Are you struggling to decide between a box type and a pad mounted transformer for your power distribution project? You’re not alone. Many engineers and project managers find this choice challenging. But what if you could easily understand the key differences and make an informed decision?

A box type transformer is an integrated power distribution unit combining a transformer, switchgear, and protective devices in one enclosure. A pad mounted transformer is a standalone oil-immersed transformer on a concrete base with enclosed terminals. Box types are ideal for urban grids and industrial zones, offering all-in-one solutions. Pad mounted transformers suit residential areas and underground networks, providing a compact, tamper-resistant design. The choice depends on installation requirements, space constraints, and specific project needs.

In this comprehensive guide, I’ll walk you through the essential differences between box type and pad mounted transformers. We’ll explore their structures, applications, advantages, and limitations. Whether you’re designing a new residential development, upgrading an industrial facility, or planning a commercial complex, this article will provide valuable insights to help you make the right choice for your specific needs.

What Is a Box Type Transformer?

Have you ever noticed those large metal cabinets in industrial areas or near commercial buildings and wondered what they are? These are often box type transformers, but what exactly are they, and why are they becoming increasingly popular in urban power distribution?

A box type transformer, also known as a compact substation or kiosk substation, is an integrated power distribution unit that combines a transformer, high-voltage switchgear, low-voltage switchboard, and protective devices within a single enclosure. It typically features a three-compartment layout: high-voltage, transformer, and low-voltage sections. Box type transformers are commonly used in urban power grids, industrial zones, and commercial complexes, offering a compact, all-in-one solution for medium-voltage power distribution, usually at 11kV or 22kV levels.

Key Features of Box Type Transformers

Let’s break down the main characteristics:

- Integrated Design

- Compartmentalized Structure

- Versatile Installation Options

- Safety and Accessibility

- Customization Possibilities

Integrated Design

All-in-one power distribution solution:

- Transformer, switchgear, and protection in one unit

- Factory-assembled and tested before delivery

- Reduced on-site work and installation time

I recently managed a project for a new shopping mall where we chose box type transformers. Their integrated design allowed us to significantly reduce the substation footprint and streamline the installation process, saving both space and time.

Compartmentalized Structure

Enhancing safety and functionality:

- High-voltage compartment: Houses incoming switchgear

- Transformer compartment: Contains the main transformer

- Low-voltage compartment: Includes outgoing distribution panels

During a recent factory tour, I observed the assembly of a box type transformer. The clear separation of compartments impressed me, showcasing how this design enhances safety and ease of maintenance.

Versatile Installation Options

Adapting to various environments:

- Above-ground installation in urban areas

- Suitable for outdoor placement with proper enclosure ratings

- Can be customized for indoor installations in some cases

Here’s a quick overview of installation options:

| Installation Type | Typical Application | Key Advantage |

|---|---|---|

| Outdoor Standalone | Industrial zones | Easy access, robust |

| Indoor Substation | Commercial buildings | Space-saving, noise reduction |

| Rooftop Installation | Urban areas | Utilizes unused space |

Safety and Accessibility

Ensuring protection and ease of maintenance:

- Interlocked compartments for operator safety

- External operation of switchgear possible

- Designed for easy access during maintenance

Customization Possibilities

Meeting specific project needs:

- Scalable capacity (typically from 100 kVA to 2500 kVA)

- Various cooling options (oil-immersed or dry-type)

- Integration of smart grid technologies possible

Key points about box type transformers:

- They offer an integrated solution for power distribution

- Feature a compartmentalized structure for safety and functionality

- Provide versatile installation options for different environments

- Ensure safety while maintaining accessibility for maintenance

- Allow for customization to meet specific project requirements

In my experience, box type transformers have been game-changers for urban power distribution projects. I recall a case where we needed to upgrade the power supply for a growing industrial park. The compact, all-in-one nature of box type transformers allowed us to increase capacity without significantly expanding the substation footprint, a crucial factor in the space-constrained environment.

For example, in a recent smart city project, we utilized box type transformers with integrated smart grid capabilities. Their ability to house advanced monitoring and control systems within the same enclosure as the transformer and switchgear was crucial in implementing a responsive, efficient power distribution network.

As we move on to discuss pad mounted transformers, keep these features of box type transformers in mind. Understanding the unique advantages of each type will help you make a more informed choice for your specific project requirements.

What Is a Pad Mounted Transformer?

Have you ever noticed those green metal boxes in residential areas and wondered about their purpose? These are often pad mounted transformers, but what exactly are they, and why are they a common sight in many neighborhoods?

A pad mounted transformer is a ground-mounted, oil-filled distribution transformer enclosed in a locked steel cabinet. It’s designed to step down medium voltage electricity (typically 11kV or 22kV) to low voltage (400V/230V) for residential and light commercial use. Unlike box type transformers, pad mounted units contain only the transformer itself, with separate termination points for high and low voltage connections. They are commonly used in underground distribution networks, residential subdivisions, and areas where aesthetics and safety are primary concerns.

Key Characteristics of Pad Mounted Transformers

Let’s examine the main features:

- Compact and Self-Contained Design

- Ground-Level Installation

- Safety and Aesthetic Considerations

- Flexibility in Power Distribution

- Maintenance and Accessibility

Compact and Self-Contained Design

Focused transformer solution:

- Houses only the transformer and necessary connections

- Oil-immersed for efficient cooling and insulation

- Tamper-resistant enclosure for public safety

I recently worked on a project upgrading a suburban power distribution system. We chose pad mounted transformers for their compact design, which allowed us to place them strategically throughout the neighborhood without disrupting the landscape.

Ground-Level Installation

Simplifying access and maintenance:

- Mounted on concrete pads at ground level

- Eliminates need for pole-mounted equipment

- Suitable for areas with underground power lines

During a recent residential development project, the ease of installing pad mounted transformers significantly reduced our construction timeline compared to traditional pole-mounted solutions.

Safety and Aesthetic Considerations

Blending function with form:

- Locked, tamper-resistant enclosures

- Low profile design minimizes visual impact

- Can be painted or landscaped around to match surroundings

Here’s a quick comparison of safety features:

| Feature | Purpose | Benefit |

|---|---|---|

| Locked Enclosure | Prevent unauthorized access | Enhanced public safety |

| Dead-front Design | Minimize exposure to live parts | Safer for technicians |

| Low Profile | Reduce visual impact | Better neighborhood aesthetics |

Flexibility in Power Distribution

Adapting to various needs:

- Available in single-phase or three-phase configurations

- Typical capacities range from 25 kVA to 2500 kVA

- Can be customized for specific voltage requirements

Maintenance and Accessibility

Ensuring long-term reliability:

- Easy ground-level access for maintenance

- Designed for quick replacement if necessary

- Often equipped with oil level and temperature indicators

Key points about pad mounted transformers:

- They offer a compact, self-contained transformer solution

- Designed for ground-level installation, ideal for underground networks

- Prioritize safety and aesthetic integration in residential areas

- Provide flexibility in power distribution configurations

- Allow for easy maintenance and accessibility

In my experience, pad mounted transformers have revolutionized residential power distribution. I recall a project where we retrofitted an older neighborhood with pad mounted units, replacing aging pole-mounted transformers. Not only did this improve the area’s visual appeal, but it also increased power reliability and simplified maintenance procedures.

For example, in a recent smart community development project, we utilized pad mounted transformers with integrated smart metering capabilities. Their ground-level installation made it easy to incorporate advanced monitoring systems, enabling efficient power management across the residential area.

As we move on to compare box type and pad mounted transformers directly, keep these characteristics in mind. Understanding the strengths and applications of each type will help you make a more informed decision for your specific project needs.

Box Type vs Pad Mounted: Key Differences in Structure and Installation?

Are you finding it challenging to decide between box type and pad mounted transformers for your project? You’re not alone. Many engineers and project managers struggle with this choice. But what are the fundamental differences in structure and installation that set these two transformer types apart?

Box type transformers are integrated units containing the transformer, switchgear, and low-voltage distribution in one enclosure. They typically have a three-compartment structure: high-voltage, transformer, and low-voltage sections. Pad mounted transformers, conversely, house only the transformer with external connections for high and low voltage. Box types are usually larger, offering a complete substation solution, while pad mounted units are more compact, focusing solely on voltage transformation. Installation methods differ significantly, with box types often requiring more substantial site preparation compared to the simpler concrete pad needed for pad mounted units.

Key Structural and Installation Differences

Let’s examine the main distinctions:

- Component Integration

- Size and Footprint

- Installation Requirements

- Accessibility and Maintenance

- Customization and Scalability

Component Integration

Differing approaches to power distribution:

- Box Type: All-in-one solution with integrated switchgear and distribution

- Pad Mounted: Transformer-only, requiring separate switchgear and distribution panels

I recently managed two similar capacity projects – one using a box type and another using a pad mounted transformer. The box type installation was completed in half the time due to its integrated design, while the pad mounted setup required additional time for connecting external switchgear.

Size and Footprint

Space considerations:

- Box Type: Larger overall footprint, but consolidates multiple components

- Pad Mounted: Smaller individual footprint, but may require additional space for separate components

During a recent urban substation upgrade, the compact nature of pad mounted transformers allowed us to fit more units in a limited space, crucial for meeting the growing power demands of the area.

Installation Requirements

Site preparation and mounting:

- Box Type: Often requires a larger concrete foundation and more complex site preparation

- Pad Mounted: Simpler installation on a basic concrete pad

Here’s a comparison of typical installation requirements:

| Aspect | Box Type Transformer | Pad Mounted Transformer |

|---|---|---|

| Foundation | Large, engineered concrete base | Simple concrete pad |

| Crane Requirement | Usually needed for placement | May be placed with a forklift |

| Cable Entry | Multiple options, often bottom entry | Typically underground entry |

| Site Preparation | More extensive, may need fencing | Minimal, often just landscaping |

Accessibility and Maintenance

Ease of servicing and repairs:

- Box Type: Compartmentalized access, potentially easier for routine checks

- Pad Mounted: Simple access to transformer, but may require opening in public areas

Customization and Scalability

Adapting to project needs:

- Box Type: Highly customizable with various internal configurations

- Pad Mounted: Standardized designs with limited customization options

Key points about structural and installation differences:

- Box type transformers offer integrated solutions, while pad mounted focus on transformation only

- Size and footprint vary significantly between the two types

- Installation requirements differ in complexity and site preparation needs

- Accessibility and maintenance approaches vary based on design

- Customization options are generally more extensive for box type units

In my experience, these structural and installation differences can significantly impact project timelines and costs. I recall a project where we initially planned to use box type transformers for a new commercial development. However, after assessing the site constraints and installation timeline, we switched to pad mounted units. This decision allowed for a more flexible layout and faster installation, crucial for meeting the project’s tight deadline.

For example, in a recent industrial park expansion, we used a combination of box type and pad mounted transformers. Box types were installed at main distribution points, leveraging their integrated design for efficient power management. Pad mounted units were used for individual lots, providing flexibility for future changes in tenant power needs.

As we move on to discuss when to choose between box type and pad mounted transformers, keep these structural and installation differences in mind. Understanding these practical aspects will help you make a more informed decision based on your specific project requirements and constraints.

When to Choose Box Type vs Pad Mounted Transformer?

Are you grappling with the decision between a box type and a pad mounted transformer for your project? You’re not alone. This choice can significantly impact your project’s timeline, budget, and long-term functionality. But how can you determine which option is best suited for your specific needs?

Choose a box type transformer when you need an all-in-one power distribution solution, especially in industrial or commercial settings with limited space for separate components. Opt for a pad mounted transformer in residential areas, underground distribution networks, or where aesthetics and public safety are primary concerns. Box types are ideal for projects requiring integrated switchgear and higher capacities, while pad mounted units excel in scenarios needing compact, standalone transformation. Consider factors like installation space, maintenance accessibility, future expandability, and local regulations when making your decision.

Key Factors in Transformer Selection

Let’s examine the main considerations:

- Application and Environment

- Space and Installation Constraints

- Power Capacity and Scalability

- Safety and Aesthetic Requirements

- Maintenance and Accessibility Needs

Application and Environment

Matching transformer type to project needs:

- Box Type: Ideal for industrial zones, commercial complexes, urban substations

- Pad Mounted: Suitable for residential areas, underground networks, public spaces

I recently worked on a project for a new shopping mall where we chose box type transformers. Their integrated design was perfect for the mall’s centralized power distribution needs, allowing us to efficiently manage the complex’s varied power requirements from a single point.

Space and Installation Constraints

Considering available area and site conditions:

- Box Type: Requires larger installation area but consolidates multiple components

- Pad Mounted: Needs less individual space but may require additional area for separate switchgear

During a recent residential development project, we opted for pad mounted transformers due to space limitations and the need to distribute them throughout the neighborhood discreetly.

Power Capacity and Scalability

Planning for current and future needs:

- Box Type: Generally available in higher capacities, easier to upgrade internal components

- Pad Mounted: Typically lower capacity range, may require full unit replacement for significant upgrades

Here’s a quick comparison of typical capacities:

| Transformer Type | Common Capacity Range | Scalability |

|---|---|---|

| Box Type | 100 kVA – 2500 kVA | High (modular internals) |

| Pad Mounted | 25 kVA – 2500 kVA | Limited (fixed design) |

Safety and Aesthetic Requirements

Meeting regulatory and community standards:

- Box Type: Fully enclosed, suitable for restricted access areas

- Pad Mounted: Tamper-resistant design, blends with residential landscapes

Maintenance and Accessibility Needs

Ensuring long-term serviceability:

- Box Type: Compartmentalized access, potentially easier for routine maintenance

- Pad Mounted: Simple access, but may require special considerations in public areas

Key points for choosing between box type and pad mounted transformers:

- Consider the specific application and environmental context

- Evaluate available space and installation constraints carefully

- Assess both current power needs and future scalability requirements

- Factor in safety regulations and aesthetic considerations

- Think about long-term maintenance and accessibility needs

In my experience, the choice between box type and pad mounted transformers often involves balancing multiple factors. I recall a case where a client initially leaned towards box type transformers for a new office park development. However, after considering the project’s phased construction plan and the need for distributed power sources, we opted for strategically placed pad mounted units. This decision provided greater flexibility for the project’s evolving needs and simplified the installation process for each phase.

For example, in a recent smart city project, we used a combination of both transformer types. Box type units were installed at main distribution hubs, leveraging their integrated design for efficient power management and smart grid integration. Pad mounted transformers were used throughout residential areas, providing a safer, more aesthetically pleasing solution for neighborhood power distribution.

As we move on to discuss the cost-effectiveness of each transformer type, keep these selection criteria in mind. Understanding when to choose each type will help you better evaluate the overall value proposition of box type versus pad mounted transformers for your specific project requirements.

Which Transformer Is More Cost-Effective for Your Project?

Are you struggling to determine whether a box type or pad mounted transformer will be more economical for your project? You’re not alone. Many project managers find it challenging to weigh the upfront costs against long-term benefits. But how can you accurately assess which option offers the best value for your specific situation?

The cost-effectiveness of box type versus pad mounted transformers depends on various factors including initial purchase price, installation costs, long-term maintenance, and project-specific requirements. Box type transformers generally have a higher upfront cost but offer integrated solutions that can reduce overall installation expenses. Pad mounted transformers are typically less expensive initially but may require additional costs for separate switchgear and protective equipment. Long-term considerations like maintenance accessibility, energy efficiency, and future expandability also play crucial roles in determining the most cost-effective choice for your project.

Key Cost Factors to Consider

Let’s examine the main elements affecting cost-effectiveness:

- Initial Purchase and Installation Costs

- Operational Efficiency and Energy Savings

- Maintenance and Repair Expenses

- Lifespan and Replacement Considerations

- Regulatory Compliance and Safety Measures

Initial Purchase and Installation Costs

Upfront investment comparison:

- Box Type: Higher unit cost but includes integrated components

- Pad Mounted: Lower individual cost but may require additional equipment purchases

I recently managed two similar capacity projects – one using a box type and another using pad mounted transformers. While the box type units were more expensive initially, the total installation cost ended up being comparable due to reduced labor and additional equipment needs.

Operational Efficiency and Energy Savings

Long-term performance factors:

- Box Type: Potentially higher efficiency due to optimized integrated design

- Pad Mounted: Efficiency can vary based on the quality of connections and external components

During a recent industrial facility upgrade, we found that the box type transformers offered slightly better overall efficiency, leading to noticeable energy savings over time.

Maintenance and Repair Expenses

Ongoing cost considerations:

- Box Type: Centralized maintenance, potentially lower long-term costs

- Pad Mounted: Simpler individual maintenance, but may require more frequent attention

Here’s a simplified comparison of maintenance aspects:

| Aspect | Box Type Transformer | Pad Mounted Transformer |

|---|---|---|

| Routine Checks | Consolidated, less frequent | More units to check, but simpler |

| Repair Complexity | Can be complex due to integration | Generally straightforward |

| Accessibility | May require specialized access | Easy ground-level access |

| Replacement Parts | Potentially more expensive | Standard parts often available |

Lifespan and Replacement Considerations

Long-term value assessment:

- Box Type: Longer potential lifespan due to protected components

- Pad Mounted: May require earlier replacement of individual units

Regulatory Compliance and Safety Measures

Meeting standards and regulations:

- Box Type: Often easier to comply with industrial safety standards

- Pad Mounted: May require additional safety measures in public areas

Key points for assessing cost-effectiveness:

- Consider both initial costs and long-term operational expenses

- Evaluate potential energy savings from improved efficiency

- Factor in ongoing maintenance and repair requirements

- Assess expected lifespan and future replacement needs

- Account for costs related to regulatory compliance and safety measures

In my experience, determining the most cost-effective option often requires a comprehensive, long-term view. I recall a project for a growing commercial district where we initially considered pad mounted transformers due to their lower upfront cost. However, after conducting a 20-year total cost of ownership analysis, including projected maintenance and energy costs, we found that box type transformers offered better long-term value. This decision proved beneficial as the district expanded, with the integrated design of the box type units accommodating increased power demands more efficiently.

For example, in a recent residential development project, we chose pad mounted transformers despite their potentially higher long-term maintenance costs. This decision was driven by the need for distributed power sources and the aesthetic requirements of the neighborhood. The lower initial cost and flexibility in placement allowed us to optimize the power distribution network within the project’s budget constraints.

As we move on to discuss top Chinese manufacturers offering both box and pad mounted transformers, keep these cost considerations in mind. Understanding the long-term financial implications will help you make a more informed decision when selecting a supplier and transformer type for your project.

Top Chinese Manufacturers Offering Box and Pad Mounted Transformers?

Are you finding it challenging to identify reliable manufacturers of box and pad mounted transformers in China? You’re not alone. With China’s vast industrial landscape, pinpointing trustworthy suppliers can be overwhelming. But which companies stand out for their quality, innovation, and export capabilities in both transformer types?

Leading Chinese manufacturers of box and pad mounted transformers include CHBEB, CHINT, TBEA, Sieyuan Electric, and Taikai Electric. These companies offer a range of products suitable for various applications, from urban power distribution to renewable energy projects. They are known for their adherence to international standards like IEC and IEEE, quality certifications such as ISO 9001 and CE marking, and their ability to provide customized solutions. These manufacturers have strong export presences in markets across Asia, Africa, the Middle East, and beyond, demonstrating their capability to meet diverse global requirements.

Leading Transformer Manufacturers in China

Let’s examine the top recommended suppliers:

- CHBEB (China Bei Er Bian)

- CHINT

- TBEA

- Sieyuan Electric

- Taikai Electric

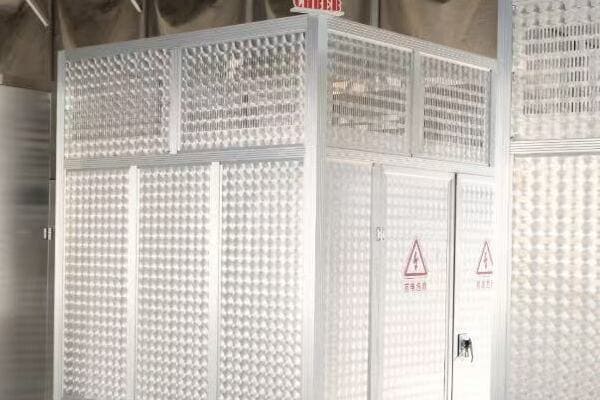

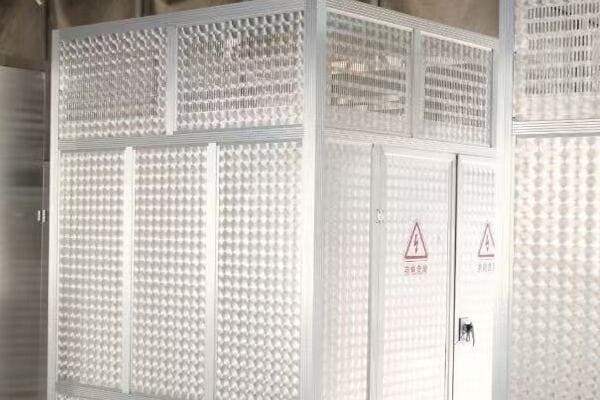

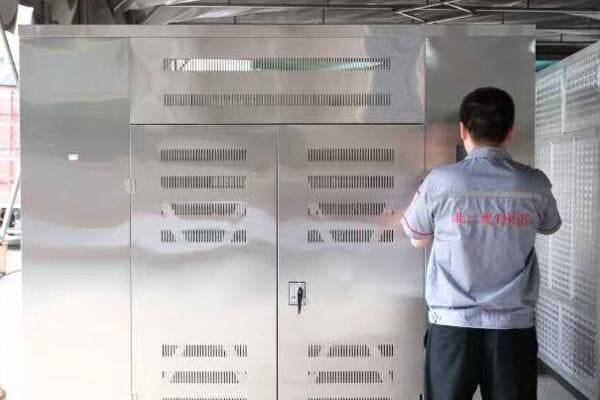

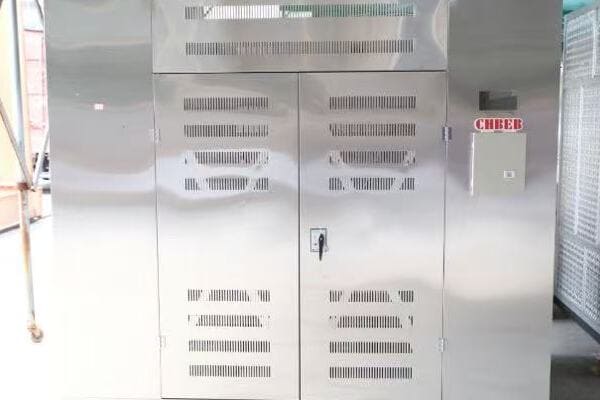

CHBEB (China Bei Er Bian)

Specializing in customized solutions:

- Box Type: 630-2500kVA, CE certified

- Pad Mounted: 11kV/0.4kV, up to 1000kVA

- Key strengths: Export-oriented, strong in Middle East and African markets

- Certifications: ISO 9001, IEC, CE

I recently visited CHBEB’s manufacturing facility and was impressed by their advanced testing lab for both box and pad mounted transformers, ensuring high-quality products for international markets.

CHINT

Comprehensive power solution provider:

- Box Type: Rapid delivery models available

- Pad Mounted: Wide range of standard configurations

- Key strengths: Cost-effective solutions, strong presence in Southeast Asia and Africa

- Certifications: CE, ISO, IEC

During a recent project in Southeast Asia, we sourced pad mounted transformers from CHINT. Their ability to provide a large quantity of standardized units quickly was crucial for meeting our tight project timeline.

TBEA

High-end transformer solutions:

- Box Type: Customizable for large projects

- Pad Mounted: High voltage range available

- Key strengths: Experience in ultra-high voltage projects, strong domestic market

- Certifications: KEMA, CNAS

Here’s a quick overview of TBEA’s offerings:

| Product Type | Voltage Range | Key Feature |

|---|---|---|

| Box Type | Up to 35kV | Highly customizable |

| Pad Mounted | Up to 35kV | Robust design for harsh environments |

Sieyuan Electric

Smart grid integration specialist:

- Box Type: GIS + CSS (Compact Substation) combinations

- Pad Mounted: Smart protection features

- Key strengths: Advanced monitoring and control systems integration

- Certifications: ISO, CE

Taikai Electric

Renewable energy focus:

- Box Type: Tailored for new energy projects

- Pad Mounted: Optimized for solar and wind farm applications

- Key strengths: Experience in renewable energy integration

- Certifications: ISO, IEC

Key points about top Chinese transformer manufacturers:

- They offer a wide range of both box and pad mounted transformers

- Many have strong capabilities in customization and R&D

- Adherence to international standards and certifications is a common feature

- Several specialize in specific applications like renewable energy or smart grids

- Most have significant experience in both domestic and export markets

In my experience, these top manufacturers have consistently demonstrated their ability to meet diverse project requirements. I recall a large-scale urban redevelopment project where we sourced both box and pad mounted transformers from multiple Chinese manufacturers on this list. By leveraging the specific strengths of each company – such as CHBEB’s customization capabilities for unique installation requirements and CHINT’s cost-effective standard units for widespread distribution – we were able to optimize the overall power distribution system while managing costs effectively.

For example, in a recent renewable energy project involving both solar and wind power integration, we utilized box type transformers from Taikai Electric for the main power collection points and pad mounted units from Sieyuan Electric for individual turbine connections. This combination allowed us to balance the need for integrated solutions at key nodes with distributed transformation across the renewable energy site.

As we conclude our exploration of box and pad mounted transformers, remember that choosing the right manufacturer is as crucial as selecting the appropriate transformer type. Consider factors like the manufacturer’s experience in your specific application area, their ability to provide technical support, and their track record in international projects when making your final decision.

Conclusion: Choose Based on Function, Layout, and Cost

Selecting between box type and pad mounted transformers depends on your project’s specific needs. Box types excel in integrated solutions for industrial and commercial settings, while pad mounted units are ideal for residential areas and underground networks. Consider factors like space constraints, power requirements, aesthetic needs, and long-term costs. Both types have their strengths, and the right choice will optimize your power distribution system’s efficiency, reliability, and cost-effectiveness.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Are you struggling to understand the complexities of power distribution systems? You’re not alone. Many engineers and project managers find oil immersed transformers particularly challenging. But what if you could easily grasp their function and importance in our electrical infrastructure?

An oil-immersed power transformer is a type of electrical transformer that uses insulating oil to cool and insulate its internal components, such as the core and windings. These transformers are widely used in medium to high-voltage power systems—typically from 10kV up to 220kV—due to their excellent thermal performance, high load capacity, and long operational lifespan. They play a crucial role in power transmission and distribution networks, industrial facilities, and renewable energy installations.

In this comprehensive guide, I’ll walk you through the essentials of oil immersed power transformers. We’ll explore their structure, working principles, and applications in modern power systems. Whether you’re designing a new substation, procuring equipment for an industrial plant, or simply expanding your engineering knowledge, this article will provide valuable insights to help you understand these critical components of our electrical infrastructure.

What Is an Oil Immersed Power Transformer?

Have you ever wondered how electricity is safely and efficiently transformed from high voltages to usable levels? The answer often lies in oil immersed power transformers. But what exactly are these devices, and why are they so prevalent in our power distribution systems?

An oil immersed power transformer is a type of electrical transformer that uses mineral oil as both an insulating medium and a coolant. It consists of a core and windings immersed in a tank filled with specially formulated transformer oil. These transformers are designed for medium to high-voltage applications, typically ranging from 10kV to 220kV. They are widely used in power substations, industrial facilities, and large-scale power distribution networks due to their high efficiency, excellent cooling capabilities, and ability to handle high power loads.

Key Characteristics of Oil Immersed Transformers

Let’s break down the main features:

- Oil-Filled Design

- Voltage and Power Ratings

- Cooling Efficiency

- Insulation Properties

- Typical Applications

Oil-Filled Design

The defining feature:

- Transformer core and windings submerged in insulating oil

- Oil serves dual purpose of cooling and electrical insulation

- Sealed tank design to prevent oil contamination

I recently inspected a newly installed 110kV oil immersed transformer at a substation. The massive oil-filled tank, standing over 5 meters tall, was a testament to the transformer’s capacity to handle high voltages and power loads.

Voltage and Power Ratings

Handling high power demands:

- Typical voltage ranges from 10kV to 220kV

- Power ratings can exceed 100MVA for large units

- Scalable designs for various power distribution needs

During a recent industrial project, we specified a 33kV/11kV oil immersed transformer rated at 20MVA. This unit efficiently handled the power distribution needs of an entire manufacturing complex.

Cooling Efficiency

Superior heat dissipation:

- Oil circulation provides excellent cooling

- Natural convection in smaller units (ONAN cooling)

- Forced oil and air cooling in larger transformers (ONAF, OFAF cooling)

Here’s a quick comparison of cooling methods:

| Cooling Method | Description | Typical Application |

|---|---|---|

| ONAN | Oil Natural, Air Natural | Small to medium transformers |

| ONAF | Oil Natural, Air Forced | Medium to large transformers |

| OFAF | Oil Forced, Air Forced | Large, high-capacity transformers |

Insulation Properties

Enhancing electrical performance:

- Oil provides superior dielectric strength

- Allows for compact designs even at high voltages

- Self-healing properties in case of minor internal faults

Typical Applications

Where you’ll find oil immersed transformers:

- Power generation plants

- Transmission and distribution substations

- Large industrial facilities

- Renewable energy installations (wind farms, solar plants)

Key points about oil immersed power transformers:

- They use oil for both cooling and insulation

- Designed for medium to high voltage applications

- Offer excellent cooling efficiency and load capacity

- Provide superior insulation properties

- Widely used in various power system applications

In my experience, the versatility of oil immersed transformers becomes particularly evident in large-scale power projects. I recall a case where we needed to upgrade a substation to accommodate increased power demand from a growing industrial zone. The oil immersed transformer we installed not only handled the higher load but also provided the flexibility to manage future expansions.

For example, in a recent renewable energy project, we used a 100MVA oil immersed transformer as the main step-up unit for a large wind farm. Its ability to handle the variable output typical of wind generation while maintaining high efficiency was crucial to the project’s success.

As we move on to discuss the main components of oil immersed transformers, keep these characteristics in mind. Understanding the basic structure and features will help you appreciate how these transformers function in various power system applications.

Main Components of an Oil Immersed Transformer?

Are you finding it challenging to visualize the internal structure of an oil immersed transformer? You’re not alone. Many engineers and technicians struggle to understand how these complex devices are put together. But what are the key components that make up an oil immersed transformer, and how do they work together?

The main components of an oil immersed transformer include the core, windings, oil tank, conservator, bushings, and cooling system. The core, typically made of silicon steel laminations, and the copper or aluminum windings are immersed in insulating oil within the main tank. The conservator acts as an expansion chamber for the oil, while bushings provide insulated entry points for electrical connections. Additional components include tap changers for voltage adjustment, cooling radiators, and various monitoring and protection devices.

Essential Components of Oil Immersed Transformers

Let’s examine the main parts:

- Core and Windings

- Oil Tank and Conservator

- Bushings and Terminals

- Cooling System

- Auxiliary Components and Protections

Core and Windings

The heart of the transformer:

- Core: Made of high-grade silicon steel laminations

- Primary winding: Connects to the input voltage

- Secondary winding: Provides the output voltage

- Insulation: Paper wrapping and oil impregnation

I recently observed the assembly of a 40MVA transformer core. The precision in stacking the laminations and the meticulous winding process was impressive, showcasing the craftsmanship involved in transformer manufacturing.

Oil Tank and Conservator

Containing and preserving the oil:

- Main tank: Houses the core, windings, and oil

- Conservator: Expansion tank for oil volume changes

- Breather: Allows air exchange while filtering moisture

During a recent maintenance inspection, I noticed how the conservator’s oil level indicator provided a quick visual check of the transformer’s oil condition, highlighting the importance of these seemingly simple components.

Bushings and Terminals

Providing electrical connections:

- High voltage bushings: For primary side connections

- Low voltage bushings: For secondary side connections

- Ground terminal: For system grounding

Here’s a quick overview of bushing types:

| Bushing Type | Voltage Range | Key Feature |

|---|---|---|

| Porcelain | Up to 36kV | Traditional, robust |

| Composite | Up to 765kV | Lightweight, high strength |

| Oil-filled | Very high voltages | Excellent insulation |

Cooling System

Managing temperature:

- Radiators: For oil circulation and cooling

- Fans: For forced air cooling in ONAF systems

- Oil pumps: For forced oil circulation in OFAF systems

Auxiliary Components and Protections

Ensuring safe and efficient operation:

- Tap changer: For voltage adjustment

- Buchholz relay: Detects gas accumulation

- Pressure relief device: Prevents tank rupture

- Temperature indicators: Monitor oil and winding temperatures

Key points about oil immersed transformer components:

- The core and windings form the transformer’s electrical heart

- The oil tank and conservator system maintain oil quality

- Bushings provide safe electrical connections

- Cooling systems are crucial for temperature management

- Auxiliary components enhance safety and performance

In my experience, understanding these components is crucial for effective transformer management and troubleshooting. I recall a case where a client was experiencing frequent Buchholz relay alarms. By thoroughly understanding the transformer’s internal structure, we were able to trace the issue to a minor oil leak in the tap changer compartment, preventing a potentially major failure.

For example, during a recent substation upgrade project, we had to specify a transformer with enhanced cooling capabilities due to the high ambient temperatures at the site. Our detailed knowledge of cooling system options allowed us to select a unit with an optimized ONAF system, ensuring reliable operation in the challenging environment.

As we move on to discuss how oil immersed transformers work, keep these components in mind. Understanding their roles and interactions is key to grasping the overall function and efficiency of these critical power system devices.

How Does an Oil Immersed Transformer Work?

Have you ever wondered about the principles behind the operation of oil immersed transformers? Many find the concept of energy transfer in these devices mystifying. But what if you could understand the fundamental processes that make these transformers so efficient and reliable?

Oil immersed transformers work based on the principle of electromagnetic induction. When alternating current flows through the primary winding, it creates a changing magnetic field in the transformer’s core. This field induces a voltage in the secondary winding, with the voltage ratio determined by the number of turns in each winding. The surrounding oil serves multiple purposes: it insulates the windings, dissipates heat generated during operation, and protects internal components from oxidation. The oil’s natural or forced circulation facilitates efficient cooling, allowing the transformer to handle high power loads continuously.

Key Operational Aspects of Oil Immersed Transformers

Let’s break down the main processes:

- Electromagnetic Induction

- Voltage Transformation

- Heat Generation and Dissipation

- Oil Circulation and Cooling

- Insulation and Protection

Electromagnetic Induction

The core principle:

- Alternating current in primary winding creates changing magnetic field

- Magnetic field induces voltage in secondary winding

- Core concentrates and directs magnetic flux

I often use a small demonstration model in training sessions to show how changing the number of turns in the secondary winding affects the output voltage, illustrating this fundamental principle of transformer operation.

Voltage Transformation

Adjusting voltage levels:

- Voltage ratio proportional to turns ratio of windings

- Step-up or step-down transformation possible

- Tap changers allow for fine voltage adjustments

During a recent project, we utilized a transformer with an on-load tap changer to maintain stable output voltage despite fluctuations in the input. This feature was crucial for maintaining power quality in a sensitive industrial process.

Heat Generation and Dissipation

Managing thermal effects:

- Copper losses in windings generate heat

- Core losses contribute to overall heat generation

- Oil absorbs and transfers heat away from active parts

Here’s a simplified view of heat sources in a transformer:

| Heat Source | Contribution | Mitigation |

|---|---|---|

| Copper Losses | 60-70% | Efficient winding design |

| Core Losses | 20-30% | High-quality core material |

| Stray Losses | 5-10% | Proper shielding and design |

Oil Circulation and Cooling

Efficient heat removal:

- Natural convection in smaller transformers (ONAN)

- Forced oil circulation in larger units (OFAF)

- External radiators and fans enhance cooling

Insulation and Protection

Ensuring safe and reliable operation:

- Oil provides high dielectric strength

- Paper insulation on windings for additional protection

- Oil prevents oxidation of internal components

Key points about how oil immersed transformers work:

- They operate based on the principle of electromagnetic induction

- Voltage transformation is achieved through winding turn ratios

- Heat generation is a natural byproduct of operation

- Oil plays a crucial role in cooling and insulation

- Various cooling methods are employed based on transformer size and load

In my experience, understanding these operational principles is crucial for effective transformer management and troubleshooting. I recall a case where a large industrial transformer was consistently running hot. By analyzing the cooling system and oil circulation patterns, we discovered that several radiator fins were partially blocked, impeding efficient heat dissipation. This insight allowed us to quickly resolve the issue and prevent potential long-term damage.

For example, in a recent power quality improvement project, we leveraged our understanding of transformer operation to design a system that minimized harmonic distortions. By carefully selecting core materials and winding configurations, we were able to reduce the impact of harmonics on the transformer, enhancing overall system efficiency and reliability.

As we move on to discuss the specific roles of transformer oil in cooling and insulation, keep these operational principles in mind. Understanding how the transformer functions as a whole will help you appreciate the critical importance of the oil in maintaining efficient and reliable performance.

Cooling and Insulation Role of Transformer Oil?

Are you curious about why oil is so crucial in power transformers? Many people underestimate the importance of transformer oil, seeing it as just another component. But what if I told you that this oil is the lifeblood of the transformer, playing multiple critical roles?

Transformer oil serves dual critical functions: cooling and insulation. As a coolant, it absorbs heat generated by the core and windings, circulating naturally or forcedly to dissipate this heat through radiators. For insulation, the oil provides high dielectric strength, preventing electrical breakdown between components. It also protects the core and windings from moisture and oxygen, extending the transformer’s lifespan. The oil’s properties, including viscosity, flash point, and dielectric strength, are carefully formulated to optimize these functions under various operating conditions.

Key Roles of Transformer Oil

Let’s examine the main functions:

- Cooling Mechanism

- Electrical Insulation

- Protection Against Oxidation and Moisture

- Diagnostic Tool

- Types of Transformer Oil

Cooling Mechanism

Efficient heat dissipation:

- Absorbs heat from core and windings

- Circulates through radiators for cooling

- Enables higher load capacity and efficiency

I recently observed a thermal imaging study of an operating transformer. The clear temperature gradients in the oil circulation paths vividly demonstrated how effectively the oil transfers heat from the internal components to the external cooling surfaces.

Electrical Insulation

Preventing electrical breakdown:

- High dielectric strength

- Fills gaps between windings and core

- Allows for compact transformer designs

During a recent high-voltage test on a newly manufactured transformer, I was impressed by how the carefully selected insulating oil allowed the unit to withstand voltages far exceeding its rated capacity, showcasing the oil’s crucial insulating properties.

Protection Against Oxidation and Moisture

Preserving internal components:

- Forms a barrier against atmospheric oxygen

- Absorbs and disperses moisture

- Extends the lifespan of paper insulation

Here’s a quick overview of oil protection features:

| Feature | Function | Benefit |

|---|---|---|

| Oxidation Inhibitors | Slow oil degradation | Extended oil life |

| Moisture Absorption | Protect paper insulation | Longer transformer life |

| Acidity Neutralizers | Prevent corrosion | Maintain component integrity |

Diagnostic Tool

Monitoring transformer health:

- Regular oil tests reveal internal conditions

- Dissolved gas analysis indicates potential faults

- Trending oil quality helps predict maintenance needs

Types of Transformer Oil

Selecting the right oil:

- Mineral oil: Most common, well-understood properties

- Silicone oil: Higher fire point, used in special applications

- Natural and synthetic esters: Biodegradable, high fire point

Key points about the role of transformer oil:

- It serves as both a coolant and an insulator

- Enables efficient heat dissipation from core and windings

- Provides crucial electrical insulation between components

- Protects internal parts from oxidation and moisture

- Acts as a valuable diagnostic tool for transformer health

In my experience, the quality and condition of transformer oil can make or break a transformer’s performance and lifespan. I recall a case where routine oil analysis revealed increasing levels of dissolved gases, indicating internal partial discharges. This early detection allowed us to schedule preventive maintenance, avoiding a potential catastrophic failure.

For example, in a recent project involving transformers installed in an environmentally sensitive area, we opted for biodegradable ester oil. This choice not only provided excellent cooling and insulation but also mitigated environmental risks associated with potential oil leaks, showcasing how oil selection can address both technical and environmental concerns.

As we move on to discuss the advantages and limitations of oil immersed transformers, keep in mind the crucial roles that oil plays. Understanding these functions will help you appreciate why oil immersed designs are preferred in many high-power applications, despite some challenges they may present.

Advantages and Limitations of Oil Immersed Transformers?

Are you weighing the pros and cons of oil immersed transformers for your project? You’re not alone. Many engineers and project managers struggle with this decision. But what are the real benefits and drawbacks of these transformers, and how do they stack up against alternatives like dry-type transformers?

Oil immersed transformers offer several advantages including excellent cooling efficiency, high overload capacity, and superior insulation properties. They are ideal for high-voltage and high-capacity applications, often more cost-effective for large power ratings, and have a longer lifespan due to the protective nature of the oil. However, they also have limitations such as higher maintenance requirements, potential environmental concerns due to oil leaks, and fire safety considerations. They are generally larger and heavier than dry-type alternatives, which can impact installation flexibility.

Key Advantages and Limitations

Let’s examine the main points:

- Cooling Efficiency and Load Capacity

- Insulation and Voltage Handling

- Lifespan and Reliability

- Environmental and Safety Considerations

- Maintenance and Cost Factors

Cooling Efficiency and Load Capacity

Advantages:

- Superior heat dissipation allows for higher load capacity

- Can handle overloads and temporary spikes in demand

- Efficient operation in high ambient temperatures

Limitations:

- Requires more space for cooling equipment

- Potential for oil leaks in the cooling system

I recently managed a project for a large industrial facility where we chose oil immersed transformers specifically for their ability to handle the variable and often high loads typical in manufacturing processes. Their overload capacity provided a crucial buffer during peak production times.

Insulation and Voltage Handling

Advantages:

- Excellent dielectric strength of oil allows for higher voltages

- Self-healing properties of liquid insulation

- Suitable for outdoor and harsh environment installations

Limitations:

- Risk of insulation degradation over time due to oil contamination

- Requires regular oil quality monitoring

During a recent high-voltage substation upgrade, we opted for oil immersed transformers due to their superior insulation properties, which were crucial for handling the 220kV primary voltage reliably.

Lifespan and Reliability

Advantages:

- Typically longer lifespan (30-40 years with proper maintenance)

- Oil protects internal components from oxidation and moisture

- Well-established technology with proven long-term reliability

Limitations:

- Lifespan heavily dependent on maintenance quality

- Oil degradation can impact long-term performance

Here’s a quick comparison of typical lifespans:

| Transformer Type | Average Lifespan | Key Factor |

|---|---|---|

| Oil Immersed | 30-40 years | Oil maintenance |

| Dry-Type | 20-30 years | Environmental conditions |

Environmental and Safety Considerations

Advantages:

- Can be designed with biodegradable oils for environmentally sensitive areas

- Suitable for outdoor installations in various climates

Limitations:

- Potential environmental hazard in case of oil leaks

- Higher fire risk compared to dry-type transformers

- May require additional containment measures

Maintenance and Cost Factors

Advantages:

- Often more cost-effective for high power ratings

- Lower losses in large capacity units

Limitations:

- Higher maintenance requirements and costs

- Periodic oil testing and potential oil replacement needed

- May require specialized handling for installation and relocation

Key points about oil immersed transformer advantages and limitations:

- They offer superior cooling and load handling capabilities

- Provide excellent insulation for high-voltage applications

- Generally have a longer lifespan with proper maintenance

- Present some environmental and safety challenges

- Require more extensive maintenance compared to dry-type alternatives

In my experience, the decision between oil immersed and dry-type transformers often involves carefully balancing these factors against specific project requirements. I recall a case where we initially considered dry-type transformers for a new data center due to fire safety concerns. However, after a comprehensive risk assessment and cost analysis, we opted for oil immersed units with enhanced fire protection systems. This decision provided the necessary power capacity and efficiency while meeting stringent safety standards through careful design and installation.

For example, in a recent renewable energy project, we chose oil immersed transformers for the main step-up application at a large solar farm. Their ability to handle the variable output efficiently, combined with their robust design for outdoor installation, made them ideal for this application. However, we also implemented advanced oil containment systems and used biodegradable oil to address environmental concerns.

As we move on to discuss typical applications of oil immersed transformers in power systems and infrastructure, keep these advantages and limitations in mind. Understanding when and where these transformers excel will help you make more informed decisions in your power system designs and upgrades.

Typical Applications in Power Systems and Infrastructure?

Are you wondering where oil immersed transformers fit into our modern power systems? You’re not alone. Many people are curious about the specific roles these transformers play in our electrical infrastructure. But in what key areas are oil immersed transformers most commonly used, and why are they preferred in these applications?

Oil immersed transformers are widely used in power generation plants, transmission substations, distribution networks, and large industrial facilities. They are essential in step-up applications at power plants, converting generator output to high transmission voltages. In substations, they step down voltages for regional distribution. Industrial applications include powering large motors, furnaces, and process equipment. Oil immersed transformers are also crucial in renewable energy systems, such as wind farms and solar plants, for grid integration. Their high efficiency, reliability, and ability to handle large power capacities make them ideal for these critical infrastructure roles.

Key Application Areas

Let’s explore the main uses:

- Power Generation Plants

- Transmission and Distribution Substations

- Industrial Facilities

- Renewable Energy Systems

- Special Applications

Power Generation Plants

Stepping up for transmission:

- Convert generator output (typically 11kV-25kV) to transmission voltages (110kV-765kV)

- Handle large power capacities (often hundreds of MVA)

- Provide reliable operation in demanding plant environments

I recently visited a coal-fired power plant where massive oil immersed transformers were used to step up the 22kV generator output to 400kV for long-distance transmission. The sheer size and capacity of these units were impressive, highlighting their crucial role in power generation.

Transmission and Distribution Substations

Managing voltage levels:

- Step down high transmission voltages to sub-transmission levels

- Further reduce voltages for local distribution networks

- Provide voltage regulation through tap changers

During a recent substation upgrade project, we installed several oil immersed transformers to step down 132kV transmission voltage to 33kV and 11kV for regional distribution. Their ability to handle large loads and provide voltage regulation was key to improving the grid’s reliability.

Industrial Facilities

Powering heavy equipment:

- Supply large motors and electric furnaces

- Provide reliable power for continuous industrial processes

- Handle harmonics and load variations in industrial environments

Here’s a quick overview of typical industrial applications:

| Industry | Common Application | Key Requirement |

|---|---|---|

| Steel Mills | Electric Arc Furnaces | High overload capacity |

| Chemical Plants | Process Equipment | Reliability in harsh environments |

| Mining | Large Motors | Robust design for variable loads |

Renewable Energy Systems

Integrating green power:

- Step up voltages from wind turbines and solar inverters

- Handle variable inputs characteristic of renewable sources

- Provide grid connection for large-scale renewable plants

Special Applications

Meeting unique needs:

- Traction substations for railways

- Mobile substations for emergency power

- Offshore platforms in oil and gas industry

Key points about oil immersed transformer applications:

- They are crucial in power generation for stepping up voltages

- Play a vital role in transmission and distribution networks

- Essential for powering large industrial equipment and processes

- Increasingly important in renewable energy integration

- Adaptable to special applications with unique requirements

In my experience, the versatility of oil immersed transformers becomes particularly evident in complex power systems. I recall a project where we designed the electrical system for a new manufacturing complex that included its own cogeneration plant. Oil immersed transformers were used at multiple points: stepping up the cogeneration output, stepping down incoming grid power, and supplying various voltage levels throughout the facility. This showcased how these transformers can form the backbone of a comprehensive power system.

For example, in a recent large-scale solar farm project, we utilized oil immersed transformers not only for the main grid connection but also at various points within the farm. Their ability to handle the variable output of the solar panels while providing the necessary voltage transformations was crucial to the project’s success.

As we conclude our exploration of oil immersed transformers, let’s look at some recommended suppliers in China. Understanding the applications where these transformers excel will help you better evaluate different manufacturers’ offerings and select the right transformer for your specific needs.

Recommended Suppliers of Oil Immersed Transformers in China?

Are you finding it challenging to identify reliable oil immersed transformer manufacturers in China? You’re not alone. With China’s vast industrial landscape, pinpointing trustworthy suppliers can be overwhelming. But which companies stand out for their quality, innovation, and export capabilities in the oil immersed transformer market?

Top recommended suppliers of oil immersed transformers in China include CHINT, CHBEB, TBEA, and XD Group. These companies offer a range of oil immersed transformers suitable for various applications, from distribution to power generation. They are known for their adherence to international standards like IEC and IEEE, quality certifications such as ISO 9001, and their ability to provide customized solutions. These manufacturers have strong export presences in markets across Asia, Africa, and the Middle East, demonstrating their capability to meet diverse global requirements.

Leading Oil Immersed Transformer Manufacturers in China

Let’s examine the top recommended suppliers:

- CHINT

- CHBEB (China Bei Er Bian)

- TBEA

- XD Group

CHINT

Comprehensive power solution provider:

- Capacity range: 100-25000 kVA

- Voltage classes: Up to 35kV

- Key strengths: Wide product range, strong R&D capabilities

- Certifications: ISO, CE, IEC

I recently visited CHINT’s manufacturing facility and was impressed by their automated production lines and rigorous testing procedures for oil immersed transformers.

CHBEB (China Bei Er Bian)

Specializing in customized solutions:

- Capacity range: 100-10000 kVA

- Voltage classes: Up to 35kV

- Key strengths: Customization capabilities, export-oriented

- Certifications: ISO 9001, IEC, CE

During a recent project in the Middle East, we sourced transformers from CHBEB. Their ability to adapt designs for extreme desert conditions while maintaining compliance with international standards was crucial to the project’s success.

TBEA

High-end transformer solutions:

- Capacity range: Up to ultra-high voltage applications

- Voltage classes: 10kV-500kV

- Key strengths: Advanced technology, experience in large-scale projects

- Certifications: KEMA, CNAS

Here’s a quick overview of TBEA’s typical offerings:

| Product Line | Voltage Range | Key Feature |

|---|---|---|

| Distribution Transformers | 10kV-35kV | High efficiency |

| Power Transformers | 110kV-500kV | Ultra-high voltage capability |

| Special Transformers | Various | Customized for specific applications |

XD Group

Comprehensive power equipment manufacturer:

- Capacity range: Wide range, including ultra-high capacity

- Voltage classes: 35kV-220kV and above

- Key strengths: Full range of power equipment, strong in EPC projects

- Certifications: ISO, CNAS, IEC

Key points about recommended Chinese suppliers:

- They offer a wide range of capacities and voltage classes

- Adhere to international standards and hold relevant certifications

- Have strong capabilities in customization and R&D

- Demonstrate significant experience in both domestic and export markets

- Provide comprehensive support from design to after-sales service

In my experience, these top manufacturers have consistently demonstrated their ability to meet diverse project requirements. I recall a large-scale grid modernization project where we sourced transformers from multiple Chinese manufacturers on this list. By leveraging the specific strengths of each company – such as TBEA’s expertise in high-voltage applications and CHBEB’s customization capabilities – we were able to optimize the overall system performance while managing costs effectively.

For example, in a recent renewable energy project involving both solar and wind power integration, we utilized transformers from CHINT for the solar farm connections and a large unit from XD Group for the main grid interconnection. This combination allowed us to balance cost-effectiveness with high-end performance where it was most needed.

Remember, when selecting a supplier, it’s crucial to consider not just the product specifications but also the manufacturer’s experience in your specific application area, their ability to provide technical support, and their track record in international projects. Always request detailed specifications, certifications, and references before making your final decision.

Conclusion

Oil immersed transformers are crucial components in power systems, offering high efficiency, reliability, and capacity for medium to high-voltage applications. They work on the principle of electromagnetic induction, with oil serving vital cooling and insulation functions. While they have limitations, their advantages make them ideal for many power generation, transmission, and industrial applications. Understanding their structure, operation, and applications is key to effective power system design and management.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Are you struggling to make sense of pad mounted transformer specifications? You’re not alone. Many engineers and procurement professionals find these technical documents overwhelming. But what if you could easily decode these specs and use them to make confident project decisions?

A pad-mounted transformer specification sheet outlines key electrical, mechanical, and environmental parameters such as rated voltage, kVA capacity, impedance, cooling method, and installation requirements. It includes connection diagrams, dimension drawings, protection features, and applicable standards like IEC 60076 or IEEE C57.12.34. Understanding these specifications is crucial for ensuring project compatibility, installation safety, and long-term performance. Misinterpreting details like vector group, tap changer type, or cable termination configuration can lead to equipment mismatch, site rework, or project delays.

In this comprehensive guide, I’ll walk you through the essential elements of pad mounted transformer specifications. We’ll explore what each parameter means in practice, how to interpret technical drawings, and common pitfalls to avoid during procurement. Whether you’re designing a new residential development or upgrading an existing power distribution system, this article will provide valuable insights to help you make informed decisions and ensure project success.

What Is a Pad Mounted Transformer Specification Sheet and Why It Matters?

Have you ever received a transformer spec sheet and felt overwhelmed by the technical jargon? You’re not alone. Many professionals in the power industry struggle to interpret these crucial documents. But why are these specification sheets so important, and what key information do they contain?

A pad mounted transformer specification sheet is a comprehensive technical document that details the transformer’s electrical, mechanical, and environmental characteristics. It typically includes parameters like rated power (kVA), voltage ratings, impedance, vector group, cooling method, and physical dimensions. These sheets also contain wiring diagrams, layout drawings, and clearance requirements. Understanding this document is crucial for proper transformer selection, project design, and procurement processes. Misinterpretation can lead to costly errors in equipment compatibility, site preparation, and regulatory compliance.

Key Components of a Transformer Specification Sheet

Let’s break down the main elements:

- Electrical Parameters

- Mechanical Specifications

- Environmental and Safety Features

- Drawings and Diagrams

- Standards and Certifications

Electrical Parameters

Core performance indicators:

- Rated power (kVA)

- Primary and secondary voltage levels

- Impedance percentage

- Vector group (e.g., Dyn11)

- Tap changer details (if applicable)

I recently worked on a project where misreading the vector group notation led to compatibility issues with the existing distribution system. This experience underscored the importance of understanding even seemingly minor details in the spec sheet.

Mechanical Specifications

Physical characteristics and installation requirements:

- Dimensions (length, width, height)

- Weight (transport and installed)

- Mounting and foundation requirements

- Cable entry and termination details

During a recent residential development project, we faced challenges because the transformer’s actual dimensions slightly exceeded those in the initial spec sheet. This discrepancy led to last-minute adjustments in the pad design, highlighting the need for thorough spec review.

Environmental and Safety Features

Ensuring reliable and safe operation:

- Cooling method (e.g., ONAN, ONAF)

- Ingress protection (IP) rating

- Noise level specifications

- Fire safety features

Here’s a quick overview of common environmental specifications:

| Feature | Typical Specification | Importance |

|---|---|---|

| Cooling Method | ONAN (Oil Natural Air Natural) | Affects installation and maintenance |

| IP Rating | IP54 or higher | Critical for outdoor installations |

| Noise Level | <50 dB at 1m | Important for residential areas |

| Operating Temperature | -25°C to +40°C | Ensures reliability in various climates |

Drawings and Diagrams

Visual representations for clarity:

- Wiring diagrams

- Outline drawings with dimensions

- Foundation and clearance requirements

Standards and Certifications

Ensuring compliance and quality:

- Applicable standards (e.g., IEC 60076, IEEE C57.12.34)

- Type test certificates

- Quality management certifications (e.g., ISO 9001)

Key points about transformer specification sheets:

- They provide comprehensive technical details essential for project planning

- Electrical parameters define the transformer’s core functionality

- Mechanical specs are crucial for site preparation and installation

- Environmental features ensure long-term reliability and safety

- Drawings and standards compliance information aid in proper implementation

In my experience, thoroughly understanding these specification sheets is crucial for project success. I recall a case where a client overlooked the tap changer specifications in a transformer for a solar farm project. This oversight led to voltage regulation issues that required costly post-installation modifications. By carefully reviewing each section of the spec sheet, we could have anticipated and prevented this problem.

For example, in a recent smart grid upgrade project, we used the detailed vector group and impedance information from the spec sheets to ensure seamless integration with the existing network infrastructure. This attention to detail in the specification review process was key to achieving the project’s power quality and reliability goals.

As we move on to discuss key technical parameters in more depth, keep in mind the critical role these specification sheets play in every stage of a transformer project, from initial design to final installation and commissioning.

Key Technical Parameters and What They Mean in Practice?

Are you finding it challenging to connect transformer specifications to real-world applications? You’re not alone. Many engineers struggle to translate technical parameters into practical design decisions. But which specifications are most critical, and how do they impact your project’s performance and safety?

Key technical parameters in pad mounted transformer specifications include rated power (kVA), voltage ratings, impedance percentage, vector group, and cooling method. Rated power determines the transformer’s load capacity, crucial for meeting current and future demand. Voltage ratings (e.g., 11kV/400V) must match your distribution system. Impedance affects short-circuit currents and protection system coordination. Vector group (e.g., Dyn11) influences grounding and parallel operation compatibility. Cooling method (e.g., ONAN) impacts noise levels, losses, and space requirements. Understanding these parameters is essential for proper transformer selection, system design, and long-term operational efficiency.

Critical Technical Parameters Explained

Let’s examine the main specifications and their practical significance:

- Rated Power (kVA)

- Voltage Ratings

- Impedance Percentage

- Vector Group

- Cooling Method

Rated Power (kVA)

Determining load capacity:

- Defines the maximum power the transformer can handle

- Critical for meeting current needs and future growth

- Affects physical size and weight of the transformer

I recently worked on a residential development project where we initially specified a 500 kVA transformer based on current load calculations. However, after considering future electric vehicle charging needs, we opted for a 750 kVA unit to accommodate long-term growth without requiring a costly upgrade later.

Voltage Ratings

Matching system requirements:

- Primary voltage (e.g., 11kV, 22kV) must match utility supply

- Secondary voltage (e.g., 400V) must suit end-user equipment

- Consider voltage regulation range for varying load conditions

During a recent industrial park project, we had to carefully select transformers with the correct primary voltage (33kV) to match the local utility supply while ensuring the secondary voltage (400V) met the diverse needs of various manufacturing tenants.

Impedance Percentage

Influencing system behavior:

- Affects short-circuit current levels

- Impacts voltage regulation under load

- Critical for coordinating protection systems

Here’s a quick guide to impedance percentages:

| Impedance % | Typical Application | Impact on System |

|---|---|---|

| 4% – 5% | Distribution transformers | Moderate fault currents, good voltage regulation |

| 6% – 8% | Larger power transformers | Lower fault currents, suitable for weaker grids |

| >8% | Special applications | Very low fault currents, may require additional voltage support |

Vector Group

Defining winding connections:

- Indicates phase shift between primary and secondary

- Affects system grounding and fault behavior

- Important for parallel operation of transformers

Cooling Method

Managing temperature and efficiency:

- ONAN (Oil Natural Air Natural): Most common for pad mounted units

- ONAF (Oil Natural Air Forced): For higher capacities or hot climates

- Impacts noise levels, losses, and maintenance requirements

Key points about technical parameters:

- Rated power must be carefully selected to meet both current and future needs

- Voltage ratings must precisely match system requirements

- Impedance percentage affects system protection and voltage regulation

- Vector group is crucial for system compatibility and parallel operation

- Cooling method influences performance, efficiency, and environmental impact

In my experience, understanding these parameters is crucial for avoiding costly mistakes. I recall a project where a mismatch in vector group notation led to issues when paralleling new transformers with existing units. This oversight resulted in circulating currents and reduced efficiency. By paying close attention to these technical details, we could have prevented this problem and ensured seamless integration.

For example, in a recent smart grid project, we utilized the impedance data from transformer specifications to accurately model the distribution network. This allowed us to optimize protection settings and improve overall system reliability. The cooling method specifications also helped us design appropriate ventilation for transformer vaults, ensuring long-term reliability in urban installations.

As we move on to discuss how to interpret transformer drawings and diagrams, keep these key parameters in mind. Understanding their practical implications will help you make more informed decisions when reviewing technical documentation and planning your power distribution projects.

Understanding Drawings: Wiring Diagrams, Layouts, and Clearance Requirements?

Are you struggling to make sense of the various drawings included in pad mounted transformer specifications? You’re not alone. Many professionals find these technical illustrations challenging to interpret. But why are these drawings so crucial, and how can you extract the vital information they contain?