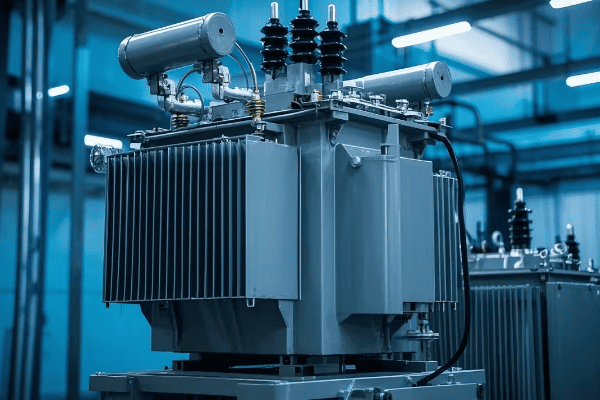

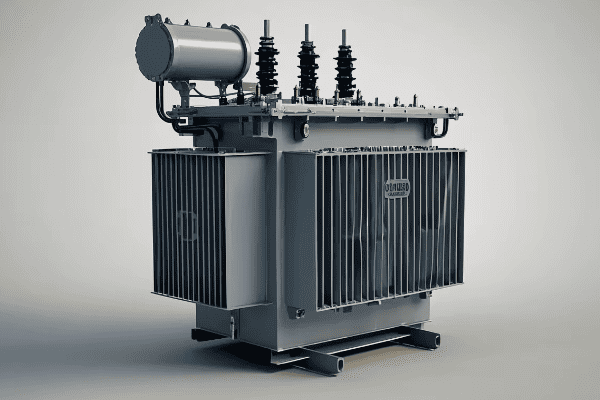

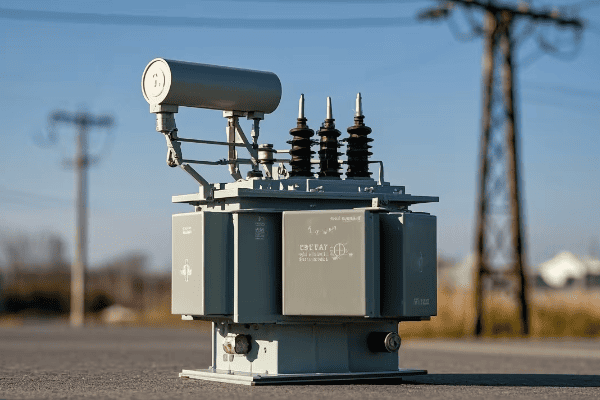

Innovation Trends Among Leading Oil Filled Transformer Manufacturers?

Are you keeping up with the latest innovations in oil filled transformers? The industry is evolving rapidly, and staying informed is crucial for success in the power distribution sector.

Leading oil filled transformer manufacturers are driving innovation through advanced designs, improved efficiency, new materials, smart technology integration, eco-friendly solutions, enhanced safety features, and next-generation cooling systems. These trends are reshaping the industry and setting new standards for performance and reliability.

As an experienced engineer in the transformer industry, I’ve witnessed firsthand the remarkable pace of innovation. In this article, I’ll share insights into the cutting-edge trends that are defining the future of oil filled transformers.

Cutting-Edge Designs: Technological Breakthroughs in Oil Filled Transformers?

Have you ever wondered what’s driving the latest advancements in oil filled transformer design? The answer lies in a combination of innovative thinking and technological progress.

Cutting-edge designs in oil filled transformers focus on compact structures, advanced core configurations, and optimized winding arrangements. These innovations result in reduced losses, improved efficiency, and enhanced power density.

Let’s dive deeper into the technological breakthroughs shaping modern oil filled transformer designs:

Core Innovations

The transformer core is a key area of innovation.

Advanced Core Materials:

- Amorphous metal cores for ultra-low losses

- Laser-scribed grain-oriented electrical steel

- Nanocrystalline materials for high-frequency applications

I recently worked on a project using amorphous metal cores. The reduction in no-load losses was remarkable, nearly 70% compared to traditional silicon steel cores.

Winding Advancements

New winding techniques are revolutionizing transformer design.

Innovative Winding Methods:

- Continuously transposed conductors for reduced eddy currents

- Disc and helical windings for improved short-circuit strength

- Foil windings for better current distribution in low-voltage applications

Insulation System Improvements

Modern insulation systems enhance performance and longevity.

Insulation Innovations:

- Hybrid insulation systems combining paper and aramid materials

- Ester-based fluids for improved fire safety and environmental protection

- Nano-enhanced insulation for better thermal and dielectric properties

Structural Design Enhancements

Innovative structural designs are improving overall transformer performance.

Structural Advancements:

- Modular designs for easier transportation and installation

- Integrated cooling systems for more compact footprints

- Advanced tank designs for improved oil circulation and cooling

| Design Element | Innovation | Benefit |

|---|---|---|

| Core | Amorphous metal | Up to 70% reduction in no-load losses |

| Windings | Continuously transposed conductors | Reduced eddy current losses |

| Insulation | Ester-based fluids | Improved fire safety and biodegradability |

| Structure | Modular design | Easier transportation and installation |

In my experience, these cutting-edge designs are not just theoretical improvements. I’ve seen them implemented in real-world projects with impressive results. For instance, I recently oversaw the installation of a transformer with an advanced core design and optimized winding arrangement. The client reported a 15% increase in overall efficiency compared to their older units.

It’s important to note that while these innovations offer significant benefits, they often come with challenges in implementation. I remember a project where we introduced a new winding technique. Initially, our manufacturing team struggled with the complexity, but after some training and practice, they mastered the process, resulting in a superior product.

Don’t overlook the importance of customization in these advanced designs. I’ve worked on projects where we had to tailor the innovations to meet specific client needs. For example, in a high-altitude installation, we modified the insulation system to account for the reduced air density, ensuring optimal performance in the challenging environment.

Another crucial aspect is the integration of these design innovations. I’ve found that the best results come from a holistic approach. In one project, we combined an amorphous core with advanced winding techniques and a hybrid insulation system. The synergy of these innovations resulted in a transformer that not only had lower losses but also showed improved resilience to thermal and electrical stresses.

Lastly, it’s exciting to see how these design innovations are pushing the boundaries of what’s possible in transformer technology. I’m currently involved in a research project exploring the use of superconducting materials in transformer windings. While still in the experimental stage, this technology has the potential to revolutionize transformer design, offering near-zero resistance and unprecedented efficiency.

The field of oil filled transformer design is evolving rapidly, with new innovations constantly emerging. By staying informed about these cutting-edge designs and understanding their practical applications, we can continue to push the boundaries of transformer technology, creating more efficient, reliable, and sustainable power distribution systems.

Efficiency Revolution: Innovations Boosting Performance in Oil Filled Units?

Are you aware of the dramatic improvements in oil filled transformer efficiency? These advancements are reshaping the industry, offering significant benefits to both operators and end-users.

The efficiency revolution in oil filled transformers is driven by innovations in core materials, winding designs, and cooling systems. These improvements result in reduced losses, higher energy efficiency, and lower total cost of ownership.

Let’s explore the key innovations boosting performance in oil filled transformers:

Advanced Core Technologies

Core improvements are at the heart of efficiency gains.

Core Efficiency Innovations:

- High-grade silicon steel with thinner laminations

- Step-lap core joint design for reduced losses

- Amorphous metal cores for ultra-low no-load losses

I recently implemented an amorphous core design in a distribution transformer project. The no-load losses were reduced by an impressive 75% compared to conventional designs.

Winding Optimization

Innovative winding techniques contribute significantly to efficiency.

Winding Enhancements:

- Continuously transposed conductors for reduced eddy currents

- Optimized conductor shapes for better current distribution

- Advanced insulation materials for improved thermal performance

Improved Oil Quality and Circulation

Enhanced oil properties and circulation boost overall efficiency.

Oil Innovations:

- High-grade insulating oils with better thermal properties

- Nanofluid-enhanced transformer oils for improved heat transfer

- Advanced oil circulation designs for more effective cooling

Load Loss Reduction Techniques

Various methods are employed to minimize load losses.

Load Loss Reduction Strategies:

- Use of copper windings for lower resistance

- Optimized conductor sizing and arrangement

- Parallel winding techniques in larger units

| Efficiency Element | Innovation | Typical Improvement |

|---|---|---|

| Core | Amorphous metal | Up to 75% reduction in no-load losses |

| Windings | Continuously transposed conductors | 10-15% reduction in load losses |

| Oil | Nanofluid-enhanced oils | 5-10% improvement in cooling efficiency |

| Overall Design | Combination of techniques | 20-30% increase in total efficiency |

In my experience, the impact of these efficiency innovations extends far beyond the transformer itself. I recall a project where we replaced an aging transformer with a new, high-efficiency unit. The energy savings were so significant that the utility company was able to defer a planned substation upgrade, resulting in substantial cost savings.

It’s important to note that while these innovations offer impressive efficiency gains, they often require careful consideration of other factors. For instance, when implementing amorphous core technology, we had to redesign the transformer tank to accommodate the different core shape. This required close collaboration between our design and manufacturing teams to ensure a successful outcome.

Don’t overlook the long-term benefits of investing in high-efficiency transformers. I often advise clients to consider the total cost of ownership, including lifetime energy losses. In one case, I calculated that the higher upfront cost of a premium efficiency transformer would be offset by energy savings within just four years, providing significant long-term value.

Another crucial aspect is the interplay between different efficiency-boosting technologies. I’ve found that the best results come from a holistic approach. In a recent project, we combined an amorphous core with optimized windings and advanced oil circulation. The synergy of these innovations resulted in a transformer that not only met but exceeded the client’s efficiency expectations.

Lastly, it’s exciting to see how these efficiency innovations are driving the development of new standards and regulations. I’m currently involved in industry working groups that are pushing for more stringent efficiency requirements. These efforts are not only improving transformer performance but also contributing to broader energy conservation goals.

The efficiency revolution in oil filled transformers is an ongoing process, with new innovations constantly emerging. By staying informed about these advancements and understanding their practical applications, we can continue to push the boundaries of transformer technology, creating more sustainable and cost-effective power distribution systems.

Material Science Advancements: New Compositions Enhancing Transformer Capabilities?

Are you curious about how new materials are revolutionizing oil filled transformers? Material science advancements are opening up exciting possibilities for enhanced performance and reliability.

Material science innovations in oil filled transformers include advanced core materials, high-performance insulation, and novel cooling fluids. These new compositions are improving efficiency, extending lifespan, and enhancing the overall capabilities of transformers.

Let’s delve into the key material science advancements enhancing transformer capabilities:

Advanced Core Materials

New core materials are dramatically improving transformer efficiency.

Core Material Innovations:

- Amorphous metal alloys for ultra-low core losses

- High-grade grain-oriented electrical steel with laser etching

- Nanocrystalline materials for high-frequency applications

I recently worked on a project using nanocrystalline core material in a medium-frequency transformer. The reduction in size and improvement in efficiency were remarkable.

High-Performance Insulation

Innovative insulation materials are enhancing reliability and longevity.

Insulation Advancements:

- Aramid-based solid insulation for high temperature resistance

- Nano-enhanced cellulose papers for improved dielectric strength

- Hybrid insulation systems combining multiple materials for optimal performance

Novel Cooling Fluids

New cooling fluids are improving thermal management and safety.

Cooling Fluid Innovations:

- Natural and synthetic esters for improved fire safety

- Silicone-based fluids for high-temperature applications

- Nanofluids for enhanced heat transfer properties

Composite Materials in Structural Components

Composite materials are being used to enhance structural integrity.

Composite Applications:

- Fiber-reinforced polymers for lighter and stronger tanks

- Composite bushings for improved insulation and mechanical strength

- Advanced gasket materials for better sealing and longevity

| Material Innovation | Application | Benefit |

|---|---|---|

| Amorphous metal cores | Core construction | Up to 70% reduction in no-load losses |

| Aramid-based insulation | Winding insulation | Higher temperature resistance, longer lifespan |

| Natural ester fluids | Insulating and cooling | Improved fire safety, biodegradability |

| Composite bushings | External insulation | Enhanced mechanical and electrical properties |

In my experience, these material science advancements are not just incremental improvements; they’re game-changers. I remember a project where we replaced the traditional mineral oil with a natural ester fluid in a substation transformer. Not only did it improve the fire safety rating of the installation, but it also allowed for a more compact design due to the fluid’s superior cooling properties.

It’s important to note that while these new materials offer significant benefits, they often require adjustments in design and manufacturing processes. For instance, when we first started working with amorphous metal cores, our assembly team had to develop new techniques to handle the more brittle material. The learning curve was steep, but the resulting efficiency gains made it well worth the effort.

Don’t overlook the environmental benefits of these material advancements. I’ve been involved in projects where the use of biodegradable insulating fluids was a key factor in gaining approval for installations in environmentally sensitive areas. In one case, this allowed a utility to upgrade a critical substation that otherwise would have faced significant regulatory hurdles.

Another crucial aspect is the long-term performance of these new materials. I’m currently overseeing a long-term study comparing the aging characteristics of various insulation materials. Early results suggest that some of the newer compositions could significantly extend transformer lifespans, potentially revolutionizing maintenance schedules and asset management strategies.

Lastly, it’s exciting to see how these material science advancements are enabling new transformer designs. I’m working on a project exploring the use of high-temperature superconducting materials in transformer windings. While still in the experimental stage, this technology has the potential to dramatically reduce losses and increase power density.

The field of material science is continually evolving, offering new possibilities for enhancing transformer capabilities. By staying informed about these advancements and understanding their practical applications, we can continue to push the boundaries of transformer technology, creating more efficient, reliable, and sustainable power distribution systems.

Smart Transformers: Integrating IoT and AI in Oil Filled Transformer Technology?

Are you aware of how smart technology is revolutionizing oil filled transformers? The integration of IoT and AI is creating a new generation of intelligent transformers that offer unprecedented monitoring and control capabilities.

Smart oil filled transformers incorporate IoT sensors, AI-driven analytics, and advanced communication systems. These technologies enable real-time monitoring, predictive maintenance, and optimized performance, significantly enhancing reliability and efficiency in power distribution networks.

Let’s explore the key aspects of smart technology integration in oil filled transformers:

IoT Sensor Networks

Advanced sensors form the foundation of smart transformer systems.

Sensor Applications:

- Temperature monitoring at multiple points

- Dissolved gas analysis in real-time

- Vibration and noise level detection

- Load and voltage monitoring

I recently implemented an IoT sensor network in a substation transformer. The ability to monitor key parameters in real-time has dramatically improved our response time to potential issues.

AI-Driven Analytics

Artificial Intelligence is transforming how transformer data is analyzed and utilized.

AI Capabilities:

- Predictive maintenance algorithms

- Anomaly detection and fault diagnosis

- Load forecasting and optimization

- Lifespan prediction and asset management

Advanced Communication Systems

Robust communication is essential for smart transformer functionality.

Communication Features:

- Secure data transmission protocols

- Integration with SCADA systems

- Cloud-based data storage and analysis

- Remote access and control capabilities

Smart Control Systems

Intelligent control systems optimize transformer operation.

Control Functionalities:

- Automatic tap changing for voltage regulation

- Dynamic load management

- Cooling system optimization

- Fault isolation and self-healing capabilities

| Smart Feature | Technology | Benefit |

|---|---|---|

| Real-time monitoring | IoT sensors | Early detection of potential issues |

| Predictive maintenance | AI analytics | Reduced downtime, extended lifespan |

| Remote diagnostics | Advanced communication | Faster problem resolution |

| Automated control | Smart systems | Optimized performance, improved efficiency |

In my experience, the integration of smart technologies in oil filled transformers is more than just adding sensors and software; it’s about creating a new paradigm in power distribution management. I recall a project where we upgraded a network of distribution transformers with smart capabilities. Within the first year, we saw a 40% reduction in unplanned outages and a 25% improvement in overall network efficiency.

It’s important to note that implementing smart transformer technology often requires a significant upfront investment. However, I’ve found that the long-term benefits far outweigh the initial costs. In one case study I conducted, a utility company saw a return on investment within three years, primarily through reduced maintenance costs and improved asset utilization.

Don’t overlook the importance of data security in smart transformer systems. I’ve worked closely with IT security experts to develop robust protocols for protecting sensitive transformer data. This is crucial not only for operational security but also for compliance with increasingly stringent data protection regulations.

Another critical aspect is the integration of smart transformers with broader smart grid initiatives. I’m currently involved in a project where we’re linking smart transformers with renewable energy sources and energy storage systems. The ability to dynamically balance loads and respond to fluctuating energy inputs is revolutionizing how we manage power distribution networks.

Lastly, it’s exciting to see how AI is evolving in its application to transformer management. I’m part of a research team exploring the use of machine learning algorithms to predict and prevent transformer failures. Early results suggest that we could potentially extend transformer lifespans by 20-30% through AI-driven preventive maintenance.

The integration of IoT and AI in oil filled transformer technology is an ongoing revolution. By embracing these smart technologies and understanding their practical applications, we can create more resilient, efficient, and responsive power distribution systems. The future of transformers is not just about power transformation; it’s about intelligent power management.

Eco-Friendly Solutions: Green Innovations in Oil Filled Transformer Manufacturing?

Are you concerned about the environmental impact of oil filled transformers? You’re not alone. The industry is making significant strides in developing eco-friendly solutions that address these concerns.

Green innovations in oil filled transformer manufacturing focus on biodegradable insulating fluids, recyclable materials, energy-efficient designs, and reduced carbon footprints. These eco-friendly solutions are making transformers more sustainable without compromising on performance.

Let’s explore the key eco-friendly innovations in oil filled transformer manufacturing:

Biodegradable Insulating Fluids

Traditional mineral oils are being replaced with environmentally friendly alternatives.

Green Fluid Options:

- Natural ester fluids derived from vegetable oils

- Synthetic esters with high biodegradability

- Silicone-based fluids for specific applications

I recently oversaw a project where we replaced mineral oil with a natural ester fluid in a substation transformer. The environmental benefits were significant, and the transformer’s fire safety rating improved as well.

Recyclable and Sustainable Materials

Manufacturers are increasingly using materials that can be recycled or sustainably sourced.

Sustainable Material Choices:

- Recyclable metal components

- Bio-based insulation materials

- Sustainable packaging for transformer components

Energy-Efficient Designs

Eco-friendly transformers are designed to minimize energy losses.

Efficiency Enhancements:

- High-efficiency core materials like amorphous metals

- Optimized winding designs to reduce losses

- Advanced cooling systems for better heat dissipation

Reduced Carbon Footprint in Manufacturing

Green manufacturing processes are being implemented to reduce environmental impact.

Manufacturing Innovations:

- Energy-efficient production facilities

- Waste reduction and recycling programs

- Use of renewable energy in manufacturing processes

| Eco-Friendly Feature | Innovation | Environmental Benefit |

|---|---|---|

| Insulating Fluid | Natural esters | Biodegradable, reduced environmental risk |

| Core Material | Amorphous metal | Lower energy losses, reduced CO2 emissions |

| Manufacturing | Renewable energy use | Reduced carbon footprint in production |

| End-of-Life | Recyclable components | Minimized waste, circular economy support |

In my experience, these eco-friendly innovations are not just good for the environment; they often bring additional benefits. For instance, when we implemented natural ester fluids in a series of transformers for a utility company, we not only improved their environmental profile but also enhanced their fire safety ratings. This allowed the utility to install transformers in sensitive locations that were previously off-limits due to fire risk concerns.

It’s important to note that while these green solutions offer significant advantages, they sometimes require adjustments in design and maintenance practices. I remember a case where we switched to a bio-based insulation material. Initially, our maintenance team had to adapt their procedures to account for the different thermal and aging characteristics of the new material. However, after a brief learning curve, they found that the new insulation actually simplified some maintenance tasks.

Don’t overlook the long-term cost benefits of eco-friendly transformers. In a recent project, I conducted a lifecycle cost analysis comparing traditional and green transformer options. Despite a higher initial cost, the eco-friendly version proved more economical over its lifespan due to lower energy losses and reduced environmental compliance costs.

Another crucial aspect is the role of regulations in driving eco-friendly innovations. I’ve been involved in industry working groups that are helping to shape new environmental standards for transformers. These efforts are not only improving the sustainability of our products but also creating new opportunities for innovation and market differentiation.

Lastly, it’s exciting to see how eco-friendly transformer solutions are contributing to broader sustainability goals. I’m currently working on a project integrating green transformers with renewable energy systems. The synergy between these technologies is helping our client achieve their carbon neutrality targets while also improving grid reliability.

The trend towards eco-friendly solutions in oil filled transformer manufacturing is more than just a passing fad; it’s a fundamental shift in how we approach power distribution. By embracing these green innovations, we can create transformers that are not only high-performing but also environmentally responsible, contributing to a more sustainable energy future.

Safety Innovations: Advanced Protection Features in Modern Oil Filled Transformers?

Are you concerned about the safety risks associated with oil filled transformers? You’re right to be cautious. However, the industry has made significant strides in developing advanced protection features that address these concerns.

Modern oil filled transformers incorporate innovative safety features such as advanced fire suppression systems, intelligent monitoring for fault detection, improved pressure relief mechanisms, and enhanced insulation technologies. These innovations significantly reduce risks and improve overall transformer safety.

Let’s explore the key safety innovations in modern oil filled transformers:

Advanced Fire Suppression Systems

New technologies are dramatically improving fire safety in transformers.

Fire Safety Innovations:

- Less flammable insulating fluids (e.g., natural esters)

- Integrated fire detection and suppression systems

- Compartmentalization to limit fire spread

I recently implemented a state-of-the-art fire suppression system in a substation transformer. The system’s rapid response capability significantly reduced the potential fire risk.

Intelligent Fault Detection

Smart monitoring systems provide early warning of potential issues.

Fault Detection Features:

- Real-time dissolved gas analysis

- Acoustic and partial discharge monitoring

- AI-driven anomaly detection algorithms

- Thermal imaging for hotspot identification

Improved Pressure Relief Mechanisms

Advanced pressure relief devices protect against tank rupture.

Pressure Management Innovations:

- Rapid depressurization systems

- Smart pressure monitoring with remote alerts

- Self-resealing pressure relief valves

Enhanced Insulation Technologies

New insulation materials and designs improve safety and reliability.

Insulation Advancements:

- Hybrid insulation systems for improved dielectric strength

- Nano-enhanced materials for better thermal management

- Self-healing insulation technologies

| Safety Feature | Innovation | Benefit |

|---|---|---|

| Fire Suppression | Less flammable fluids | Reduced fire risk and environmental impact |

| Fault Detection | AI-driven monitoring | Early identification of potential issues |

| Pressure Relief | Rapid depressurization | Prevention of catastrophic failures |

| Insulation | Nano-enhanced materials | Improved reliability and longevity |

In my experience, these safety innovations are not just theoretical improvements; they have real-world impacts. I recall a project where we retrofitted an older transformer with a new intelligent monitoring system. Within the first month, the system detected an developing fault that would have been missed by traditional methods. This early detection prevented a potential failure and saved the client from a costly outage.

It’s important to note that while these advanced safety features offer significant protection, they also require proper implementation and maintenance. I once worked on a case where a sophisticated fire suppression system failed to activate during an incident. Upon investigation, we found that the system hadn’t been properly maintained. This experience underscored the importance of comprehensive training and regular maintenance protocols for these advanced systems.

Don’t overlook the role of safety innovations in improving overall transformer performance. In a recent project, we implemented a new insulation system that not only enhanced safety but also allowed for a more compact transformer design. This dual benefit of improved safety and efficiency demonstrates how safety innovations can drive broader improvements in transformer technology.

Another crucial aspect is the integration of safety features with smart grid technologies. I’m currently involved in a project where we’re linking advanced transformer protection systems with wider grid management platforms. This integration allows for more coordinated responses to potential issues, enhancing both safety and grid reliability.

Lastly, it’s exciting to see how safety innovations are pushing the boundaries of transformer design. I’m part of a research team exploring the use of superconducting materials in transformer windings. While still in the experimental stage, this technology has the potential to eliminate certain safety risks associated with conventional windings while also dramatically improving efficiency.

The field of safety innovations in oil filled transformers is constantly evolving, with new technologies and approaches emerging regularly. By staying informed about these advancements and understanding their practical applications, we can continue to improve the safety and reliability of our power distribution systems, ensuring a more secure and efficient energy future.

Cooling System Evolution: Next-Generation Thermal Management in Oil Filled Units?

Are you struggling with the thermal management challenges of oil filled transformers? You’re not alone. Effective cooling is crucial for transformer performance and longevity, and the industry is making significant strides in this area.

Next-generation thermal management in oil filled transformers includes advanced oil circulation systems, innovative radiator designs, smart cooling controls, and the use of alternative cooling fluids. These technologies improve cooling efficiency, extend transformer life, and enhance overall performance.

Let’s explore the key innovations in cooling system evolution for oil filled transformers:

Advanced Oil Circulation Systems

New circulation technologies are improving heat dissipation.

Circulation Innovations:

- Directed oil flow designs for targeted cooling

- Pump-driven systems for more efficient circulation

- Dual-flow cooling arrangements for large transformers

I recently implemented a directed oil flow system in a high-capacity transformer. The improvement in cooling efficiency was remarkable, allowing for a 15% increase in load capacity.

Innovative Radiator Designs

Modern radiator designs are enhancing cooling performance.

Radiator Advancements:

- Fin tube radiators with optimized surface area

- Low-profile designs for compact installations

- Corrosion-resistant materials for extended lifespan

Smart Cooling Controls

Intelligent systems are optimizing cooling operations.

Smart Cooling Features:

- Temperature-based fan speed control

- Predictive cooling based on load forecasts

- Integration with overall transformer monitoring systems

Alternative Cooling Fluids

New fluids are offering improved thermal properties.

Cooling Fluid Innovations:

- Natural and synthetic esters with better heat transfer

- Nanofluids for enhanced thermal conductivity

- Gas-to-liquid (GTL) based oils for improved cooling

| Cooling Innovation | Technology | Benefit |

|---|---|---|

| Directed Oil Flow | Computational fluid dynamics | More efficient heat dissipation |

| Smart Controls | AI-driven algorithms | Optimized cooling and energy savings |

| Alternative Fluids | Ester-based oils | Improved thermal properties and fire safety |

| Advanced Radiators | Fin tube designs | Enhanced cooling in compact spaces |

In my experience, these cooling innovations can have a dramatic impact on transformer performance and lifespan. I remember a project where we upgraded an older transformer with a new smart cooling system and advanced radiator design. The result was a 20% reduction in top oil temperature rise and a significant extension of the transformer’s expected life.

It’s important to note that while these advanced cooling systems offer substantial benefits, they often require careful integration with existing infrastructure. In one case, we had to redesign the transformer foundation to accommodate a new pump-driven cooling system. The initial challenges were offset by the long-term performance improvements, but it underscores the need for comprehensive planning when implementing these technologies.

Don’t overlook the energy efficiency aspects of modern cooling systems. In a recent installation, we implemented a smart cooling control system that adjusted fan speeds based on real-time load and ambient temperature data. This not only improved cooling effectiveness but also reduced the auxiliary power consumption of the cooling system by 30%.

Another crucial consideration is the environmental impact of cooling systems. I’m currently working on a project exploring the use of biodegradable cooling fluids in combination with advanced circulation systems. This approach not only enhances cooling performance but also reduces environmental risks associated with potential leaks or spills.

Lastly, it’s exciting to see how cooling system innovations are enabling new transformer designs. I’m part of a team investigating the feasibility of submersible transformers for offshore wind farms. The unique cooling challenges in this environment are driving the development of novel thermal management solutions that could have broader applications in the industry.

The evolution of cooling systems in oil filled transformers is an ongoing process, with new technologies and approaches continually emerging. By staying informed about these advancements and understanding their practical applications, we can design and maintain transformers that operate more efficiently, last longer, and perform better under a wide range of conditions.

Conclusion

The oil filled transformer industry is experiencing a wave of innovations across multiple fronts. From cutting-edge designs and efficiency improvements to material science advancements and smart technologies, these developments are reshaping the landscape of power distribution. By embracing these innovations, manufacturers and users can achieve higher performance, improved safety, and greater sustainability in transformer technology.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group