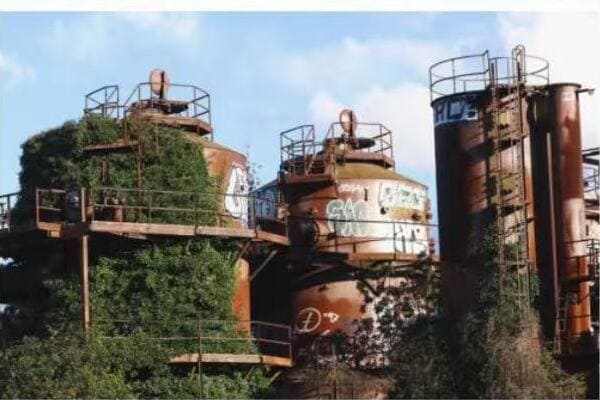

Have you ever walked past a power station and thought, "This could be so much more"? Seattle did, and the result is nothing short of revolutionary. The Denny Substation is changing how we think about urban infrastructure.

Denny Substation in Seattle is a groundbreaking project that combines a fully functioning electrical substation with public spaces and amenities. It reimagines industrial infrastructure as an integral part of the urban fabric, offering community benefits while meeting the city’s growing energy needs.

As an electrical engineer who’s worked on numerous substation projects, I was skeptical when I first heard about Denny Substation. But after visiting the site and studying its design, I’m convinced it’s a game-changer for urban power infrastructure. Let me take you on a tour of this innovative project and show you why it matters.

Architectural Innovation: Blending Power Infrastructure with Urban Design in Denny Substation?

When you think of a power substation, what comes to mind? Probably not an award-winning piece of architecture. But Denny Substation is changing that perception, one visitor at a time.

Denny Substation’s design seamlessly integrates industrial functionality with aesthetic appeal. Its sloped walls, public art installations, and transparent sections allow passersby to glimpse the inner workings of the substation, demystifying power infrastructure while enhancing the urban landscape.

I’ve seen my fair share of substations, but Denny is in a league of its own. Let’s break down what makes its architecture so innovative:

Form Meets Function: The Substation’s Unique Design

The substation’s design is a masterclass in blending form and function:

-

Sloped Walls

- Reduce the visual bulk of the building

- Create a dynamic, sculptural form

-

Transparent Sections

- Allow public viewing of internal equipment

- Educate visitors about power infrastructure

-

Integrated Public Art

- Enhances aesthetic appeal

- Reflects local culture and history

Public Engagement Through Design

Denny Substation goes beyond just looking good:

| Feature | Purpose | Benefit |

|---|---|---|

| Elevated Walkway | Provides views into the substation | Educates public about power systems |

| Interactive Exhibits | Explains substation operations | Increases energy awareness |

| Open Spaces | Creates gathering areas | Fosters community engagement |

Challenges in Blending Infrastructure and Architecture

Designing Denny Substation wasn’t without its challenges:

-

Safety Considerations

- Ensuring public safety near high-voltage equipment

- Implementing secure yet visually appealing barriers

-

Noise Mitigation

- Designing acoustically insulated walls

- Strategically placing noisy equipment

-

Electromagnetic Field (EMF) Management

- Careful layout to minimize EMF exposure in public areas

- Using advanced shielding techniques

I remember discussing these challenges with the project team. We had to think outside the box to find solutions that didn’t compromise the substation’s functionality or aesthetic vision.

The Impact on Urban Planning

Denny Substation is more than just a pretty face:

- It sets a new standard for infrastructure design in urban areas

- It demonstrates that utility buildings can contribute positively to cityscapes

- It encourages public engagement with typically "invisible" city systems

As I walked around the substation, I couldn’t help but imagine how this approach could transform other urban infrastructure projects. The possibilities are exciting.

Remember, Denny Substation isn’t just about making a power facility look good. It’s about reimagining how our cities can integrate essential infrastructure in ways that benefit and engage the community. It’s a bold step towards more livable, understandable urban environments.

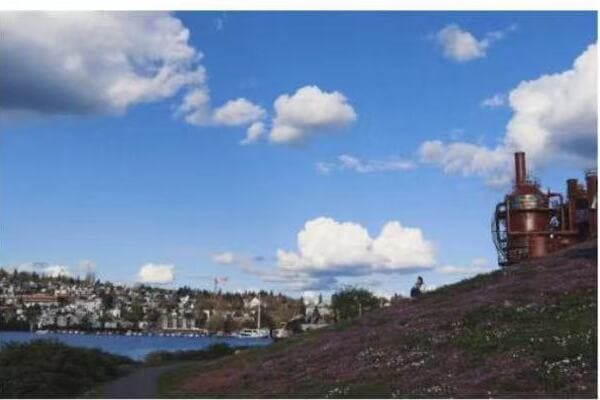

Community Integration: Public Spaces and Amenities Within a Functioning Power Facility?

When was the last time you thought of hanging out at a power substation? Probably never. But Denny Substation is changing that narrative, turning a typically off-limits area into a community hub.

Denny Substation incorporates various public amenities, including a quarter-mile walking loop, dog park, meeting spaces, and educational exhibits. These features transform the substation from a purely industrial site into a multifunctional community space, all while maintaining its core function as a power facility.

As someone who’s spent years working on traditional substations, I was amazed by Denny’s approach. Let’s explore how this substation has become an integral part of its community:

Reimagining Public Spaces

Denny Substation offers a range of public amenities:

-

Walking Loop

- Quarter-mile elevated path

- Provides unique views of the city and substation

-

Off-Leash Dog Park

- Safe space for pets in an urban environment

- Encourages community gatherings

-

Community Meeting Rooms

- Available for public use

- Fosters local engagement and activities

-

Educational Exhibits

- Interactive displays about energy and sustainability

- Promotes public understanding of power systems

Balancing Public Access and Operational Safety

Integrating public spaces with a functioning substation presented unique challenges:

| Challenge | Solution | Benefit |

|---|---|---|

| Safety Concerns | Clear barriers and signage | Safe public access |

| Noise Issues | Advanced sound insulation | Quiet public areas |

| EMF Exposure | Strategic equipment placement | Minimal EMF in public spaces |

| Security | Monitored access points | Protected critical infrastructure |

I was particularly impressed with how the design team addressed these challenges without compromising the substation’s welcoming atmosphere.

Community Engagement and Education

Denny Substation goes beyond providing spaces; it actively engages the community:

-

Energy Education Programs

- School field trips

- Adult learning workshops

-

Public Art Installations

- Rotating exhibits by local artists

- Permanent pieces integrated into the structure

-

Sustainability Demonstrations

- Showcasing green technologies

- Inspiring visitors to adopt eco-friendly practices

During my visit, I saw a group of students on a field trip, eagerly learning about power generation. It was a stark contrast to the "keep out" mentality of traditional substations.

The Social Impact of an Open Substation

The integration of Denny Substation into the community fabric has far-reaching effects:

-

Increased Public Awareness

- Better understanding of power infrastructure

- Greater appreciation for energy conservation

-

Enhanced Neighborhood Amenities

- Improved quality of life for local residents

- Increased property values in the area

-

Community Cohesion

- New gathering spaces for social interaction

- Platform for community events and activities

Challenges and Lessons Learned

Implementing this community-integrated model wasn’t without its hurdles:

-

Initial Public Skepticism

- Concerns about safety and EMF exposure

- Addressed through transparent communication and education

-

Operational Complexities

- Balancing public access with facility maintenance

- Developing new protocols for a unique situation

-

Cost Considerations

- Higher initial investment compared to traditional substations

- Long-term benefits in public relations and community development

As I reflected on these challenges, I realized that Denny Substation’s approach, while more complex, offers a blueprint for how infrastructure can positively contribute to urban life.

Remember, Denny Substation isn’t just powering homes and businesses; it’s powering community engagement and education. It’s a testament to how thoughtful design can transform a necessary piece of infrastructure into a valuable community asset.

Balancing Act: Meeting Seattle’s Energy Needs While Creating an Inviting Urban Environment?

How do you reconcile the industrial nature of a power substation with the desire for inviting urban spaces? This was the challenge faced by Seattle City Light, and their solution at Denny Substation is nothing short of ingenious.

Denny Substation successfully balances Seattle’s growing energy demands with the need for attractive urban spaces. It incorporates state-of-the-art electrical equipment within an architecturally striking and publicly accessible design, demonstrating that utility infrastructure can enhance rather than detract from the urban environment.

As an electrical engineer, I’ve always been fascinated by the technical aspects of substations. But Denny takes it to a whole new level by marrying technical excellence with urban design. Let’s dive into how they achieved this balance:

Technical Prowess Meets Urban Aesthetics

Denny Substation is a marvel of engineering and design:

-

Electrical Capacity

- 405 megavolt-amperes (MVA) capacity

- Serves Seattle’s growing downtown and South Lake Union areas

-

Compact Design

- Uses gas-insulated switchgear (GIS) to minimize footprint

- Allows for more public space within the site

-

Noise Reduction

- Advanced sound-absorbing materials

- Strategic equipment placement to minimize noise pollution

| Feature | Technical Benefit | Urban Benefit |

|---|---|---|

| GIS Technology | Reduced equipment size | More space for public amenities |

| Underground Cabling | Improved reliability | Cleaner visual aesthetics |

| Modular Design | Easier future upgrades | Adaptable public spaces |

Innovative Design Solutions

The substation’s design tackles several challenges:

-

Visual Impact

- Sloped walls reduce perceived height

- Green walls and landscaping soften industrial appearance

-

Public Safety

- Clear separation between public and operational areas

- Educational signage about electrical safety

-

Environmental Considerations

- Rainwater harvesting system

- Energy-efficient lighting and HVAC systems

I was particularly impressed by how the design team turned potential problems into opportunities for innovation.

Balancing Operational Needs with Public Access

Maintaining a functioning substation while allowing public access required careful planning:

-

Secure Perimeters

- Clear boundaries between public and restricted areas

- Advanced security systems to protect critical infrastructure

-

Flexible Spaces

- Areas that can be repurposed for maintenance when needed

- Public spaces designed to not interfere with substation operations

-

Educational Integration

- Viewing windows into operational areas

- Interactive displays explaining substation functions

During my tour, I noticed how seamlessly the public areas blended with the operational sections. It’s a testament to thoughtful design and planning.

The Impact on Seattle’s Energy Infrastructure

Denny Substation isn’t just about looks; it’s a crucial part of Seattle’s power grid:

-

Increased Capacity

- Supports urban growth and development

- Enhances grid reliability in downtown areas

-

Smart Grid Integration

- Advanced monitoring and control systems

- Prepared for future energy technologies

-

Renewable Energy Support

- Designed to handle variable inputs from renewable sources

- Promotes Seattle’s clean energy goals

Challenges in Implementation

Creating this balanced environment wasn’t without its hurdles:

-

Regulatory Compliance

- Meeting both energy and public space regulations

- Developing new standards for this hybrid model

-

Cost Management

- Higher initial investment than traditional substations

- Justifying expenses for public amenities

-

Operational Adjustments

- Training staff for a public-facing facility

- Developing new maintenance protocols

As I discussed these challenges with the project team, I was struck by their innovative problem-solving approaches. They didn’t just overcome obstacles; they turned them into opportunities for improvement.

Remember, Denny Substation isn’t just about providing power or creating public spaces. It’s about reimagining what urban infrastructure can be. It shows that with creativity and commitment, we can create facilities that serve multiple purposes, enriching our cities in more ways than one.

Sustainability and Technology: Green Features and Smart Grid Capabilities of Denny Substation?

In an era where sustainability is no longer optional, how does a power substation – traditionally seen as an energy-hungry facility – become a beacon of green technology? Denny Substation provides a compelling answer to this question.

Denny Substation incorporates numerous sustainable features and smart grid technologies. From its energy-efficient design and rainwater harvesting system to its advanced monitoring and control capabilities, the substation sets new standards for environmentally responsible and technologically advanced power infrastructure.

As someone who’s passionate about integrating sustainability into power systems, I was eager to explore Denny’s green features. Let’s dive into what makes this substation a leader in sustainable and smart technology:

Green Building Design

Denny Substation’s commitment to sustainability starts with its very structure:

-

Energy-Efficient Building Envelope

- High-performance insulation

- Double-paned, low-E windows

-

Green Roof

- Reduces urban heat island effect

- Improves stormwater management

-

Sustainable Materials

- Recycled and locally sourced materials

- Low-VOC paints and adhesives

| Feature | Environmental Benefit | Operational Benefit |

|---|---|---|

| LED Lighting | Reduced energy consumption | Lower maintenance costs |

| Natural Ventilation | Decreased HVAC needs | Improved air quality |

| Solar Panels | On-site renewable energy | Reduced grid dependency |

Water Conservation Measures

The substation takes water management seriously:

-

Rainwater Harvesting System

- Collects and stores rainwater for non-potable uses

- Reduces demand on municipal water supply

-

Low-Flow Fixtures

- Minimizes water usage in public areas

- Sets an example for water conservation

-

Drought-Resistant Landscaping

- Reduces irrigation needs

- Promotes native plant species

During my visit, I was impressed by how these water-saving features were seamlessly integrated into the substation’s design.

Smart Grid Integration

Denny Substation is at the forefront of smart grid technology:

-

Advanced Monitoring Systems

- Real-time data on power flow and equipment status

- Predictive maintenance capabilities

-

Automated Control Systems

- Rapid response to grid fluctuations

- Improved power quality and reliability

-

Integration with Renewable Energy Sources

- Ability to handle variable inputs from solar and wind

- Support for distributed energy resources

Energy Efficiency in Operations

The substation doesn’t just distribute power; it uses it wisely:

-

High-Efficiency Transformers

- Reduce energy losses during voltage conversion

- Exceed current efficiency standards

-

Optimized Cooling Systems

- Use of natural convection where possible

- Energy-efficient mechanical cooling when necessary

-

Demand Response Capabilities

- Ability to adjust operations based on grid demands

- Supports overall grid stability and efficiency

I was particularly fascinated by how these efficiency measures were implemented without compromising the substation’s core functions.

Environmental Impact Reduction

Denny Substation goes beyond energy and water savings:

-

Noise Reduction Measures

- Sound-absorbing materials and designs

- Minimizes impact on surrounding neighborhood

-

EMF Mitigation

- Strategic equipment placement and shielding

- Ensures public safety in and around the facility

-

Air Quality Considerations

- Use of SF6 gas alternatives where possible

- Monitoring and containment systems for emissions

Challenges in Implementing Green Technologies

Integrating these sustainable features wasn’t without its challenges:

-

Initial Cost Considerations

- Higher upfront investment for green technologies

- Need to justify long-term benefits

-

Technological Integration

- Ensuring compatibility between various smart systems

- Maintaining cybersecurity in an increasingly connected environment

-

Regulatory Navigation

- Meeting both energy and environmental regulations

- Setting new standards for green substation design

As I discussed these challenges with the project team, I was impressed by their commitment to overcoming obstacles in pursuit of sustainability.

Future-Proofing the Substation

Denny Substation isn’t just built for today; it’s designed for the future:

-

Expandable Smart Grid Capabilities

- Ready for future technological advancements

- Adaptable to changing energy landscapes

-

Climate Change Considerations

- Designed to withstand potential environmental changes

- Flexible operations to adapt to shifting energy demands

-

Community Education Programs

- Ongoing initiatives to promote sustainability awareness

- Inspiring visitors to adopt eco-friendly practices

Remember, Denny Substation isn’t just a power distribution facility; it’s a living laboratory for sustainable urban infrastructure. It demonstrates that with innovative thinking and commitment, we can transform traditionally industrial facilities into beacons of sustainability and technological innovation.

A New Paradigm: Lessons from Denny Substation for Future Urban Infrastructure Projects?

Can a single substation project change the way we think about urban infrastructure? Denny Substation in Seattle proves that it can, offering valuable lessons for cities worldwide.

Denny Substation sets a new standard for urban infrastructure projects, demonstrating that essential utilities can be integrated into the urban fabric in ways that benefit the community. It offers lessons in public engagement, sustainable design, and the fusion of technology with urban planning.

As an engineer who’s worked on numerous infrastructure projects, I’ve seen firsthand how Denny Substation is reshaping our approach to urban planning. Let’s explore the key lessons this innovative project offers:

Rethinking Public Engagement

Denny Substation revolutionizes how we involve the public in infrastructure projects:

-

Early Community Involvement

- Engaged residents in the design process from the start

- Incorporated community feedback into final plans

-

Transparency in Development

- Regular public updates throughout construction

- Open houses and tours to explain the project

-

Ongoing Educational Programs

- Continuous engagement through on-site exhibits

- School programs and community workshops

| Engagement Method | Traditional Approach | Denny Substation Approach |

|---|---|---|

| Public Meetings | Limited, formal sessions | Frequent, interactive workshops |

| Information Sharing | Technical documents | Accessible displays and tours |

| Community Input | Minimal consideration | Integral to design process |

Integrating Infrastructure with Urban Design

The project showcases how infrastructure can enhance rather than detract from urban spaces:

-

Multifunctional Design

- Combines utility function with public amenities

- Creates value beyond its primary purpose

-

Aesthetic Consideration

- Architecturally significant design

- Enhances the visual appeal of the neighborhood

-

Public Space Creation

- Incorporates parks, walkways, and gathering areas

- Turns utility land into community assets

During my visits to Denny Substation, I’ve been struck by how seamlessly it blends into the urban landscape while still standing out as a unique landmark.

Sustainability as a Core Principle

Denny Substation demonstrates how infrastructure projects can lead in sustainability:

-

Green Building Practices

- LEED certification standards

- Use of recycled and sustainable materials

-

Energy Efficiency

- Innovative cooling and lighting systems

- On-site renewable energy generation

-

Water Conservation

- Rainwater harvesting and reuse

- Drought-resistant landscaping

Embracing Technological Innovation

The project showcases the potential of smart infrastructure:

-

Advanced Grid Management

- Real-time monitoring and control systems

- Preparation for future smart city integration

-

Flexible Design for Future Technologies

- Adaptable spaces for equipment upgrades

- Ready for emerging energy technologies

-

Data-Driven Operations

- Use of IoT sensors for predictive maintenance

- Optimization of energy distribution based on usage patterns

Challenges and Solutions in Implementation

Implementing this new paradigm wasn’t without obstacles:

-

Regulatory Hurdles

- Navigating existing zoning laws

- Setting new precedents for mixed-use utility spaces

-

Cost Justification

- Higher initial investment than traditional substations

- Demonstrating long-term community and operational benefits

-

Operational Complexities

- Managing public access alongside utility operations

- Ensuring security without creating a fortress-like atmosphere

As I discussed these challenges with project leaders, I was impressed by their innovative problem-solving approaches and commitment to the vision.

Lessons for Future Projects

Denny Substation offers valuable insights for other cities and infrastructure planners:

-

Holistic Planning

- Consider infrastructure as part of the urban ecosystem

- Look for opportunities to create multi-use spaces

-

Community-Centric Design

- Prioritize community needs and input

- Create infrastructure that adds value to neighborhoods

-

Forward-Thinking Technology Integration

- Design for future technological advancements

- Incorporate smart systems from the ground up

-

Sustainability Focus

- Make environmental responsibility a core design principle

- Showcase green technologies to educate and inspire

-

Transparency and Education

- Use infrastructure projects as opportunities for public education

- Be open about processes, challenges, and benefits

The Ripple Effect

The impact of Denny Substation extends beyond Seattle:

-

Inspiring Other Cities

- Serving as a model for urban infrastructure projects worldwide

- Encouraging rethinking of existing utility spaces

-

Changing Public Perception

- Transforming the image of utility infrastructure

- Fostering public interest in and understanding of power systems

-

Influencing Policy and Regulation

- Prompting updates to urban planning guidelines

- Encouraging more flexible approaches to infrastructure development

Remember, Denny Substation isn’t just a one-off project; it’s a blueprint for the future of urban infrastructure. It shows us that with creativity, community engagement, and a commitment to sustainability, we can transform necessary utilities into valuable community assets. As cities worldwide grapple with aging infrastructure and growing populations, the lessons from Denny Substation offer a path forward – one where our urban necessities become opportunities for innovation, education, and community building.

Conclusion

Denny Substation represents a paradigm shift in urban infrastructure design, seamlessly blending functionality with community engagement and sustainability. It sets a new standard for how cities can integrate essential utilities into the urban fabric, creating value beyond power distribution.

Have you ever wondered about those fenced-off areas filled with electrical equipment? They’re more important than you might think. These are electrical substations, and they’re vital to our power grid.

An electrical substation is a key part of the power grid that transforms voltage levels, switches connections, and helps distribute electricity. It acts as a control center for the flow of electrical power, ensuring safe and efficient energy delivery from power plants to homes and businesses.

As an electrical engineer who’s spent years working with substations, I can tell you they’re fascinating places. They’re like the heart of our power system, pumping electricity to where it’s needed. Let’s dive into the world of substations and discover why they’re so crucial to our daily lives.

The Basics of Electrical Substations: Functions and Importance in Power Distribution?

Ever flipped a light switch and wondered how that electricity got to your home? The journey involves electrical substations, but what exactly do they do? Let’s shed some light on this often-overlooked part of our power system.

Electrical substations serve three main functions: voltage transformation, circuit switching, and power system control. They’re essential for efficient power distribution, helping to step voltage up for long-distance transmission and down for local use, while also providing crucial safety and control mechanisms.

I remember my first visit to a substation as a young engineer. The scale and complexity of the equipment were overwhelming. But once I understood the basic functions, it all started to make sense. Let me break it down for you:

Voltage Transformation: The Heart of Substation Operations

Substations are all about managing voltage levels:

-

Step-Up Transformation

- Increases voltage for long-distance transmission

- Reduces power losses over long distances

-

Step-Down Transformation

- Decreases voltage for local distribution

- Makes electricity safe for home and business use

Circuit Switching: Managing Power Flow

Substations act like traffic controllers for electricity:

| Function | Purpose | Benefit |

|---|---|---|

| Connecting/Disconnecting Lines | Control power flow | Flexibility in power distribution |

| Isolating Faulty Sections | Prevent widespread outages | Improved system reliability |

| Load Balancing | Optimize power distribution | Efficient use of resources |

System Control and Protection

Substations play a crucial role in maintaining grid stability:

-

Monitoring

- Real-time tracking of power flow and equipment status

- Early detection of potential issues

-

Protection

- Automatic fault detection and isolation

- Prevents damage to expensive equipment

-

Power Quality Management

- Maintains consistent voltage and frequency

- Ensures reliable power supply to consumers

I once worked on a project to upgrade an old substation’s control systems. The improvement in response time and accuracy was remarkable. It showed me how crucial these control functions are for a stable power supply.

The Importance of Substations in Power Distribution

Substations are more than just a collection of electrical equipment:

-

Efficiency Enablers

- Allow for efficient long-distance power transmission

- Reduce energy losses in the distribution process

-

Grid Stability Guardians

- Help maintain consistent power quality

- Respond quickly to changes in demand or supply

-

Safety Enforcers

- Provide multiple layers of protection against electrical faults

- Ensure safe voltage levels for end-users

-

Flexibility Providers

- Allow for easy integration of new power sources

- Enable quick reconfiguration of power flow paths

Remember, every time you use electricity, you’re benefiting from the work done by substations. They’re the unsung heroes of our power grid, working tirelessly to ensure we have safe, reliable electricity whenever we need it.

Anatomy of a Substation: Key Components and Their Roles in Power Management?

Have you ever looked at a substation and wondered what all those strange-looking pieces of equipment do? It’s like a complex puzzle, but each piece has a crucial role. Let’s unravel this mystery together.

A typical substation consists of several key components: transformers for voltage changes, circuit breakers for protection, busbars for power distribution, insulators for safety, and control systems for management. Each component plays a vital role in ensuring the safe and efficient flow of electricity through the power grid.

As someone who’s spent countless hours designing and working with these components, I can tell you that understanding their functions is key to grasping how our power system works. Let’s break down the main parts:

Transformers: The Voltage Changers

Transformers are the workhorses of a substation:

- Function: Change voltage levels

- Types:

- Step-up transformers (increase voltage)

- Step-down transformers (decrease voltage)

I once worked on replacing an old transformer in a city substation. The new unit was so much more efficient that it reduced energy losses by 30%. It showed me how crucial good transformer design is for energy conservation.

Circuit Breakers: The Safety Guards

These devices are like the fuses in your home, but on a much larger scale:

| Type | Function | Application |

|---|---|---|

| Air Circuit Breakers | Interrupt current flow in air | Low to medium voltage |

| Oil Circuit Breakers | Use oil for arc extinction | Medium to high voltage |

| SF6 Circuit Breakers | Use sulfur hexafluoride gas | High voltage applications |

Busbars: The Power Highways

Busbars are the main conductors in a substation:

- Purpose: Distribute power to different circuits

- Materials: Usually made of copper or aluminum

- Configuration: Can be in various arrangements for flexibility

Insulators: The Safety Barriers

Insulators prevent electricity from flowing where it shouldn’t:

- Types:

- Porcelain insulators

- Polymer insulators

- Function: Provide electrical isolation and mechanical support

Control and Protection Systems: The Brains of the Operation

These systems monitor and manage the substation:

- SCADA (Supervisory Control and Data Acquisition) systems

- Protective relays

- Metering equipment

I remember implementing a new SCADA system in a large substation. The improvement in response time and the ability to predict potential issues before they occurred was impressive.

Switchgear: The Power Directors

Switchgear equipment controls the flow of electricity:

- Function: Connect and disconnect various electrical equipment

- Types:

- Air-insulated switchgear (AIS)

- Gas-insulated switchgear (GIS)

Capacitor Banks: The Power Quality Improvers

These devices help maintain voltage levels and improve power factor:

- Purpose: Provide reactive power compensation

- Benefit: Improve overall system efficiency

Grounding Systems: The Safety Nets

Proper grounding is crucial for safety:

- Function: Provide a path for fault currents

- Components: Ground rods, grounding grids, and connections

Remember, each of these components works together in a carefully orchestrated system. It’s this integration that allows substations to perform their crucial role in our power grid. Understanding these components helps us appreciate the complexity and importance of substations in our daily lives.

Voltage Transformation: How Substations Enable Efficient Power Transmission?

Have you ever wondered why we need different voltage levels in our power system? The answer lies in the magic of voltage transformation, a key function of electrical substations. Let’s explore how this process works and why it’s so important.

Substations use transformers to change voltage levels, enabling efficient power transmission over long distances and safe distribution to end-users. High voltages reduce power losses during transmission, while lower voltages are safer for local distribution. This voltage transformation is crucial for the overall efficiency and safety of our power grid.

As an engineer who’s worked on numerous substation projects, I’ve seen firsthand how crucial voltage transformation is. Let me break down this process for you:

The Need for Voltage Transformation

Why do we need to change voltage levels? Here’s the simple explanation:

-

High Voltage for Transmission

- Reduces power losses over long distances

- Allows for more efficient use of conductor materials

-

Lower Voltage for Distribution

- Safer for local use

- Compatible with consumer appliances and equipment

How Transformers Work

Transformers are the key to voltage transformation:

- Basic Principle: Electromagnetic induction

- Components:

- Primary winding (input)

- Secondary winding (output)

- Iron core

I remember explaining this to a group of students once. I used the analogy of water pressure in pipes. High voltage is like high water pressure – great for moving water (or electricity) over long distances, but too powerful for home use.

Types of Voltage Transformation in Substations

Substations perform different types of voltage transformations:

| Type | Purpose | Example |

|---|---|---|

| Step-Up | Increase voltage for transmission | 20kV to 400kV |

| Step-Down | Decrease voltage for distribution | 400kV to 33kV |

| Distribution | Further reduce for end-user | 33kV to 415/240V |

Efficiency Gains Through Voltage Transformation

The benefits of proper voltage transformation are significant:

-

Reduced Power Losses

- High voltage transmission reduces I²R losses

- Can save millions in energy costs annually

-

Improved Power Quality

- Helps maintain consistent voltage levels

- Reduces voltage drops over long distances

-

Increased Transmission Capacity

- Higher voltages allow more power on existing lines

- Delays need for new transmission corridors

Challenges in Voltage Transformation

While voltage transformation is crucial, it comes with challenges:

-

Equipment Costs

- High-voltage transformers are expensive

- Require significant investment in infrastructure

-

Safety Concerns

- Higher voltages require more stringent safety measures

- Need for larger clearances and robust insulation

-

Maintenance Requirements

- Regular testing and maintenance are crucial

- Specialized skills needed for high-voltage equipment

I once worked on a project to upgrade a substation from 230kV to 500kV. The challenges were significant, but the benefits in terms of increased capacity and reduced losses were well worth it.

The Future of Voltage Transformation

As our power needs evolve, so does voltage transformation technology:

-

Smart Transformers

- Incorporate digital monitoring and control

- Allow for more flexible voltage regulation

-

Higher Voltage Levels

- Ultra-high voltage transmission (1000kV and above)

- Enables even more efficient long-distance power transfer

-

Integration with Renewable Energy

- Handling variable inputs from wind and solar

- Bidirectional power flow capabilities

Remember, every time you plug in a device, you’re benefiting from the voltage transformation that occurs in substations. It’s a crucial process that enables our modern electrical grid to function efficiently and safely.

Types of Substations: From Transmission to Distribution in the Electrical Grid?

Did you know that not all substations are created equal? Just as our cities have different types of roads – from highways to local streets – our power grid has different types of substations. Each plays a unique role in getting electricity from power plants to your home.

Electrical substations come in several types, each serving a specific purpose in the power grid. The main types include transmission substations, distribution substations, and switching substations. Each type handles different voltage levels and performs specific functions in the process of delivering electricity from generation to end-users.

In my years working with power systems, I’ve had the chance to work on various types of substations. Each has its own challenges and unique features. Let’s explore the main types:

Transmission Substations: The Power Highways

Transmission substations are like the interstate highways of the power grid:

- Function: Handle very high voltages (typically 230kV to 765kV)

- Purpose:

- Connect power plants to the transmission network

- Transfer large amounts of power over long distances

I once worked on a 500kV transmission substation. The scale of the equipment and the amount of power it handled was awe-inspiring.

Sub-Transmission Substations: The Regional Connectors

These substations act as a bridge between transmission and distribution:

- Voltage Levels: Typically 69kV to 138kV

- Role:

- Step down voltage from transmission levels

- Distribute power to smaller geographical areas

Distribution Substations: Bringing Power to Communities

Distribution substations are where power gets ready for local use:

| Feature | Purpose | Typical Values |

|---|---|---|

| Input Voltage | Receive power from sub-transmission | 69kV – 138kV |

| Output Voltage | Prepare for local distribution | 4kV – 34.5kV |

| Service Area | Local communities | Towns, neighborhoods |

Switching Substations: The Traffic Controllers

These substations don’t change voltage levels but play a crucial role:

- Function: Route power between different lines or circuits

- Importance:

- Enhance system reliability

- Allow for maintenance without widespread outages

I remember working on a switching substation upgrade that significantly improved the grid’s flexibility in a large urban area.

Customer Substations: Power for Large Consumers

Some large industrial or commercial customers have their own substations:

- Purpose: Provide power at the right voltage for specific industrial processes

- Ownership: Often owned and operated by the customer

Mobile Substations: Power on the Go

These are temporary or emergency substations:

- Use: Provide power during emergencies or maintenance

- Advantage: Can be quickly deployed to restore power

Specialized Substations

Some substations serve specific purposes:

-

Converter Substations:

- Convert between AC and DC power

- Used in long-distance HVDC transmission

-

Traction Substations:

- Power electric railway systems

- Convert power to suitable form for trains

Comparing Substation Types

Each type of substation has its unique characteristics:

-

Size:

- Transmission substations: Largest

- Distribution substations: Smaller, more numerous

-

Equipment:

- Transmission: Larger transformers, higher-rated circuit breakers

- Distribution: Smaller equipment, more focused on local needs

-

Complexity:

- Switching substations: Often most complex in terms of connections

- Distribution: Simpler layout, focused on voltage step-down

-

Location:

- Transmission: Often in remote areas

- Distribution: Closer to population centers

-

Automation Level:

- Modern substations of all types: Increasing use of automation

- Transmission and large distribution: Often fully automated

Remember, these different types of substations work together in a complex network. They form the backbone of our power distribution system, ensuring that electricity is efficiently and safely delivered from power plants to our homes and businesses. Understanding these types helps us appreciate the intricate system that powers our daily lives.

Modern Substation Technology: Safety, Efficiency, and Smart Grid Integration?

Ever wondered how our power grid keeps up with our growing energy needs? The answer lies in the cutting-edge technology used in modern substations. These aren’t your grandfather’s power stations – they’re high-tech hubs of innovation.

Modern substations incorporate advanced technologies for improved safety, efficiency, and integration with smart grids. Key features include digital control systems, real-time monitoring, automated fault detection, and the ability to integrate renewable energy sources. These technologies enhance reliability, reduce maintenance costs, and support the evolving needs of our power infrastructure.

As someone who’s been involved in substation upgrades and new installations, I’ve seen firsthand how technology is transforming these critical facilities. Let’s explore the key advancements:

Digital Control Systems: The Brain of Modern Substations

Digital systems have revolutionized substation operations:

-

SCADA (Supervisory Control and Data Acquisition)

- Real-time monitoring and control

- Remote operation capabilities

-

Intelligent Electronic Devices (IEDs)

- Combine multiple functions in one unit

- Improve reliability and reduce wiring complexity

I remember upgrading an old electromechanical relay system to a modern digital one. The improvement in response time and accuracy was remarkable.

Advanced Protection Systems

Modern protection systems offer enhanced grid security:

| Feature | Benefit | Example |

|---|---|---|

| Adaptive Protection | Adjusts to changing grid conditions | Self-adjusting relay settings |

| Wide Area Protection | Coordinates across multiple substations | Prevents cascading failures |

| High-Speed Communication | Faster fault detection and isolation | Fiber optic-based systems |

Smart Grid Integration

Modern substations are key players in smart grid technology:

-

Two-Way Communication

- Enables real-time data exchange with control centers

- Supports demand response and load balancing

-

Renewable Energy Integration

- Handles variable inputs from solar and wind sources

- Supports bidirectional power flow

-

Energy Storage Systems

- Integrates battery storage for grid stability

- Helps manage peak loads and intermittent generation

I once worked on a project integrating a large solar farm with a substation. The challenges of managing variable power input were significant, but the smart grid technologies made it possible.

Efficiency Improvements

Modern substations are designed for maximum efficiency:

-

Advanced Transformers

- Use of amorphous core materials

- Reduce energy losses by up to 70% compared to older models

-

Gas-Insulated Switchgear (GIS)

- Compact design reduces substation footprint

- Lower maintenance requirements

-

Condition-Based Maintenance

- Uses sensors and analytics to predict equipment failures

- Reduces downtime and extends equipment life

Enhanced Safety Features

Safety is a top priority in modern substation design:

-

Arc Flash Mitigation

- Rapid detection and quenching of electrical arcs

- Reduces risk of injury and equipment damage

-

Advanced Grounding Systems

- Improved protection against step and touch potentials

- Use of computer modeling for optimal design

-

Remote Operations

- Reduces need for on-site personnel in hazardous conditions

- Allows for quick response to emergencies

I recall implementing an advanced arc flash protection system in a substation. The peace of mind it provided to the maintenance team was invaluable.

Environmental Considerations

Modern substations are designed with environmental impact in mind:

-

SF6 Gas Alternatives

- Use of eco-friendly insulating gases

- Reduces greenhouse gas emissions

-

Noise Reduction

- Advanced designs to minimize operational noise

- Important for substations in urban areas

-

Oil Containment

- Improved systems to prevent and contain oil spills

- Protects surrounding soil and water resources

Cybersecurity Measures

With increased connectivity comes the need for robust cybersecurity:

-

Firewalls and Encryption

- Protects against unauthorized access

- Secures communication channels

-

Access Control Systems

- Biometric and multi-factor authentication

- Limits physical and digital access to critical systems

-

Regular Security Audits

- Identifies and addresses vulnerabilities

- Ensures compliance with industry standards

Future Trends in Substation Technology

The evolution of substation technology is ongoing:

-

AI and Machine Learning

- Predictive maintenance and fault diagnosis

- Optimizes power flow and grid stability

-

Internet of Things (IoT)

- Increased use of sensors for real-time monitoring

- Enables more granular control of grid operations

-

High-Temperature Superconducting Equipment

- Reduces power losses

- Allows for more compact substation designs

-

Virtual and Augmented Reality

- Enhances training and maintenance procedures

- Provides real-time information to field technicians

Remember, these technological advancements are not just about improving efficiency and reliability. They’re about creating a more resilient, flexible, and sustainable power grid that can meet the challenges of the 21st century. As our energy needs evolve, so too will the technology that powers our world.

Conclusion

Electrical substations are crucial components of our power grid, transforming and distributing electricity safely and efficiently. From basic voltage transformation to smart grid integration, substations continue to evolve, embracing new technologies to meet our growing energy needs and environmental challenges.

Have you ever wondered how electricity from power plants reaches your home safely? The answer lies in a device you’ve probably never thought about: the electric transformer. This unsung hero of our power grid is essential to modern life.

An electric transformer is a device that changes the voltage of electrical power without altering its frequency. It enables efficient power transmission over long distances and safe use in homes and businesses by stepping voltage up or down as needed.

As an electrical engineer with years of experience in power systems, I’ve seen firsthand how crucial transformers are to our daily lives. In this article, I’ll break down the basics of transformers, explaining how they work and why they’re so important in our modern world.

The Basics of Transformer Operation: Understanding Electromagnetic Induction?

Have you ever been puzzled by how transformers work their magic? The key lies in a principle called electromagnetic induction. It’s not as complicated as it sounds, and understanding it will unlock the mystery of transformer operation.

Transformers operate on the principle of electromagnetic induction. When an alternating current flows through one coil (primary), it creates a changing magnetic field. This field induces a voltage in another nearby coil (secondary), effectively transferring electrical energy between the two coils.

Let me take you through the fascinating world of electromagnetic induction and how it powers transformer operation. It’s a bit like a magic trick, but with science!

The Magic of Magnetic Fields

At the heart of transformer operation is the relationship between electricity and magnetism:

-

Changing Electric Current Creates Magnetic Field

- When electric current flows through a wire, it creates a magnetic field around it

- If the current is alternating (AC), the magnetic field constantly changes

-

Changing Magnetic Field Induces Electric Current

- When a changing magnetic field passes through a coil of wire, it induces a voltage in that coil

- This induced voltage can create a current in a closed circuit

This two-way relationship is the foundation of transformer operation.

How Transformers Harness Electromagnetic Induction

Here’s a step-by-step breakdown of how a transformer uses this principle:

-

Primary Coil Excitation

- AC power is applied to the primary coil

- This creates a changing magnetic field in the transformer core

-

Magnetic Field in the Core

- The core, usually made of iron, concentrates and directs the magnetic field

- This field is shared by both primary and secondary coils

-

Secondary Coil Induction

- The changing magnetic field induces a voltage in the secondary coil

- The magnitude of this voltage depends on the number of turns in the coils

The Importance of Alternating Current (AC)

Transformers only work with AC power. Here’s why:

- AC constantly changes direction

- This changing current creates a continuously varying magnetic field

- A steady DC current would only create a static magnetic field, which wouldn’t induce voltage in the secondary coil

I remember a student once asking why we don’t use transformers with DC power. It was a great opportunity to explain the crucial role of AC in transformer operation.

Factors Affecting Transformer Efficiency

Several factors influence how well a transformer performs its electromagnetic induction:

-

Core Material

- High-quality magnetic materials improve field strength

- Modern transformers often use silicon steel or amorphous metals

-

Coil Design

- The number of turns in each coil affects voltage transformation

- Coil geometry impacts efficiency and heat dissipation

-

Frequency

- Higher frequencies can allow for smaller, more efficient transformers

- But most power systems operate at fixed frequencies (50 or 60 Hz)

Real-World Applications

Understanding electromagnetic induction in transformers helps explain various applications:

- Power Distribution: Stepping voltage up for long-distance transmission and down for local use

- Electronics: Small transformers in chargers and adapters

- Industrial Equipment: Large transformers in manufacturing plants

Challenges and Innovations

While the basic principle remains the same, transformer technology continues to evolve:

-

Reducing Losses

- Core losses (hysteresis and eddy currents)

- Copper losses in windings

-

Improving Efficiency

- Advanced core materials

- Better cooling methods

-

Size and Weight Reduction

- High-frequency transformers for certain applications

- New designs for compact power supplies

Remember, every time you plug in a device or turn on a light, you’re benefiting from the principle of electromagnetic induction in transformers. It’s a testament to how fundamental scientific principles can have profound impacts on our daily lives.

Anatomy of an Electric Transformer: Key Components and Their Functions?

Ever looked at a transformer and wondered what’s inside that metal box? You’re not alone. The inner workings of a transformer can seem mysterious, but once you understand its key components, you’ll see how elegantly simple these devices really are.

An electric transformer consists of several key components: a primary coil, a secondary coil, a core, insulation, and a cooling system. Each part plays a crucial role in the transformer’s function of converting voltage levels while maintaining power integrity.

Let’s dive into the anatomy of a transformer. I’ll break down each component and explain its role, drawing from my years of experience designing and working with these essential devices.

The Heart of the Transformer: Coils and Core

Primary and Secondary Coils

The coils are where the electrical magic happens:

-

Primary Coil

- Receives input power

- Creates changing magnetic field

-

Secondary Coil

- Picks up the magnetic field

- Produces output power

The number of turns in each coil determines the voltage transformation ratio.

The Core: Magnetic Field Superhighway

The core is crucial for efficient operation:

- Material: Usually laminated steel or ferrite

- Function: Concentrates and directs magnetic field

- Design: Shaped to minimize losses

I once worked on a project where changing the core material improved efficiency by 2%. It might not sound like much, but in large power systems, it’s a significant saving.

Insulation: Keeping Things Separate and Safe

Proper insulation is vital for safety and efficiency:

-

Coil Insulation

- Prevents short circuits between turns

- Materials: Enamel, paper, or synthetic materials

-

Oil Insulation (in larger transformers)

- Provides both insulation and cooling

- Requires regular testing and maintenance

-

Air Gaps

- Used in some designs to control magnetic properties

Cooling Systems: Managing the Heat

Transformers generate heat, and managing it is crucial:

| Cooling Method | Typical Application | Advantages |

|---|---|---|

| Oil-Filled | Large power transformers | Excellent cooling, long life |

| Air-Cooled | Smaller distribution transformers | Simple, low maintenance |

| Dry-Type | Indoor or sensitive environments | No oil leakage risk |

In my early career, I worked on a project to retrofit an old oil-filled transformer with a modern cooling system. The improvement in efficiency and lifespan was remarkable.

Structural Components: Holding It All Together

These parts ensure the transformer’s integrity:

-

Tank or Enclosure

- Protects internal components

- Contains insulating oil in oil-filled types

-

Bushings

- Insulated passages for connections

- Critical for preventing flashovers

-

Tap Changers

- Allow for voltage adjustment

- Can be manual or automatic

Protective Devices: Ensuring Safe Operation

Safety is paramount in transformer design:

-

Pressure Relief Devices

- Prevent explosion in case of internal pressure build-up

-

Buchholz Relay (in oil-filled transformers)

- Detects gas accumulation or oil loss

- Can trigger alarms or shutdowns

-

Temperature Monitors

- Track winding and oil temperatures

- Prevent overheating damage

Monitoring and Control Equipment

Modern transformers often include:

- Sensors for temperature, pressure, and oil level

- Data loggers for performance tracking

- Smart controls for remote operation

Putting It All Together: How Components Interact

Understanding how these components work together is key:

- Power Input: Enters through primary bushings to primary coil

- Magnetic Field Generation: Primary coil creates field in core

- Power Transfer: Core transfers field to secondary coil

- Voltage Transformation: Secondary coil outputs different voltage

- Heat Management: Cooling system dissipates generated heat

- Safety Oversight: Protective devices monitor for issues

Innovations in Transformer Components

The field is constantly evolving:

- Advanced Core Materials: Amorphous metals for lower losses

- Solid-State Transformers: Using power electronics for more flexible voltage control

- Smart Monitoring: IoT integration for predictive maintenance

Remember, while the basic principle of transformers hasn’t changed much since their invention, the materials and technologies used in their components are constantly improving. This ongoing evolution ensures that transformers continue to meet the growing demands of our power-hungry world efficiently and safely.

Voltage Transformation Explained: Step-Up and Step-Down Processes in Power Distribution?

Have you ever wondered how electricity from a power plant can travel hundreds of miles and still safely power your home appliances? The secret lies in the voltage transformation capabilities of electric transformers. This process is fundamental to our entire power distribution system.

Voltage transformation in transformers involves step-up and step-down processes. Step-up transformers increase voltage for efficient long-distance transmission, while step-down transformers reduce voltage for safe local distribution and consumption. This process is crucial for minimizing power losses and ensuring electrical safety.

Let me walk you through the fascinating world of voltage transformation. As someone who’s designed and implemented transformer systems, I can tell you that this process is the backbone of our entire electrical grid.

The Basics of Voltage Transformation

At its core, voltage transformation is about the relationship between the number of turns in the primary and secondary coils:

- Step-Up Transformation: Secondary has more turns than primary

- Step-Down Transformation: Primary has more turns than secondary

The voltage ratio is directly proportional to the turns ratio:Voltage Ratio = Primary Voltage / Secondary Voltage = Secondary Turns / Primary Turns

Step-Up Transformation: Powering Long-Distance Transmission

Step-up transformers are crucial at power plants. Here’s why:

-

Increase Voltage for Transmission

- Typical generation voltage: 10-25 kV

- Transmission voltage: 100-765 kV

-

Reduce Current for Same Power

- Lower current means less power loss in transmission lines

- Power (P) = Voltage (V) × Current (I)

-

Enable Efficient Long-Distance Power Transfer

- High voltage allows power to travel hundreds of miles with minimal losses

I once worked on a project to upgrade a power plant’s step-up transformer. The new transformer increased transmission voltage from 230 kV to 500 kV, reducing transmission losses by over 30%.

Step-Down Transformation: Bringing Power to Consumers

As power gets closer to end-users, we need to step the voltage down:

-

Substation Transformers

- Reduce transmission voltage to distribution levels (typically 4-35 kV)

-

Distribution Transformers

- Further reduce voltage for residential use (120/240 V in the US)

-

Safety and Appliance Compatibility

- Lower voltages are safer for consumer use

- Household appliances are designed for these lower voltages

The Transformation Process: A Closer Look

Let’s break down what happens inside the transformer:

-

Primary Coil Excitation

- AC power creates changing magnetic field

-

Magnetic Field in Core

- Field strength proportional to primary current and turns

-

Secondary Coil Induction

- Changing field induces voltage in secondary coil

- Induced voltage proportional to turns ratio

Efficiency Considerations in Voltage Transformation

Transformers are highly efficient, but some losses occur:

| Loss Type | Cause | Mitigation |

|---|---|---|

| Core Losses | Hysteresis and eddy currents in core | Use of high-quality core materials |

| Copper Losses | Resistance in windings | Optimal winding design, larger conductors |

| Stray Losses | Leakage flux | Proper shielding and core design |

Modern transformers can achieve efficiencies over 99%, but even small improvements can lead to significant energy savings in large power systems.

Real-World Applications of Voltage Transformation

-

Renewable Energy Integration

- Step-up transformers for wind farms and solar plants

-

Industrial Power Supply

- Custom voltage levels for manufacturing processes

-

Electric Vehicle Charging

- Step-down transformers in charging stations

-

Smart Grid Technologies

- Transformers with on-load tap changers for voltage regulation

Challenges in Voltage Transformation

-

Voltage Regulation

- Maintaining consistent output voltage under varying loads

-

Harmonics

- Dealing with non-sinusoidal waveforms in modern power systems

-

Overloading

- Managing peak demands without compromising transformer life

Innovations in Voltage Transformation

The field is constantly evolving:

-

Solid-State Transformers

- Use power electronics for more flexible voltage control

-

Smart Transformers

- Incorporate sensors and controls for real-time adjustments

-

High-Temperature Superconducting Transformers

- Promise even higher efficiencies and power densities

Remember, every time you use electricity, you’re benefiting from a complex system of voltage transformations. From the power plant to your wall outlet, transformers work tirelessly to ensure that electricity is transmitted efficiently and used safely. It’s a testament to the ingenuity of electrical engineering and the importance of understanding these fundamental processes.

Types of Transformers: From Distribution to Power Electronics Applications?

Have you ever noticed the variety of transformers around you? From the large units in substations to the tiny ones in your phone charger, transformers come in many shapes and sizes. But what are the different types, and how do they serve various applications?

Transformers come in various types, each designed for specific applications. These include power transformers for bulk energy transfer, distribution transformers for local power supply, instrument transformers for measurement, and electronic transformers for low-power applications. Each type has unique characteristics suited to its role.

As someone who’s worked with a wide range of transformer types, I can tell you that understanding these differences is crucial for anyone involved in electrical systems. Let’s explore the main categories and their applications.

Power Transformers: The Backbone of Electrical Grids

Power transformers handle the heavy lifting in our electrical systems:

-

Step-Up Power Transformers

- Location: Power plants

- Function: Increase voltage for long-distance transmission

- Capacity: Can handle hundreds of MVA

-

Step-Down Power Transformers

- Location: Substations

- Function: Reduce voltage for distribution networks

- Features: Often equipped with tap changers for voltage regulation

I once worked on installing a 500 MVA transformer at a major substation. The sheer size and complexity of these units are awe-inspiring.

Distribution Transformers: Bringing Power to Consumers

These are the workhorses of local power distribution:

- Location: Neighborhoods, poles, or ground-mounted

- Function: Reduce voltage to levels suitable for homes and businesses

- Types:

- Pole-mounted (for overhead lines)

- Pad-mounted (for underground distribution)

Instrument Transformers: Precision in Measurement

These specialized transformers are crucial for monitoring and protection:

-

Current Transformers (CTs)

- Function: Measure high currents safely

- Applications: Metering, protection relays

-

Voltage Transformers (VTs) or Potential Transformers (PTs)

- Function: Step down high voltages for measurement

- Applications: Voltage monitoring, metering

Special-Purpose Transformers

These transformers serve specific industrial or commercial needs:

-

Isolation Transformers

- Function: Provide electrical isolation between circuits

- Applications: Medical equipment, sensitive electronics

-

Autotransformers

- Feature: Single winding acts as both primary and secondary

- Advantage: Smaller, lighter, and often more efficient

-

Three-Phase Transformers

- Function: Handle three-phase power systems

- Applications: Industrial power systems, large commercial buildings

Electronic Transformers: Powering Our Digital World

These small but crucial transformers are everywhere in modern electronics:

-

Flyback Transformers

- Function: Provide isolated power in switched-mode power supplies

- Applications: TVs, computer monitors

-

Audio Transformers

- Function: Couple audio signals between circuits

- Applications: High-fidelity audio equipment, telecommunications

-

Pulse Transformers

- Function: Transmit digital pulses while providing isolation

- Applications: Digital circuits, signal processing

I remember designing a custom pulse transformer for a high-speed data transmission system. The challenge of balancing signal integrity with isolation requirements was fascinating.

Comparison of Transformer Types

Let’s break down the key characteristics of different transformer types:

| Type | Size | Voltage Range | Efficiency | Key Feature |

|---|---|---|---|---|

| Power | Very Large | High (>33kV) | >99% | High capacity |

| Distribution | Medium | Medium (≤33kV) | 98-99% | Widespread use |

| Instrument | Small | Varies | N/A | High accuracy |

| Electronic | Very Small | Low (<1kV) | Varies | Compact design |

Specialized Transformers for Emerging Technologies

As technology evolves, new types of transformers are emerging:

-

Solid-State Transformers

- Function: Combine power electronics with traditional transformer principles

- Advantage: Offer more control over power flow and quality

-

Superconducting Transformers

- Feature: Use superconducting materials for windings

- Benefit: Extremely low losses and high power density

-

Smart Transformers

- Function: Incorporate digital monitoring and control capabilities

- Application: Key components in smart grid systems

Choosing the Right Transformer

Selecting the appropriate transformer type is crucial. Factors to consider include:

-

Power Requirements

- Voltage levels (input and output)

- Power capacity needed

-

Environmental Conditions

- Indoor vs. outdoor installation

- Temperature extremes

- Humidity and pollution levels

-

Space Constraints

- Available installation area

- Weight limitations

-

Regulatory Compliance

- Energy efficiency standards

- Safety regulations

-

Cost Considerations

- Initial investment

- Operational costs (efficiency, maintenance)

The Future of Transformer Technology

The field of transformer design is constantly evolving:

-

Integration with Renewable Energy

- Transformers designed for variable input from solar and wind sources

-

Improved Materials

- Development of new core materials for even higher efficiencies

-

Digital Twin Technology

- Virtual models for predictive maintenance and optimization

-

Eco-Friendly Designs

- Focus on biodegradable insulating fluids and recyclable materials

Remember, while the basic principle of transformers remains the same, the variety of types and ongoing innovations reflect the diverse and evolving needs of our electrical systems. From powering entire cities to charging your smartphone, transformers play a vital role in every aspect of our electrified world.

The Role of Transformers in Modern Power Systems: Efficiency, Safety, and Technological Advancements?

Have you ever wondered how our power systems manage to keep up with the ever-increasing demand for electricity? The answer lies largely in the continuous evolution of transformer technology. Transformers are not just passive components; they’re at the forefront of making our power systems more efficient, safe, and technologically advanced.

Modern transformers play a crucial role in enhancing power system efficiency, ensuring electrical safety, and enabling technological advancements. They incorporate smart technologies for real-time monitoring, use advanced materials for higher efficiency, and support the integration of renewable energy sources into the grid.

As someone who’s been involved in the development and implementation of transformer technologies, I can tell you that the role of transformers in modern power systems is more critical than ever. Let’s explore how these devices are shaping the future of electricity.

Efficiency: The Key to Sustainable Power Systems

Transformers are at the heart of efforts to improve overall power system efficiency:

-

Advanced Core Materials

- Amorphous metal cores reduce losses by up to 70% compared to traditional silicon steel

- Nanocrystalline materials promise even further improvements

-

Improved Winding Designs

- Optimized geometries reduce copper losses

- Use of high-temperature superconducting materials in experimental designs

-

Better Cooling Systems

- Advanced oil formulations for more effective heat dissipation

- Innovative cooling fin designs for air-cooled transformers

I once worked on a project replacing old transformers with new, high-efficiency models in a city’s distribution network. The energy savings were equivalent to powering several thousand homes!

Safety: Protecting People and Equipment

Modern transformers incorporate numerous safety features:

-

Arc Flash Mitigation

- Improved insulation systems

- Rapid fault detection and isolation

-

Fire Safety

- Use of less flammable insulating fluids

- Advanced fire suppression systems in large transformers

-

Environmental Protection

- Biodegradable oils to minimize environmental impact in case of leaks

- Better containment systems for oil-filled transformers

Technological Advancements: Smart Transformers for a Smart Grid

The integration of digital technologies is revolutionizing transformer capabilities:

-

Real-Time Monitoring

- Sensors for temperature, oil quality, and load

- Continuous health assessment and predictive maintenance

-

Smart Controls

- On-load tap changers for dynamic voltage regulation

- Integration with grid management systems for optimal power flow

-

Data Analytics

- Use of big data and AI for performance optimization

- Predictive modeling for asset management

Supporting Renewable Energy Integration

Transformers play a crucial role in integrating renewable energy sources:

-

Handling Variable Inputs

- Designed to manage fluctuating power from wind and solar sources

-

Bi-Directional Power Flow

- Enable power flow from distributed generation back to the grid

-

High-Frequency Operation

- Compact designs for offshore wind applications

Comparison: Traditional vs. Modern Transformers

Let’s look at how modern transformers stack up against their traditional counterparts:

| Aspect | Traditional Transformers | Modern Smart Transformers |

|---|---|---|

| Efficiency | Good (>98%) | Excellent (>99%) |

| Monitoring | Periodic manual checks | Continuous real-time monitoring |

| Control | Limited, often manual | Advanced, automated |

| Safety Features | Basic | Comprehensive |

| Grid Integration | Passive | Active, bi-directional |

Challenges and Future Directions

Despite advancements, challenges remain:

-

Cybersecurity

- Protecting smart transformers from cyber threats

-

Cost

- Balancing advanced features with economic viability

-

Retrofitting

- Upgrading existing infrastructure with new technologies

Future developments I’m excited about include:

-

Quantum Sensors

- Ultra-precise monitoring of transformer parameters

-

Self-Healing Materials

- Transformers that can repair minor damage autonomously

-

AI-Driven Optimization

- Transformers that adapt their operation in real-time based on grid conditions

Best Practices for Implementing Advanced Transformers

Based on my experience, here are some key considerations:

-

Holistic Approach

- Consider the entire power system, not just individual components

-

Lifecycle Cost Analysis

- Look beyond initial costs to long-term benefits

-

Phased Implementation

- Start with pilot projects to test new technologies

-

Workforce Training

- Ensure personnel are equipped to handle new technologies

-

Regulatory Engagement

- Work with regulators to update standards for new technologies

Remember, transformers are not just about converting voltages anymore. They are becoming intelligent, adaptive components of our power systems. As we move towards a more electrified and sustainable future, the role of transformers will only grow in importance. Their evolution is a testament to the ingenuity of electrical engineering and the critical role these devices play in powering our world safely and efficiently.

Conclusion

Electric transformers are fundamental to modern power systems, enabling efficient energy transmission and distribution. From basic operation principles to advanced applications, transformers continue to evolve, playing a crucial role in our increasingly electrified world.

Are you puzzled by those green boxes you see in your neighborhood? You’re not alone. These mysterious units play a crucial role in powering our homes and businesses, yet many people don’t know what they are.

Pad mounted transformers are ground-level electrical distribution devices that convert high voltage electricity to lower, usable voltages. They are essential in modern power grids, providing safe, efficient, and aesthetically pleasing power distribution in urban and suburban areas.

As an electrical engineer with years of experience in power distribution, I’ve seen firsthand how pad mounted transformers have revolutionized our energy landscape. In this article, I’ll break down what these transformers are, how they work, and why they’re so important in our modern world.

Structure and Function: Understanding the Anatomy of Pad Mounted Transformers?

Have you ever wondered what’s inside those green boxes? The structure of pad mounted transformers is fascinating, and understanding it is key to appreciating their role in our power grid.

Pad mounted transformers consist of a transformer core and windings enclosed in a tamper-resistant, weatherproof cabinet. They typically include high and low voltage compartments, bushings for connections, and safety features like fuses and switches.

Let me take you on a tour of a pad mounted transformer’s anatomy. It’s a bit like peeling an onion, with each layer serving a crucial purpose.

External Cabinet: The First Line of Defense

The outer shell of a pad mounted transformer is more than just a box:

- Material: Usually made of steel or stainless steel

- Design: Tamper-resistant and weatherproof

- Access: Lockable doors for authorized personnel only

- Color: Often green to blend with surroundings

I once worked on a project where we had to custom-design cabinets to match the aesthetic of a historic district. It’s amazing how versatile these units can be!

Internal Components: Where the Magic Happens

Inside the cabinet, you’ll find the heart of the transformer:

Transformer Core and Windings

- Core: Made of laminated steel sheets

- Primary Winding: Connects to high voltage input

- Secondary Winding: Provides lower voltage output

Insulation and Cooling

- Oil-filled designs: Use mineral oil for insulation and cooling

- Dry-type designs: Use air or other gases for cooling

Safety and Control Features

- Fuses: Protect against overcurrents

- Switches: Allow for isolation and maintenance

- Bushings: Insulated points where wires enter/exit the transformer

Compartmentalization: Safety by Design

One of the key features of pad mounted transformers is their compartmentalized design:

| Compartment | Purpose | Access |

|---|---|---|

| High Voltage | Houses primary connections | Limited access |

| Low Voltage | Contains secondary bushings | More accessible |