Are you struggling to understand the role of low voltage transformers in electrical systems? You’re not alone. Many engineers and project managers find themselves confused by the intricacies of these crucial components. But what if you had a clear, comprehensive guide that breaks down everything you need to know about low voltage transformers?

A low voltage transformer is an electrical device that reduces higher input voltages to safer, lower output voltages—typically below 1000 volts—making them suitable for residential, commercial, and industrial applications. These transformers are commonly used to power lighting systems, control panels, and sensitive electronic equipment where standard high-voltage levels would be unsafe or incompatible. They play a crucial role in ensuring safe and efficient power distribution in various settings.

In this comprehensive guide, I’ll walk you through the world of low voltage transformers. We’ll explore what they are, how they work, their typical voltage ranges, and their common applications. Whether you’re a seasoned engineer or new to the field, this article will provide valuable insights to help you make informed decisions about low voltage transformer selection and use.

What Is a Low Voltage Transformer?

Have you ever wondered how the high voltages from power lines are safely reduced for use in our homes and offices? The answer lies in low voltage transformers. But what exactly is a low voltage transformer, and why is it so important in our electrical systems?

A low voltage transformer is a device designed to step down higher voltages to levels below 1000 volts, typically for end-use applications. These transformers take input voltages such as 480V or 220V and convert them to safer, usable voltages like 120V, 24V, or even lower. They are essential for powering everyday electrical devices, lighting systems, and control equipment while ensuring user safety and equipment protection.

Understanding Low Voltage Transformers

Let’s break down the key aspects of low voltage transformers:

- Definition and Purpose

- Voltage Ranges

- Types of Low Voltage Transformers

- Safety Features

- Common Applications

Definition and Purpose

A low voltage transformer is:

- An electrical device that reduces voltage to safer levels

- Designed for end-use power distribution

- Crucial for powering most electrical equipment we use daily

I recently worked on a project upgrading a commercial building’s electrical system. We used several low voltage transformers to step down the 480V supply to 120V for office equipment and 24V for the building’s control systems, showcasing their versatility.

Voltage Ranges

Typical voltage ranges include:

- Primary (input) voltages: Often 480V, 240V, or 220V

- Secondary (output) voltages: Commonly 120V, 24V, 12V, or lower

During a recent industrial automation project, we implemented a range of low voltage transformers, some stepping down 480V to 120V for general use, and others providing 24V DC for PLC and sensor systems.

Types of Low Voltage Transformers

Common types include:

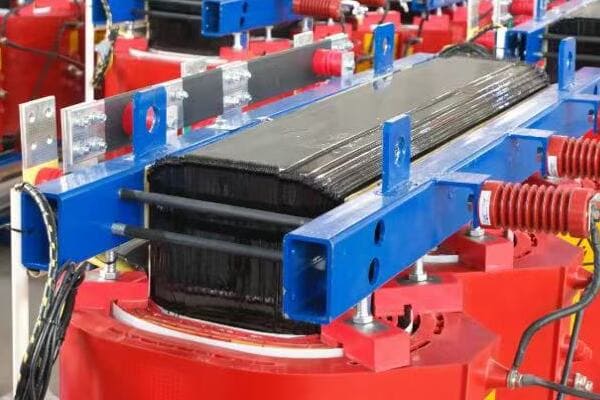

- Dry-type transformers

- Encapsulated transformers

- Control transformers

- Isolation transformers

Here’s a quick overview of low voltage transformer types:

| Type | Description | Best For |

|---|---|---|

| Dry-type | Air-cooled, no liquid insulation | Indoor, commercial use |

| Encapsulated | Sealed in epoxy resin | Harsh environments |

| Control | Precise voltage regulation | Industrial control systems |

| Isolation | Provides electrical isolation | Sensitive electronic equipment |

Safety Features

Key safety aspects:

- Electrical isolation between primary and secondary windings

- Overload protection mechanisms

- Thermal protection in many models

Common Applications

Where you’ll find low voltage transformers:

- Residential and commercial lighting systems

- Office and home appliances

- Industrial control panels

- HVAC systems

- Elevators and escalators

Key points about low voltage transformers:

- They step down voltage to safer, usable levels

- Typically handle voltages below 1000V on the secondary side

- Come in various types for different applications

- Incorporate important safety features

- Essential for powering most electrical devices we use daily

In my experience, understanding the role of low voltage transformers is crucial for anyone involved in electrical system design or management. I recall a case where a client was experiencing frequent equipment failures in their office. Upon investigation, we discovered that they were using equipment rated for 120V directly on a 240V supply. By installing appropriate low voltage transformers, we not only resolved the failure issues but also significantly improved the overall safety of their electrical system.

As we move on to discuss how low voltage transformers work, keep in mind that these devices are fundamental to the safe and efficient distribution of electricity in our daily lives. Their proper selection and application are key to ensuring the reliability and safety of electrical systems in various settings.

How Do Low Voltage Transformers Work?

Have you ever wondered about the magic behind powering your household appliances safely from the high-voltage electricity entering your home? The secret lies in the operation of low voltage transformers. But how exactly do these devices work to convert high voltages into safer, usable levels?

Low voltage transformers work on the principle of electromagnetic induction. They consist of two coils of wire (primary and secondary) wound around a magnetic core. When alternating current flows through the primary coil, it creates a changing magnetic field. This field induces a voltage in the secondary coil. The ratio of turns in the primary and secondary coils determines the voltage transformation. By having fewer turns in the secondary coil, the transformer steps down the voltage to a lower, safer level.

Exploring the Working Mechanism

Let’s break down the operation into key components:

- Electromagnetic Induction

- Core and Windings

- Turns Ratio and Voltage Transformation

- Load and No-Load Operation

- Efficiency and Losses

Electromagnetic Induction

The fundamental principle:

- Changing magnetic field induces voltage in a conductor

- Alternating current creates this changing field

- Faraday’s law of induction governs this process

I often use a simple demonstration with a small model transformer to show how changing the current in one coil induces voltage in another, even when they’re not in direct contact.

Core and Windings

Key components:

- Core: Usually made of laminated silicon steel

- Primary winding: Connects to input voltage

- Secondary winding: Provides output voltage

During a recent factory tour, I observed the precision involved in winding transformers. The careful layering of windings and core laminations is crucial for efficient operation.

Turns Ratio and Voltage Transformation

How voltage is stepped down:

- Turns ratio = Primary turns / Secondary turns

- Voltage ratio = Primary voltage / Secondary voltage

- Fewer secondary turns result in lower output voltage

Here’s a simplified example of turns ratio and voltage:

| Primary Turns | Secondary Turns | Input Voltage | Output Voltage |

|---|---|---|---|

| 1000 | 100 | 240V | 24V |

| 500 | 250 | 120V | 60V |

| 1000 | 50 | 480V | 24V |

Load and No-Load Operation

Behavior under different conditions:

- No-load: Minimal current in primary, core losses present

- Under load: Current in secondary affects primary current

- Voltage regulation maintains output under varying loads

Efficiency and Losses

Factors affecting performance:

- Core losses (hysteresis and eddy currents)

- Copper losses in windings

- Efficiency typically high, often above 95%

Key points about how low voltage transformers work:

- They operate based on electromagnetic induction

- The core and windings are crucial components

- Turns ratio determines the voltage transformation

- They behave differently under load and no-load conditions

- Efficiency is generally high, but losses do occur

In my experience, understanding these principles is crucial for effective transformer management. I recall a case where a client was experiencing unexpectedly high energy bills. Upon investigation, we found that their low voltage transformers were oversized for the actual load, leading to unnecessary core losses. By replacing them with appropriately sized units, we significantly improved the overall efficiency of their electrical system.

For example, during a recent energy audit of a commercial building, we used thermal imaging to observe the heat distribution in various low voltage transformers. This allowed us to identify units that were operating inefficiently due to poor load matching or aging insulation, leading to targeted replacements that improved the building’s overall energy efficiency.

As we move on to discuss voltage ranges and common specifications, keep these working principles in mind. Understanding how low voltage transformers function at their core will help you appreciate the importance of proper sizing and selection for specific applications.

Voltage Range and Common Specifications?

Are you finding it challenging to navigate the world of low voltage transformer specifications? You’re not alone. Many professionals struggle to understand the standardized ratings and how they apply to different applications. But what exactly are these specifications, and how do they impact transformer selection and use?

Low voltage transformers typically handle input voltages up to 1000V, with common primary voltages including 480V, 240V, and 220V. Output voltages commonly range from 120V down to 12V or lower. Capacity ratings usually span from 25VA to 500kVA. These transformers are designed for either 50Hz or 60Hz operation, depending on the region. Other key specifications include insulation class, temperature rise, and enclosure type (often specified by IP ratings for environmental protection).

Understanding Transformer Specifications

Let’s break down the key specifications:

- Voltage Ranges

- Power Ratings

- Frequency Standards

- Insulation Classes

- Environmental Protection Ratings

Voltage Ranges

Common input and output voltages:

- Primary (input): 480V, 240V, 220V

- Secondary (output): 120V, 24V, 12V, 5V

I recently worked on a project where we needed to power various systems in a new office building. We used a combination of 480V to 120V transformers for general power and 240V to 24V units for the building’s automation systems.

Power Ratings

Capacity ranges:

- Small control transformers: 25VA to 5kVA

- Larger distribution transformers: Up to 500kVA

During a recent industrial upgrade, we installed a series of low voltage transformers ranging from 5kVA for control circuits to 300kVA for powering production equipment, showcasing the wide range of available capacities.

Frequency Standards

Regional variations:

- 50Hz: Common in Europe, Asia, Africa

- 60Hz: Standard in North America, parts of South America

Here’s a quick overview of common specifications:

| Specification | Common Values | Notes |

|---|---|---|

| Input Voltage | 480V, 240V, 220V | Depends on region and application |

| Output Voltage | 120V, 24V, 12V, 5V | Based on end-use requirements |

| Power Rating | 25VA – 500kVA | Varies widely with application |

| Frequency | 50Hz or 60Hz | Region-dependent |

| Insulation Class | B (130°C), F (155°C), H (180°C) | Affects temperature handling |

Insulation Classes

Temperature handling capabilities:

- Class B: 130°C

- Class F: 155°C

- Class H: 180°C

Environmental Protection Ratings

IP (Ingress Protection) ratings:

- IP00: No special protection

- IP23: Protected against solid objects over 12mm, spraying water

- IP54: Dust protected, splash-proof

Key points about low voltage transformer specifications:

- Voltage ranges are standardized but vary by application and region

- Power ratings cover a wide range to suit different needs

- Frequency standards are region-specific

- Insulation classes determine temperature handling capabilities

- Environmental ratings are crucial for proper application selection

In my experience, understanding these specifications is crucial for effective transformer selection. I recall a project where a client in the food processing industry needed transformers for their production line. By carefully considering the voltage requirements, load capacity, and the wash-down environment (requiring a high IP rating), we were able to select transformers that not only met their power needs but also withstood the challenging environmental conditions.

For example, in a recent data center project, we had to navigate the complex power requirements of various IT equipment. We used a combination of transformers with different voltage outputs and power ratings, all selected based on their efficiency ratings and ability to handle the continuous load typical in data center environments.

As we move on to discuss common applications of low voltage transformers, keep these specifications in mind. They play a crucial role in determining which transformers are suitable for specific uses and how they integrate into various electrical systems.

Common Applications of Low Voltage Transformers?

Have you ever wondered where all those low voltage transformers end up being used? From the devices in your home to large industrial machines, low voltage transformers play a crucial role in powering our world. But what are the most common applications for these versatile devices, and why are they so important in these settings?

Low voltage transformers find widespread use in residential, commercial, and industrial applications. They are essential in lighting systems, powering household appliances, and office equipment. In industrial settings, they’re crucial for control systems, motors, and automation equipment. Low voltage transformers are also vital in specialized fields like healthcare (powering medical devices), transportation (in elevators and electric vehicle charging stations), and in IT infrastructure (data centers and telecommunications). Their ability to provide safe, efficient power makes them indispensable in modern electrical systems.

Exploring Key Applications

Let’s examine the main areas where low voltage transformers are commonly used:

- Residential and Commercial Lighting

- Industrial Control Systems

- Consumer Electronics and Appliances

- Healthcare and Medical Equipment

- Transportation and Infrastructure

- Renewable Energy Systems

Residential and Commercial Lighting

Illuminating our spaces:

- Step-down transformers for LED lighting systems

- Landscape lighting transformers

- Emergency lighting power supplies

I recently worked on a project retrofitting an old warehouse into a modern office space. We used multiple low voltage transformers to power an energy-efficient LED lighting system, significantly reducing the building’s energy consumption.

Industrial Control Systems

Powering automation:

- Control panel transformers

- PLC (Programmable Logic Controller) power supplies

- Sensor and instrumentation power

During a recent factory automation upgrade, we installed numerous small control transformers to power various sensors, actuators, and control panels, forming the backbone of the facility’s new smart manufacturing system.

Consumer Electronics and Appliances

Everyday devices:

- Chargers for laptops and mobile devices

- Power supplies for home entertainment systems

- Transformers in large appliances (e.g., washing machines)

Here’s a quick overview of common applications:

| Sector | Application | Typical Transformer Type |

|---|---|---|

| Residential | Home lighting | Small, encapsulated |

| Commercial | Office equipment | Dry-type, various sizes |

| Industrial | Motor controls | Control transformers |

| Healthcare | Medical imaging | Isolation transformers |

| Transportation | EV charging stations | Step-down, high efficiency |

Healthcare and Medical Equipment

Ensuring safe, reliable power:

- Isolation transformers for sensitive medical devices

- MRI and X-ray machine power supplies

- Hospital room general-purpose transformers

Transportation and Infrastructure

Keeping things moving:

- Elevator and escalator control systems

- Traffic signal power supplies

- Electric vehicle charging stations

Renewable Energy Systems

Supporting green technology:

- Solar inverter transformers

- Wind turbine control systems

- Battery storage system interfaces

Key points about low voltage transformer applications:

- They are crucial in both residential and commercial lighting systems

- Industrial control and automation heavily rely on low voltage transformers

- Consumer electronics and appliances often incorporate small transformers

- Healthcare applications require specialized, high-reliability transformers

- Transportation and infrastructure systems use various low voltage transformers

- Renewable energy systems integrate these transformers for power conversion and control

In my experience, the versatility of low voltage transformers becomes particularly evident in complex, multi-faceted projects. I recall a recent smart building project where we integrated various low voltage transformers throughout the structure. From powering the LED lighting and HVAC controls to supplying the building’s security systems and EV charging stations in the parking garage, these transformers were the unsung heroes enabling the building’s advanced functionality.

For example, in a cutting-edge manufacturing facility I consulted on, we implemented a network of low voltage transformers to power a diverse array of systems. This included precision control equipment for robotic assembly lines, power supplies for quality control sensors, and even specialized transformers for the facility’s advanced energy management system. The project highlighted how low voltage transformers are essential in creating flexible, efficient, and intelligent industrial environments.

As we move on to discuss the advantages of using low voltage transformers, keep these diverse applications in mind. Understanding where and how these transformers are used helps appreciate their importance in our daily lives and various industries.

Advantages of Using Low Voltage Transformers?

Have you ever wondered why low voltage transformers are so widely used across different sectors? The answer lies in their numerous benefits. But what specific advantages do these transformers offer, and how do they impact safety, efficiency, and overall system performance?

Low voltage transformers offer several key advantages including enhanced safety, improved energy efficiency, and better voltage regulation. They provide electrical isolation, reducing the risk of electric shock. These transformers can be more energy-efficient than their high voltage counterparts in certain applications, leading to reduced power losses. They also offer better voltage stability for sensitive equipment. Additionally, low voltage transformers are often more compact, easier to install and maintain, and can be customized for specific applications, making them versatile solutions for various power needs.

Key Advantages of Low Voltage Transformers

Let’s explore the main benefits:

- Enhanced Safety

- Improved Energy Efficiency

- Better Voltage Regulation

- Electrical Isolation

- Compact Size and Easy Installation

Enhanced Safety

Reducing electrical hazards:

- Lower voltage means reduced risk of electric shock

- Safer for end-user interaction with powered devices

- Compliance with safety standards for various applications

I recently managed a project upgrading a school’s electrical system. By implementing low voltage transformers for classroom equipment and lighting, we significantly improved the overall safety for students and staff.

Improved Energy Efficiency

Optimizing power usage:

- Reduced power losses in short-distance distribution

- Better efficiency in low-power applications

- Ability to match transformer size to actual load requirements

During an energy audit for a small manufacturing plant, we found that replacing their oversized transformers with properly sized low voltage units resulted in a 5% reduction in overall energy consumption.

Better Voltage Regulation

Maintaining stable power:

- Improved voltage stability for sensitive equipment

- Ability to compensate for voltage fluctuations

- Critical for precision instruments and control systems

Here’s a comparison of voltage regulation in different scenarios:

| Scenario | Without LV Transformer | With LV Transformer |

|---|---|---|

| Voltage Fluctuation | ±10% | ±2% |

| Load Changes | Significant impact | Minimal impact |

| Long Cable Runs | Voltage drop issues | Compensated |

Electrical Isolation

Protecting circuits and equipment:

- Separation of primary and secondary circuits

- Reduction of electrical noise and interference

- Critical for medical and sensitive electronic equipment

Compact Size and Easy Installation

Practical benefits:

- Smaller footprint compared to high voltage equipment

- Easier to integrate into existing systems

- Simpler maintenance and replacement procedures

Key advantages of using low voltage transformers:

- They significantly enhance electrical safety in various applications

- Can lead to improved energy efficiency in certain scenarios

- Provide better voltage regulation for sensitive equipment

- Offer crucial electrical isolation for many applications

- Their compact size and ease of installation provide practical benefits

In my experience, these advantages often make low voltage transformers the preferred choice for many projects. I recall a renovation project for an old industrial building being converted into a mixed-use space. By choosing low voltage transformers for different sections of the building, we were able to create separate, safe electrical systems for the residential, commercial, and light industrial areas. This not only improved safety but also allowed for more efficient energy management across the diverse uses of the space.

For instance, in a recent project for a high-tech research facility, we implemented a network of low voltage transformers to power various sensitive instruments. The electrical isolation and superior voltage regulation provided by these transformers were crucial in ensuring accurate measurements and reliable operation of the facility’s advanced equipment. This showcased how the advantages of low voltage transformers can be critical in specialized, high-precision environments.

As we move on to discuss how to choose the right low voltage transformer for your project, keep these advantages in mind. They play a crucial role in decision-making processes for electrical system design and management, especially when balancing safety, efficiency, and performance requirements.

Choosing the Right Low Voltage Transformer for Your Project?

Are you feeling overwhelmed by the options when it comes to selecting a low voltage transformer for your project? You’re not alone. Many engineers and project managers struggle with this decision. But how can you ensure you’re making the best choice for your specific needs?

Choosing the right low voltage transformer involves considering several key factors: voltage requirements, power capacity needs, environmental conditions, efficiency ratings, and specific application demands. Start by determining the exact input and output voltages required. Then, calculate the total power load the transformer needs to handle. Consider the installation environment, including temperature, humidity, and potential exposure to contaminants. Look at efficiency ratings, especially for continuous operation. Finally, factor in any special requirements like regulatory compliance or specific features needed for your application.

Key Factors in Transformer Selection

Let’s break down the main considerations:

- Voltage Requirements

- Power Capacity

- Environmental Factors

- Efficiency and Performance

- Special Features and Compliance

Voltage Requirements

Matching transformer to your system:

- Determine exact input voltage available

- Specify required output voltage(s)

- Consider voltage regulation needs

I recently worked on a project where the client initially requested a 240V to 120V transformer. After a thorough analysis of their equipment, we realized some devices required 24V DC. This led us to select a multi-tap transformer with additional rectification, ensuring all voltage needs were met efficiently.

Power Capacity

Ensuring adequate power supply:

- Calculate total connected load

- Factor in potential future expansion

- Consider peak load vs. continuous operation

During a recent industrial automation upgrade, we carefully assessed both current and projected power needs. By choosing a transformer with 20% extra capacity, we provided room for future expansion without significant oversizing.

Environmental Factors

Adapting to installation conditions:

- Temperature range at the installation site

- Humidity and potential for condensation

- Presence of dust, chemicals, or other contaminants

Here’s a quick guide for environmental considerations:

| Environment | Recommended Features | Example |

|---|---|---|

| Indoor, Clean | Standard enclosure | Office building |

| Outdoor | Weather-resistant, IP65+ | Street lighting |

| High Humidity | Sealed, anti-corrosion | Coastal installations |

| Dusty | Filtered ventilation | Factory floor |

Efficiency and Performance

Optimizing operational costs:

- Check efficiency ratings, especially for continuous operation

- Consider no-load losses for intermittent use applications

- Evaluate temperature rise and cooling methods

Special Features and Compliance

Meeting specific project requirements:

- Regulatory compliance (e.g., UL, CE, CSA)

- Special features (e.g., taps, electrostatic shielding)

- Noise level requirements for sensitive environments

Key points for choosing the right low voltage transformer:

- Accurately determine voltage requirements for both input and output

- Calculate power needs carefully, including future expansion

- Consider the environmental conditions at the installation site

- Evaluate efficiency and performance metrics for long-term operation

- Ensure compliance with relevant standards and any special feature needs

In my experience, the process of selecting the right transformer often involves balancing multiple factors. I recall a project for a data center where we needed to power both IT equipment and cooling systems. The challenge was to find transformers that could handle the high continuous load efficiently while also providing the clean power necessary for sensitive computing equipment. We ended up choosing high-efficiency, K-rated transformers with electrostatic shielding to meet both the power demand and power quality requirements.

For example, in a recent renewable energy project, we faced the challenge of integrating solar inverters with the local grid. The selection process involved finding transformers that could handle the variable output from the solar panels, meet strict grid connection standards, and operate efficiently in an outdoor environment. This required careful consideration of voltage regulation capabilities, efficiency across different load levels, and robust environmental protection.

Remember, choosing the right low voltage transformer is crucial for the safety, efficiency, and reliability of your electrical system. Take the time to thoroughly assess your needs and consult with experts if necessary. The right choice will not only meet your current requirements but also provide flexibility for future needs and contribute to the overall success of your project.

Conclusion

Low voltage transformers are essential components in modern electrical systems, offering safe and efficient power distribution for a wide range of applications. From lighting and consumer electronics to industrial control systems and renewable energy, these transformers play a crucial role in our daily lives and various industries. Understanding their function, specifications, and advantages is key to making informed decisions in electrical system design and management.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Are you struggling to understand the world of standard transformers? You’re not alone. Many engineers and project managers find themselves confused by the variety of transformer types and their applications. But what if you had a clear, comprehensive guide that breaks down everything you need to know about standard transformers?

A standard transformer is a pre-designed electrical device used to transfer electrical energy between circuits at defined voltage and power levels. Unlike custom transformers, standard models follow widely accepted industry specifications, making them ideal for fast deployment, mass production, and easy integration into power systems. These transformers are commonly available in fixed ratings—such as 100kVA, 250kVA, and 1000kVA—and are used across residential, industrial, and utility-scale applications.

In this comprehensive guide, I’ll walk you through the world of standard transformers. We’ll explore what they are, the common types you’ll encounter, typical ratings and voltage classes, and their applications in power systems. Whether you’re a seasoned engineer or new to the field, this article will provide valuable insights to help you make informed decisions about standard transformer selection and use.

What Is a Standard Transformer?

Have you ever wondered why some transformers are called "standard" while others are "custom"? The answer lies in their design and manufacturing process. But what exactly makes a transformer "standard," and why is this distinction important in the power industry?

A standard transformer is a mass-produced electrical device designed to meet common power distribution needs. These transformers are built to predetermined specifications, including standardized voltage ratings, power capacities, and physical dimensions. Unlike custom transformers, standard models are not tailored for specific applications but are designed to meet a wide range of general power transformation requirements. They are widely used in residential, commercial, and industrial settings due to their reliability, cost-effectiveness, and quick availability.

Understanding Standard Transformers

Let’s break down the key aspects of standard transformers:

- Definition and Characteristics

- Design Standardization

- Manufacturing Process

- Advantages Over Custom Units

- Common Applications

Definition and Characteristics

A standard transformer is:

- Designed for general-purpose use

- Built to predetermined specifications

- Available in fixed ratings and sizes

I recently worked on a project upgrading a residential area’s power distribution. We chose standard transformers because their pre-defined ratings perfectly matched the neighborhood’s power needs without requiring custom designs.

Design Standardization

Key aspects of standardization:

- Voltage ratings follow industry norms (e.g., 480V, 4160V, 13.8kV)

- Power ratings in standard increments (e.g., 100kVA, 500kVA, 1000kVA)

- Cooling methods and insulation types are standardized

During a recent factory tour, I observed how standardization allows for efficient production lines, with multiple units of the same design being manufactured simultaneously.

Manufacturing Process

Mass production benefits:

- Economies of scale reduce costs

- Consistent quality control

- Faster production and delivery times

Here’s a simplified view of the standard transformer manufacturing process:

| Stage | Description | Benefit of Standardization |

|---|---|---|

| Design | Use of pre-approved designs | Reduced engineering time |

| Core Assembly | Automated stacking of laminations | Consistent core quality |

| Winding | Machine-wound coils | Uniform winding tension |

| Assembly | Standardized assembly procedures | Consistent build quality |

| Testing | Automated test sequences | Reliable performance verification |

Advantages Over Custom Units

Benefits of choosing standard transformers:

- Lower cost due to mass production

- Shorter lead times

- Easier maintenance and part replacement

- Widely available technical support

Common Applications

Where you’ll find standard transformers:

- Residential power distribution

- Commercial buildings

- Industrial facilities

- Utility substations

Key points about standard transformers:

- They are designed for general-purpose use in common applications

- Standardization allows for efficient manufacturing and lower costs

- Fixed ratings and sizes cover most typical power needs

- They offer quicker delivery and easier maintenance than custom units

- Widely used across various sectors due to their versatility

In my experience, the value of standard transformers becomes particularly evident in large-scale projects. I recall a case where we needed to upgrade the power distribution for an entire industrial park. By using standard transformers, we were able to quickly source and install units that met the diverse needs of different businesses within the park, all while keeping costs manageable and maintenance simple.

As we move on to discuss common types of standard transformers, keep in mind that these standardized designs form the backbone of our power distribution systems. Understanding their characteristics and applications is crucial for anyone involved in electrical engineering or power system management.

Common Types of Standard Transformers?

Have you ever wondered about the different types of transformers you see in various electrical installations? From utility poles to industrial complexes, transformers come in various shapes and sizes. But what are the most common types of standard transformers, and how do they differ in their applications?

Common types of standard transformers include distribution transformers, power transformers, isolation transformers, and instrument transformers. Distribution transformers are used to step down voltage for final power distribution. Power transformers handle high voltages in transmission systems. Isolation transformers provide electrical separation between circuits. Instrument transformers, including current (CT) and potential (PT) transformers, are used for measurement and protection in electrical systems. Each type serves specific functions in power distribution and control.

Exploring Standard Transformer Types

Let’s examine the main types of standard transformers:

- Distribution Transformers

- Power Transformers

- Isolation Transformers

- Instrument Transformers

- Auto-Transformers

Distribution Transformers

The workhorses of local power delivery:

- Step down voltage for end-user consumption

- Typically range from 5 kVA to 5000 kVA

- Common in residential and commercial areas

I recently oversaw the installation of several pad-mounted distribution transformers in a new suburban development. These units efficiently stepped down the 13.8kV primary voltage to 240/120V for residential use.

Power Transformers

Handling high voltages in transmission:

- Used in substations and power plants

- Typically above 5 MVA capacity

- Handle voltages from 69 kV to 765 kV

During a recent substation upgrade project, we installed a 100 MVA power transformer to step down transmission voltage from 230 kV to 69 kV, showcasing the critical role these units play in power transmission.

Isolation Transformers

Providing electrical separation:

- Used for noise reduction and safety

- Common in sensitive electronic equipment

- Typically 1:1 voltage ratio

Here’s a quick comparison of transformer types:

| Type | Primary Use | Typical Capacity Range | Key Feature |

|---|---|---|---|

| Distribution | Local power delivery | 5 kVA – 5000 kVA | Voltage step-down |

| Power | Transmission systems | > 5 MVA | High voltage handling |

| Isolation | Circuit separation | 1 VA – 1000 kVA | Noise reduction |

| Instrument (CT/PT) | Measurement & Protection | N/A | High accuracy |

Instrument Transformers

Precision measurement and protection:

- Current Transformers (CT): Measure high currents

- Potential Transformers (PT): Measure high voltages

- Used in metering and protective relaying

Auto-Transformers

Efficient voltage adjustment:

- Single winding shared by primary and secondary

- Used for small voltage changes

- Common in voltage regulators

Key points about common standard transformer types:

- Distribution transformers are crucial for local power delivery

- Power transformers handle high voltages in transmission systems

- Isolation transformers provide electrical separation for safety and noise reduction

- Instrument transformers are essential for accurate measurement and protection

- Auto-transformers offer efficient solutions for small voltage adjustments

In my experience, understanding these different types of standard transformers is crucial for effective power system design. I recall a project where we had to integrate a new industrial facility into an existing power grid. By carefully selecting the right combination of power and distribution transformers, we were able to efficiently step down the incoming high voltage to various levels required by different parts of the facility.

For example, in a recent smart grid implementation project, we used a combination of standard power transformers for the main substation and multiple distribution transformers equipped with smart monitoring capabilities throughout the network. This approach allowed for efficient power distribution while providing real-time data for grid management.

As we move on to discuss typical ratings and voltage classes, keep these transformer types in mind. Understanding their characteristics and applications will help you appreciate how their ratings are determined and applied in various power system scenarios.

Typical Ratings and Voltage Classes?

Are you finding it challenging to navigate the world of transformer ratings and voltage classes? You’re not alone. Many professionals in the power industry struggle to understand the standardized ratings and how they apply to different applications. But what exactly are these ratings, and how do they impact transformer selection and use?

Standard transformers come in a range of typical ratings and voltage classes to meet various power distribution needs. Common power ratings include 100 kVA, 250 kVA, 500 kVA, 1000 kVA, and 2500 kVA. Voltage classes typically range from low voltage (below 1 kV) to medium voltage (1 kV to 35 kV) for distribution transformers, and high voltage (above 35 kV) for power transformers. These standardized ratings ensure compatibility, ease of replacement, and efficient power system design across different applications and regions.

Understanding Transformer Ratings and Voltage Classes

Let’s break down the key aspects:

- Power Ratings (kVA)

- Voltage Classes

- Insulation Levels

- Temperature Rise Ratings

- Regional Standards and Differences

Power Ratings (kVA)

Common capacity ratings:

- Distribution transformers: 25, 50, 100, 250, 500, 1000 kVA

- Power transformers: 5, 10, 20, 40 MVA and above

I recently worked on a project where we needed to upgrade a commercial building’s power supply. We chose a 500 kVA transformer, which provided ample capacity for current needs and future expansion.

Voltage Classes

Standard voltage levels:

- Low Voltage (LV): Below 1 kV (e.g., 240/120V, 480V)

- Medium Voltage (MV): 1 kV to 35 kV (e.g., 4.16 kV, 13.8 kV)

- High Voltage (HV): Above 35 kV (e.g., 69 kV, 138 kV, 230 kV)

During a recent grid modernization project, we had to carefully select transformers that could handle the transition from 69 kV transmission lines to 13.8 kV distribution circuits, and finally to 480V for industrial use.

Insulation Levels

Standardized insulation classes:

- Class A: 105°C

- Class B: 130°C

- Class F: 155°C

- Class H: 180°C

Here’s a quick overview of voltage classes and typical applications:

| Voltage Class | Range | Common Applications |

|---|---|---|

| Low Voltage | < 1 kV | Residential, Small Commercial |

| Medium Voltage | 1 kV – 35 kV | Industrial, Large Commercial |

| High Voltage | > 35 kV | Transmission, Substations |

Temperature Rise Ratings

Standard temperature rise ratings:

- 55°C rise (65°C average winding temperature rise)

- 65°C rise (80°C average winding temperature rise)

- 80°C rise (95°C average winding temperature rise)

Regional Standards and Differences

Variations in global standards:

- ANSI/IEEE (North America): 60 Hz, emphasis on 480V

- IEC (International): 50 Hz, emphasis on 400V

- Specific country standards (e.g., GB in China, IS in India)

Key points about transformer ratings and voltage classes:

- Power ratings are standardized for easy selection and replacement

- Voltage classes correspond to different levels of power distribution

- Insulation classes determine temperature handling capabilities

- Temperature rise ratings affect efficiency and lifespan

- Regional standards can impact specific ratings and designs

In my experience, understanding these ratings is crucial for effective transformer selection. I recall a project where we were upgrading a manufacturing facility’s power system. By carefully analyzing the load requirements and future growth plans, we were able to select a 2500 kVA, 13.8 kV/480V transformer with a 65°C rise rating. This choice not only met the current power needs but also provided headroom for future expansion while ensuring efficient operation in the facility’s demanding environment.

For example, in a recent international project, we had to navigate the differences between ANSI and IEC standards. We chose transformers that could handle both 50 Hz and 60 Hz frequencies, with voltage taps that allowed for adjustment between 400V and 480V on the secondary side. This flexibility ensured that the transformers could be used effectively across different global locations.

As we move on to discuss applications of standard transformers in power systems, keep these ratings and classes in mind. They play a crucial role in determining which transformers are suitable for specific applications and how they integrate into the broader power distribution network.

Applications of Standard Transformers in Power Systems?

Have you ever wondered how electricity gets from power plants to your home or office? Standard transformers play a crucial role in this journey, but where exactly are they used, and why are they so important in our power systems? Understanding the applications of standard transformers can help you appreciate the complexity of our electrical infrastructure.

Standard transformers are widely used across various sectors of power systems. In utility applications, they step down high transmission voltages to distribution levels. In industrial settings, they provide appropriate voltages for machinery and equipment. Commercial and residential areas use them for final voltage reduction for end-user consumption. Renewable energy systems, like solar and wind farms, use standard transformers to integrate power into the grid. These transformers are essential for maintaining voltage levels, isolating circuits, and ensuring efficient power distribution throughout the electrical network.

Exploring Applications of Standard Transformers

Let’s examine the main areas where standard transformers are used:

- Utility Power Distribution

- Industrial Applications

- Commercial and Residential Use

- Renewable Energy Integration

- Special Applications

Utility Power Distribution

The backbone of the power grid:

- Substation transformers for voltage step-down

- Pole-mounted transformers in residential areas

- Pad-mounted transformers in urban settings

I recently worked on a project upgrading a suburban power network. We installed several 500 kVA pad-mounted transformers to step down 13.8 kV to 240/120V, significantly improving the reliability of power delivery to homes.

Industrial Applications

Powering manufacturing and processing:

- Large power transformers for factory main supplies

- Distribution transformers for various voltage levels within facilities

- Specialized transformers for industrial processes (e.g., arc furnaces)

During a recent factory automation project, we used a combination of 2500 kVA and 1000 kVA transformers to efficiently distribute power to different production lines, each with unique voltage requirements.

Commercial and Residential Use

Bringing power to everyday life:

- Small to medium-sized transformers in office buildings

- Residential distribution transformers

- Lighting transformers for outdoor and public spaces

Here’s a quick overview of transformer applications in different sectors:

| Sector | Typical Transformer Types | Common Ratings |

|---|---|---|

| Utility | Power, Distribution | 5 MVA – 100 MVA |

| Industrial | Power, Distribution | 500 kVA – 10 MVA |

| Commercial | Distribution | 75 kVA – 2500 kVA |

| Residential | Distribution | 25 kVA – 167 kVA |

Renewable Energy Integration

Supporting green power:

- Step-up transformers at wind farms

- Solar inverter transformers

- Grid connection transformers for renewable plants

Special Applications

Unique uses of standard transformers:

- Isolation transformers in sensitive electronic equipment

- Voltage regulators in long distribution lines

- Mobile substations for temporary power needs

Key points about standard transformer applications:

- They are crucial in stepping down voltages from transmission to distribution levels

- Industrial applications require a range of transformer sizes and types

- Commercial and residential use typically involves smaller distribution transformers

- Renewable energy systems rely on transformers for grid integration

- Special applications showcase the versatility of standard transformers

In my experience, the versatility of standard transformers becomes particularly evident in complex projects. I recall a case where we were designing the power distribution system for a new mixed-use development that included residential, commercial, and light industrial areas. By carefully selecting a range of standard transformers – from large substation units to smaller pad-mounted distributors – we were able to create an efficient, reliable power network that met the diverse needs of all users.

For example, in a recent smart city project, we implemented a hierarchical transformer system. We used large standard power transformers at the main substations, medium-sized units for district distribution, and smaller transformers with smart monitoring capabilities at the neighborhood level. This approach not only ensured efficient power distribution but also allowed for better load management and fault detection across the entire city grid.

As we move on to discuss the advantages of using standard transformers, keep in mind how their widespread applications contribute to their benefits in terms of cost, availability, and ease of maintenance.

Advantages of Using Standard Transformers?

Have you ever wondered why standard transformers are so widely used in power systems? The answer lies in their numerous advantages. But what specific benefits do these transformers offer, and how do they impact project timelines, costs, and overall system reliability?

Standard transformers offer several key advantages including cost-effectiveness, quick availability, ease of replacement, and simplified maintenance. Their mass production leads to lower unit costs and shorter lead times compared to custom units. Standardized designs ensure compatibility across different manufacturers, making replacements and upgrades easier. Additionally, standard transformers often come with extensive performance data and are compliant with widely recognized industry standards, simplifying the design and approval processes for power system projects.

Key Advantages of Standard Transformers

Let’s explore the main benefits:

- Cost-Effectiveness

- Quick Availability and Shorter Lead Times

- Ease of Replacement and Maintenance

- Reliability and Performance Data

- Compliance with Industry Standards

Cost-Effectiveness

Economical benefits of standardization:

- Lower manufacturing costs due to mass production

- Reduced engineering and design costs

- Economies of scale in material procurement

I recently managed a project upgrading a large industrial complex’s power distribution system. By opting for standard transformers, we achieved a 20% cost saving compared to custom units, without compromising on performance.

Quick Availability and Shorter Lead Times

Advantages in procurement:

- Often available from stock or with short lead times

- Faster project completion and commissioning

- Reduced downtime in case of replacements

During an emergency replacement at a critical facility, we were able to source and install a standard 1000 kVA transformer within 48 hours, minimizing disruption to operations.

Ease of Replacement and Maintenance

Simplified logistics and operations:

- Interchangeability between different manufacturers

- Readily available spare parts

- Technicians familiar with standard designs

Here’s a comparison of maintenance aspects:

| Aspect | Standard Transformers | Custom Transformers |

|---|---|---|

| Spare Parts | Readily available | Often require special orders |

| Technician Familiarity | High | May require specialized training |

| Replacement Time | Typically shorter | Can be significantly longer |

| Documentation | Standardized, easily accessible | Often unique to each unit |

Reliability and Performance Data

Proven track record:

- Extensive field data on performance and reliability

- Well-understood failure modes and maintenance needs

- Easier to predict lifecycle costs

Compliance with Industry Standards

Meeting regulatory requirements:

- Designed to comply with widely recognized standards (e.g., IEEE, IEC)

- Simplifies approval processes in different jurisdictions

- Ensures compatibility with existing infrastructure

Key advantages of using standard transformers:

- They offer significant cost savings through mass production

- Quick availability reduces project timelines and downtime

- Standardization simplifies replacement and maintenance procedures

- Extensive performance data aids in system design and planning

- Compliance with industry standards ensures broad applicability

In my experience, these advantages often make standard transformers the go-to choice for many projects. I recall a large-scale grid modernization project where we needed to replace hundreds of aging transformers across a wide urban area. By choosing standard units, we were able to streamline the procurement process, ensure consistent quality across all installations, and significantly reduce the overall project timeline.

For instance, in a recent renewable energy project involving multiple solar farms, we used standard transformers for both the inverter stations and the grid connection points. This decision not only reduced costs but also allowed for a modular approach to the farm’s design, making future expansions much easier to plan and implement.

As we move on to compare standard and custom transformers, keep these advantages in mind. They play a crucial role in decision-making processes for power system design and management, especially when balancing performance needs with budget and time constraints.

Standard vs Custom Transformers: Which One Do You Need?

Are you torn between choosing a standard transformer or investing in a custom solution? This decision can significantly impact your project’s success, efficiency, and long-term costs. But how do you know which option is right for your specific needs?

Choosing between standard and custom transformers depends on your specific requirements, budget, and timeline. Standard transformers are typically less expensive, readily available, and suitable for common applications. They’re ideal for projects with typical voltage and power requirements, standard environmental conditions, and where quick deployment is crucial. Custom transformers, while more costly and time-consuming to produce, offer optimized performance for unique or demanding applications. They’re necessary when standard units can’t meet specific voltage, size, environmental, or regulatory requirements.

Comparing Standard and Custom Transformers

Let’s break down the key factors to consider:

- Application Requirements

- Cost Considerations

- Lead Time and Availability

- Performance and Efficiency

- Flexibility and Future-Proofing

Application Requirements

Matching transformer to needs:

- Standard: Suitable for common voltage and power ratings

- Custom: Necessary for unique specifications or environments

I recently worked on a project for a data center where we initially considered custom transformers. However, after careful analysis, we found that standard units met all our requirements, saving both time and money.

Cost Considerations

Balancing budget and performance:

- Standard: Lower upfront costs due to mass production

- Custom: Higher initial investment, potentially lower long-term costs for specific applications

During a recent industrial upgrade, we found that while the custom transformer cost 40% more upfront, its improved efficiency for the specific load profile resulted in a positive ROI within 3 years.

Lead Time and Availability

Timing your project needs:

- Standard: Readily available, shorter lead times

- Custom: Longer production time, typically 12-24 weeks or more

Here’s a simplified comparison of lead times and costs:

| Aspect | Standard Transformers | Custom Transformers |

|---|---|---|

| Lead Time | 1-8 weeks | 12-24+ weeks |

| Initial Cost | Lower | Higher |

| Availability | Often in stock | Built to order |

| Design Flexibility | Limited | High |

Performance and Efficiency

Meeting specific operational needs:

- Standard: Designed for average conditions, may have compromises

- Custom: Optimized for specific operating conditions, potentially higher efficiency

Flexibility and Future-Proofing

Adapting to changing needs:

- Standard: Limited options, may require future replacements

- Custom: Can be designed with future expansion in mind

Key points in choosing between standard and custom transformers:

- Standard transformers are ideal for common, straightforward applications

- Custom units are necessary for unique or demanding requirements

- Cost and lead time heavily favor standard transformers

- Performance optimization may justify custom designs in some cases

- Long-term flexibility can be a deciding factor for growing operations

In my experience, the choice between standard and custom transformers often comes down to a careful analysis of both immediate needs and long-term goals. I recall a project for a specialized manufacturing facility where we initially leaned towards custom transformers due to some unique voltage requirements. However, after consulting with several manufacturers, we discovered that a combination of standard transformers with minor modifications could meet our needs at a fraction of the cost and lead time of fully custom units.

For example, in a recent renewable energy project, we faced the challenge of integrating a large wind farm into an existing grid with fluctuating voltage levels. While custom transformers seemed necessary at first, we ultimately designed a solution using standard transformers with advanced on-load tap changers. This approach provided the necessary voltage regulation while maintaining the benefits of standard units in terms of cost and availability.

Remember, the choice between standard and custom transformers isn’t always clear-cut. It requires a thorough understanding of your current needs, future plans, and the specific constraints of your project. Careful consideration of these factors, along with consultation with experienced professionals, will help ensure you make the best decision for your unique situation.

Conclusion

Standard transformers are essential components in power systems, offering reliability, cost-effectiveness, and quick availability for a wide range of applications. They come in various types and ratings to meet common power distribution needs across utility, industrial, commercial, and residential sectors. While custom transformers have their place in specialized applications, standard units are often the go-to choice for efficient and economical power system design and management.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Are you struggling with power issues that standard transformers can’t solve? You’re not alone. Many industries face unique challenges that off-the-shelf solutions simply can’t address. But what if there was a way to get a transformer perfectly tailored to your specific needs?

Custom transformers are power transformers specifically designed to meet unique voltage, load, or environmental requirements that standard models cannot fulfill. They are tailored solutions for industries with special power needs, such as unusual voltages, extreme environments, or specific safety standards. Custom transformers can improve efficiency, safety, and performance in applications where standard units fall short, making them invaluable for specialized industrial, medical, and technological applications.

In this comprehensive guide, I’ll walk you through the world of custom transformers. We’ll explore what they are, when you need them, and how they can dramatically improve your power system’s performance and safety. Whether you’re an engineer facing a unique power challenge or a project manager looking for the best solution, this article will provide valuable insights to help you make informed decisions about custom transformer solutions.

What Is a Custom Transformer?

Have you ever found yourself in a situation where standard transformers just don’t cut it? Maybe you’re dealing with an unusual voltage requirement or a harsh environment that off-the-shelf units can’t handle. This is where custom transformers come into play. But what exactly is a custom transformer, and how does it differ from standard models?

A custom transformer is a power transformer specifically designed to meet unique voltage, load, or environmental requirements that standard models cannot fulfill. These transformers are tailored to the exact specifications of a particular application, offering optimized performance, size, efficiency, and safety features. Custom transformers can vary in voltage ratings, physical dimensions, cooling methods, and even incorporate special materials to withstand extreme conditions.

Understanding Custom Transformers

Let’s break down the key aspects of custom transformers:

- Definition and Purpose

- Key Customizable Features

- Design Process Overview

- Advantages Over Standard Models

- Common Applications

Definition and Purpose

A custom transformer is:

- Designed for specific application requirements

- Built to order, not mass-produced

- Optimized for unique operational conditions

I recently worked on a project for a specialized manufacturing facility where we needed a transformer that could handle both 50Hz and 60Hz frequencies. This level of flexibility isn’t available in standard models, showcasing the need for custom solutions.

Key Customizable Features

Common areas of customization include:

- Voltage ratings and taps

- Physical dimensions and form factor

- Cooling systems

- Insulation materials

- Environmental protection (e.g., for marine or explosive atmospheres)

During a recent consultation for a data center in the Middle East, we designed a custom transformer with enhanced cooling capabilities to withstand the extreme desert heat, a feature not typically found in standard units.

Design Process Overview

The custom transformer design process typically involves:

- Detailed client requirement analysis

- Electrical and mechanical design

- Material selection

- Prototype development and testing

- Final production and quality assurance

Here’s a simplified view of the custom transformer design process:

| Stage | Description | Key Considerations |

|---|---|---|

| Requirements Gathering | Understand client needs | Voltage, load, environment |

| Design | Electrical and mechanical planning | Efficiency, size, safety |

| Prototyping | Build and test initial model | Performance verification |

| Production | Manufacture final product | Quality control, standards compliance |

Advantages Over Standard Models

Benefits of custom transformers:

- Optimized performance for specific applications

- Improved efficiency and reduced losses

- Better fit for space constraints or unusual environments

- Compliance with specific industry standards or regulations

Common Applications

Industries often requiring custom transformers:

- Renewable energy (wind, solar)

- Oil and gas

- Marine and offshore

- Medical equipment

- Specialized manufacturing

Key points about custom transformers:

- They are designed for specific, unique requirements

- Customization can cover various aspects from electrical to physical features

- The design process is collaborative and iterative

- They offer advantages in performance and efficiency for specialized applications

- Custom transformers are common in industries with non-standard power needs

In my experience, the value of custom transformers becomes particularly evident in challenging projects. I recall a case where a client in the aerospace industry needed a transformer that could withstand extreme vibration and altitude changes. By working closely with their engineers, we developed a custom solution that not only met their unique requirements but also improved the overall reliability of their system.

As we move on to discuss when you might need a custom transformer, keep in mind that these tailored solutions are about more than just unusual specifications. They’re about optimizing your entire power system for peak performance, efficiency, and reliability in your specific operating conditions.

When Do You Need a Custom Transformer?

Have you ever found yourself in a situation where standard transformers just don’t seem to fit your project’s requirements? You’re not alone. Many engineers and project managers face scenarios where off-the-shelf solutions fall short. But how do you know when it’s time to consider a custom transformer?

You need a custom transformer when your power requirements go beyond what standard models can offer. This typically includes scenarios with unusual voltage or frequency needs, extreme environmental conditions, strict space constraints, or specific industry regulations. Custom transformers are also necessary when you need to optimize efficiency for unique load profiles, require special safety features, or need to integrate with non-standard systems. Essentially, if your power needs are unique, a custom transformer might be your best solution.

Scenarios Requiring Custom Transformers

Let’s explore common situations where custom transformers are necessary:

- Unusual Voltage or Frequency Requirements

- Extreme Environmental Conditions

- Space Constraints

- Specific Industry Regulations

- Unique Load Profiles

Unusual Voltage or Frequency Requirements

When standard doesn’t fit:

- Non-standard voltage levels

- Multiple input or output voltages

- Frequency conversion needs (e.g., 50Hz to 60Hz)

I recently worked on a project for an international manufacturing facility that needed to operate machinery from different global regions. We designed a custom transformer capable of handling multiple input voltages and frequencies, ensuring seamless operation regardless of the equipment’s origin.

Extreme Environmental Conditions

Adapting to challenging environments:

- High temperature or humidity

- Corrosive atmospheres

- High altitude operations

- Underwater or marine applications

During a recent offshore wind farm project, we developed custom transformers designed to withstand saltwater spray, high winds, and constant vibration – conditions that would quickly deteriorate standard units.

Space Constraints

When size matters:

- Compact designs for limited spaces

- Unusual form factors to fit specific enclosures

- Integration with existing equipment

Here’s a quick overview of how custom transformers can address space issues:

| Constraint | Custom Solution | Benefit |

|---|---|---|

| Height Limit | Low-profile design | Fits in restricted vertical spaces |

| Narrow Spaces | Elongated form factor | Utilizes available horizontal space |

| Irregular Shapes | Customized enclosure | Integrates with non-standard equipment |

Specific Industry Regulations

Meeting stringent standards:

- Medical equipment safety requirements

- Military and aerospace specifications

- Nuclear power plant regulations

Unique Load Profiles

Optimizing for specific usage patterns:

- Pulsed power applications

- Highly variable loads

- Energy-efficient designs for specific duty cycles

Key indicators that you need a custom transformer:

- Your voltage or frequency requirements don’t match standard offerings

- Your operating environment is extreme or unusual

- You have strict space limitations that standard units can’t meet

- You need to comply with specific industry regulations

- Your load profile is unique and requires optimized efficiency

In my experience, the need for custom transformers often becomes apparent when standard solutions create inefficiencies or compromises. I recall a project for a data center where the client initially tried to use multiple standard transformers to meet their power needs. This approach led to increased complexity, higher losses, and maintenance issues. By switching to a custom-designed transformer, we were able to simplify their system, improve efficiency, and reduce long-term operational costs.

For example, in a recent renewable energy project, we faced the challenge of integrating a large solar farm with an existing grid that had fluctuating voltage levels. A custom transformer with advanced voltage regulation capabilities was the key to ensuring stable power output and maximizing energy harvesting efficiency.

As we move on to discuss why custom transformers can improve performance and safety, keep these scenarios in mind. Understanding when you need a custom solution is the first step towards optimizing your power system for your specific needs and operating conditions.

Why a Custom Transformer Can Improve Performance and Safety?

Have you ever wondered why some power systems seem to operate more efficiently and safely than others? The secret often lies in the use of custom transformers. But how exactly do these tailored solutions enhance performance and safety in ways that standard transformers can’t?

Custom transformers can significantly improve performance and safety by optimizing design for specific operational requirements. They offer enhanced efficiency by minimizing losses for unique load profiles, improved thermal management for challenging environments, and tailored safety features for specific industry standards. Custom transformers can also provide better voltage regulation, reduced harmonics, and improved overload capacity. These benefits lead to increased reliability, longer equipment lifespan, and often result in lower total cost of ownership despite higher initial investment.

Key Improvements Offered by Custom Transformers

Let’s explore the main areas where custom transformers excel:

- Enhanced Efficiency

- Improved Thermal Management

- Tailored Safety Features

- Better Voltage Regulation

- Reduced Harmonics and EMI

Enhanced Efficiency

Optimizing for specific needs:

- Designed for actual load profile, not generic scenarios

- Reduced core and copper losses

- Optimized transformer size and weight

I recently worked on a project for a renewable energy facility where we designed a custom transformer that improved overall system efficiency by 2.5%. This seemingly small improvement translated to significant energy savings over the system’s lifetime.

Improved Thermal Management

Adapting to environmental challenges:

- Custom cooling systems for extreme temperatures

- Specialized insulation for high-humidity environments

- Optimized heat dissipation in confined spaces

During a recent data center upgrade, we implemented a custom transformer with advanced liquid cooling, allowing for higher power density and improved reliability in the facility’s hot-aisle containment system.

Tailored Safety Features

Meeting specific safety standards:

- Customized protection against overloads and short circuits

- Enhanced fire safety features for sensitive environments

- Specialized designs for hazardous locations

Here’s a comparison of safety features in standard vs custom transformers:

| Safety Aspect | Standard Transformer | Custom Transformer |

|---|---|---|

| Overload Protection | Generic settings | Tailored to specific load profile |

| Fire Safety | Basic compliance | Enhanced features for specific environments |

| EMI Shielding | Standard levels | Optimized for sensitive equipment |

Better Voltage Regulation

Maintaining stable output:

- Designed for specific input voltage fluctuations

- Improved tap changing mechanisms

- Optimized for dynamic load changes

Reduced Harmonics and EMI

Addressing power quality issues:

- Custom designs to mitigate harmonic distortion

- Enhanced EMI shielding for sensitive environments

- Integration of harmonic mitigation techniques

Key benefits of custom transformers for performance and safety:

- Efficiency optimized for actual operating conditions

- Thermal management tailored to specific environments

- Safety features designed for particular industry needs

- Improved voltage stability under varying conditions

- Enhanced power quality through reduced harmonics and EMI

In my experience, the performance and safety improvements of custom transformers often lead to significant long-term benefits. I recall a project for a pharmaceutical manufacturing facility where we replaced a standard transformer with a custom unit designed to handle their specific load profile and stringent cleanliness requirements. The result was not only improved energy efficiency but also enhanced production reliability due to better voltage stability and reduced risk of contamination from transformer failures.

For example, in a recent project for an offshore oil platform, we designed a custom transformer that could withstand the corrosive sea air, extreme temperatures, and constant vibration. This tailored solution not only improved the platform’s operational efficiency but also significantly enhanced safety by reducing the risk of electrical fires in this hazardous environment.

As we move on to discuss how custom transformers are designed and manufactured, keep in mind these performance and safety benefits. Understanding the potential improvements can help you better appreciate the value of the custom design process and its impact on your specific application.

How Custom Transformers Are Designed and Manufactured?

Have you ever wondered about the process behind creating a transformer that perfectly fits your unique needs? The journey from concept to final product in custom transformer manufacturing is a fascinating blend of engineering expertise and precision craftsmanship. But what exactly goes into designing and building these tailored power solutions?

Custom transformers are designed and manufactured through a collaborative process involving detailed client consultations, specialized engineering, and precision manufacturing. The process typically includes requirements analysis, electrical and mechanical design, material selection, prototyping, testing, and final production. Each step is tailored to meet specific performance, safety, and environmental needs. Advanced software tools, such as finite element analysis, are often used to optimize designs before production begins. This meticulous process ensures that the final product meets all client specifications and regulatory standards.

The Custom Transformer Creation Process

Let’s break down the key stages:

- Requirements Analysis and Specification

- Electrical and Mechanical Design

- Material Selection

- Prototyping and Testing

- Final Production and Quality Assurance

Requirements Analysis and Specification

Understanding client needs:

- Detailed discussions with client engineers

- Analysis of operational environment and constraints

- Definition of performance requirements and standards

I recently started a project for a solar power plant where the initial consultation revealed unique voltage fluctuation challenges. This insight was crucial in shaping our design approach for a custom transformer that could handle these variations efficiently.

Electrical and Mechanical Design

Creating the blueprint:

- Core and winding design optimization

- 3D modeling for mechanical fit and cooling

- Finite element analysis for electromagnetic and thermal performance

During a recent design phase for a marine transformer, we used advanced simulation software to model salt spray exposure, ensuring our design could withstand years of corrosive environments.

Material Selection

Choosing the right components:

- Selection of core materials (e.g., silicon steel, amorphous metals)

- Winding conductor choice (copper vs aluminum)

- Insulation and cooling system materials

Here’s a simplified view of material considerations:

| Component | Options | Selection Criteria |

|---|---|---|

| Core | Silicon Steel, Amorphous Metal | Efficiency, Cost, Size |

| Windings | Copper, Aluminum | Conductivity, Weight, Cost |

| Insulation | Epoxy, Oil, Gas | Temperature Class, Environment |

Prototyping and Testing

Validating the design:

- Building of prototype units

- Comprehensive testing under simulated conditions

- Design refinement based on test results

Final Production and Quality Assurance

Bringing the design to life:

- Scaling up for production

- Implementing strict quality control measures

- Final testing and certification

Key aspects of custom transformer design and manufacturing:

- Thorough understanding of client requirements is crucial

- Advanced design tools ensure optimal performance

- Material selection significantly impacts transformer characteristics

- Prototyping and testing are vital for design validation

- Rigorous quality control ensures the final product meets all specifications