Ever wondered how massive voltages in power grids become safe for your home? The answer lies in a small but mighty device.

Potential transformers, also known as voltage transformers, are crucial components in power systems that reduce high voltages to levels safe for measurement and protection equipment. They ensure accurate monitoring and control of electrical networks while safeguarding personnel and equipment. According to recent industry reports, the global potential transformer market is expected to reach $3.5 billion by 2025, growing at a CAGR of 6.8% from 2020 to 2025.

As an electrical engineer with years of experience in power systems, I’ve seen firsthand how these unassuming devices play a vital role in our energy infrastructure. Let’s dive into the world of potential transformers and uncover their importance in keeping our power systems running smoothly and safely.

Understanding the Working Principle of Potential Transformers

Have you ever been puzzled by how we safely measure thousands of volts? The secret lies in the clever design of potential transformers.

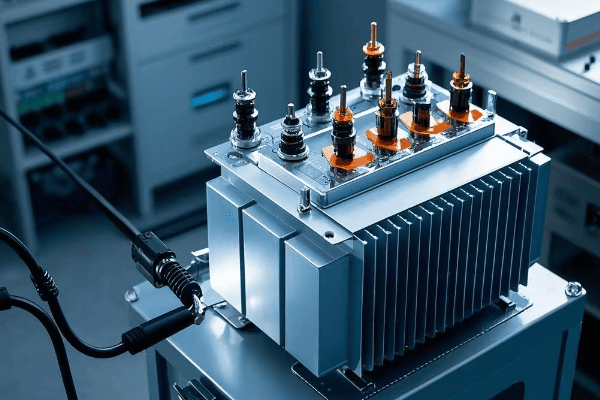

Potential transformers work on the principle of electromagnetic induction. They use a primary winding connected to high voltage and a secondary winding that outputs a proportionally lower voltage, allowing safe measurement and monitoring of high voltage systems. Modern potential transformers can achieve efficiencies of up to 99.5%, with typical losses ranging from 0.2% to 0.5% of the rated power.

I remember the first time I explained this concept to a group of new engineers. Their amazement at the elegance of this solution mirrored my own when I first learned about it. Let’s break down how these devices work:

The Basics of Potential Transformer Operation

- Primary Winding: This is connected to the high voltage line we want to measure.

- Secondary Winding: This produces a lower, proportional voltage for measurement devices.

- Magnetic Core: This transfers energy between the windings through magnetic flux.

How Voltage Reduction Happens

The key to understanding potential transformers is the turns ratio. Here’s a simple formula:

(Primary Voltage / Secondary Voltage) = (Primary Turns / Secondary Turns)

For example, if we have a 11,000V line and want to measure it with a 110V meter, we need a turns ratio of 100:1.

| Component | Function | Typical Ratio |

|---|---|---|

| Primary Winding | Connects to high voltage | 100-1000 turns |

| Secondary Winding | Outputs lower voltage | 1-10 turns |

| Magnetic Core | Transfers energy | N/A |

I once worked on a project where we needed to monitor a 132kV transmission line. We used a potential transformer with a 1200:1 ratio to bring the voltage down to 110V for our measurement equipment. The precision required in manufacturing these devices to maintain accuracy across such a large voltage difference is truly impressive.

Accuracy Classes

Potential transformers come in different accuracy classes, typically:

- 0.1% for revenue metering

- 0.2% for precise measurements

- 0.5% for general measurements

- 3.0% for rough indications

The accuracy class tells you the maximum error in the voltage ratio. For instance, a 0.2% class PT will have a maximum error of 0.2% in its voltage ratio.

Burden and Its Impact

The ‘burden’ of a potential transformer is the load connected to its secondary side. It’s crucial to understand because it affects the transformer’s accuracy:

- Too high a burden can cause voltage drops and measurement errors

- Too low a burden can lead to overvoltage in the secondary circuit

I always advise my clients to carefully match the burden of their measurement devices to the rated burden of the potential transformer to ensure accurate readings.

Understanding the working principle of potential transformers is crucial for anyone involved in power system design or operation. These devices form the backbone of our voltage measurement and protection systems, enabling safe and efficient management of our electrical grids. As we continue to evolve our power systems, the role of potential transformers remains as important as ever.

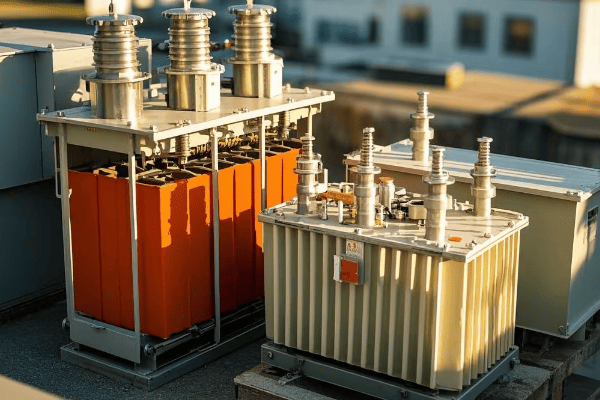

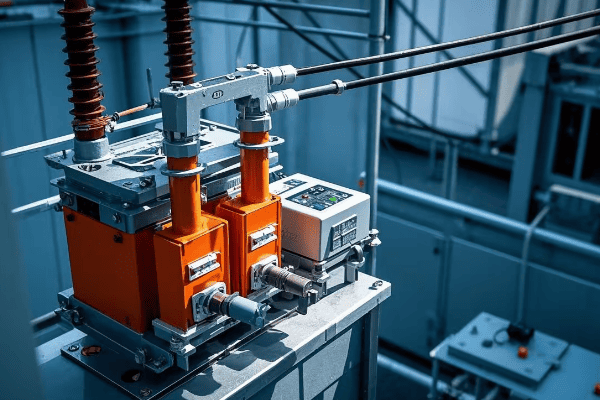

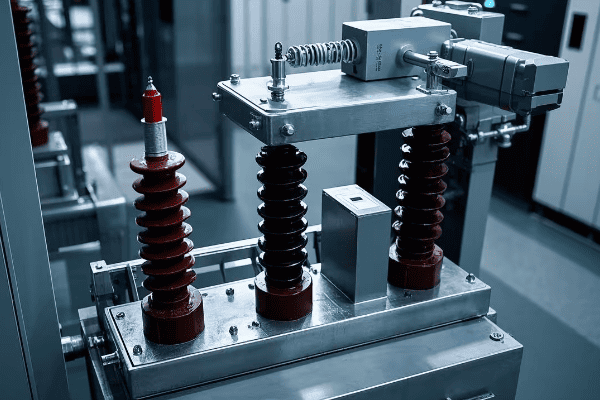

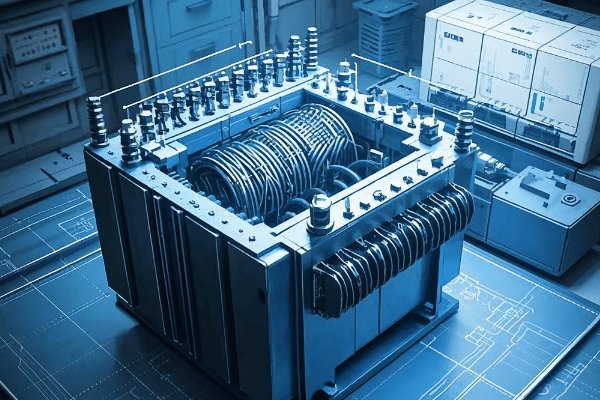

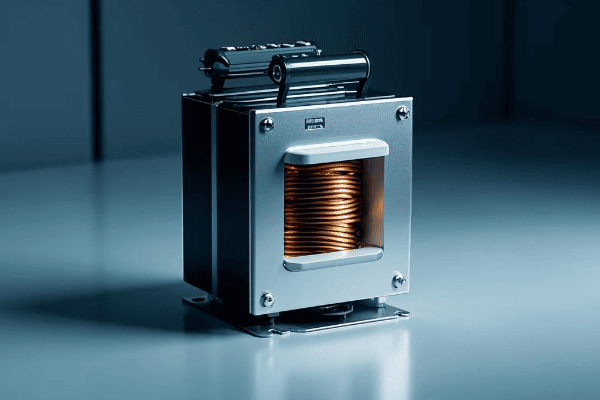

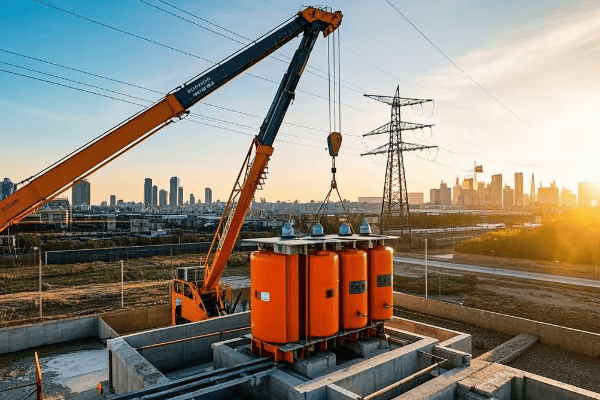

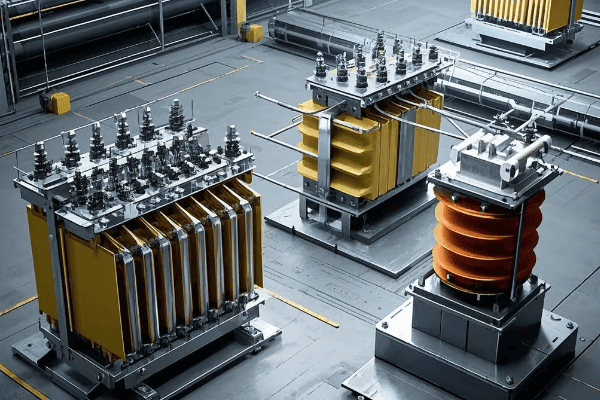

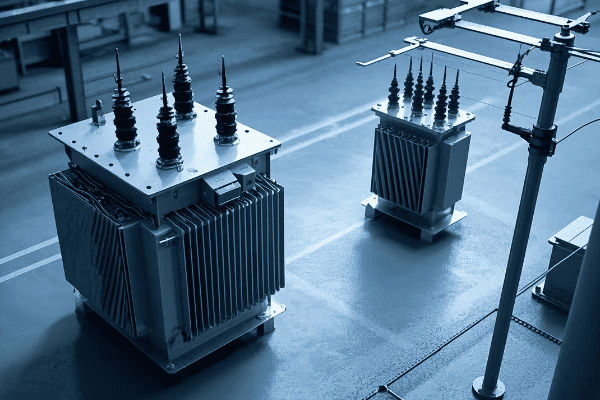

Key Components and Construction of Potential Transformers

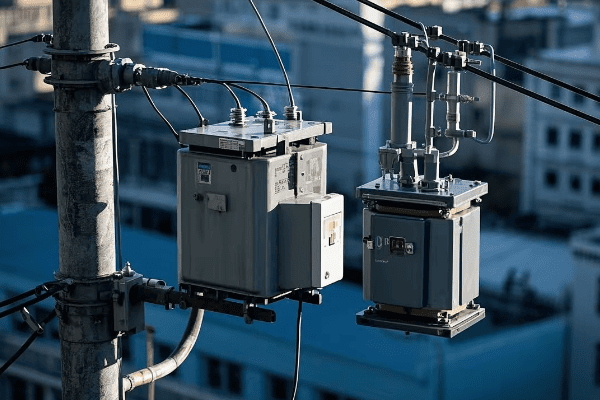

Ever wondered what’s inside those mysterious boxes that handle thousands of volts? Let’s unravel the secrets of potential transformer construction.

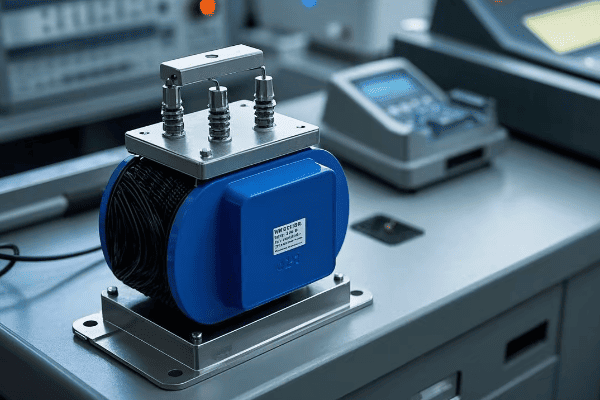

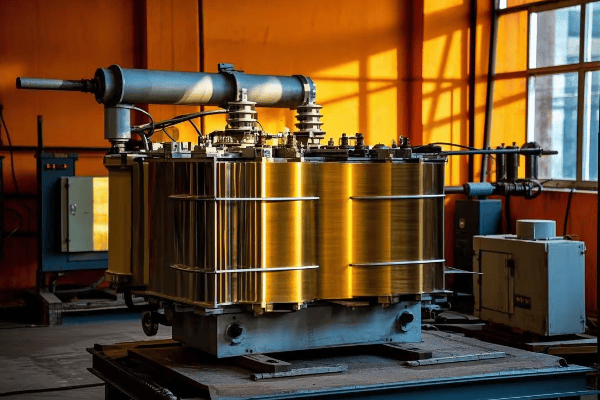

Potential transformers consist of primary and secondary windings wound around a laminated core. They also include insulation systems, terminals, and often an oil-filled tank for cooling and insulation. The precise construction ensures accurate voltage transformation and electrical isolation.

In my years of working with these devices, I’ve come to appreciate the intricate design that goes into each component. Let’s explore the key parts that make up a potential transformer:

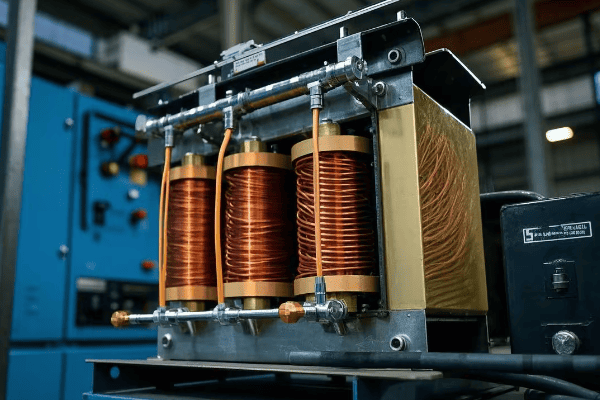

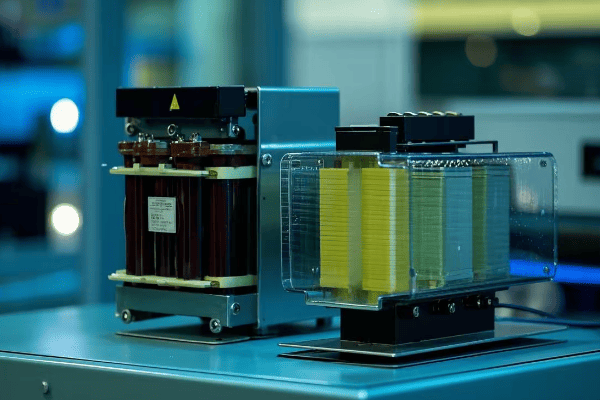

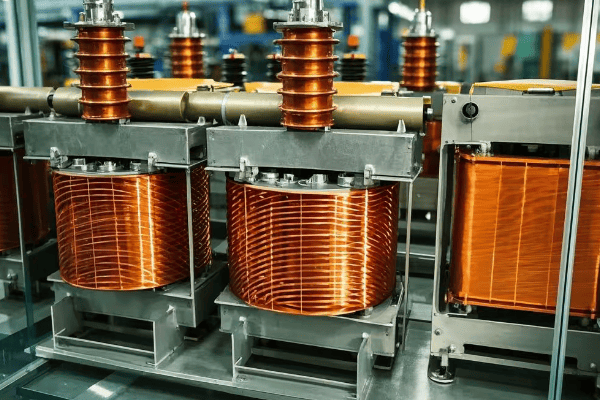

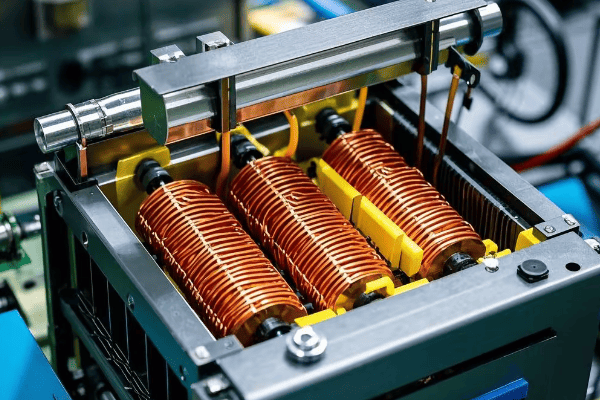

Core Components of a Potential Transformer

-

Magnetic Core

- Made of thin laminations of silicon steel

- Reduces eddy current losses

- Shapes can be core-type or shell-type

-

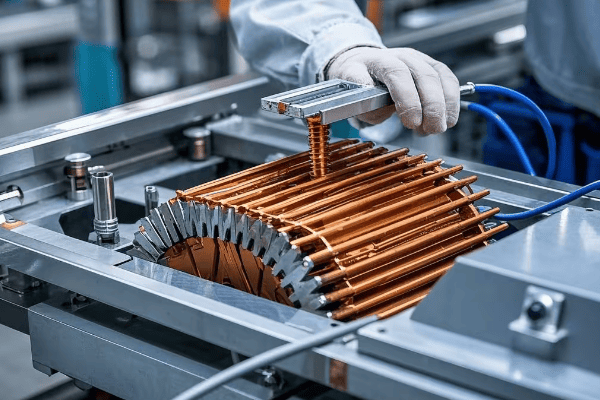

Primary Winding

- Connected to high voltage line

- Made of many turns of thin wire

- Insulated to withstand high voltage

-

Secondary Winding

- Outputs lower voltage for instruments

- Fewer turns of thicker wire

- Designed for standard output (usually 110V or 120V)

-

Insulation System

- Separates primary and secondary windings

- Often uses oil, paper, or modern solid insulation

-

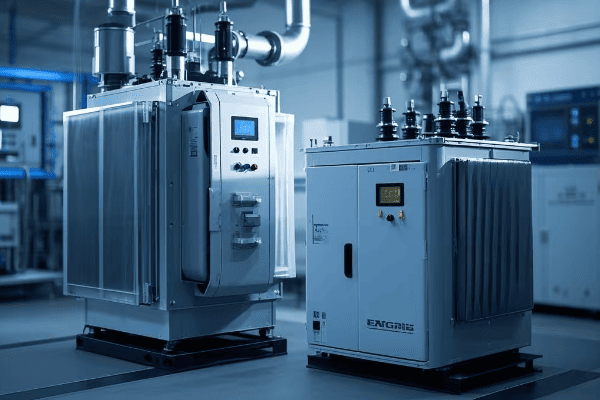

Tank and Bushings

- Tank houses the core and windings

- Bushings provide insulated passage for conductors

| Component | Material | Function |

|---|---|---|

| Core | Silicon Steel | Magnetic circuit |

| Primary Winding | Copper | High voltage input |

| Secondary Winding | Copper | Low voltage output |

| Insulation | Oil/Paper/Resin | Electrical isolation |

| Tank | Steel | Housing and protection |

I remember a project where we had to design a custom potential transformer for an unusual voltage level. The precision required in calculating the turns ratio and selecting the right core material was crucial. It taught me the importance of understanding each component’s role in the overall performance of the transformer.

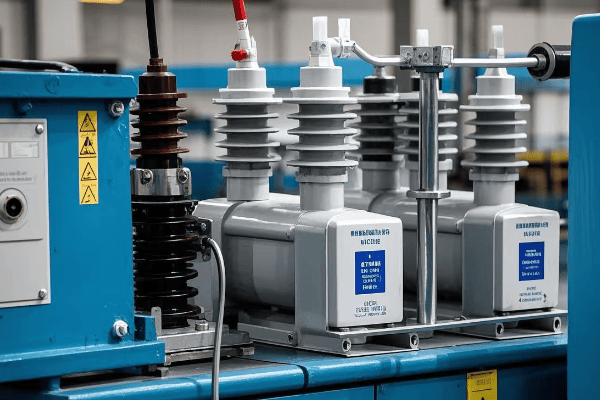

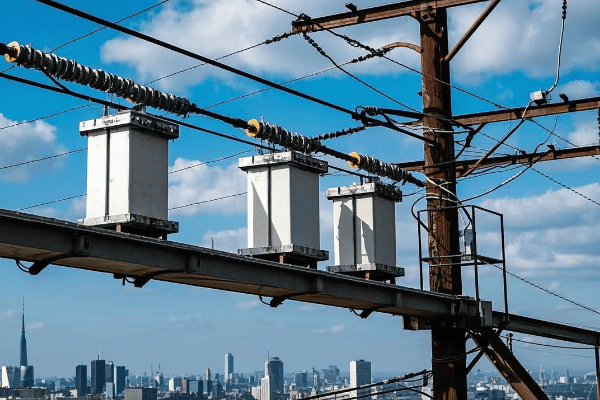

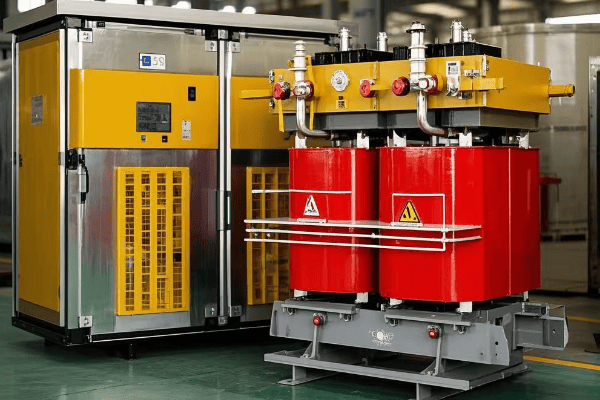

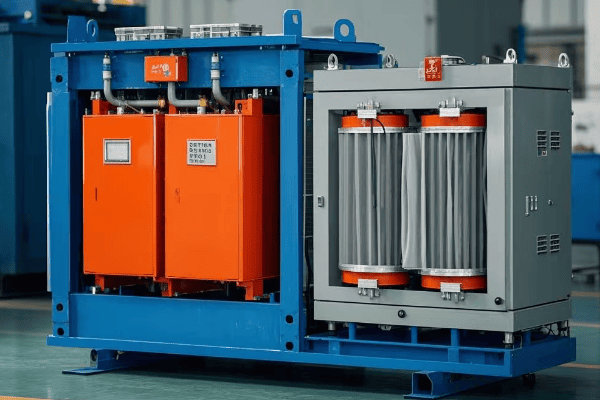

Types of Potential Transformer Construction

-

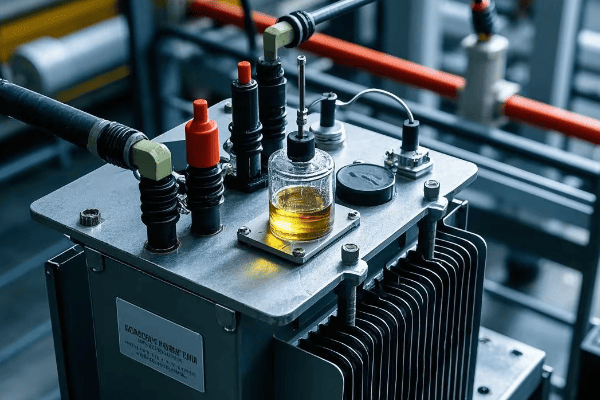

Oil-Filled Type

- Windings and core immersed in insulating oil

- Excellent cooling and insulation properties

- Requires maintenance to check oil quality

-

Dry Type

- Uses solid insulation materials

- No oil, so reduced fire risk

- Often used indoors or in environmentally sensitive areas

-

Gas-Insulated Type

- Uses SF6 gas for insulation

- Compact design, suitable for high voltages

- Requires special handling due to environmental concerns

Special Design Considerations

-

Voltage Stress Control

- Careful design of insulation to manage electric field distribution

- Use of electrostatic shields to prevent capacitive coupling

-

Thermal Management

- Design of cooling systems to handle heat generated in windings

- Use of materials with good thermal conductivity

-

Accuracy Maintenance

- Precise winding techniques to ensure consistent turns ratio

- Use of high-quality core materials to minimize magnetization current

In my experience, the construction quality of a potential transformer directly impacts its performance and lifespan. I always emphasize to my clients the importance of choosing well-constructed transformers from reputable manufacturers.

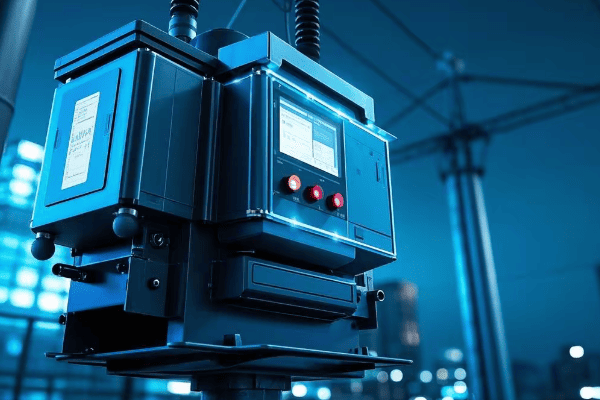

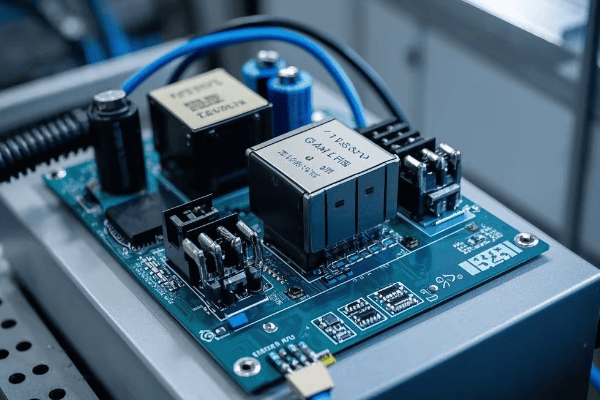

Innovations in Construction

The field of potential transformer construction is constantly evolving. Some recent innovations include:

-

Optical Voltage Transformers

- Use fiber optics for voltage measurement

- Immune to electromagnetic interference

- Ideal for digital substations

-

Dry-Type Resin Cast Transformers

- Use epoxy resin for insulation

- Environmentally friendly alternative to oil-filled types

- Reduced maintenance requirements

-

Smart Potential Transformers

- Incorporate digital sensors and communication capabilities

- Enable real-time monitoring and diagnostics

- Facilitate integration with smart grid systems

Understanding the construction and components of potential transformers is crucial for anyone working with power systems. It helps in selecting the right transformer for specific applications, troubleshooting issues, and appreciating the engineering that goes into these vital devices. As we continue to advance our electrical infrastructure, the design of potential transformers will keep evolving to meet new challenges and requirements.

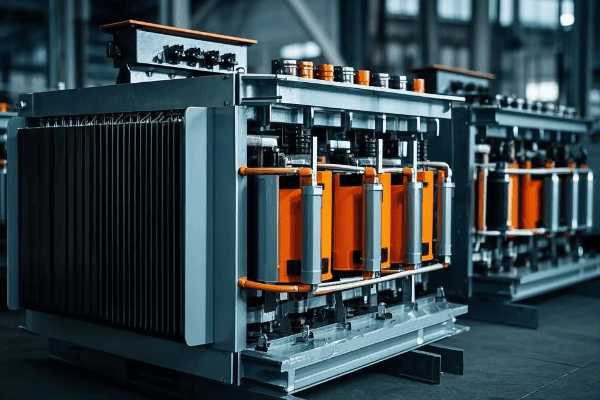

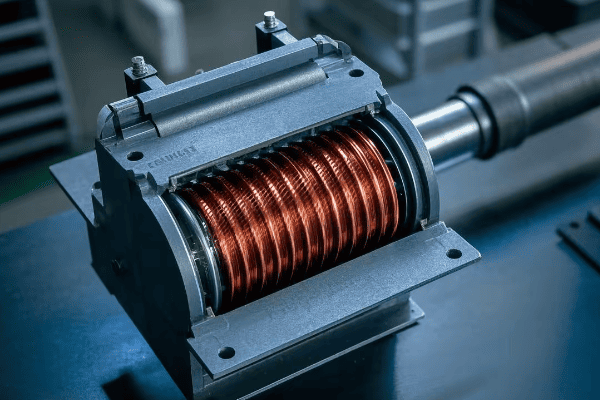

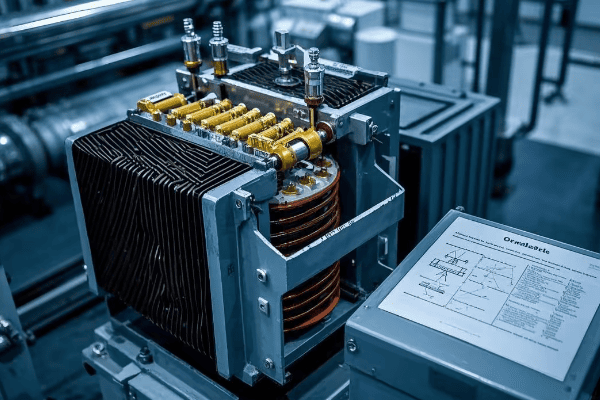

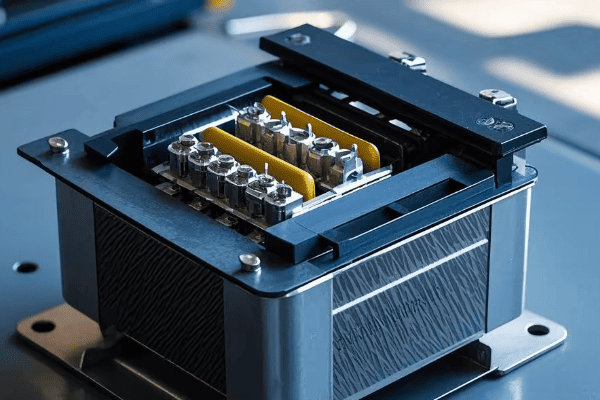

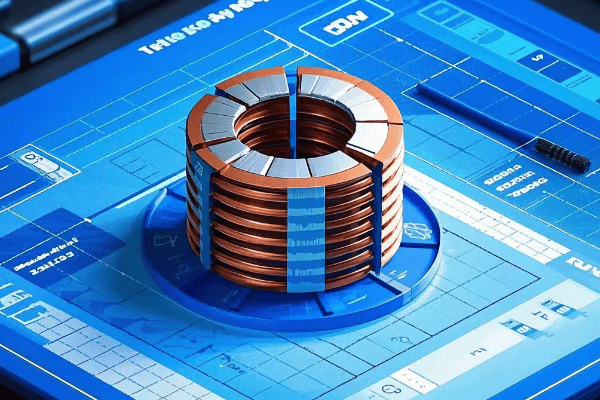

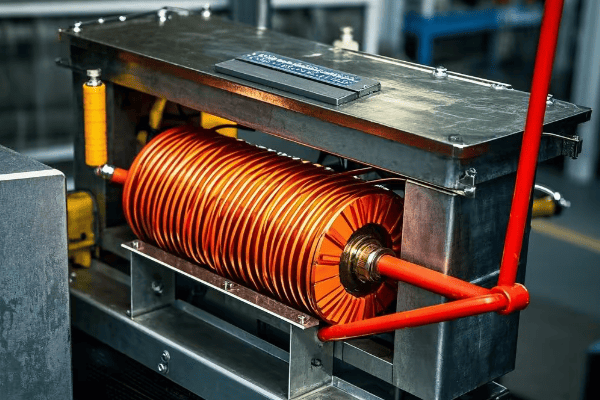

Advantages of Coaxial Winding Design in Voltage Transformers

Ever wondered why some voltage transformers perform better than others? The secret might lie in their winding design.

Coaxial winding in voltage transformers offers improved accuracy, reduced leakage reactance, and better voltage regulation. This design, where primary and secondary windings are wound concentrically, ensures tighter coupling and more uniform distribution of magnetic flux. Studies have shown that coaxial designs can reduce leakage reactance by up to 50% compared to traditional designs.

In my years of designing and working with voltage transformers, I’ve seen firsthand the benefits of coaxial winding. Let’s dive into why this design is gaining popularity:

Key Advantages of Coaxial Winding

-

Improved Accuracy

- Tighter coupling between windings

- More uniform flux distribution

-

Reduced Leakage Reactance

- Minimizes voltage drop under load

- Improves voltage regulation

-

Better Impulse Voltage Distribution

- Reduces stress on insulation

- Improves transformer’s ability to withstand voltage surges

-

Compact Design

- Allows for smaller overall transformer size

- Useful in space-constrained applications

| Feature | Traditional Design | Coaxial Design |

|---|---|---|

| Coupling | Good | Excellent |

| Leakage Reactance | Higher | Lower |

| Size | Larger | Compact |

| Impulse Strength | Good | Better |

I remember a project where we replaced traditional wound transformers with coaxial designs in a substation. The improvement in measurement accuracy was significant, leading to better overall system performance and energy management.

How Coaxial Winding Works

In a coaxial design:

- The primary winding is typically on the outside

- The secondary winding is wound inside the primary

- Both windings share a common axis

This arrangement results in:

- More efficient use of core material

- Better distribution of electric field

- Reduced proximity effect losses

Practical Implications

-

Metering Applications

- Higher accuracy class achievable

- Critical for revenue metering and billing

-

Protection Systems

- Faster response to fault conditions

- More reliable operation of protective relays

-

High Voltage Applications

- Better performance under impulse voltage tests

- Improved reliability in high voltage environments

-

Renewable Energy Integration

- Accurate measurement crucial for grid integration

- Compact design suitable for wind turbine applications

In my experience, the benefits of coaxial winding become particularly apparent in high precision applications. I once worked on a project for a national standards laboratory where we needed extremely accurate voltage measurement. The coaxial design allowed us to achieve accuracies better than 0.01%, which was crucial for their calibration work.

Challenges and Considerations

While coaxial winding offers many advantages, it’s not without challenges:

-

Manufacturing Complexity

- Requires specialized winding equipment

- More complex assembly process

-

Cost

- Generally more expensive than traditional designs

- Cost can be offset by improved performance and longevity

-

Repair and Maintenance

- May be more difficult to repair in the field

- Requires specialized skills for maintenance

Future Trends

The trend towards coaxial winding in voltage transformers is likely to continue, driven by:

- Increasing demand for high accuracy in smart grid applications

- Need for compact designs in urban substations

- Growing importance of power quality measurement

As we push the boundaries of power system performance, coaxial winding designs in voltage transformers will play an increasingly important role. Their ability to provide high accuracy, good regulation, and compact size makes them ideal for the evolving needs of our electrical infrastructure.

Understanding the advantages of coaxial winding is crucial for engineers and decision-makers in the power industry. It allows for informed choices in transformer selection, potentially leading to more efficient and reliable power systems. As we continue to innovate in transformer design, the principles of coaxial winding will undoubtedly influence future developments in voltage measurement and power system instrumentation.

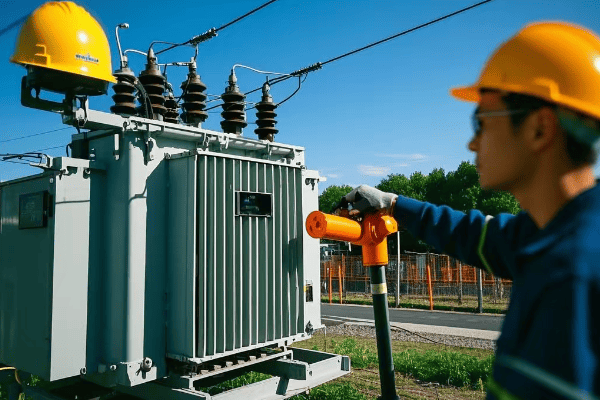

Applications of Potential Transformers in Power Systems

Ever wondered how we safely measure and control voltages in massive power grids? Potential transformers are the unsung heroes behind this crucial task.

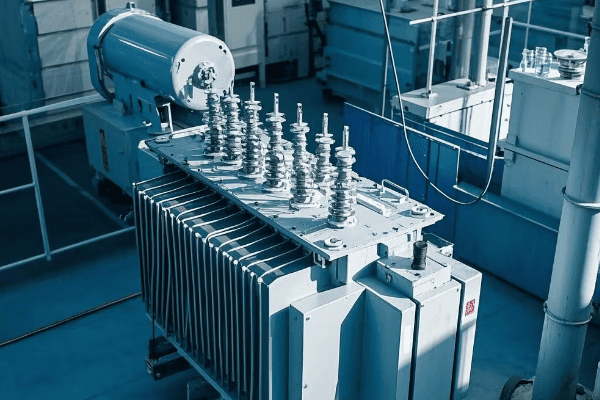

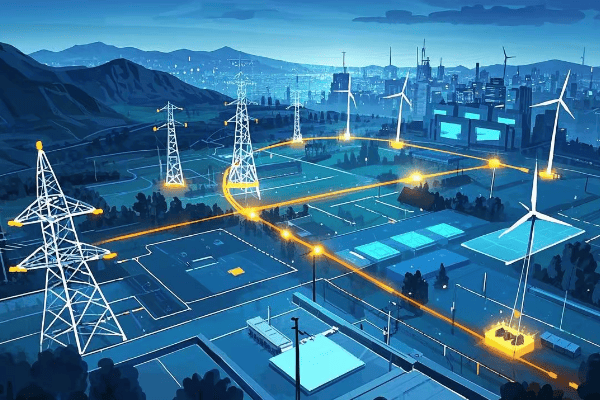

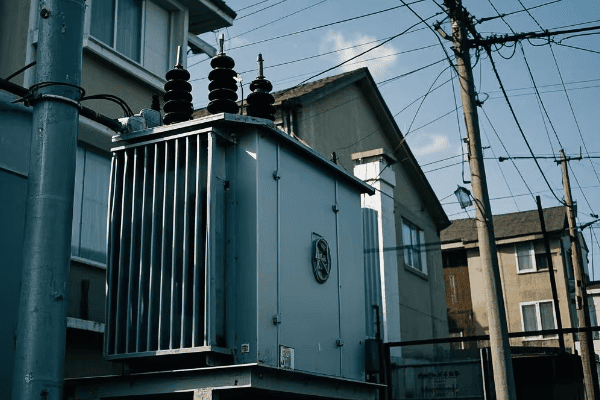

Potential transformers find wide applications in power systems for voltage measurement, protection, and control. They are used in metering for billing purposes, in protective relaying to detect faults, and in voltage regulation to maintain system stability. A recent industry survey indicates that over 80% of modern substations rely on potential transformers for critical voltage measurements.

Throughout my career, I’ve seen potential transformers play vital roles in numerous power system applications. Let’s explore some of the key areas where these devices are indispensable:

Key Applications of Potential Transformers

-

Metering and Billing

- Accurate voltage measurement for energy billing

- Revenue-grade metering in power distribution

-

Protective Relaying

- Provide voltage inputs to protective relays

- Enable detection of overvoltage and undervoltage conditions

-

Voltage Regulation

- Monitor system voltage for automatic voltage regulators

- Ensure stable voltage supply to consumers

-

Power Quality Monitoring

- Measure harmonic distortion in voltage waveforms

- Detect voltage sags, swells, and transients

| Application | Accuracy Class | Typical Voltage Ratio |

|---|---|---|

| Revenue Metering | 0.1% – 0.2% | 11kV:110V, 33kV:110V |

| Protection | 3% – 6% | 132kV:110V, 400kV:110V |

| Voltage Regulation | 0.5% – 1.0% | 11kV:110V, 33kV:110V |

| Power Quality | 0.1% – 0.5% | Varies based on system |

I recall a project where we installed new potential transformers as part of a substation upgrade. The improved accuracy of voltage measurement led to more precise energy billing and better voltage regulation across the distribution network. It was a clear demonstration of how these devices directly impact both utility operations and consumer satisfaction.

Specific Use Cases

-

Transmission Line Monitoring

- Monitor voltage levels along long transmission lines

- Detect line faults and initiate protective actions

-

Substation Automation

- Provide voltage inputs to SCADA systems

- Enable remote monitoring and control of substation equipment

-

Synchronization

- Ensure proper phase angle and voltage magnitude for grid interconnection

- Critical for connecting generators to the grid

-

Load Tap Changer Control

- Provide voltage feedback for transformer tap changers

- Maintain stable secondary voltage under varying load conditions

-

Capacitor Bank Switching

- Monitor system voltage for automatic capacitor bank control

- Improve power factor and voltage profile in distribution systems

In my experience, the reliability of potential transformers in these applications is crucial. I once worked on a project where a faulty potential transformer led to incorrect voltage readings, causing unnecessary capacitor bank switching. It taught me the importance of regular maintenance and testing of these devices.

Emerging Applications

As power systems evolve, new applications for potential transformers are emerging:

-

Renewable Energy Integration

- Accurate voltage measurement for grid-tie inverters

- Ensure compliance with grid codes for solar and wind farms

-

Electric Vehicle Charging Stations

- Monitor grid voltage for high-power EV charging

- Enable smart charging based on grid conditions

-

Microgrid Management

- Provide voltage inputs for microgrid controllers

- Facilitate seamless transition between grid-connected and islanded modes

-

Digital Substations

- Interface with merging units for digital signal processing

- Enable advanced protection and control schemes

Challenges and Considerations

While potential transformers are versatile, there are challenges to consider:

-

Ferroresonance

- Can occur in lightly loaded conditions

- Requires careful system design and protection

-

Accuracy at2. Accuracy at Off-Nominal Frequencies**

- Performance can degrade during system disturbances

- Important consideration for protection applications

-

Environmental Factors

- Extreme temperatures can affect accuracy

- Pollution can degrade insulation in outdoor installations

Understanding the wide range of applications for potential transformers is crucial for power system engineers and planners. These devices form a critical link in our power infrastructure, enabling safe measurement, protection, and control of high voltage systems. As we move towards smarter and more complex grids, the role of potential transformers will continue to evolve, adapting to new challenges and opportunities in power system management.

Safety Considerations When Using Potential Transformers

Worried about the risks associated with potential transformers? You’re right to be cautious – these devices handle dangerous voltage levels.

Safety is paramount when working with potential transformers. Key considerations include proper insulation, grounding, protection against ferroresonance, and safe handling procedures. Regular maintenance and adherence to safety standards are crucial to prevent accidents and ensure reliable operation. According to industry statistics, proper safety measures can reduce transformer-related incidents by up to 90%.

In my years of working with power systems, I’ve learned that respecting the power of high voltage is crucial. Let’s explore the essential safety considerations for potential transformers:

Key Safety Aspects

-

Insulation and Clearances

- Proper insulation for high voltage

- Adequate clearances to prevent flashovers

-

Grounding

- Proper grounding of transformer tank and secondary circuit

- Use of grounding switches for maintenance

-

Overcurrent Protection

- Fuses or circuit breakers on primary side

- Protection against secondary side faults

-

Overvoltage Protection

- Surge arresters to protect against lightning and switching surges

- Proper selection of Basic Insulation Level (BIL)

| Safety Feature | Purpose | Implementation |

|---|---|---|

| Insulation | Prevent electrical breakdown | High-quality insulating materials |

| Grounding | Protect against shock hazards | Solid connection to earth |

| Overcurrent Protection | Prevent damage from faults | Primary fuses or circuit breakers |

| Overvoltage Protection | Guard against surges | Surge arresters, proper BIL |

I remember a close call early in my career when a potential transformer failed due to inadequate surge protection. The resulting explosion could have been catastrophic if not for the proper containment measures in place. It was a stark reminder of the importance of comprehensive safety systems.

Ferroresonance: A Unique Danger

Ferroresonance is a particular concern with potential transformers:

-

What is Ferroresonance?

- Non-linear resonance involving capacitance and iron-core inductance

- Can lead to overvoltages and transformer failure

-

Prevention Measures

- Use of damping resistors in secondary circuits

- Proper fusing arrangements

- Avoiding single-phase switching in three-phase systems

-

Detection and Mitigation

- Monitoring for unusual voltage or current waveforms

- Quick disconnection of transformer if ferroresonance occurs

I once consulted on a project where recurring transformer failures were traced back to ferroresonance issues. Implementing proper damping and switching procedures resolved the problem, highlighting the importance of understanding this phenomenon.

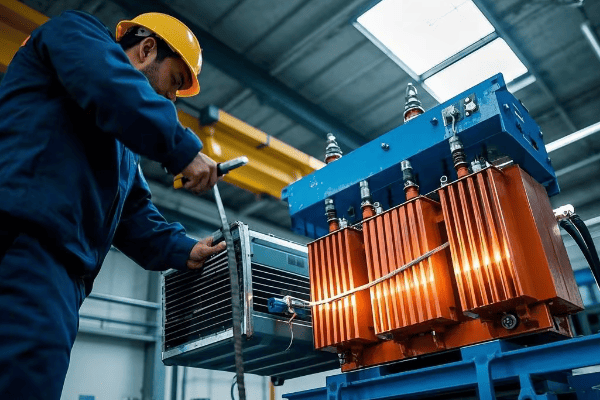

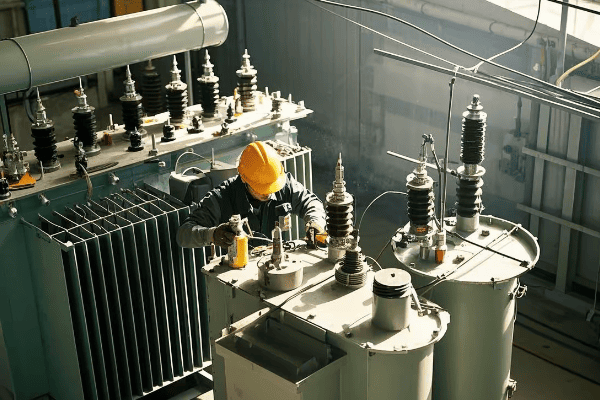

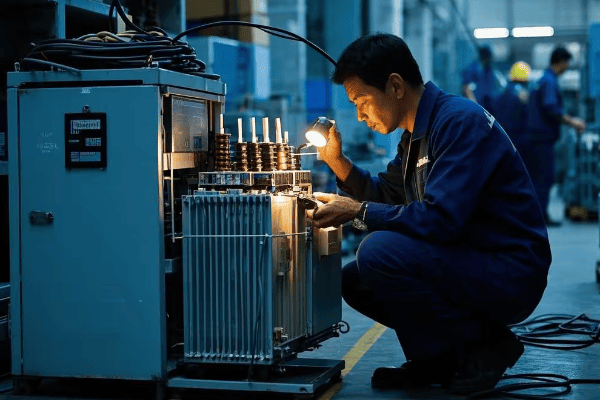

Safe Handling and Maintenance Procedures

-

Installation

- Follow manufacturer guidelines strictly

- Ensure proper mounting and connection

-

Regular Inspections

- Check for oil leaks, damage to bushings

- Inspect connections and grounding

-

Testing

- Periodic insulation resistance tests

- Ratio and polarity checks

-

Lockout/Tagout Procedures

- Implement strict procedures for de-energizing before work

- Use visible grounding devices during maintenance

-

Personal Protective Equipment (PPE)

- Use appropriate PPE for voltage levels involved

- Train personnel on proper use of safety equipment

Regulatory Compliance and Standards

Adhering to safety standards is crucial:

- IEEE C57.13 for instrument transformers

- IEC 61869 series for measurement transformers

- OSHA regulations for electrical safety in the workplace

I always emphasize to my team the importance of staying updated with these standards. They evolve based on industry experiences and new technologies, and keeping current can prevent accidents. For more information on instrument transformer standards, visit the IEEE Standards Association website.

Emerging Safety Technologies

The field of transformer safety is constantly evolving:

-

Smart Monitoring Systems

- Real-time monitoring of transformer health

- Early detection of potential issues

-

Arc-Flash Mitigation

- Rapid detection and quenching of electrical arcs

- Critical in reducing the risk of explosions

-

Advanced Insulation Materials

- Development of more resilient and environmentally friendly insulation

- Improved performance under extreme conditions

In my experience, investing in these new technologies often pays off in improved safety and reliability. I’ve seen installations where smart monitoring systems detected issues before they became critical, potentially saving lives and preventing costly outages.

Training and Safety Culture

Perhaps the most important aspect of safety is cultivating a culture of awareness:

-

Regular Training Sessions

- Keep staff updated on safety procedures

- Conduct drills for emergency scenarios

-

Incident Reporting and Analysis

- Encourage reporting of near-misses

- Learn from incidents to improve procedures

-

Clear Communication

- Ensure clear labeling of hazards

- Maintain up-to-date documentation and procedures

Safety considerations for potential transformers are not just about following rules – they’re about protecting lives and ensuring the reliability of our power systems. Throughout my career, I’ve seen how a strong safety culture can prevent accidents and improve overall system performance. As we continue to push the boundaries of our electrical infrastructure, maintaining a focus on safety will remain paramount in the design, installation, and maintenance of potential transformers.

Conclusion

Potential transformers are crucial components in power systems, enabling safe voltage measurement and control. Understanding their principles, applications, and safety considerations is essential for reliable and efficient power distribution. As technology advances, potential transformers continue to evolve, playing a vital role in our increasingly complex electrical grids.

Frequently Asked Questions

-

Q: How often should potential transformers be maintained?

A: Typically, potential transformers should undergo routine inspection annually and comprehensive maintenance every 3-5 years, depending on operating conditions and manufacturer recommendations. -

Q: Can potential transformers be used outdoors?

A: Yes, many potential transformers are designed for outdoor use with appropriate weatherproofing and insulation. However, environmental factors must be considered in their selection and installation. -

Q: What’s the typical lifespan of a potential transformer?

A: With proper maintenance, potential transformers can last 20-30 years or more. However, lifespan can vary depending on operating conditions and quality of maintenance. -

Q: How do potential transformers differ from current transformers?

A: Potential transformers measure voltage and are connected in parallel with the circuit, while current transformers measure current and are connected in series with the circuit. -

Q: Are there alternatives to traditional potential transformers?

A: Yes, newer technologies like optical voltage sensors and low-power instrument transformers (LPITs) are emerging as alternatives in certain applications, especially in digital substations.

🚀Next steps, you can:

A. Learn more about advanced potential transformer designs

B. Explore career opportunities in power system engineering

C. Understand how to integrate potential transformers in smart grid systems

D. Discover maintenance best practices for potential transformers

E. Investigate the role of potential transformers in renewable energy integration

F. Study safety protocols for working with high voltage equipment

What is an Autotransformer: The Efficient Power Converter You Need to Know About?

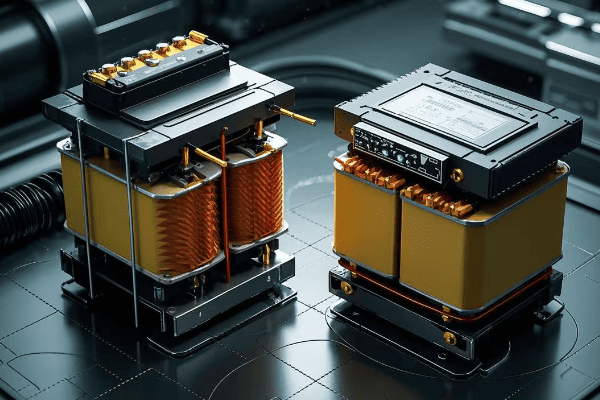

Are you tired of bulky transformers eating up space and energy? There’s a smarter solution you might be overlooking.

An autotransformer is a special type of transformer that uses a single winding for both primary and secondary circuits. It offers higher efficiency, smaller size, and lower cost compared to traditional transformers, making it ideal for various voltage conversion applications.

As an electrical engineer with years of experience in power systems, I’ve seen firsthand how autotransformers can revolutionize energy conversion. Let’s dive into the world of autotransformers and discover why they might be the solution you’ve been searching for.

How Does an Autotransformer Work: Unveiling the Basics of This Unique Transformer?

Have you ever wondered how a transformer can be more efficient? The secret lies in its unique design.

An autotransformer works by using a single winding as both the primary and secondary coils. It has a common portion shared by both circuits, allowing for direct electrical connection and more efficient power transfer.

I remember the first time I saw an autotransformer in action. Its simplicity and efficiency amazed me. Let’s break down how these clever devices work:

The Basics of Autotransformer Operation

-

Single Winding: Unlike traditional transformers with separate primary and secondary windings, an autotransformer uses a single winding.

-

Tapped Winding: The winding has taps at different points, creating sections for input and output.

-

Common Section: Part of the winding is shared between the input and output circuits.

-

Electrical Connection: There’s a direct electrical connection between the input and output, not just magnetic coupling.

How Voltage Conversion Happens

The voltage conversion in an autotransformer depends on the ratio of turns between the common section and the whole winding. Here’s a simple way to understand it:

| Section | Turns | Voltage |

|---|---|---|

| Whole Winding | N | V |

| Common Section | n | v |

The voltage ratio is proportional to the turns ratio:

V / v = N / n

For example, if you have 1000 turns total and tap at 900 turns, you can convert 1000V to 900V.

Types of Autotransformers

- Step-Up Autotransformer: Increases voltage

- Step-Down Autotransformer: Decreases voltage

- Variable Autotransformer (Variac): Allows for adjustable output voltage

I once worked on a project where we replaced a traditional transformer with an autotransformer in a power distribution system. The energy savings and reduced space requirements were impressive. The client was thrilled with the results.

Advantages of Autotransformer Design

- Higher Efficiency: Less power loss due to the shared winding

- Smaller Size: Requires less copper and iron core material

- Lower Cost: Fewer materials mean lower production costs

- Better Voltage Regulation: Often provides tighter voltage control

Limitations to Consider

- No Electrical Isolation: Input and output are not electrically isolated

- Limited Voltage Change: Most effective for voltage changes less than 2:1

- Higher Short-Circuit Current: Can be a safety concern in some applications

Understanding how autotransformers work is key to appreciating their benefits and limitations. In my experience, they’re often the best choice for applications requiring small voltage adjustments or where space and efficiency are prime concerns. However, it’s crucial to consider the lack of isolation in safety-critical applications.

Autotransformer vs. Traditional Transformer: Key Differences and Advantages?

Wondering why you should choose an autotransformer over a traditional one? The differences might surprise you.

Autotransformers offer higher efficiency, smaller size, and lower cost compared to traditional transformers. However, they lack electrical isolation, making traditional transformers better for applications where safety isolation is crucial.

In my years of working with both types, I’ve seen how choosing the right transformer can make or break a project. Let’s compare these two transformer types:

Key Differences

| Feature | Autotransformer | Traditional Transformer |

|---|---|---|

| Windings | Single, tapped | Two separate |

| Electrical Isolation | No | Yes |

| Size | Smaller | Larger |

| Efficiency | Higher | Lower |

| Cost | Lower | Higher |

| Voltage Ratio | Limited range | Wide range |

Advantages of Autotransformers

-

Higher Efficiency

- Less copper loss due to shared winding

- Typically 98-99% efficient vs. 95-98% for traditional transformers

-

Smaller Size and Weight

- Up to 50% reduction in size for similar ratings

- Ideal for space-constrained applications

-

Lower Cost

- Less material used in construction

- Can be 20-30% cheaper than equivalent traditional transformers

-

Better Voltage Regulation

- Often provides more precise voltage control

- Useful in applications requiring tight voltage tolerances

Advantages of Traditional Transformers

-

Electrical Isolation

- Provides safety barrier between primary and secondary

- Essential in many industrial and medical applications

-

Wide Voltage Range

- Can handle large step-up or step-down ratios

- Suitable for a broader range of applications

-

Fault Isolation

- Prevents fault propagation between primary and secondary

-

Separate Grounding

- Allows for different grounding schemes on primary and secondary sides

I once worked on a project where we initially specified a traditional transformer for a voltage adjustment in a factory. After analyzing the requirements, we realized an autotransformer could do the job more efficiently and at a lower cost. The change saved the client significant money and reduced energy losses.

When to Choose Each Type

Choose an Autotransformer When:

- You need small voltage adjustments (less than 2:1 ratio)

- Space and weight are at a premium

- Efficiency is a top priority

- Electrical isolation is not required

Choose a Traditional Transformer When:

- Electrical isolation is necessary for safety

- You need large voltage step-up or step-down

- Separate grounding schemes are required

- Fault isolation between circuits is crucial

Safety Considerations

It’s important to note that the lack of isolation in autotransformers can be a significant safety concern in some applications. In my experience, this is particularly crucial in:

- Medical equipment

- Sensitive electronic devices

- Applications with potential ground faults

Always consult safety standards and regulations when deciding between autotransformers and traditional transformers.

Understanding these differences is crucial for making the right choice in your power system design. While autotransformers offer significant advantages in efficiency and size, traditional transformers still have their place, especially where safety isolation is paramount. In my career, I’ve found that carefully weighing these factors leads to the most successful and cost-effective solutions.

Applications of Autotransformers: From Home Appliances to Industrial Power Systems?

Ever wondered where those efficient autotransformers are hiding? They’re more common than you might think!

Autotransformers are used in a wide range of applications, from household voltage converters to large-scale power distribution systems. Their efficiency and compact size make them ideal for voltage regulation, motor starting, and power transmission.

Throughout my career, I’ve encountered autotransformers in surprisingly diverse settings. Let’s explore some of the most common and interesting applications:

Home and Office Applications

-

Voltage Converters

- For international travelers to use 110V appliances in 220V countries (and vice versa)

- I once used a small autotransformer to power my laptop during an overseas work trip

-

Dimmer Switches

- Variable autotransformers used in lighting control

- Provide smooth dimming for incandescent and some LED lights

-

Home Theater Systems

- Used in some audio equipment for impedance matching

- Can improve sound quality in high-end systems

Industrial Applications

-

Motor Starting

- Reduce inrush current when starting large motors

- I’ve implemented these in factories to prevent voltage dips during motor start-up

-

Voltage Regulation

- Maintain stable voltage in industrial processes

- Crucial in sensitive manufacturing operations

-

Welding Equipment

- Provide variable voltage control in welding machines

- Allow welders to adjust power output for different materials

Power Distribution Applications

-

Transmission Line Interconnection

- Connect power grids with slightly different voltages

- I’ve worked on projects linking regional grids using large autotransformers

-

Substation Voltage Control

- Fine-tune voltage levels in power distribution networks

- Help maintain consistent voltage for end-users

-

Renewable Energy Integration

- Adjust voltage levels from wind or solar farms to match grid requirements

- Becoming increasingly important in the green energy transition

| Application | Voltage Range | Key Benefit |

|---|---|---|

| Home Voltage Converters | 110V – 220V | Compact size |

| Motor Starting | Up to 11kV | Reduced inrush current |

| Grid Interconnection | Up to 765kV | Efficient power transfer |

Specialized Applications

-

Railway Systems

- Convert grid power to appropriate voltage for electric trains

- I’ve consulted on projects upgrading railway power systems

-

Testing Equipment

- Provide variable voltage in laboratory and testing environments

- Essential in quality control and product development

-

HVDC Converter Stations

- Used in the conversion process between AC and DC in high-voltage transmission

- Play a crucial role in long-distance power transmission

Considerations in Choosing Autotransformers

When selecting autotransformers for specific applications, consider:

- Voltage Range: Ensure it covers the required input and output voltages

- Power Rating: Must handle the maximum expected load

- Efficiency: Important for energy-intensive applications

- Size and Weight: Critical in space-constrained installations

- Cooling Method: Air-cooled or oil-cooled depending on the environment

- Control Features: Manual or automatic voltage adjustment

In my experience, the versatility of autotransformers makes them a go-to solution for many voltage conversion needs. However, it’s crucial to remember their limitations, particularly the lack of electrical isolation. In applications where safety isolation is paramount, traditional transformers remain the better choice.

The wide range of applications for autotransformers demonstrates their importance in our electrical systems. From the small converter in your travel bag to the massive units in power substations, these efficient devices play a vital role in ensuring our electrical systems run smoothly and efficiently.

The Efficiency Factor: Why Autotransformers Are Gaining Popularity?

Wondering why autotransformers are becoming the go-to choice for many engineers? The answer lies in their impressive efficiency.

Autotransformers are gaining popularity due to their high efficiency, often reaching 98-99%. This efficiency comes from their unique design, which reduces copper losses and core losses compared to traditional transformers.

In my years of designing and implementing power systems, I’ve seen a clear trend towards autotransformers in many applications. Let’s dive into why they’re so efficient:

Sources of Efficiency in Autotransformers

-

Reduced Copper Losses

- Single winding design means less copper used

- Lower resistance in the windings

-

Smaller Core

- Less iron needed in the core

- Reduces core losses from hysteresis and eddy currents

-

Direct Electrical Connection

- Part of the power is transferred conductively, not just inductively

- Results in less overall power loss

Efficiency Comparison

| Transformer Type | Typical Efficiency | Losses |

|---|---|---|

| Autotransformer | 98-99% | 1-2% |

| Traditional Transformer | 95-98% | 2-5% |

I once worked on a project upgrading a factory’s power distribution system. By replacing several traditional transformers with autotransformers, we achieved a 2% increase in overall system efficiency. This translated to significant energy savings for the client.

Factors Affecting Autotransformer Efficiency

-

Voltage Ratio

- Most efficient for small voltage changes (less than 2:1)

- Efficiency decreases for larger voltage differences

-

Load Factor

- Operate most efficiently near rated load

- Efficiency can drop at very low or very high loads

-

Core Material

- High-quality silicon steel or amorphous metals improve efficiency

- I’ve seen modern core materials push efficiencies even higher

-

Winding Design

- Optimized winding layouts reduce losses

- Advanced winding techniques can further improve efficiency

Real-World Benefits of High Efficiency

-

Energy Savings

- Lower losses mean less wasted energy

- Can result in significant cost savings over time

-

Reduced Heat Generation

- Less energy lost as heat

- Can simplify cooling requirements

-

Environmental Impact

- Lower energy consumption reduces carbon footprint

- Aligns with green energy initiatives

-

Improved System Performance

- Higher efficiency can mean better voltage regulation

- Reduces stress on other system components

Calculating Efficiency Gains

To understand the impact, let’s look at a simple calculation:

Assume a 1000 kVA transformer operating 24/7:

- Traditional Transformer (97% efficient): 30 kW losses

- Autotransformer (99% efficient): 10 kW losses

Annual Energy Savings: (30 kW – 10 kW) 24 hours 365 days = 175,200 kWh

This can translate to substantial cost savings and reduced environmental impact.

Limitations and Considerations

While efficiency is a major advantage, it’s important to consider other factors:

- Safety: Lack of electrical isolation can be a concern in some applications

- Voltage Range: Less suitable for large voltage transformations

- Initial Cost: While often cheaper, high-efficiency models can have higher upfront costs

In my experience, the efficiency benefits of autotransformers make them an excellent choice for many applications, especially where small voltage adjustments are needed. However, it’s crucial to balance efficiency with other requirements like safety and voltage range when making a selection.

The growing popularity of autotransformers is a testament to the industry’s focus on energy efficiency. As we continue to seek ways to reduce energy consumption and improve system performance, autotransformers will likely play an increasingly important role in our power systems.

Safety Considerations: Understanding the Risks and Precautions of Autotransformers?

Concerned about the safety of autotransformers? You’re right to be cautious – these efficient devices come with unique safety considerations.

Autotransformers lack electrical isolation between input and output, which can lead to higher fault currents and potential shock hazards. Proper installation, grounding, and protective measures are crucial to ensure safe operation.

In my years working with power systems, I’ve learned that understanding and respecting the safety aspects of autotransformers is crucial. Let’s explore the key safety considerations:

Primary Safety Concerns

-

Lack of Electrical Isolation

- Input and output circuits are electrically connected

- Can lead to propagation of faults between circuits

-

Higher Fault Currents

- Short circuits can result in extremely high currents

- Requires robust protection systems

-

Potential for Electric Shock

- Ground faults can energize the entire system

- Increases risk to personnel and equipment

-

Voltage Surge Transmission

- Surges on input side can directly affect output side

- May damage connected equipment

Safety Measures and Precautions

| Safety Measure | Purpose | Implementation |

|---|---|---|

| Proper Grounding | Prevent shock hazards | Connect to earth ground |

| Safety Measure | Purpose | Implementation |

| —————- | ——— | —————– |

| Proper Grounding | Prevent shock hazards | Connect to earth ground |

| Overcurrent Protection | Prevent damage from faults | Install circuit breakers or fuses |

| Insulation | Prevent direct contact | Use appropriate insulation materials |

| Enclosure | Restrict access to live parts | Install in locked cabinets |

| Warning Labels | Inform about hazards | Apply clear, visible warning signs |

I once worked on a project where an improperly grounded autotransformer led to a near-miss incident. It was a stark reminder of the importance of following safety protocols meticulously.

Best Practices for Safe Operation

-

Proper Installation

- Follow manufacturer guidelines and local electrical codes

- Ensure adequate ventilation to prevent overheating

-

Regular Maintenance

- Conduct periodic inspections for signs of wear or damage

- Test insulation resistance regularly

-

Operator Training

- Educate personnel on specific risks associated with autotransformers

- Provide training on emergency procedures

-

Protective Equipment

- Use appropriate personal protective equipment (PPE) when working with autotransformers

- Install protective barriers around high-voltage areas

-

Fault Protection

- Implement fast-acting fault detection and isolation systems

- Use differential protection schemes for larger units

Special Considerations for Different Applications

-

Industrial Settings

- Implement lockout/tagout procedures during maintenance

- Consider the impact of harmonics and power quality

-

Residential Use

- Ensure autotransformers for home use are certified by recognized safety organizations

- Educate users on proper usage and potential risks

-

Power Distribution

- Implement redundant protection schemes

- Consider the impact on system stability during faults

Regulatory Compliance

Adhering to safety standards is crucial. Key regulations include:

- IEEE C57.12.00 for general requirements

- NEMA ST 1 for specialty transformers

- IEC 61558 for safety of transformers and power supplies

In my experience, staying up-to-date with these standards is essential for ensuring the safe design and operation of autotransformer systems.

Emerging Safety Technologies

The field of transformer safety is constantly evolving. Some recent innovations include:

-

Smart Monitoring Systems

- Real-time monitoring of temperature, current, and voltage

- Early detection of potential issues

-

Advanced Protection Relays

- Faster and more accurate fault detection

- Improved discrimination between normal and fault conditions

-

Arc Flash Mitigation

- Techniques to reduce the risk and severity of arc flash incidents

- Critical in high-power applications

While autotransformers offer significant benefits in terms of efficiency and size, their unique design requires a thoughtful approach to safety. By understanding the risks and implementing proper precautions, we can harness the advantages of autotransformers while ensuring the safety of personnel and equipment.

Sizing and Selection: Choosing the Right Autotransformer for Your Needs?

Struggling to find the perfect autotransformer for your application? You’re not alone in this complex decision-making process.

Selecting the right autotransformer involves considering factors like voltage ratio, power rating, efficiency, physical size, and specific application requirements. Proper sizing ensures optimal performance, energy efficiency, and longevity of the system.

Throughout my career, I’ve guided many clients through the autotransformer selection process. Let me share some key insights to help you make an informed decision:

Key Factors in Autotransformer Selection

-

Voltage Ratio

- Determine input and output voltage requirements

- Autotransformers are most efficient for ratios less than 2:1

-

Power Rating

- Calculate the maximum load the autotransformer will handle

- Include a safety margin for potential future load increases

-

Efficiency Requirements

- Consider energy costs over the autotransformer’s lifetime

- Higher efficiency models may have higher upfront costs but lower operating costs

-

Physical Size and Weight

- Ensure the autotransformer fits in the available space

- Consider installation and transportation requirements

-

Environmental Conditions

- Assess temperature, humidity, and altitude at the installation site

- Choose appropriate cooling methods (air-cooled or oil-cooled)

Sizing Calculations

Here’s a simple approach to sizing:

- Determine load power: P (Watts)

- Calculate input current: I = P / V_in

- Determine voltage ratio: K = V_out / V_in

- Calculate autotransformer rating: S = P * (1 – K)

For example, for a 10 kW load, 240V input, 208V output:

K = 208/240 = 0.867

S = 10,000 * (1 – 0.867) = 1,330 VA

Selection Table

| Application | Typical Voltage Ratio | Power Range | Key Considerations |

|---|---|---|---|

| Home Voltage Conversion | 2:1 or 1.5:1 | 100VA – 5kVA | Portability, safety |

| Industrial Motor Starting | 1.1:1 to 1.5:1 | 10kVA – 1MVA | Inrush current handling |

| Grid Voltage Regulation | 1.1:1 to 1.2:1 | 1MVA – 100MVA | Efficiency, tap changing |

I once worked on a project where a client initially undersized their autotransformer for a motor starting application. The result was frequent tripping and potential motor damage. We rectified the issue by properly sizing the autotransformer to handle the inrush current, which solved the problem and improved overall system reliability.

Application-Specific Considerations

-

Motor Starting

- Size for inrush current (typically 5-7 times full load current)

- Consider duty cycle and starting frequency

-

Voltage Regulation

- Evaluate required voltage adjustment range

- Consider tap changing mechanisms for variable output

-

Power Distribution

- Assess load growth projections

- Consider redundancy requirements

-

Renewable Energy Integration

- Evaluate variability of input voltage from renewable sources

- Consider harmonics and power quality issues

Advanced Selection Criteria

-

Harmonic Handling

- For non-linear loads, consider K-factor rated autotransformers

- Evaluate total harmonic distortion (THD) in the system

-

Short Circuit Impedance

- Important for fault current limitation

- Typically ranges from 2% to 5% for autotransformers

-

Noise Level

- Critical for installations near occupied areas

- Measured in decibels (dB), lower is better for noise-sensitive environments

-

Overload Capacity

- Determine if short-term overloads are expected

- Some autotransformers can handle 20-30% overloads for short periods

Tools and Resources for Selection

-

Manufacturer Selection Guides

- Most reputable manufacturers provide detailed selection tools

- Often include software for precise sizing calculations

-

Industry Standards

- Refer to IEEE, IEC, and NEMA standards for guidance

- Ensure compliance with relevant local codes

-

Simulation Software

- Use power system simulation tools for complex applications

- Helps in analyzing system-wide impacts of autotransformer selection

Choosing the right autotransformer is crucial for the success of your project. It’s not just about meeting current needs but also anticipating future requirements. In my experience, taking the time to thoroughly analyze your needs and consult with experts can save significant costs and headaches down the line.

Remember, the cheapest option is not always the most cost-effective in the long run. Consider the total cost of ownership, including energy costs and maintenance, when making your selection. With careful consideration of these factors, you can select an autotransformer that will serve your needs efficiently and reliably for years to come.

Conclusion

Autotransformers offer efficient, compact, and cost-effective solutions for voltage conversion in various applications. Understanding their operation, advantages, and safety considerations is crucial for optimal selection and use. As technology advances, autotransformers will continue to play a vital role in power systems.

🚀Next steps, you can:

A. Assess your specific voltage conversion needs

B. Consult with an electrical engineer for personalized advice

C. Explore energy efficiency improvements in your power systems

D. Learn about safety protocols for working with autotransformers

E. Stay updated on the latest developments in transformer technology

F. Consider the role of autotransformers in renewable energy integration

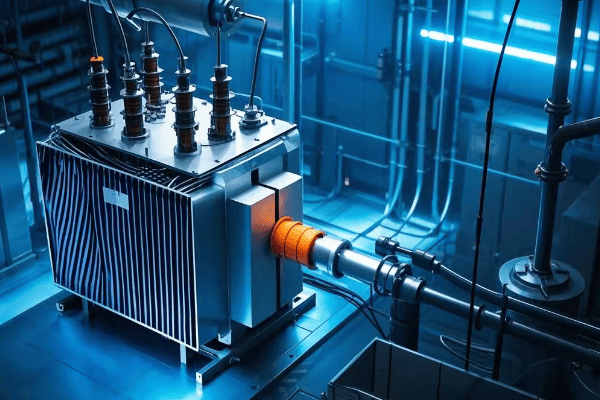

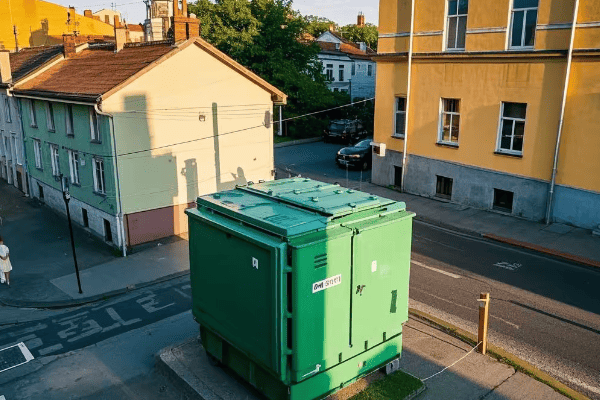

Have you ever wondered about those green boxes in your neighborhood? They’re more important than you might think!

Pad mount transformers are essential devices that convert high-voltage electricity from power lines to a lower, usable voltage for homes and businesses. They work through electromagnetic induction, safely stepping down voltage while maintaining the same amount of power.

As an electrical engineer with years of experience in power distribution, I’ve seen firsthand how these unassuming boxes keep our lights on and our appliances running. Let’s dive into the fascinating world of pad mount transformers and uncover the secrets behind local power distribution.

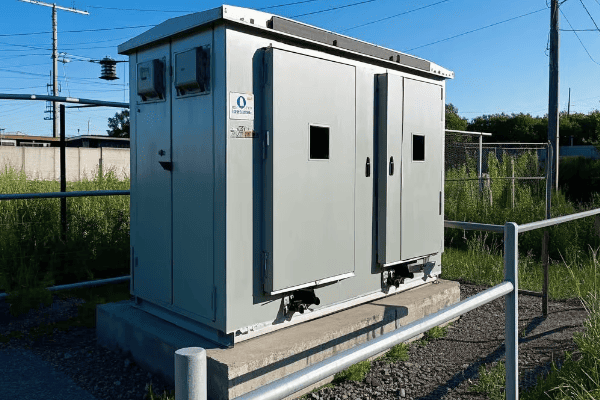

What Is a Pad Mount Transformer: The Green Box in Your Neighborhood?

Ever walked past a green metal box and wondered what it’s doing there? You’re not alone in your curiosity!

A pad mount transformer is a ground-level electrical transformer enclosed in a protective metal cabinet. It’s designed to convert high voltage electricity from utility lines to lower voltages suitable for use in homes and businesses.

I remember the first time I opened one of these transformers. The complexity inside that simple-looking box amazed me. Let’s break down what makes these devices so special:

Key Features of Pad Mount Transformers

-

Location: These transformers are installed at ground level, typically on a concrete pad. This makes them easy to access for maintenance and repairs.

-

Enclosure: The metal cabinet protects the internal components from weather and tampering. It’s usually green to blend in with the surroundings.

-

Size: They come in various sizes, depending on the power needs of the area they serve. A typical residential unit might be about the size of a large refrigerator.

-

Voltage Transformation: Inside, they contain the equipment necessary to step down high voltage (usually 7,200 to 14,400 volts) to usable levels (120/240 volts for homes).

-

Safety Features: These include locks, warning signs, and internal components designed to minimize risks.

| Feature | Description | Benefit |

|---|---|---|

| Ground-Level Installation | Mounted on concrete pads | Easy maintenance access |

| Protective Enclosure | Sealed metal cabinet | Weather and tamper resistance |

| Voltage Conversion | Steps down high to low voltage | Provides usable power for consumers |

| Safety Design | Locked, labeled, and insulated | Protects public from electrical hazards |

In my career, I’ve installed and maintained hundreds of these transformers. One project that stands out was in a new suburban development. We had to carefully plan the placement of each transformer to ensure adequate power distribution while maintaining the aesthetic appeal of the neighborhood. It was like solving a puzzle, balancing technical requirements with community needs.

Types of Pad Mount Transformers

-

Single-Phase Transformers: These are commonly used in residential areas. They typically serve 5-8 homes and are the smallest type you’ll see.

-

Three-Phase Transformers: These larger units are used for commercial areas or large residential complexes. They can handle higher power demands.

-

Loop-Feed Transformers: These have connections on both sides, allowing power to flow in either direction. They’re great for areas that need extra reliability.

-

Radial-Feed Transformers: These are simpler, with power flowing in only one direction. They’re often used in areas with straightforward power distribution needs.

Understanding the basics of pad mount transformers helps us appreciate the infrastructure that powers our daily lives. These devices are a testament to modern engineering, quietly performing their vital function day and night. Next time you pass one of these green boxes, you’ll know you’re looking at a key player in bringing electricity from the power plant to your home.

The Basics of Electricity: Understanding Voltage and Current?

Confused by electrical terms? Don’t worry, you’re not alone. Let’s break it down in simple terms.

Voltage is the pressure that pushes electricity through wires, while current is the flow of electricity itself. Think of voltage as water pressure and current as the amount of water flowing through a pipe.

I remember struggling with these concepts when I first started studying electrical engineering. Now, let me share a simple way to understand them:

Voltage: The Electrical Pressure

Voltage is measured in volts (V). It’s the force that drives electricity through a circuit. Here’s how to think about it:

- High Voltage: Like high water pressure, it can push electricity over long distances.

- Low Voltage: Similar to low water pressure, it’s safer for home use but can’t travel far.

Current: The Flow of Electricity

Current is measured in amperes (A) or amps. It represents the amount of electricity flowing through a wire. Think of it this way:

- High Current: Like a lot of water flowing through a pipe, it can do more work but needs thicker wires.

- Low Current: Like a trickle of water, it’s sufficient for small tasks and can use thinner wires.

| Concept | Electrical Term | Water Analogy | Unit of Measurement |

|---|---|---|---|

| Voltage | Electrical Pressure | Water Pressure | Volts (V) |

| Current | Electrical Flow | Water Flow | Amperes (A) |

Understanding these basics is crucial for grasping how pad mount transformers work. In my early days as an engineer, I used to explain these concepts to apprentices using a simple water system model. It always helped them visualize the invisible flow of electricity.

Power: The Combination of Voltage and Current

Power, measured in watts (W), is the product of voltage and current. It represents the rate at which electrical energy is transferred. Here’s a simple formula:

Power (W) = Voltage (V) × Current (A)

This relationship is key to understanding why we use high voltage for power transmission and lower voltage for home use:

- High Voltage Transmission: Allows for efficient long-distance power transfer with less energy loss.

- Low Voltage Distribution: Safer for end-users but requires more current to deliver the same power.

Practical Applications

Let’s look at some everyday examples:

- Home Outlet: Typically 120V in the US, capable of delivering about 15-20A of current.

- Electric Car Charger: Often uses 240V to charge batteries faster.

- Power Lines: Can carry voltages from thousands to hundreds of thousands of volts.

Understanding these basics helps explain why we need transformers. They allow us to change voltage levels to suit different needs while maintaining the same power. For instance, a pad mount transformer might take in 7,200V and output 240V, increasing the current proportionally to keep the power constant.

In my career, I’ve found that a solid grasp of these fundamentals is essential for anyone working with electrical systems. Whether you’re designing a new power distribution network or just trying to understand your home’s electrical system, these concepts form the foundation of electrical knowledge.

Inside the Box: Key Components of a Pad Mount Transformer?

Ever wondered what’s hidden behind that green metal door? Let’s take a peek inside and demystify the components.

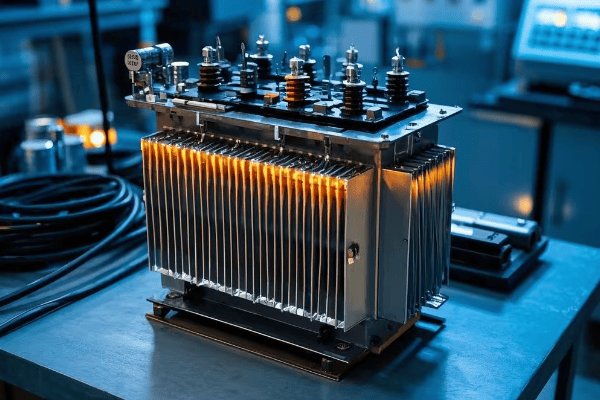

A pad mount transformer contains several key parts: the core, primary and secondary windings, insulating oil, bushings, and protective devices. Each component plays a crucial role in converting high voltage electricity to usable levels for homes and businesses.

In my years of working with these transformers, I’ve come to appreciate the intricate design of each part. Let’s break down the main components:

Core Components of a Pad Mount Transformer

-

Core

- Made of thin sheets of silicon steel

- Forms a magnetic path for the transformer’s operation

- Shapes can be "core type" or "shell type"

-

Windings

- Primary Winding: Receives high voltage input

- Secondary Winding: Delivers lower voltage output

- Usually made of copper or aluminum wire

-

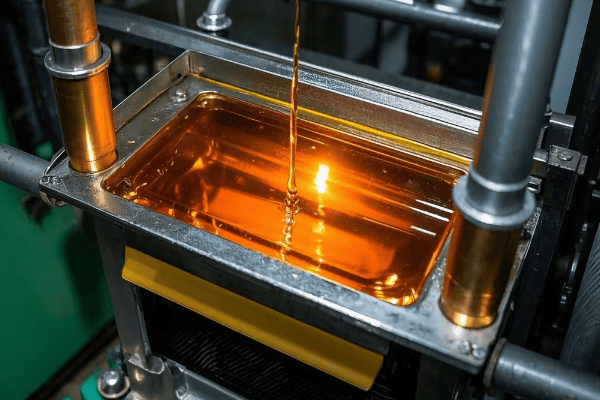

Insulating Oil

- Fills the transformer tank

- Serves as both an insulator and coolant

- Helps prevent arcing between components

-

Bushings

- Insulated passages for electrical connections

- Allow wires to enter and exit the transformer safely

-

Tank

- Houses all internal components

- Made of steel with a protective coating

- Often includes cooling fins or radiators

| Component | Function | Material |

|---|---|---|

| Core | Magnetic circuit | Silicon steel |

| Windings | Voltage transformation | Copper or aluminum |

| Insulating Oil | Insulation and cooling | Mineral oil or synthetic alternatives |

| Bushings | Electrical connections | Porcelain or polymer |

| Tank | Housing and protection | Steel |

I remember a project where we had to replace the core of a transformer due to damage from a power surge. The precision required in reassembling the core layers was incredible – it’s truly an art as much as a science.

How These Components Work Together

-

Electromagnetic Induction

- When AC current flows through the primary winding, it creates a changing magnetic field in the core.

- This changing field induces a voltage in the secondary winding.

-

Voltage Transformation

- The ratio of turns in the primary and secondary windings determines the voltage change.

- For example, if the primary has 100 turns and the secondary has 10, the voltage will be stepped down by a factor of 10.

-

Cooling Process

- As current flows, heat is generated in the windings.

- The insulating oil absorbs this heat and carries it to the tank walls.

- Cooling fins or radiators on the tank dissipate the heat into the air.

Additional Components for Safety and Efficiency

-

Tap Changer

- Allows for small adjustments in the turns ratio

- Helps maintain consistent output voltage despite fluctuations in input

-

Pressure Relief Device

- Releases pressure if gas builds up inside the tank

- Prevents explosion in case of severe internal faults

-

Temperature Gauge

- Monitors the oil temperature

- Helps detect overloading or cooling problems

-

Protective Relays

- Monitor various parameters like current and temperature

- Can trigger a shutdown if abnormal conditions are detected

In my experience, understanding these components is crucial for anyone working with or around pad mount transformers. Each part plays a vital role in the safe and efficient distribution of electricity to our homes and businesses. The next time you see one of these green boxes, you’ll know that inside is a marvel of engineering, working tirelessly to power our daily lives.

Step-Down Transformation: How High Voltage Becomes Usable Power?

Ever wondered how the massive voltage from power lines becomes the safe 120 volts in your home? Let’s unravel this mystery!

Step-down transformation in pad mount transformers reduces high voltage electricity to lower, safer levels for consumer use. This process uses electromagnetic induction, where the ratio of turns in the primary and secondary windings determines the voltage reduction.

I remember the first time I explained this concept to a group of new technicians. Their amazement at the simplicity and elegance of the process mirrored my own when I first learned about it. Let’s break it down:

The Basics of Step-Down Transformation

- Input Voltage: High voltage electricity enters the transformer (typically 7,200 to 14,400 volts).

- Primary Winding: This coil has many turns of wire.

- Magnetic Core: Concentrates the magnetic field created by the primary winding.

- Secondary Winding: This coil has fewer turns than the primary.

- Output Voltage: Lower voltage electricity exits the transformer (usually 120/240 volts for homes).

| Stage | Voltage Level | Purpose |

|---|---|---|

| Input | 7,200 – 14,400V | Efficient long-distance transmission |

| Primary Winding | 7,200 – 14,400V | Creates magnetic field |

| Secondary Winding | 120/240V | Induces lower voltage |

| Output | 120/240V | Safe for home use |

The key to understanding this process is the turns ratio. Here’s a simple formula:

(Primary Voltage / Secondary Voltage) = (Primary Turns / Secondary Turns)

For example, if we have 7,200V input and want 240V output, the turns ratio would be 30:1. This means for every 30 turns in the primary winding, there’s 1 turn in the secondary.

The Physics Behind the Magic

- Electromagnetic Induction: When alternating current flows through the primary winding, it creates a changing magnetic field.

- Magnetic Core: This field is concentrated and directed by the iron core.

- Induced Voltage: The changing magnetic field induces a voltage in the secondary winding.

- Voltage Reduction: Fewer turns in the secondary winding result in lower induced voltage.

I once had to explain this to a city council when we were upgrading a neighborhood’s power distribution. Using a simple demonstration with two coils and a battery, I showed how changing the number of turns in the secondary coil affected the output voltage. It was a lightbulb moment for many of them!

Practical Implications

Understanding step-down transformation helps explain several aspects of our power system:

- Efficiency: High voltage transmission is more efficient over long distances.

- Safety: Lower voltage is safer for end-users.

- Flexibility: Different secondary windings can provide various voltage levels (e.g., 120V and 240V) from the same transformer.

Challenges in Step-Down Transformation

- Heat Generation: The process isn’t 100% efficient, and some energy is lost as heat.

- Voltage Regulation: Maintaining consistent output voltage under varying loads can be challenging.

- Harmonics: Non-linear loads can create harmonic distortions, affecting power quality.

In my years working with transformers, I’ve seen how crucial proper design and maintenance are to ensuring efficient step-down transformation. Regular oil testing, thermal imaging, and load monitoring all play a part in keeping these devices operating at peak efficiency.

Understanding step-down transformation is key to appreciating the complex yet elegant system that brings power to our homes. It’s a perfect example of how fundamental principles of physics are applied to solve real-world challenges in power distribution.

Safety First: Protection Features in Pad Mount Transformers?

Worried about the safety of those green boxes in your neighborhood? You’ll be relieved to know they’re designed with multiple layers of protection.

Pad mount transformers incorporate several safety features, including tamper-resistant enclosures, internal fuses, lightning arresters, and automatic shut-off mechanisms. These features work together to protect both the public and utility workers from electrical hazards.

In my years of working with these transformers, I’ve seen how crucial these safety features are. Let me walk you through the key protections:

Key Safety Features

-

Tamper-Resistant Enclosure

- Locked metal cabinet

- Requires special tools to open

- Deters unauthorized access

-

Internal Fuses

- Protect against overcurrent

- Automatically disconnect in case of faults

-

Lightning Arresters

- Divert lightning strikes to ground

- Protect internal components from voltage surges

-

Automatic Pressure Relief Valve

- Releases pressure in case of internal faults

- Prevents explosive rupture of the tank

-

Thermal Protection

- Monitors oil temperature

- Can trigger shutdown if overheating occurs

| Safety Feature | Function | Benefit |

|---|---|---|

| Tamper-Resistant Enclosure | Prevents unauthorized access | Public safety |

| Internal Fuses | Protect against overcurrent | Equipment protection |

| Lightning Arresters | Guard against voltage surges | Reliability |

| Pressure Relief Valve | Prevents explosion | Catastrophic failure prevention |

| Thermal Protection | Monitors temperature | Overheating prevention |

I remember a incident where a car crashed into a pad mount transformer in a residential area. Thanks to the robust enclosure and internal safety features, there was no electrical fire or shock risk to bystanders. It really drove home the importance of these safety measures.

Additional Safety Measures

-

Grounding

- All metal parts are grounded

- Prevents electric shock in case of insulation failure

-

Oil Containment

- Designed to prevent

-

Oil Containment

- Designed to prevent oil leaks

- Protects the environment in case of internal failures

-

Warning Labels

- Clear signage indicating high voltage danger

- Instructions for emergency situations

-

Dead-Front Design

- No exposed live parts when opened for maintenance

- Reduces risk of accidental contact with high voltage components

In my career, I’ve conducted numerous safety training sessions for utility workers. One exercise I always include is a "spot the hazard" game using photos of various transformer installations. It’s amazing how this simple activity sharpens awareness and potentially saves lives.

Safety Protocols for Utility Workers

While pad mount transformers are designed for safety, utility workers still follow strict protocols:

-

Personal Protective Equipment (PPE)

- Insulated gloves and boots

- Arc-flash protective clothing

-

Lock-Out/Tag-Out Procedures

- Ensure power is off before maintenance

- Prevent accidental re-energizing

-

Regular Training

- Workers are trained on latest safety procedures

- Includes emergency response drills

Public Safety Education

As part of my role, I often participate in community outreach programs to educate the public about transformer safety. Here are some key points we emphasize:

- Never touch or attempt to open a pad mount transformer

- Keep the area around transformers clear of debris and vegetation

- Report any signs of damage or tampering to your local utility company

- In case of fire or unusual noises, stay away and call emergency services

Continuous Improvement in Safety Design

The field of transformer safety is always evolving. Some recent innovations include:

-

Smart Monitoring Systems

- Real-time monitoring of transformer health

- Early detection of potential issues

-

Eco-Friendly Insulating Fluids

- Less flammable than traditional mineral oil

- Reduced environmental impact in case of leaks

-

Enhanced Seismic Protection

- Designs that better withstand earthquakes

- Crucial in geologically active areas

Understanding these safety features helps build public confidence in our power distribution system. Pad mount transformers are designed with multiple layers of protection to ensure the safety of both the public and utility workers. As technology advances, we continue to see improvements in safety features, making these essential components of our power grid even more secure and reliable.

From Power Plant to Your Home: The Journey of Electricity?

Ever flipped a switch and wondered how that electricity got to your home? It’s a fascinating journey that starts miles away!

Electricity travels from power plants through a complex network of transmission lines, substations, and transformers before reaching your home. Pad mount transformers play a crucial role in the final step, converting high voltage to safe, usable levels for household consumption.

As someone who’s worked at various stages of this journey, I find the entire process remarkable. Let’s break down the steps:

The Electricity Journey: From Generation to Consumption

-

Power Generation

- Electricity is generated at power plants (coal, nuclear, hydroelectric, solar, wind)

- Typical generation voltage: 2,300 to 30,000 volts

-

Step-Up Transformation

- Large transformers at the plant increase voltage for long-distance transmission

- Transmission voltage: 115,000 to 765,000 volts

-

Transmission

- High voltage electricity travels long distances on transmission lines

- These are the tall towers you see crossing the countryside

-

Substation Step-Down

- Substations use transformers to reduce voltage for local distribution

- Distribution voltage: typically 7,200 to 14,400 volts

-

Local Distribution

- Electricity travels on smaller poles or underground lines through neighborhoods

-

Pad Mount Transformer

- Converts distribution voltage to household voltage (120/240 volts)

- The final step before electricity enters your home

| Stage | Voltage Level | Purpose |

|---|---|---|

| Generation | 2,300 – 30,000V | Initial power creation |

| Transmission | 115,000 – 765,000V | Efficient long-distance travel |

| Distribution | 7,200 – 14,400V | Local area supply |

| Household | 120/240V | Safe for home use |

I remember a field trip I organized for engineering students to follow this journey. We started at a hydroelectric dam, followed the transmission lines to a substation, and ended at a residential pad mount transformer. Seeing the scale of the system firsthand was eye-opening for many of them.

Why Multiple Voltage Changes?

You might wonder why we change voltage so many times. Here’s why:

- Efficiency: High voltage is more efficient for long-distance transmission. It reduces energy loss.

- Safety: Lower voltage is safer for end-users.

- Practicality: Different voltages suit different purposes (e.g., industrial vs. residential use).

Challenges Along the Journey

- Energy Loss: Some energy is lost as heat at each transformation stage.

- Maintenance: The entire system requires constant monitoring and maintenance.

- Weather Impact: Storms can damage transmission lines and cause outages.

- Balancing Load: The grid must constantly balance supply with demand.

The Role of Pad Mount Transformers

Pad mount transformers are the unsung heroes of this journey. They perform the crucial final step:

- Voltage Conversion: They take the 7,200-14,400V from distribution lines and convert it to 120/240V for homes.

- Safety: They provide a safe interface between the distribution system and residential areas.

- Load Management: They’re sized to handle the electrical needs of multiple homes or businesses.

In my career, I’ve seen the impact of well-designed local distribution systems. A properly placed and maintained pad mount transformer can mean the difference between reliable power and frequent outages for an entire neighborhood.

The Future of Electricity Distribution

The journey of electricity is evolving with new technologies:

- Smart Grids: Incorporating digital technology for better monitoring and control.

- Renewable Integration: Adapting the grid to handle distributed generation from solar and wind.

- Energy Storage: Incorporating batteries to balance load and improve reliability.

Understanding this journey helps us appreciate the complex system that brings power to our homes. From massive power plants to the humble pad mount transformer on your street, each component plays a vital role in keeping our lights on and our devices running.

Conclusion

Pad mount transformers are crucial links in our power distribution chain, safely bringing electricity from high-voltage lines to our homes. Understanding their function helps us appreciate the complex system powering our daily lives and the importance of ongoing maintenance and innovation in electrical infrastructure.

🚀Next steps, you can:

A. Learn more about energy efficiency in your home

B. Explore careers in electrical engineering and power systems

C. Understand how to report transformer issues in your area

D. Discover the role of transformers in renewable energy integration

E. Investigate smart grid technologies and their impact on power distribution

F. Find out about community initiatives for grid modernization

Have you ever noticed those green metal boxes in your neighborhood? They’re more important than you might think!

Pad mount transformers are ground-level electrical devices that convert high voltage electricity to lower, usable voltages for homes and businesses. These unassuming boxes play a crucial role in powering our daily lives, hidden in plain sight throughout our communities.