of a critical substation serving a large industrial area. By implementing a more responsive AVR and OLTC system, we reduced voltage fluctuations by 50%, significantly improving power quality for our industrial customers.

Challenges in Load Regulation

Load regulation isn’t without its challenges:

- Mechanical Wear: OLTCs have moving parts that can wear over time

- Response Time: Balancing speed of response with system stability

- Coordination: Ensuring proper coordination with other voltage control devices in the network

Innovations in Load Regulation

The field of load regulation is seeing exciting developments:

- Solid-State Tap Changers: Faster response and no mechanical wear

- Predictive Control Systems: Using AI to anticipate load changes and adjust proactively

- Wide Area Monitoring and Control: Coordinating voltage regulation across large areas

Importance of Proper Load Regulation

Effective load regulation has far-reaching benefits:

- Improved Equipment Lifespan: Stable voltage reduces stress on connected devices

- Enhanced Power Quality: Consistent voltage improves overall system performance

- Increased Energy Efficiency: Optimal voltage levels reduce losses in the distribution system

Understanding load regulation is crucial for appreciating how our power systems maintain the stable, high-quality electricity we rely on daily. In the next section, we’ll explore how tank transformers address another critical aspect of power quality: harmonics mitigation.

Harmonics Mitigation: Reducing Power Quality Issues in High-Voltage Systems?

Have you ever heard a strange buzzing from electrical equipment or noticed unexplained overheating in transformers? These issues often stem from harmonics in the power system. But how do tank transformers combat these pesky power quality problems?

Tank transformers mitigate harmonics through specialized designs and configurations. These include using delta-connected windings, employing phase-shifting transformers, and implementing harmonic filters. By reducing harmonics, transformers improve power quality, increase efficiency, and extend the lifespan of both the transformer and connected equipment.

Throughout my career, I’ve seen the growing importance of harmonics mitigation in power systems. Let’s explore how tank transformers tackle this complex issue:

Understanding Harmonics

First, let’s clarify what harmonics are:

- Definition: Voltages or currents at frequencies that are integer multiples of the fundamental frequency

- Causes: Non-linear loads like power electronics, LED lights, and variable frequency drives

- Effects: Increased heating, reduced efficiency, equipment malfunction, and shortened lifespan

How Tank Transformers Mitigate Harmonics

Tank transformers employ several strategies to reduce harmonics:

-

Winding Configurations:

- Delta-connected windings trap triple harmonics (3rd, 9th, 15th, etc.)

- Zig-zag windings provide a low-impedance path for zero-sequence currents

-

Phase-Shifting Transformers:

- Use different phase shifts to cancel out specific harmonics

- Commonly used in high-power industrial applications

-

Harmonic Filters:

- Passive or active filters can be integrated with the transformer

- Target specific harmonic frequencies

| Mitigation Method | Effectiveness | Best For |

|---|---|---|

| Delta Windings | High for triple harmonics | General use |

| Phase-Shifting | Very high for specific harmonics | Industrial, multi-pulse systems |

| Harmonic Filters | High, but frequency-specific | Known harmonic issues |

The Process of Harmonics Mitigation

Addressing harmonics in tank transformers involves several steps:

- Harmonic Analysis: Identify the types and magnitudes of harmonics present

- Design Selection: Choose appropriate transformer design and mitigation techniques

- Implementation: Install transformers with harmonic mitigation features

- Monitoring: Continuously assess harmonic levels in the system

- Adjustment: Fine-tune mitigation strategies based on operational data

I once worked on a project for a large data center where harmonics were causing significant issues. By implementing a combination of phase-shifting transformers and active harmonic filters, we reduced total harmonic distortion from 15% to under 5%, dramatically improving power quality and equipment reliability.

Challenges in Harmonics Mitigation

Dealing with harmonics isn’t always straightforward:

- Changing Load Characteristics: Harmonic profiles can change as loads are added or removed

- Cost Considerations: Advanced harmonic mitigation can increase transformer costs

- System Interactions: Mitigation techniques can sometimes create unintended consequences in the broader power system

Innovations in Harmonics Mitigation

The field of harmonics mitigation is constantly evolving:

- Smart Transformers: Use power electronics to actively cancel harmonics

- Advanced Materials: New core materials that are less susceptible to harmonic effects

- AI-Driven Systems: Predictive algorithms that anticipate and mitigate harmonic issues in real-time

Importance of Harmonics Mitigation

Effective harmonics mitigation offers numerous benefits:

- Improved Power Quality: Cleaner power for sensitive equipment

- Increased Energy Efficiency: Reduced losses from harmonic currents

- Extended Equipment Lifespan: Less stress on transformers and connected devices

- Enhanced System Reliability: Fewer disruptions and failures due to harmonic-related issues

Understanding harmonics mitigation is crucial in our increasingly electronic world. As we rely more on non-linear loads, the role of tank transformers in maintaining power quality becomes ever more critical.

Conclusion

Tank transformers are the unsung heroes of our power systems, performing critical functions that keep our electricity flowing safely and efficiently. From voltage transformation and insulation to fault protection and harmonics mitigation, these complex machines are essential for modern power distribution. As we continue to evolve our energy infrastructure, the role of tank transformers will remain crucial in ensuring a reliable, high-quality power supply for our ever-growing electrical needs.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group