Choosing the wrong transformer causes project failures and high costs. Understanding their core differences is key to making the right choice for your power system’s safety and reliability.

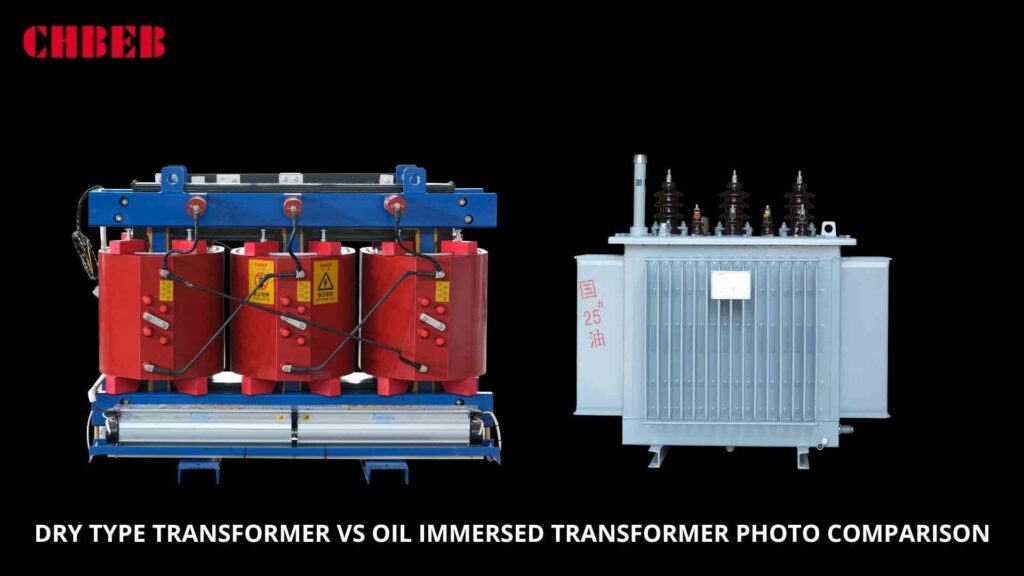

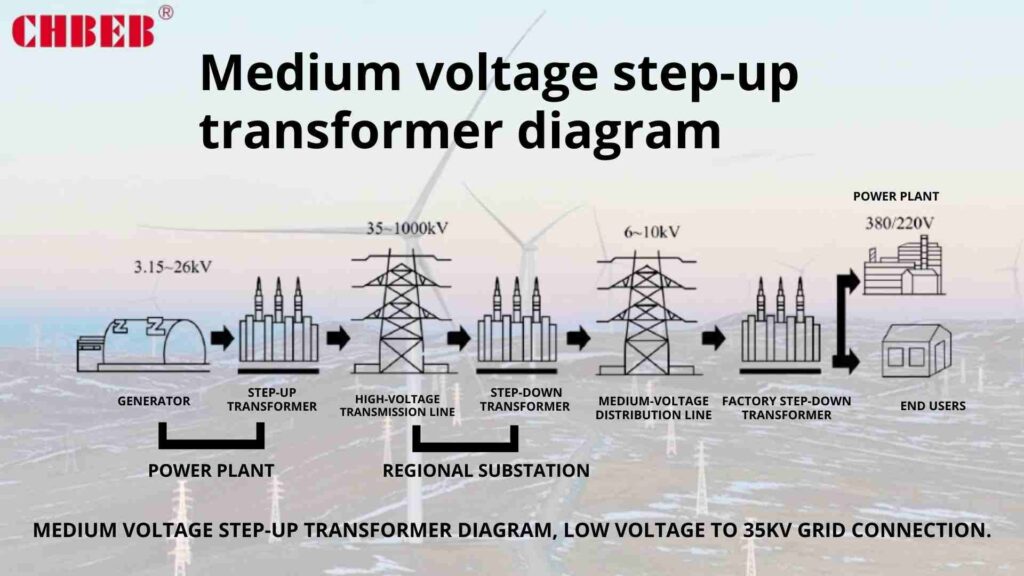

The main difference is their cooling method and where they are used. Oil-immersed transformers use special oil to cool down, making them ideal for outdoor, high-power applications. Dry-type transformers use air for cooling, making them safer for indoor spaces like buildings and data centers.

On the surface, they both transform voltage. But if you look closer, their construction, manufacturing process1, and best use cases are completely different. Getting this choice right is fundamental to building a reliable and safe electrical system. Let’s dive into what really sets them apart, so you can choose the right one for your next project without any guesswork.

What is the core difference between them?

Are you confused about which transformer2 to specify for your project? Making the wrong choice leads to wasted money, project delays, and serious safety risks down the line. Let’s simplify it.

Oil-immersed transformers use oil for cooling and are built for outdoor, high-power jobs. Think of them as the heavy-duty workhorses. Dry-type transformers use air for cooling, so they are smaller, cleaner, and perfect for indoor locations where fire safety is the top priority.

To make it even clearer, I often compare them to an “outdoor giant” versus an “indoor specialist.” Each is designed for a specific environment, and using one where the other belongs is asking for trouble.

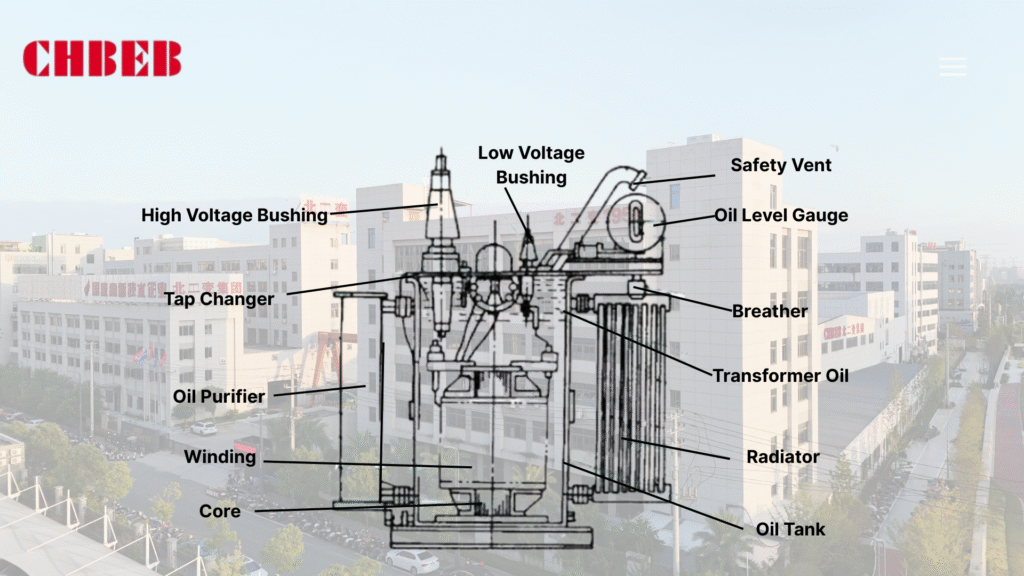

Oil-Immersed: The Outdoor Workhorse

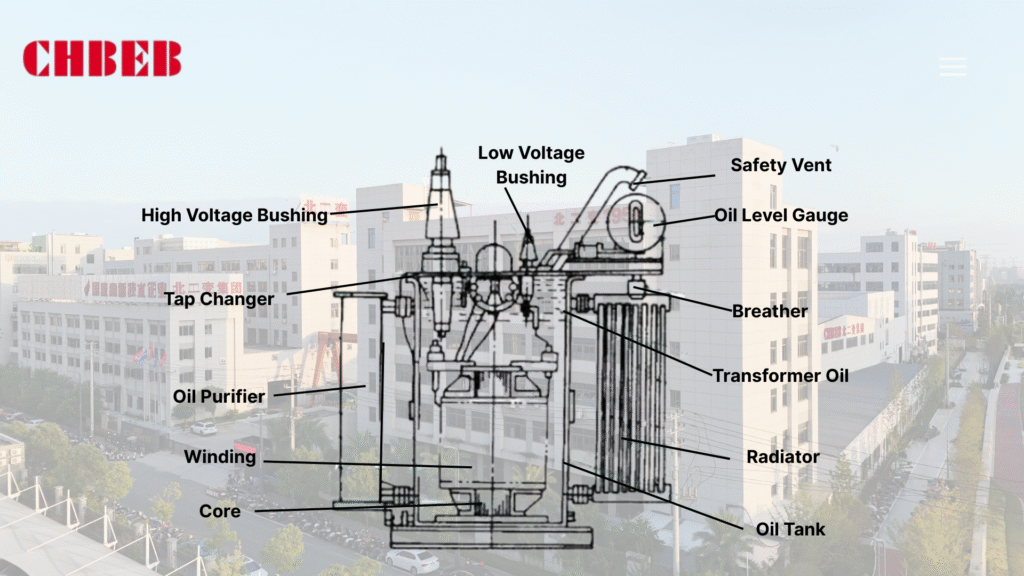

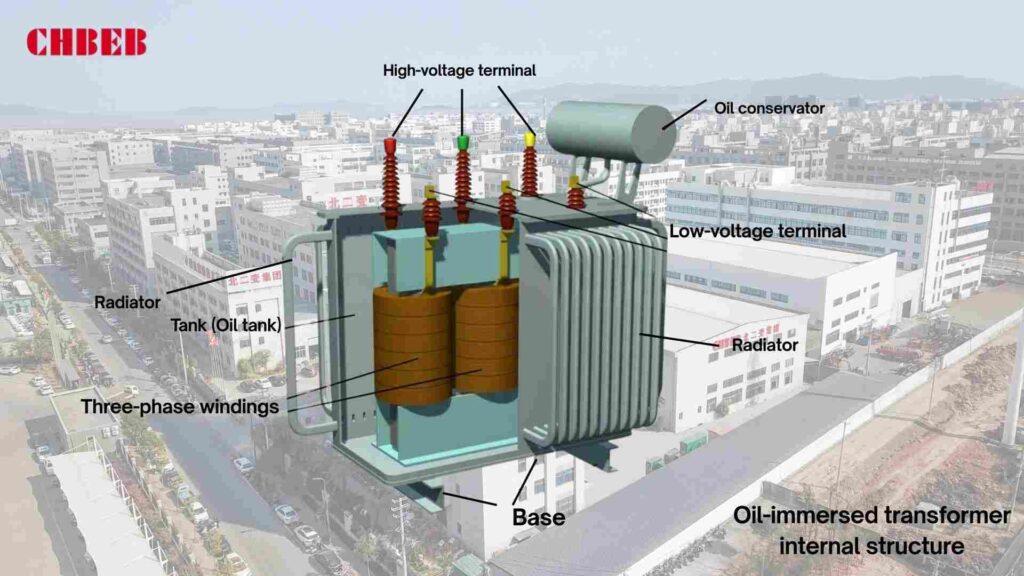

This type is a big, heavy unit filled with transformer oil. The oil serves two purposes: it acts as an insulator and, more importantly, it transfers heat away from the core and coils. This makes them great at handling large power loads and temporary overloads. You will see them everywhere outdoors—in substations powering a neighborhood, at large industrial plants, or in open-air power distribution yards. Their main drawback is the oil itself. It can leak, it is flammable, and it needs to be maintained.

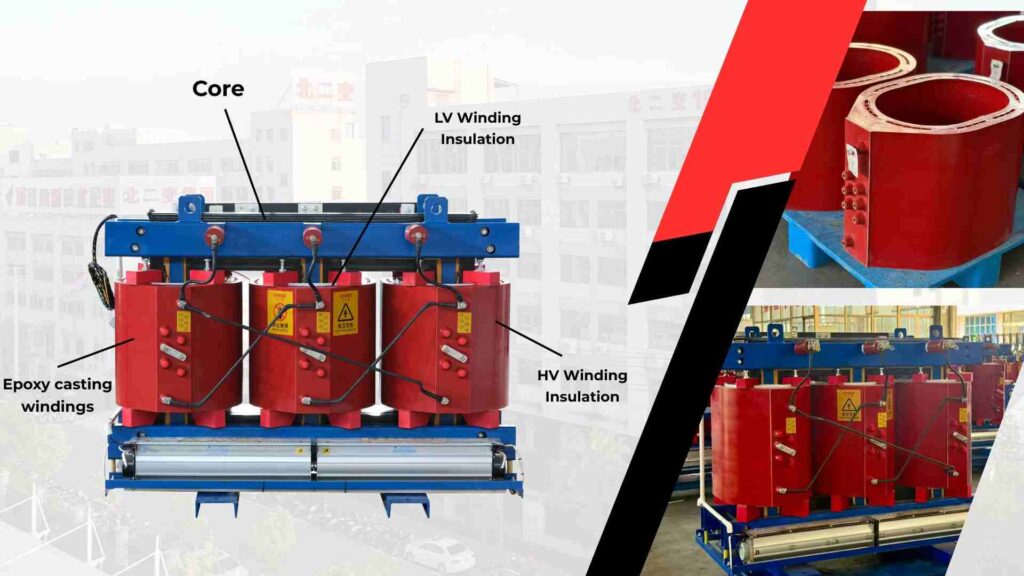

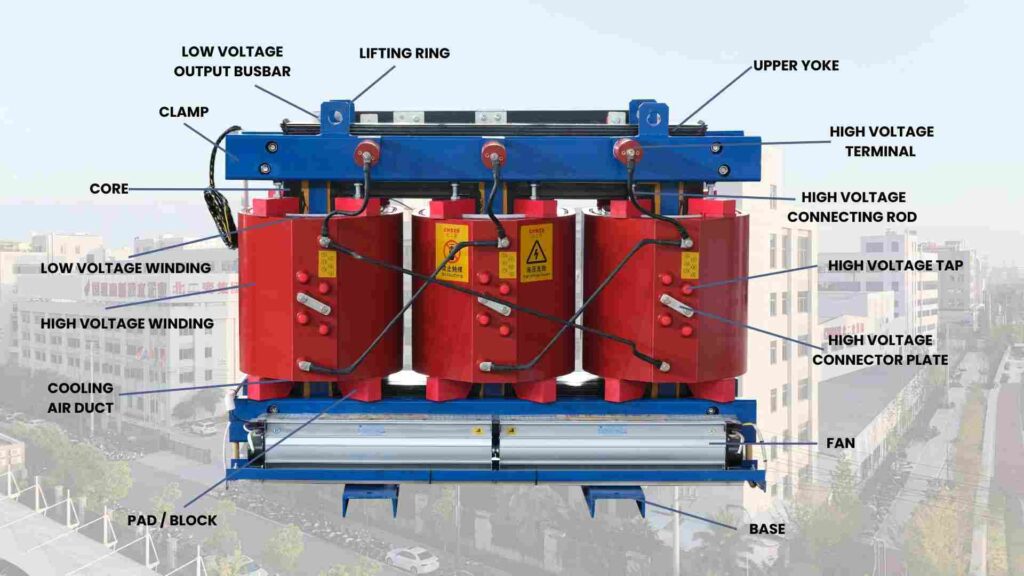

Dry-Type: The Indoor Specialist

This transformer looks more like a clean, metal cabinet. It has no oil. Instead, its coils are sealed in epoxy resin and it cools itself with the surrounding air, sometimes with the help of fans. This design makes it much safer for indoor use. There is no risk of oil leaks3 or fires. That is why they are the standard choice for commercial buildings, hospitals, data centers, and factory floors. Their downside is that they are more sensitive to moisture and don’t handle overloads as well as their oil-filled counterparts.

Here is a simple table to summarize the key differences:

| Feature | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling Medium | Transformer Oil | Air (Natural or Forced) |

| Typical Location | Outdoor (substations, factory yards) | Indoor (buildings, data centers) |

| Size & Weight | Large and heavy | Smaller and lighter |

| Key Advantage | Excellent heat dissipation, high overload capacity | High safety (no oil), low maintenance |

| Key Disadvantage | Fire/leak risk, needs oil maintenance | Sensitive to moisture, lower overload capacity |

Are they equally difficult to manufacture?

Do you think all transformers are just a core with some wires wrapped around it? This simple view leads many to source from cheap factories, resulting in equipment that fails prematurely. Let’s look at the real manufacturing challenges.

No, their manufacturing is completely different and requires specialized skills. Oil-immersed transformers need perfect sealing to prevent oil leaks and fires. Dry-type transformers need advanced epoxy casting without any air bubbles to prevent electrical failure. Only experienced manufacturers can produce high-quality versions of either.

When you look inside our factory, you see that the production lines for these two types have very different critical control points. A small factory might be able to make a basic version of one, but they will not have the technology or quality control to make a reliable, high-performance model.

The Challenge of Oil-Immersed: Sealing and Purity

For an oil-immersed transformer, everything comes down to containing the oil. The steel tank must be welded perfectly, with no pinholes. A tiny leak can lead to a short circuit, fire, or environmental contamination. The oil itself is just as important. We filter our transformer oil at least three times to get the impurity content below 0.01%. Any more than that, and the oil could fail to insulate properly. Finally, the silicon steel sheets that make up the core must be stacked with less than 0.1mm of error. Any more, and the transformer will overheat and waste energy.

The Challenge of Dry-Type: Insulation and Casting

With a dry-type transformer, the difficulty is in the insulation. We use a high-temperature epoxy resin4 to completely encapsulate the coils. This process, called vacuum casting5, is extremely precise. It must be done in a vacuum to ensure there are absolutely no air bubbles trapped in the resin. A single bubble creates a weak spot in the insulation that can cause the coil to burn out under load. The surface of the coil also needs a special treatment to protect it from moisture. Without it, the transformer would be unreliable in humid environments.

What are their biggest weaknesses?

Every piece of equipment has a weakness. Ignoring a transformer’s “fatal flaw” can lead to unexpected downtime, expensive repairs, and dangerous situations for your personnel. Knowing these weaknesses helps you prepare and choose wisely.

The biggest fear for an oil-immersed transformer is an oil leak or oil aging, which requires costly maintenance. The biggest fear for a dry-type transformer is high heat, moisture, and dust. These conditions can destroy its insulation and cause it to fail unexpectedly.

Understanding these vulnerabilities is not about avoiding these transformers. It is about matching them to the right environment and planning the right maintenance schedule. A good plan turns a potential weakness into a manageable characteristic.

The “Achilles’ Heel” of Oil-Immersed Transformers

The main problem is, and always will be, the oil. After years of exposure to outdoor weather, the rubber seals on the tank can become brittle and crack, causing oil leaks. This is not just a maintenance headache; it is an environmental hazard that can require a full shutdown for repairs. Second, the oil itself degrades over time. After 2-3 years, it oxidizes and loses its insulating properties. It must be tested and eventually replaced, which adds to the lifetime operating cost of the transformer.

The “Achilles’ Heel” of Dry-Type Transformers

Dry-type transformers are sensitive to their operating environment. Their number one enemy is heat. If the indoor space has poor ventilation or if summer temperatures get too high, the coil temperature can exceed 155°C. This will rapidly age the epoxy insulation and drastically shorten the transformer’s life. Their other enemies are moisture and dust. In a humid or dusty place like a textile mill, moisture and dust can build up on the coils. This lowers the insulation resistance and can lead to frequent tripping or even a complete short circuit.

| Transformer Type | Primary Weakness 1 | Primary Weakness 2 |

|---|---|---|

| Oil-Immersed | Oil Leaks (from aging seals) | Oil Aging (requires replacement) |

| Dry-Type | Overheating (in poor ventilation) | Moisture & Dust Contamination |

What are the most critical manufacturing steps?

How can you tell a high-quality transformer from a low-quality one just by looking at a spec sheet? A single shortcut in the manufacturing process can cause a catastrophic failure years later. You need to know what to ask a supplier.

For oil-immersed units, the most vital step is vacuum oil filling to remove all air. For dry-type units, it is the bubble-free vacuum casting of the epoxy resin. These two steps are the most difficult to master and are what separates a world-class manufacturer from the rest.

Over my years in this business, I have seen failures that all trace back to one of these critical steps being done poorly. That is why we invest so heavily in the machinery and quality control for these specific processes. They are not negotiable.

Three Hurdles for Oil-Immersed Transformers

- Core Stacking (Foundation): The process starts with precisely stacking silicon steel sheets. If the alignment is off by more than 0.1mm, magnetic losses increase, causing the transformer to run hot and inefficiently. We scrap any core that does not meet this tolerance.

- Vacuum Oil Filling (Most Difficult!): This is the make-or-break step. We place the assembled transformer in a large vacuum chamber and inject the purified oil. The vacuum pulls every last air bubble out of the windings and insulation. Air bubbles in the oil will lead to electrical discharge and eventual failure.

- Seal Testing (Crucial): After filling, we pressurize the tank to 0.3 MPa with air and submerge it in water for 24 hours. We watch for any bubbles, no matter how small. Any unit that shows even the slightest leak is rejected and disassembled.

Three Hurdles for Dry-Type Transformers

- Coil Winding (Foundation): The copper wire must be wound tightly and evenly. Any gaps or unevenness will create hot spots on the coil when the transformer is under load, which can lead to insulation failure.

- Epoxy Resin Casting (Most Difficult!): This is our most controlled process. The mold is heated to 60-80°C, and the epoxy resin is injected very slowly under vacuum. We monitor the process in real-time to ensure the bubble rate is below 0.1%. Any higher is a safety risk.

- Insulation & Temperature Rise Test (Crucial): Every single dry-type transformer we make goes through a final test. We run it at full load until its temperature stabilizes at 155°C and keep it there for 48 hours. We monitor its insulation resistance and performance to ensure it can handle real-world stress without degrading.

Where can I find reliable transformer manufacturers?

Do you believe all manufacturers are the same? Sourcing from the wrong region can mean you get a product that is not built for your standards, uses substandard materials, and fails prematurely. Location matters.

For top-tier dry-type transformers[^6], focus on manufacturers in the Suzhou and Shanghai area, which is a hub for precision electronics. For robust oil-immersed transformers[^7], look to the industrial clusters in Taizhou and Liaocheng. Be careful with low-cost factories in other regions.

In China, different regions have developed different specialties over decades. Knowing where to look gives you a huge advantage in finding a partner who truly understands the technology you need.

The Hub for High-End Dry-Type: Jiangsu & Shanghai

This region is the heart of China’s electronics industry. Manufacturers here have access to the best epoxy resin materials and the most advanced precision casting equipment. They have deep experience meeting the demanding quality standards for data centers, high-rise buildings, and international projects. If you need a high-performance dry-type transformer for a critical application, this is where you should look.

The Hub for Robust Oil-Immersed: Jiangsu & Shandong

Manufacturers in cities like Taizhou (where one of our bases is) and Liaocheng have a long history of making heavy electrical equipment. They have perfected the processes of oil purification, tank welding, and sealing. Many top factories here, including us, use imported sealing gaskets that last three times longer than standard ones. This is the best region for sourcing large, reliable oil-immersed transformers for utility and industrial projects.

What to Watch Out For: Low-End Production

In other regions, like parts of Hebei and Henan, you will find many smaller factories focused on producing low-cost transformers. To cut costs, they often use cheaper seals, do not purify their oil thoroughly, and have bubbles in their dry-type casting. These products might work for temporary power or very low-demand situations, but they are prone to leaks and insulation failure. For any serious project, it is a risk not worth taking.

How does choosing the right transformer solve real-world problems?

Is all this technical detail just theory? A project in a harsh environment with the wrong equipment is a recipe for constant problems and budget overruns. Here is a real story of how we helped a client succeed.

We helped an Uzbekistan client by providing a custom solution for their textile park. We supplied a high-temperature-rated oil-immersed unit for outdoors and a special dust-proof dry-type unit for indoors. This solved their environmental challenges, met local standards, and cut their maintenance costs by 60%.

I remember this project clearly because the client flew to our factory with samples from their previous supplier. They were frustrated with constant failures and wanted to see our process firsthand.

The client was building a large textile park in Tashkent. They had two big challenges. First, their outdoor substation needed a 2000kVA transformer that could handle summer heat up to 44°C and frequent salt-dust storms. They were worried a standard oil-immersed unit would leak. Second, their indoor workshops needed 1000kVA transformers, but the air was filled with textile dust. They feared a standard dry-type unit would clog up and fail. On top of that, all equipment had to be UZCERT certified.

During their visit, we focused on their pain points. We showed them our oil-immersed production line, highlighting the imported high-temperature seals and our vacuum oil-filling process that gets impurity levels down to 0.005%. We even ran a 48-hour test for them in a 45°C environmental chamber, and the transformer showed zero leaks. For the dry-type unit, we demonstrated our bubble-free casting and a special anti-dust coating we apply to the coils. We did a live dust-spray test, and the insulation resistance remained perfect.

The client was convinced. They saw our UZCERT documents and that our product labels and manuals were already in Uzbek. They signed a three-year supply contract on the spot. Two years later, they told me, “The outdoor transformer hasn’t leaked a drop of oil, and the indoor one has never tripped. Your products are perfectly adapted to our environment, and our maintenance costs are down 60%.”

Conclusion

Choosing between oil-immersed and dry-type transformers is about matching the product to the application. Understanding their differences in cooling, manufacturing, and weaknesses ensures you select a reliable and cost-effective solution.

⚙️ CHBEB — Reliable Partner for Dry Type Distribution Transformers

When it comes to dry type transformer manufacturing, CHBEB stands among China’s most experienced and trusted suppliers. With over 60 years of transformer production expertise, the company has mastered both technical precision and global reliability — serving utilities, EPC contractors, and industrial buyers worldwide.

Our Manufacturing Network

CHBEB operates two factories in Wenzhou, one in Nanjing, and a Beijing office, ensuring large-scale production capacity and fast global delivery. Each factory is equipped with advanced VPI and Cast Resin production lines that comply with IEC 600762, ISO9001, and CE standards.

Why CHBEB for Dry Type Transformers:

- High-End Materials: Every unit uses 100% new copper, Class F/H insulation, and premium silicon steel for maximum efficiency.

- Full Testing Assurance: All dry type transformers undergo strict routine and type tests — including insulation resistance, partial discharge, and temperature rise.

- Proven Reliability: CHBEB is a qualified supplier for the State Grid Corporation of China, maintaining a zero-accident record in global projects.

- Fast OEM/ODM Service: From prototype to batch delivery, customized orders can be completed in as little as one week for urgent projects.

- Global Focus: With exports to Russia, Southeast Asia, Africa, and Belt & Road countries, CHBEB supports local distributors and contractors with on-site service and certification assistance.

- Green Manufacturing: Our dry type transformers are designed for fire safety, low noise, and eco-compliance, ideal for hospitals, schools, and renewable energy systems.

💡 Looking for a reliable dry type transformer manufacturer that combines Chinese manufacturing strength with international quality?

👉 Contact CHBEB today at [email protected] or visit www.chbeb-ele.com to get your customized solution or download our full dry type transformer catalog.

- Understanding the manufacturing process can help you identify quality transformers. ↩︎

- Understanding the various type of transformer can help you choose the right one for your project. ↩︎

- Explore the causes of oil leaks to better maintain and choose oil-immersed transformers. ↩︎

- Learn about epoxy resin’s importance in ensuring the reliability of dry-type transformers. ↩︎

- Understand the vacuum casting process to appreciate its role in transformer quality. ↩︎

In-Depth Engineering: How Pad-Mounted Transformers Master the Heat Challenge

Introduction

In residential, business, and utility networks, pad-mounted transformers function quietly, but they are always combating heat. As heat builds up inside a sealed enclosure, the insulation weakens, efficiency drops, and the risk of overheating increases. This article explains how pad-mounted transformers use physics, materials, and design to manage heat, ensuring long-term reliability in real-world conditions.

Thermal Fundamentals: Heat Generation, Transfer Paths, and Cooling Mechanism

When purchasers think that small oil-immersed pad-mounted units run cool on their own, heat becomes a concern. In reality, every watt of loss turns into heat that becomes trapped inside a metal cabinet. This is one of the main challenges of pad-mounted transformer cooling. Anyone specifying, designing, or servicing these units must understand how heat forms, flows, and exits the system.

Heat Sources: Decomposing No-Load Losses, Load Losses, and Heat Generation

Transformers that are buried or have limited airflow need stricter control of temperature rise than units installed in open-air environments.

No-load losses — the heat source that never stops

The magnetic core of the transformer generates no-load losses, including:

- Hysteresis losses caused by the changing magnetic field

- Eddy current losses1 moving through the silicon steel

These losses keep pad-mounted transformers continuously warm, regardless of how much power they are delivering.

Load Losses: The Most Important Heating Factor

I²R losses occur when current flows through the windings due to the resistance of the copper.

- More load → more heat

- Overload → rapid increase in transformer temperature

- Harmonics → extra heating in both the winding and structural parts

Many field technicians search “why is my pad-mounted transformer overheating” because even small overloads can push temperatures inside a sealed enclosure far beyond the design limit.If you want a deeper understanding of how transformer insulation and oil behave under rising temperature, you may also refer to our guide “Unlocking Transformer Oil’s Superpowers: Why Is Oil Essential for Transformer Operation?” — it explains how oil aging, oxidation, and moisture all accelerate heat-related failures.

Losses from stray and harmonic waves

When stray flux interacts with structural metal parts, it produces localized hotspots that raise the temperature inside a pad-mounted transformer.

Modern loads such as EV chargers, inverters, and commercial drives introduce harmonics that significantly increase losses. If not controlled, these harmonic effects can shorten the lifespan of pad-mounted transformers.

Transfer Path: The Oil-Immersed Transformer’s Three-Step Cooling (Conduction–Convection–Radiation)

The reliability of an oil-immersed pad-mount transformer depends on how well it handles three cooling stages:

1. Conduction: Heat Moves into the Oil

Windings and the core transfer heat into the transformer oil. The efficiency of this stage depends on:

- Hot oil rises

- Cool oil sinks

- Vertical ducts and proper geometry ensure smooth flow

Any blockage disrupts circulation, causing the transformer to heat up faster and age more quickly.

2. Convection: Oil Moves Around and Moves Heat Up

Natural convection circulates oil in ONAN systems:

- Hot oil rises

- Cool oil sinks

- Vertical ducts and proper geometry ensure smooth flow

Any blockage disrupts circulation, causing the transformer to heat up faster and age more quickly.

3. Radiation: Heat escapes the tank and enters the air around it.

When heat reaches the tank wall, it transfers to the surrounding air. Pad-mounted transformers rely heavily on:

- Cooling fins

- High-emissivity coatings

- Adequate airflow inside the pad enclosure

If airflow is restricted, pad-mounted transformer cooling becomes the limiting factor.

Design and Longevity: Hot Spot Control and Dynamic Load Management

Heat is most harmful when it concentrates in hot spots. If the temperature limit of a pad-mounted transformer is reached, insulation life drops very quickly.

Arrhenius Law2 and Why Hot-Spot Control Matters

Arrhenius’s thermal-aging principle states:

Every 6 °C increase in hotspot temperature cuts insulation life in half.

To manage this risk, companies use:

- IEEE/IEC thermal models

- Fiber-optic temperature sensors

- Digital twins that simulate IEEE C57.91 pad-mount temperature rise

These tools help identify worst-case hotspots before production.

Choosing the right materials and insulation

The quality of the material affects how long it can last under heat:

- AAramid paper can endure higher temperatures than cellulose paper.

- Natural and synthetic ester oils can handle more heat stress.

- Class H insulation supports higher pad-mount hot-spot temperatures.

Better insulation means the pad-mounted transformer will last longer.

Harmonics, overload, and environmental stress

Pad-mounted transformers now face higher thermal stress because of:

- EV charging loads

- Solar PV inverters

- Unbalanced three-phase demand

- High urban ambient temperatures

These factors can cause unexpected overheating, especially in sealed cabinets with limited airflow.

Practical Application: Thermal Optimization and Monitoring

Pad-mounted transformers are only reliable when the heat is always kept in check. Some of the best ways in the business are:

Fin and Radiator Optimization

Manufacturers make cooling work better by changing:

- Fin height and depth

- Space between radiators

- The shape of the air channel

- Emissivity of thermal coating

Better fins mean that the temperature of the transformer rises less.

Internal Oil Duct Engineering

Oil ducts that are made the right way:

- Increase convection circulation

- Prevent stagnant hot-oil pockets

- Reduce hotspot acceleration

Good duct design is essential for stable cooling in a pad-mounted transformer.

Active Cooling Solutions

Most pad-mounted devices use natural cooling, but when the load is high, they may require:

- Air-blowing fans

- Smart thermostats

- Ester oils that tolerate higher temperatures

These enhancements help prevent the pad-mounted transformer from overheating during peak load conditions.

Digital Monitoring and Predictive Control

Real-time monitoring is used by modern pad-mounted transformers:

- Hot-spot sensors

- SCADA-based temperature monitoring

- Predictive analytics for forecasting overloads

This turns the transformer from a passive asset into an actively monitored component, helping prevent failures before they occur.

Pad-Mounted Transformer Overheating — Common Buyer Questions Answered

“Why is a pad-mounted transformer hotter than a transformer in a substation?”

Because pad-mounted units have less room to move about. A regular substation transformer features big radiators, open air, and good airflow.

A pad-mount is inside a sealed metal cabinet that doesn’t get much airflow and is often warmer near the ground.

Higher temperature rise when there is less airflow and the same losses.

This is totally normal as long as the unit stays within its temperature range.

“What is the highest temperature that a transformer can safely reach at a hot spot?”

Most oil-immersed pad-mounted transformers follow the same rules as IEC and IEEE standards:

- 110°C hot spot for mineral oil

- Natural ester oil has a hot spot between 120 and 130°C.

If the pad-mount hot-spot stays above these limits for a long time, the insulation will age much faster.

Short peaks are fine. Long peaks are not.

“How does high temperature really shorten the life of a transformer?”

Heat is the murderer that doesn’t make noise.

Arrhenius’s laws for aging say:

Every 6–7°C rise in the temperature of a hot spot roughly cuts the life of insulation in half.

High heat dries up insulation, oxidizes oil, raises acidity, and lowers dielectric strength. This is why controlling the temperature is one of the most important factors affecting how long a pad-mounted transformer lasts.

“How do engineers figure out how hot a transformer gets?”

It usually originates from two parts:

- Load losses → find out how much the winding temperature rises

- Core losses → find out how much the oil temperature goes up

Manufacturers use both thermal models (IEEE C57.91) and practical tests:

- Indicators for winding temperature

- Measurements of top oil

- Hot-spot multipliers

The end result is a difference between the calculated and measured temperature rise at rated load. This ensures the device stays within safe limits.

“Do harmonics really make a transformer hotter?”

Of course, especially in networks today.

Harmonics from PCs, EV chargers, VFDs, and inverters increase:

- Eddy-current losses

- Stray-flux heating

- Non-sinusoidal current

This extra heat often doesn’t show up in simple load calculations. That’s why environments with high harmonics sometimes need a K-factor-rated transformer, better oil circulation, or larger cooling capacity.

“How does ONAN cooling really work in a pad-mounted transformer?”

What ONAN stands for:

Oil Natural → oil moves about on its own

Air Natural → air naturally cools the radiator

The hot oil rises to the top, cools off in the radiators, and then descends back down.

No pumps. No fans.

It’s easy to use, dependable, and quiet, but it also means the transformer depends on:

- Oil duct design

- Free passage of air

- Good arrangement of fins and radiators

If there is a blockage or limited airflow inside the pad enclosure, the temperature can go up.

“What is the normal oil temperature while the machine is running?”

Normal ranges in the field:

- Top oil temperature between 45–65°C under normal load

- 70–85°C during high load or hot weather

- 90–100°C in rare cases (acceptable only for short periods)

What matters most is not the total number, but:

- The rate of increase

- The hot-spot temperature

- Whether the temperature stays stable or keeps rising

A pad-mounted transformer that warms up and then stabilizes is good.

A unit that keeps heating up continuously needs to be checked.

⚙️ CHBEB — Real Engineering Behind Every Pad-Mounted Transformer

At CHBEB, we don’t rely on generic designs or outsourced assembly.

We engineer pad-mounted transformers with real thermal science — the kind that survives harsh climates, harmonic-heavy networks, and urban distribution loads.

What makes CHBEB different?

🔹 We understand heat.

Every design is built with IEEE C57.91 thermal modeling, optimized oil ducts, and verified hot-spot calculations.

🔹 We are more reliable than typical Chinese factories.

Our transformers go through full temperature-rise testing, not just routine tests.

🔹 We’re a practical, battle-tested manufacturer.

No exaggerated claims. Every rating, test, and drawing is backed by real factory capability.

🔹 We support your project like an engineering partner, not just a supplier.

Load analysis, harmonic assessment, cooling checks, installation environment review — we handle them with you.

🔹 We do true OEM/ODM with international standards.

IEC 60076, IEEE C57, ANSI, CE — all supported, with documented compliance.

This is why CHBEB transformers run reliably across Southeast Asia, the Middle East, Africa, Russia/CIS, and utility networks worldwide.

When heat control matters, CHBEB delivers transformers that stay cool, stable, and safe.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

Heat is the number one factor that determines whether a pad-mounted transformer operates reliably or fails early. When buyers understand how pad-mounted transformer cooling works — from oil circulation and fin design to hot-spot behavior and IEEE temperature-rise limits — they can choose equipment that stays stable even under overload, harmonics, and harsh ambient conditions.

For project owners, EPC contractors, and utility engineers, proper control of pad-mounted transformer temperature rise is more than a technical requirement — it directly affects insulation life, long-term operating cost, and grid reliability. By evaluating cooling design, hotspot limits, harmonic impact, and enclosure airflow before purchase, buyers can avoid overheating issues, extend transformer lifespan, and reduce unexpected outages in the field.

China Power Transformer Market Survey: Sourcing HV Capabilities and International OEM Solutions

Introduction

It can be hard to buy high-voltage transformers from China since there are so many factories, too many claims about what they can do, and not enough information. When a bad choice can put off the whole substation, purchasers need to know exactly who can install HV equipment and how to check their skills. This guide will help you understand.

Capability Verification: Manufacturer Qualifications, Technical Barriers, and OEM Solutions

It’s not hard to find a factory that makes transformers. The tricky thing is finding one that can really make HV-grade (110–220 kV) equipment. A lot of suppliers say they can do HV on paper, but they really depend on outsourcing or third-party test labs. This part helps purchasers tell the difference between true capabilities and marketing noise.

Market Landscape: State-Owned Giants vs. Specialized Private Enterprises

There are two main groups that shape China’s HV transformer industry: state-owned enterprises (SOEs) and private HV producers that focus on exports. Their roles, capabilities, and ideal project types are all very different.

✅ Market Positioning Overview(表格对比)

| Category | State-Owned Giants (SOEs) | Specialized Private HV Manufacturers |

|---|---|---|

| Representative Companies | TBEA, XD Group, Baoding, Shenyang | Export-focused 35–220 kV factories |

| Voltage Capability | 220–1000 kV (UHV leader) | 35–220 kV (main export range) |

| Core Strengths | Full HV labs, impulse platforms, national EPC capability | Fast response, OEM/ODM customization, flexible standards |

| Project Type | National grid, UHV, mega energy projects | International utilities, industry substations, data centers |

| Lead Time | Longer (government cycle) | Faster (commercial cycle) |

| Customization | Limited | Strong (OEM/ODM friendly) |

| Pricing | High | Moderate / optimized |

| Ideal For Buyers | Ultra-high voltage projects, government EPC | Export projects needing flexibility, standards compliance, and OEM solutions |

✅ Summary

- SOEs are suitable for government EPC projects and ultra-high-voltage (330–1000 kV) projects.

- For international 35–220 kV, OEM/ODM, industrial substations, and fast-delivery needs, specialized private businesses are the best choice.

Private HV manufacturers offer the best mix of price, performance, and flexibility for 80% of buyers around the world.

Technical Depth: HV Manufacturing Barriers, Partial Discharge Control, and HV Test Labs

Making high-voltage transformers requires a lot more than just bigger tanks and thicker copper. To really have HV capacity, you need to get beyond four engineering problems:

✅ 1. High-precision insulation engineering – creepage distance, radial insulation, interlayer strength

✅ 2. Partial discharge control – PD < 5 pC at rated voltage

✅ 3. HV core and winding accuracy – step-lap steel, tension control, burr suppression

✅ 4. High-voltage test infrastructure – impulse tests, induced AC tests, temperature-rise platforms

A real HV factory MUST have:

- Lightning impulse test lab

- Induced overvoltage test capability

- PD test room ≤ 5 pC

- Full temperature-rise test platform

- Routine IEC/IEEE acceptance test capability

A major danger for purchasers from other countries is that a supplier may not be able to show original test records, HV lab photos, or videos of actual testing.

Collaboration & Procurement: Quality Compliance, Acceptance Protocols, and Supply Chain Management

Even when capability is established, controlling standards, testing, documentation, logistics, and production risk is still necessary for successful HV procurement.

International Standards: Ensuring compliance with IEEE, IEC, and target-grid rules

Most of the time, transformers are rejected for shipment not because of hardware issues, but because they don’t meet the required standards.

HV transformers must comply with the electrical code of the destination country, not the supplier’s default standards.

✅ Key Regional Standards Overview(表格对比)

| Region | Standard Framework | Special Requirements |

|---|---|---|

| Middle East | IEC 60076 + Utility Specs | High ambient, sand/dust, PD stability |

| North America | IEEE C57 Series | Cooling class, OLTC logic, NEMA enclosure |

| Africa | IEC + local addenda | Grounding, overload conditions |

| Southeast Asia | IEC + tropical version | Humidity control, corrosion resistance |

A true OEM supplier will adapt:

- Core steel grade

- HV insulation clearances

- OLTC/DETC options

- Cooling class (ONAN/ONAF/OFAF)

- Accessories required by grid code

Real compliance is proven through:

✅ Third-party witnessed FAT reports

✅ Previous export references

✅ Type-test certificates

Not through brochures or marketing statements.

Risk Control: FAT Acceptance, Lead Time Management, and Full Life-Cycle Support

There are many high-risk moments in the process of buying an HV transformer. Strong providers aid buyers through every step.

✅ 1. FAT (Factory Acceptance Test)

A complete FAT should include:

- Winding resistance, ratio, vector group

- No-load & load loss measurement

- PD test at rated voltage

- Applied voltage / induced voltage test

- OLTC mechanical & electrical inspection

- Temperature-rise test (where applicable)

FAT can be:

- Customer-witnessed onsite

- Third-party witnessed (SGS / BV / TÜV)

- Livestreamed with real-time measurement screens

✅ 2. Lead Time & Production Risk

Typical manufacturing cycles:

| Voltage Class | Average Lead Time |

|---|---|

| 110 kV | 90–120 days |

| 132–150 kV | 120–150 days |

| 220 kV | 150–210 days |

Key risk factors:

- Core steel procurement

- OLTC delivery schedule

- HV lab queue time

- Oversized packing preparation

Reliable suppliers issue weekly QC progress reports.

✅ 3. Life-Cycle Support

Long-term reliability after installation depends on more than just manufacture; it also depends on assistance.

Strong OEM suppliers provide:

- Oil testing frequency guidance

- OLTC maintenance schedule

- Condition monitoring recommendations

- Emergency support response within 24 hours

- Remote diagnostics or onsite service (region-dependent)

Friendly, Buyer-Focused FAQ: What Global Buyers Really Want to Know

1. “Who makes the most transformers in China?” Do I have to buy from them?

Most people instinctively think of TBEA and XD Group, and certainly, they are the major companies operating China’s 220–1000 kV grid.

But many new buyers don’t realize this:

👉 You don’t need a national giant unless your project is UHV-level.

For export projects between 110–220 kV, specialized private HV manufacturers often provide you:

- Faster lead time

- More flexible engineering

- Real OEM customization

- Much better pricing

Same technological skills, but without the huge government bureaucracy.

2. “Can Chinese manufacturers really produce 220 kV or even 500 kV transformers?”

Yes, absolutely — but not every factory that claims ‘HV capability’ actually has it.

A real HV-capable factory will be very open about showing:

- Their high-voltage impulse test hall

- PD readings (≤5 pC) shown live on camera

- Photos or videos of previous 110–220–500 kV projects

- Third-party witnessed test reports (SGS / BV / TÜV)

If a supplier hesitates or can’t show proof, that’s your signal to walk away.

3. “How do I verify that their HV test lab is real, not just marketing photos?”

Here’s what experienced EPC buyers do:

✅ Ask for a live video walk-through, not just pictures

✅ Request original impulse and PD test reports (not screenshots)

✅ Ask for real-time PD readings during a call

✅ Send SGS/BV if the project is critical

A legitimate factory will never refuse — they’re usually proud to show their test bay.

4. “Where does FAT usually happen for big transformers? Can it be done externally?”

FAT for HV transformers must happen in the manufacturer’s own test hall — HV test equipment cannot be moved.

A proper FAT includes:

- Ratio, vector group, and winding resistance

- No-load + load losses

- Induced & applied voltage tests

- Partial discharge

- OLTC operation

- Temperature-rise (for large units or per spec)

Good suppliers will stream the entire FAT live, with on-screen measurements — this is now standard for overseas projects.

5. “Can a Chinese transformer really meet IEEE / ANSI requirements?”

Yes — but only if you choose the right supplier.

China has factories that:

- Export to North America

- Build fully IEEE C57-compliant units

- Use NEMA-rated enclosures

- Follow ANSI cooling and OLTC logic

If your supplier cannot show previous IEEE export records, choose one who can.

IEEE compliance is not difficult — experience is the real differentiator.

6. “How long is the lead time for an OEM HV transformer?”

Typical timelines:

- 110 kV: 90–120 days

- 132–150 kV: 120–150 days

- 220 kV: 150–210 days

Delays usually come from:

- OLTC delivery (MR/Reinhausen parts)

- Core steel supply

- Test-lab scheduling for impulse tests

A trustworthy OEM factory will give weekly updates with photos — so you always know what stage your transformer is in.

7. “How do you ship a heavy transformer safely over long distances?”

For big units, the logistics matter almost as much as the manufacturing.

Most exports use:

- Flat Rack (FR) for 20–60 tonne units

- Break Bulk for oversized cargo

- RoRo when mounted on a platform

- Low-bed trailers + escorts for inland transport

The important part?

👉 Vibration recording

👉 Moisture protection

👉 Center-of-gravity calculation

👉 ICC-A marine insurance

A good supplier will prepare all of this automatically — not wait for you to ask.

⚙️ CHBEB — Reliable Partner for Substation and Power Transformer Solutions

In the transformer industry, not every manufacturer truly understands how to apply IEEE C57.91 in real design work, thermal modeling, or FAT validation.

For CHBEB, this knowledge is not theoretical — it is built from decades of experience.

Over the past 60 years, CHBEB has grown from a small winding workshop into a multi-facility transformer manufacturer, with two factories in Wenzhou, a complete assembly plant in Nanjing, and an international operations center in Beijing. We supply oil-immersed and dry-type transformers to utilities, EPC contractors, and industrial clients worldwide — and many of them first came to us because they needed a partner who could help them solve challenges related to standards, climate adaptation, or compliance.

What we focus on is simple:

make the engineering clear, make the risks visible, and make every transformer traceable — from thermal performance to climate suitability.

For oil-immersed transformers, our capabilities include:

- ONAN / ONAF / OFAF thermal design

- Hot-spot and top-oil simulations based on IEEE models

- A 50 MVA temperature-rise test platform

- 110–220 kV impulse and AC withstand capability

- Derating and thermal correction for desert and tropical climates

For dry-type transformers, our facilities operate:

- VPI and Cast Resin production lines

- <5 pC partial discharge control

- Class F and H insulation systems

- Custom design for distribution and industrial applications

Compared with large state-owned enterprises, our strength often lies in flexibility:

Need a non-standard voltage? We can build it.

Need IEEE and IEC thermal logic unified into one FAT report? We’ll prepare it for you.

Tight schedule? We prioritize your test bay time to reduce waiting.

Complex climate or grid requirements? We calculate all Annex-B or regional derating factors and integrate them into the design.

Clients who work with us know that CHBEB’s value is not “selling a transformer.”

It is ensuring that every step — design, testing, packaging, shipping, commissioning — stays under control and with full transparency.

This is why CHBEB transformers operate reliably across Russia, Southeast Asia, the Middle East, Africa, and other demanding environments. From 50 kVA units to 220 kV substation transformers, each one reflects a long-term commitment rather than a one-time transaction.

If your project involves IEEE or IEC compliance, thermal verification, FAT witness tests, climate adaptation, or custom engineering, we aim to be the technical team you can ask, trust, and rely on — anytime.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

China’s HV transformer market is wide, but true capability is narrow. The real challenge for overseas buyers is not choosing a factory — it is verifying who can genuinely build, test, and certify 110–220 kV equipment without outsourcing or risking compliance failure.

By focusing on three essentials — capability verification, standards alignment, and full FAT transparency — buyers can reduce project risk, avoid costly delays, and secure long-term grid reliability. State-owned giants remain unmatched for UHV projects, but for 35–220 kV export applications, specialized private HV manufacturers offer the optimal balance of performance, customization, and delivery speed.

With structured supplier evaluation and strict acceptance protocols, importing high-voltage transformers no longer needs to be a gamble. Choosing partners who provide real test data, real engineering depth, and real accountability is the key to ensuring every unit that leaves China arrives ready for safe, certified operation in your grid.

Understanding IEEE Guide C57.91 for Loading Mineral-Oil-Immersed Transformers

Introduction

If you’ve ever been next to a buzzing transformer on a hot summer afternoon and thought, “Can I push this thing a little harder?” — The answer is IEEE C57.911. It’s not a textbook; it’s the industry’s guide to how much oil you can put in a transformer before it starts to age too quickly.

What C57.91 Covers: Scope, Thermal Model, and Loading Categories

IEEE C57.91 doesn’t tell you how to make a transformer; it informs you how to use one. It’s about finding the right balance between heat, insulating life, and real-world performance.

Scope and Assumptions (65 °C system and related IEEE standards)

The tutorial is about transformers that are bathed in mineral oil and have an insulating system that can handle 65 °C. These are the workhorses of the grid. It is related to standards such as IEEE C57.12.00 (design) and IEEE C57.104 (gas analysis).

The assumptions are easy to understand yet important:

- Ambient temperature is roughly 30 °C (normal service condition)

- Normal oil flow (ONAN/ONAF cooling)

- Steady loading, no big spikes or short bursts

In real life, though, a lot of grids operate hotter than that, especially in the Middle East, Africa, and Southeast Asia. This is when engineers start to deliberately bend the “book values.”

Thermal Basics: Top Oil, Hot Spot, and Aging Factor

The guide’s thermal model is based on three temperatures that all operators should be aware of:

- Top-oil temperature (TOT) is the average temperature of the oil in the tank.

- The warmest place in the windings is the hot-spot temperature (HST).

- Aging factor (FAA) – how quickly the insulation breaks down at that HST

The truth is that the aging rate doubles for every 6 °C climb above 110 °C2.

If your hot spot stays at 125 °C for a long time, your “30-year” transformer can age like it’s 15.

You don’t have to memorize the equations, but you do need to understand what they signify. When the oil is getting close to 85 °C and the room temperature is still rising, it’s not just heat; it’s years of service life slowly burning away.

Loading Classes: Normal, Planned Overload, Emergency

C57.91 gives engineers three “zones” of operation that they really use:

| Category | Typical Use | What It Means |

|---|---|---|

| Normal Loading | Daily operation | Everything stays within design temperature |

| Planned Overload | Seasonal or demand peak | Safe if pre-calculated and monitored |

| Emergency Loading | Grid contingency | Acceptable for short periods, but with known life loss |

Utilities frequently reside somewhere between “normal” and “planned.” The key is knowing how long you can stay there and when to let the unit cool down.

A Step-by-Step Way to Apply C57.91 on Real Projects

Inputs You Need: Nameplate, Cooling, Ambient/Load Curve

Check the nameplate before you open any spreadsheet. The transformer’s birth certificate shows its voltage, cooling class, rise limits, and MVA ratings.

Then gather:

- Ambient profile (highs and lows per day)

- Load curve (hourly or seasonal)

- ONAN, ONAF, and OFAF are all types of cooling configurations.

These data points are used by your thermal model. You’re guessing if you don’t have them.

Do the Math: From Temperatures to Life-Loss & Risk

The instruction shows you how to figure out how much the temperature will climb, but here’s the quick version:

- More load means more losses, which means more heat.

- More heat means a higher hot spot and faster aging of the insulation.

Field engineers typically make it easier by using “life loss per day” measures. For instance:

- 110 °C HST → normal

- 120 °C: about twice as long as aging

- 130 °C = emergency; you’re devouring years in hours

Digital monitoring systems now use C57.91-based algorithms to turn heat readings into remaining life. This lets operators see risk in real time.

Operate Safely: Monitoring, Derating in Hot Climates, Recovery

C57.91’s default assumptions stop working when the temperature outside reaches 45 °C. You will need to lower the capacity or enhance the airflow.

In real life, engineers follow three rules:

- Don’t go after short-term load at the expense of long-term life.

- Plan out cooldown cycles. It takes a few days for a transformer that has been pushed to a hot area of 130 °C for an hour to get back to normal load.

- Don’t trust your gut; use data. A hand on the tank can’t tell you as much as modern monitoring tools like fiber optics, SCADA, and thermal cameras can.

Beyond the Guide: Updates, IEC Comparison, and Digital Practices

C57.91 isn’t set in stone; updated versions work with current oils, ester fluids, and smart grid monitoring.

Annex A (Bubble Inception) & Clause-7 Update Trend

One important update that many developers miss is bubble inception.

When winding hot areas reach about 140 °C, the moisture in the paper transforms into vapor, which makes gas bubbles that can flash over when there is too much voltage.

That’s why Annex A now sets explicit limits on the moisture content of oil and the temperatures at which it can safely overload. This is especially important for ester-based oils, which act differently than mineral oils.

IEEE vs IEC 60076-7: What Changes for Your Numbers

Engineers working across regions often compare IEEE and IEC calculations.

- IEEE (C57.91) uses a 110 °C reference hot-spot.

- IEC 60076-7 works at 98 °C.

The difference may seem little, but it might change your predicted “safe load” by a few percent, which is sometimes the difference between passing and failing a utility audit.

If your project goes outside the rules (for example, sending goods from China to the EU or GCC), choose one model and make sure it is evident in the FAT report.

Dynamic Ratings with SCADA/Online Models

Dynamic transformer rating is a new thing in the field. It uses C57.91’s math with real-time SCADA systems.

Instead of considering the nameplate MVA as a constant, operators now change the loading according on the actual oil and air temperature.

This allows utilities run closer to full capacity on cool nights and automatically lower their output during heat waves.

The end result? More flexibility in the grid without shortening the life of the transformers.

🔍 Frequently Asked Questions (FAQ): What Buyers & Engineers Really Ask About IEEE C57.91

Q1. How does IEEE C57.91 affect the lifetime of my transformer?

Most failures aren’t electrical — they’re thermal.

IEEE C57.91 quantifies exactly how temperature shortens insulation life.

Every 6 °C rise in the hot-spot temperature above 110 °C roughly cuts insulation life in half.

That’s why CHBEB designs and tests all oil-immersed units with a proven thermal margin, allowing controlled overloads without unexpected aging.

Q2. My project site runs above 40 °C. Will standard transformers fail faster?

Yes — unless they’re derated or adapted.

The IEEE guide assumes 30 °C ambient, but CHBEB engineers apply Annex B correction factors and enhanced cooling (ONAF/ODAF) for tropical or desert environments.

This ensures your transformer delivers full capacity — safely — even in 45 °C+ climates.

Q3. I want to use ester oil for environmental compliance. Is it compatible with IEEE C57.91?

Absolutely.

Later revisions of C57.91 include ester oils with higher flash points and better biodegradability.

CHBEB routinely builds ester-based designs for green substations and metro systems, validated through bubble inception and hot-spot margin testing per Clause 7 of the guide.

Q4. How can I prove my transformer meets IEEE loading limits during FAT?

C57.91 isn’t just theory — it defines measurable parameters.

During FAT, CHBEB performs:

- Temperature-rise tests to verify top-oil and hot-spot values.

- Load-loss and efficiency tests for thermal balance.

- DGA and insulation checks to confirm no overheating or gas formation.

All test data are recorded and shared in your project documentation, ensuring IEEE traceability from factory to grid.

Q5. My utility follows IEC 60076, not IEEE. Will there be a conflict?

No conflict — just calibration.

IEEE uses a 110 °C reference hot-spot, IEC uses 98 °C.

CHBEB engineers routinely harmonize both standards in a unified thermal model and FAT report, so your equipment meets dual compliance for international acceptance.

Q6. How can I monitor transformer loading and lifetime in real time?

CHBEB offers integrated SCADA-ready thermal monitoring systems based on IEEE C57.91 algorithms.

They continuously calculate thermal aging, hot-spot rise, and remaining service life — allowing predictive maintenance instead of reactive repair.

Looking for how these thermal limits influence substation design? →Substation Transformer Selection

⚙️ CHBEB — Engineering Compliance into Every Transformer

At CHBEB, IEEE C57.91 isn’t just a reference — it’s part of our design DNA.

For over 60 years, we’ve built oil-immersed and dry-type transformers that meet or exceed both IEEE and IEC thermal performance standards.

Our Strengths

- Design Integrity: All models simulated through IEEE C57.91 thermal analysis and CFD airflow modeling.

- Verified Quality: Factory Acceptance Tests performed under IEC 60076 & IEEE C57.12.90, witnessed by SGS/BV when required.

- Global Adaptability: Proven performance in 45 °C deserts, coastal humidity zones, and tropical grids.

- Full Compliance Support: CHBEB provides IEEE-based loading reports and certification packs for EPC and utility audits.

From Wenzhou to Nanjing to Beijing, CHBEB delivers not just transformers — but confidence.

When your specification mentions IEEE C57.91, our engineering ensures it’s not a checkbox — it’s a guarantee.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

IEEE C57.91 makes one thing clear: a transformer’s life is defined by heat. By understanding hot-spot limits, temperature rise, and controlled overload rules, engineers can run a transformer harder when needed—without sacrificing decades of service life. For projects in hot climates or high-demand networks, following C57.91 is the simplest way to reduce thermal risk, avoid premature aging, and keep grid performance predictable.

From China to the World: A Complete Procurement and Logistics Guide for Substation-Grade Transformers

Introduction

Importing a substation transformer from China is no small task. It involves technical compliance, complex logistics, and legal scrutiny. From supplier qualification to customs clearance, understanding each step ensures your investment arrives safely, performs reliably, and meets every standard required by your grid authority.

Procurement Preparation: Selecting Top Suppliers and Ensuring Technical Compliance

Transformer procurement begins long before any contract is signed. Success depends on choosing qualified suppliers, verifying compliance, and aligning specifications with both international standards and destination-country regulations.

Supplier Prequalification: Certifications, Capacity, and Project Experience

Not all transformer factories are built for substation-grade equipment.

A capable supplier should meet the following benchmarks:

- Certifications: ISO 9001 / 14001 / 45001, IEC 60076 type test reports1, and utility approvals (e.g., State Grid, DEWA, or KPLC).

- Production Capacity: Annual output above 3,000 MVA, with access to 50 MVA+ testing platforms.

- Project Portfolio: References for utility-scale or EPC projects in at least three international markets.

- Design Flexibility: Ability to provide OEM/ODM services, adapt to non-standard voltage levels, and meet regional climatic conditions.

Factories with integrated winding, core, and enclosure production reduce outsourcing risks and ensure consistent quality.

Compliance Foundation: Specifications, IEEE/UL Standards, and Mandatory Certifications

Every destination country enforces its own electrical safety framework. To avoid costly rework or rejection at customs, engineers must cross-check key standards early2:

| Standard | Region | Scope |

|---|---|---|

| IEC 60076 | Global | Transformer design, testing, and performance |

| IEEE C57 Series | North America | Cooling, insulation, and loading guides |

| UL / CSA | USA / Canada | Safety compliance and labeling |

| CE / UKCA | EU / UK | EMC and low-voltage directive |

| SASO / GSO / SONCAP | Middle East / Africa | Import conformity certificates |

Document alignment between technical datasheet, GA drawing, and nameplate is essential. Mismatches can delay certification or cause re-inspection at ports.

Process Execution: Quality Inspection, International Logistics, and Risk Control

After design approval, the challenge shifts to managing quality consistency, safe shipment, and cost predictability throughout the export journey.

Quality Acceptance: The FAT (Factory Acceptance Test) Workflow and Key Indicators

Before shipment, every power transformer undergoes FAT testing under witness from the client or third-party inspector (e.g., SGS, BV, or TÜV).

A complete FAT includes:

- Ratio and Polarity Test – Confirms correct voltage conversion.

- Winding Resistance and Vector Group Check – Verifies electrical balance.

- No-Load and Load Loss Tests – Measures energy efficiency and core performance.

- Induced Voltage & Applied Voltage Tests – Ensures dielectric integrity.

- Temperature Rise Test – Confirms cooling design under rated load.

Acceptance requires results to stay within IEC 60076 tolerance limits, with detailed test reports sealed and signed before release.

Logistics and Packaging: Oversized Transport and Anti-Vibration Safeguards

Substation transformers are often oversized and overweight cargo, requiring specialized transport methods.

Typical export modes include:

- Flat Rack Container (FR): For units up to 60 tons; suitable for seaport loading with lashing chains and corner locks.

- Break Bulk Shipment: For ultra-large transformers exceeding FR dimensions; loaded directly onto vessel deck.

- Roll-on/Roll-off (RoRo): For crated or trailer-mounted assemblies.

Packaging uses IPPC-certified wooden crates, shock absorbers, and moisture-proof film. Vibration sensors and temperature loggers can be added for long voyages.

For inland delivery, hydraulic low-bed trailers and escort permits ensure safe transit through tunnels or bridges.

Cost and Risk: Incoterms, Customs, and Anti-Dumping Considerations

A clear understanding of Incoterms 2020 prevents disputes over cost and liability:

| Term | Risk Transfer Point | Buyer’s Responsibility |

|---|---|---|

| EXW | Factory gate | Full transport, insurance, export clearance |

| FOB (China Port) | Onboard vessel | Freight and insurance |

| CIF | Destination port | Import duty, unloading |

| DAP / DDP | Buyer’s site | Only final inspection |

Pro tip: For heavy transformers, choose FOB or CIF terms to maintain control over shipping insurance and logistics provider selection.

In addition, importers should check:

- Customs Codes (HS 8504.22.00) to confirm duty rate.

- Anti-Dumping Policies, especially in regions like the EU or India.

- Country-of-Origin labeling and conformity marks (CE / UKCA / GCC).

Freight cost volatility and currency fluctuation also affect total landed cost. Having multiple freight quotes and insurance coverage reduces exposure to delays or damage.

🔍 Frequently Asked Questions (FAQ): Importing Substation Transformers from China

1. Who are the leading substation transformer manufacturers in China?

China hosts several major transformer producers, but CHBEB stands out for its proven track record with State Grid projects and international EPC cooperation. We supply 35 kV–500 kV oil-immersed and dry-type transformers compliant with IEC 60076 and IEEE C57 standards.

2. How much does it cost to ship a 50 MVA power transformer from China?

Shipping depends on the transformer’s size, port distance, and Incoterm. A 50 MVA unit usually weighs 60–80 tons and is shipped via Flat Rack (FR) or Break Bulk. Typical freight costs range from USD 8,000–25,000 depending on route and insurance coverage.

3. What does a FAT (Factory Acceptance Test) include?

A complete FAT covers ratio and polarity tests, winding resistance, vector group verification, no-load and load losses, induced and applied voltage tests, and temperature rise. These ensure compliance with IEC 60076 and your project’s technical datasheet.

4. What export or import documentation is required?

Standard paperwork includes the commercial invoice, packing list, certificate of origin, FAT report, IEC/CE certificate, and if applicable, SASO, GSO, or SONCAP conformity documents for Middle East or African destinations.

5. Who handles customs clearance and duties?

For FOB or CIF terms, the buyer handles customs at destination; under DDP or DAP, CHBEB manages the entire process—including import declaration, duty payment, and last-mile delivery. Our logistics team works with certified forwarders for smooth clearance.

6. How can I ensure my transformer meets IEEE and IEC standards?

All CHBEB transformers undergo type and routine tests witnessed by third parties such as SGS, TÜV, or BV. We provide full IEC 60076 / IEEE C57 compliance reports and documentation packages for import approval and project audit requirements.

7. How do I arrange marine insurance for large transformers?

High-value transformers are insured under All-Risk Marine Cargo policies (ICC A). CHBEB assists clients in arranging coverage up to 110% of invoice value, including inland transit protection and temperature/vibration monitoring during shipping.

⚙️ CHBEB — Your Reliable Partner for Substation Transformer Import and Engineering

For over six decades, CHBEB has been a trusted name in the global transformer industry, providing OEM/ODM solutions for utilities, EPC contractors, and industrial clients across Russia, Southeast Asia, Africa, and Belt & Road countries.

- 🌐 Global Export Expertise: Specialized in high-voltage transformers (35 kV – 500 kV) with full export documentation, FAT reports, and IEC/IEEE certification.

- 🏭 Factory Strength: Three manufacturing bases in Wenzhou and Nanjing, plus a logistics hub in Beijing ensuring rapid production and dispatch.

- 🔬 Engineering Assurance: Every transformer is tested under IEC 60076, with optional third-party witnessing and DGA/OLTC monitoring systems.

- 📦 End-to-End Logistics: From packaging design to marine insurance, CHBEB guarantees safe and traceable delivery for every shipment.

- 📈 Technical Support: Our international engineers assist in transformer selection, grid compliance, and on-site installation guidance.

At CHBEB, we don’t just manufacture transformers — we deliver confidence from factory to grid. Whether you’re importing your first substation transformer or managing a nationwide project rollout, our team ensures every step is certified, traceable, and risk-free.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

Conclusion

Importing a substation transformer from China doesn’t have to be complicated — it just requires structure, verification, and reliable partnerships. From supplier prequalification and FAT testing to shipping, insurance, and customs clearance, each step builds the foundation for a safe and compliant power project.

The key to success lies in aligning engineering accuracy with trade discipline — ensuring that every transformer not only meets IEC and IEEE standards but also arrives on-site fully certified, damage-free, and ready for energization.

With the right supplier, the process becomes predictable, transparent, and scalable — transforming what was once a logistical challenge into a repeatable, high-efficiency model for global energy infrastructure.

Substation Transformer Selection: The Ultimate Trade-Off Between Dry and Oil-Immersed Technologies | CHBEB

Introduction

Choosing the right transformer for a substation project is the most important decision that every project has to make.

Should you choose a transformer that is dry or one that is immersed in oil?

This choice affects not only performance but also safety, maintenance, and the cost of running the machine over the long term.

Engineers, EPC contractors, and investors may make decisions that last by knowing these trade-offs.

Performance & Safety: Cooling Efficiency, Capacity Limits, and Environmental Risks

Transformers at substations operate under high stress and must deliver exceptional reliability. The right technology for each application depends on cooling method, installation environment, and safety requirements.

Thermal Difference: Oil’s High-Capacity Advantage vs. Dry-Type’s Safety First

The key distinction between the two technologies lies in how they manage heat.

Oil-Immersed Transformers use mineral or ester-based oil for both cooling and insulation.

The oil circulates naturally (ONAN) or through pumps and fans (ONAF, OFAF) to maintain optimal temperature and thermal conductivity1.

Best for:

- Substations with a lot of power, up to 1,000 MVA

- Long-term use in industry or transmission

- Harsh conditions outside or near the coast

Pros:

- Better at getting rid of heat

- Ability to handle a lot of extra work

- Performance that stays stable over long periods of use

On the other hand, dry-type transformers use air or resin insulation technologies such as VPI (Vacuum Pressure Impregnation) or Cast Resin.

They are typically rated below 20 MVA, making them ideal for indoor or fire-sensitive environments.

Pros:

- No chance of oil leaking

- Very good fire safety

- Little upkeep

| Parameter | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling Medium | Mineral / Ester Oil | Air / Epoxy Resin |

| Typical Capacity | 5–1000 MVA | ≤20 MVA |

| Cooling Efficiency | High | Moderate |

| Fire Safety | Medium (improved with ester oil) | High |

| Maintenance | Regular oil checks | Minimal |

| Best Use Case | Outdoor substations, plants | Indoor or public areas |

👉In short, oil-immersed models have a higher power density, whereas dry-type units put safety and environmental compliance first.

Environmental Compliance: Noise, Fire Rating, and Installation Requirements

Modern substation designs must meet regulations for noise, fire, and the environment.

Noise:

Oil-immersed transformers are quieter because the oil absorbs vibrations in the core.

Step-lap silicon steel designs keep noise levels below 55 dB, meeting IEC 60076 standards2.

Dry-type transformers can be a little louder, but enclosures or vibration mounts can reduce the noise easily.

Fire safety:

Dry-type transformers are suitable for indoor use because they use Class F/H resin that puts out fires on its own.

Oil units now use synthetic ester oils, which are biodegradable and non-flammable, greatly reducing fire risks.

IRequirements for installation:

Oil-immersed: needs fire walls and containment pits to ensure safety.

Also requires ventilation for cooling, especially in confined spaces.

Typical applications:

- High-load outdoor sites → Oil-immersed

- Indoor, compact, or public areas → Dry-type

Insurance companies and regulators are increasingly favoring low-risk transformer installations, which is why dry-type units are becoming more common in modern infrastructure.

Economics: Balancing CAPEX and OPEX

Total ownership cost (TCO) — not just the initial price — is an important factor when choosing a substation transformer.

Oil-immersed transformers

- Lower initial cost (about 20–30% less for the same capacity)

- Require oil sampling, filtering, and replacement every 3–5 years

- Have slightly higher insurance and containment costs

Dry-Type Transformers

- Higher initial cost due to resin and insulation materials

- Minimal maintenance — only air filter cleaning and temperature checks

- No oil waste or disposal costs, ideal for areas with strict environmental regulations

| Cost Element | Oil-Immersed | Dry-Type |

|---|---|---|

| Purchase Price | Lower | Higher |

| Maintenance | Regular oil service | Minimal |

| Installation | Fire wall & oil pit | Simple indoor setup |

| Efficiency | Higher (liquid cooling) | Slightly lower |

| Lifetime | 30–40 years | 25–30 years |

✅ Conclusion: After 25 years, both have about the same TCO. Oil kinds are better in terms of capacity and cost, whereas dry types are better in terms of safety and ease of use.

Scenario-Based Selection: Matching Type to Application

Every project has its own set of rules and conditions.

Here’s how to choose the right transformer technology for your situation:

| Scenario | Recommended Type | Reason |

|---|---|---|

| Underground / Metro | Dry-Type | Fire-safe and compact |

| Data Center / Hospital | Dry-Type | Clean operation, low noise |

| Power Plant / Utility Substation | Oil-Immersed | High capacity and durability |

| Coastal or Outdoor Areas | Oil-Immersed (Ester Oil) | Weather-resistant and eco-safe |

| Urban Commercial Building | Dry-Type | Safe for people, zero leakage |

Ester oil-filled transformers are a new type of hybrid design that combines liquid cooling with fire-resistant performance. They are part of the global drive toward greener, higher-capacity systems.

🔎 Learn more about dry-type transformer selection and design in our in-depth Dry Type Transformer Guide 2025 — covering insulation types, VPI vs. cast resin, and IEC 60076 standards.

⚙️ CHBEB — Reliable Partner for Substation Transformer Solutions

For over 60 years, CHBEB has specialized in substation and distribution transformer engineering, offering both dry-type and oil-immersed solutions designed to meet global standards.

Why Choose CHBEB

- 🏭 Manufacturing Strength: Factories in Wenzhou and Nanjing, plus a logistics hub in Beijing, enabling fast production and delivery.

- 🔬 Engineering Expertise: All products tested under IEC 60076 and ISO 9001, ensuring reliability in every voltage class.

- 🌍 Global Reach: Trusted by utilities and EPCs in Russia, Southeast Asia, Africa, and Belt & Road countries.

- ⚡ Customized Design: From 50 kVA to 1000 MVA — tailored for your voltage, climate, and project needs.

- 📈 End-to-End Support: From selection consultation to installation guidance and certification documentation.

At CHBEB, we don’t just build transformers — we engineer reliability into every grid we power.

👉 Looking for a distribution transformer manufacturer that combines Chinese manufacturing strength with international standards?Contact CHBEB for a tailored solution or Download our full transformer catalog here.

🔍 Frequently Asked Questions (FAQ): Substation Transformer Selection

1. What’s the main difference between dry and oil-immersed substation transformers?

Oil-immersed transformers use liquid insulation for higher capacity and better heat dissipation.

Dry types rely on resin or air, offering fire safety and minimal maintenance — ideal for indoor or compact setups.

2. Which type is more suitable for high-voltage substations?

Oil-immersed transformers (ONAF/OFAF) handle up to 1000 MVA and are preferred for 110–500 kV systems.

Dry types are typically used below 35 kV.

3. Which transformer is safer for populated areas?

Dry-type transformers, thanks to their non-flammable insulation, are safer for metro, hospital, or commercial installations.

4. How long does each type last?

Oil-immersed: 30–40 years with proper oil monitoring and OLTC care.

Dry-type: 25–30 years with minimal servicing.

5. Can CHBEB help me choose the right substation transformer?

Absolutely. Our engineering team provides technical selection reports, thermal simulations, and custom designs for your project environment.

Conclusion

The choice between dry-type and oil-immersed transformers isn’t about which is superior — it’s about which fits your substation’s voltage, environment, and safety requirements.

Oil-immersed designs remain the benchmark for high-capacity and outdoor installations, providing excellent thermal efficiency and long service life. Dry-type transformers, on the other hand, are the preferred option for indoor, public, or fire-sensitive sites where safety and simplicity outweigh raw capacity.

For EPCs, utilities, and engineers, the smartest decision lies in evaluating total cost of ownership, installation context, and compliance standards — not just initial price.

When reliability, certification, and lifecycle performance truly matter, CHBEB’s engineering team stands ready to help you select, customize, and deliver substation transformers that keep your grid safe, efficient, and future-ready.

In-Depth Understanding: The Core Function and Grid Role of Substation Power Transformers

Introduction

A substation transformer is a silent workhorse that sits at the center of every power system. It makes sure that electricity flows smoothly from generation to consumers. These huge devices, on the other hand, can take enormous voltages, manage complicated cooling, and keep stability throughout whole regional networks. To understand how modern power systems stay reliable and efficient, you need to know what their roles are.

Fundamentals: Definition, Structure, and Dual Purpose

Before we get into how substations move power across the grid, it’s important to know what makes a substation power transformer different in terms of design and function.

Definition and Positioning: What Sets Them Apart from Distribution Units

A substation power transformer is a large device that transfers electricity between voltage levels in the transmission system. It typically operates at 110–500 kV and handles over 100 MVA of power.

In contrast, distribution transformers reduce voltage for end users—usually below 35 kV—and serve localized loads such as homes or businesses.

| Type | Voltage Range | Capacity | Function |

|---|---|---|---|

| Substation Power Transformer | 110–500 kV | 60–1000 MVA | Interconnects generation and transmission systems |

| Distribution Transformer | ≤35 kV | 50–2500 kVA | Supplies local distribution networks |

The main distinction is where the grid is located. Substation transformers are the “main gatekeepers” for regional power transfer. They are located at generation, transmission, or primary substations.

Core Structure: Key Components and Complex Cooling Systems of Large Transformers

The design of a substation transformer is far more complicated than that of smaller dry-type or pad-mounted devices. Three main engineering systems affect how well it works:

- Active Part (Core and Windings)

The laminated magnetic core efficiently guides magnetic flux, while the copper or aluminum windings handle large currents with minimal loss. - System for Cooling

Large transformers generate significant heat. They rely on oil circulation and forced-air or water cooling, as defined by IEC and IEEE cooling codes such as:- ONAN (Oil Natural Air Natural): passive circulation for mild loads.

- ONAF (Oil Natural Air Forced): adds fans to enhance cooling efficiency.

- OFWF (Oil Forced Water Forced): used in very high-power transformers, including 500 kV grid units.

- Bushings and Tanks

The primary tank, which is usually made of welded steel, holds insulating oil and keeps its shape even when it gets hot. Bushings constructed of porcelain or composite materials safely move high-voltage wires in and out of the unit.

These systems work together to create a balance of electrical efficiency, mechanical strength, and thermal regulation.

The Grid Nexus: How Substation Transformers Ensure Efficient Power Transfer

Substation transformers are the main link between the generation, transmission, and distribution layers of the electrical grid. They not only change voltage, but also maintain power flow, reduce losses, and stabilize voltage levels as loads fluctuate.

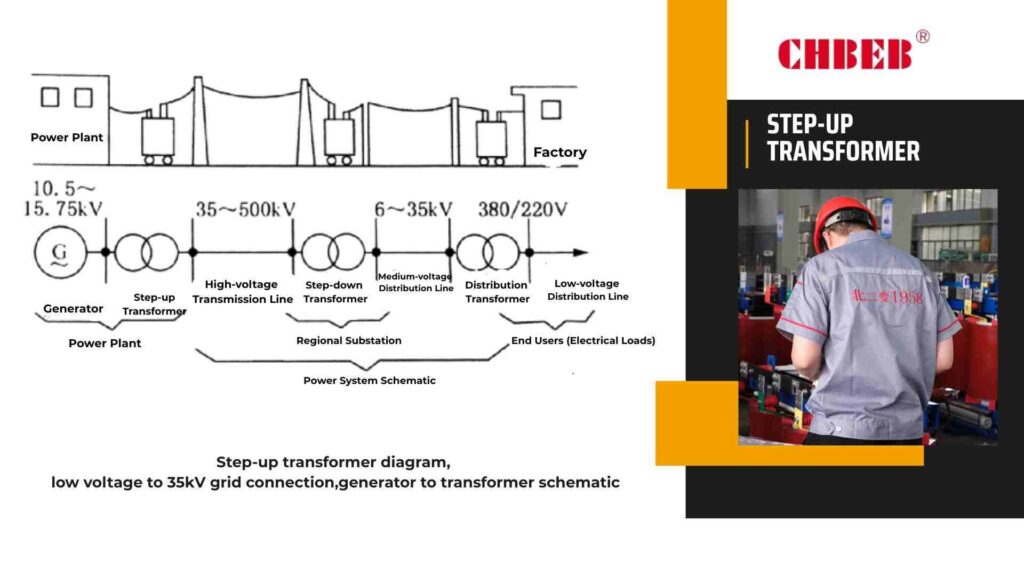

The Two Main Tasks in the Grid: Step-Up and Step-Down on the Energy Journey

Electricity is generated at medium voltages (typically 11–25 kV). Power plants use step-up transformers to increase voltage to hundreds of kilovolts, significantly reducing current and line losses, making long-distance transmission more efficient.

At the receiving end, step-down transformers in major substations lower the voltage again for safe and efficient distribution to businesses and regional networks.

This two-way procedure shows how electrical energy moves: