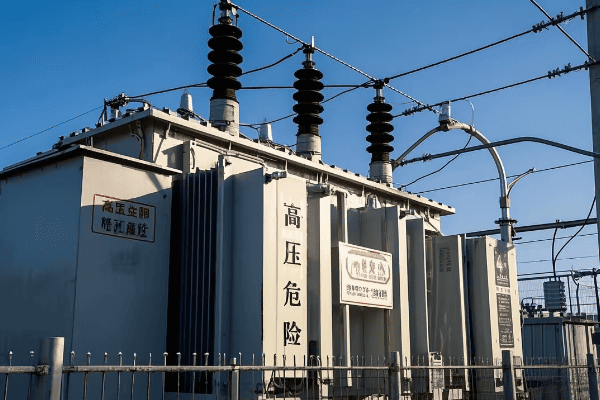

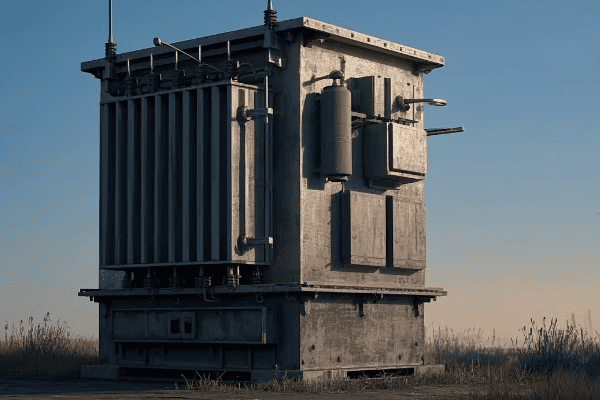

Top 10 Pad Mounted Transformer Manufacturers: Innovations Shaping the Future of Power Distribution?

Top 10 Pad Mounted Transformer Manufacturers: Innovations Shaping the Future of Power Distribution?

The power distribution industry is changing fast. New technologies are making transformers more efficient and eco-friendly. This is exciting for engineers like me.

In this article, I’ll introduce you to the top 10 pad mounted transformer manufacturers. These companies are leading the way with innovative designs. Their work is shaping the future of power distribution, making it more efficient and sustainable.

As an electrical engineer with years of experience, I’ve seen firsthand how important these innovations are. Let’s dive in and explore what these top manufacturers are doing to change the industry.

Top 10 Pad Mounted Transformer Manufacturers 2025: Global Leaders Driving Innovation in Power Distribution

In my years working with transformers, I’ve seen many companies come and go. But some have stood the test of time, always pushing the boundaries of what’s possible.

The top 10 pad mounted transformer manufacturers are ABB, Siemens, Schneider Electric, Eaton, GE, Hitachi ABB Power Grids, Prolec GE, Howard Industries, Cooper Power Systems, and ERMCO. These companies are known for their quality products and innovative solutions.

Let’s take a closer look at each of these industry leaders:

ABB

ABB is a Swiss-Swedish multinational corporation. They’re known for their cutting-edge technology in electrification, robotics, and industrial automation.

Siemens

Siemens is a German conglomerate. They’re one of the world’s largest producers of energy-efficient technologies.

Schneider Electric

This French multinational company specializes in digital automation and energy management.

Eaton

Eaton is an American multinational power management company. They provide energy-efficient solutions that help customers manage electrical, hydraulic, and mechanical power.

GE

General Electric is an American multinational conglomerate. They operate in various sectors, including power, renewable energy, and digital industry.

Hitachi ABB Power Grids

This is a joint venture between Hitachi and ABB. They focus on pioneering technologies for a sustainable energy future.

Prolec GE

Prolec GE is a joint venture between GE and Xignux. They’re a leading manufacturer of transformers and related products.

Howard Industries

Howard Industries is an American company known for its high-quality distribution transformers.

Cooper Power Systems

Now part of Eaton, Cooper Power Systems has a long history of providing innovative power delivery solutions.

ERMCO

ERMCO is an American company specializing in the manufacture of distribution transformers and components.

| Manufacturer | Known For | Key Innovation |

|---|---|---|

| ABB | Cutting-edge technology | Digital transformers |

| Siemens | Energy-efficient technologies | Sensformer advanced |

| Schneider Electric | Digital automation | EcoStruxure™ platform |

| Eaton | Power management solutions | Cooper Power series transformers |

| GE | Diverse energy solutions | Prolec-GE’s PROLEC PLUS™ |

| Hitachi ABB Power Grids | Sustainable energy technologies | TXpert™ Ecosystem |

| Prolec GE | High-quality transformers | PROLEC PLUS™ technology |

| Howard Industries | Distribution transformers | Smart Grid transformers |

| Cooper Power Systems | Innovative power delivery | Envirotran™ transformers |

| ERMCO | Distribution transformers | Transformer Health Monitoring |

These companies are not just manufacturing transformers; they’re shaping the future of power distribution. Their innovations are making our power grids smarter, more efficient, and more reliable.

Cutting-Edge Technologies Revolutionizing Pad Mounted Transformers for Smarter, Greener Power Distribution

In my career, I’ve seen many technological advancements. But the recent innovations in pad mounted transformers are truly exciting. They’re changing the game in power distribution.

The latest innovations in pad mounted transformers include smart monitoring systems, advanced cooling technologies, and eco-friendly insulation materials. These technologies are making transformers more efficient, reliable, and environmentally friendly.

Let’s explore some of these cutting-edge technologies:

Smart Monitoring Systems

Smart monitoring systems are revolutionizing how we manage transformers. These systems use sensors to collect real-time data on transformer performance. This data includes temperature, oil levels, and load conditions.

I remember when we had to physically check transformers for issues. Now, with smart monitoring, we can detect problems before they become serious. This predictive maintenance approach saves time and money.

Advanced Cooling Technologies

Cooling is crucial for transformer efficiency and longevity. New cooling technologies are making a big difference.

One exciting innovation is the use of phase-change materials (PCMs). PCMs absorb excess heat when the transformer is under heavy load. They then release this heat when the load decreases. This helps maintain a more stable temperature, reducing wear and tear on the transformer.

Eco-Friendly Insulation Materials

Traditional transformer insulation often uses mineral oil. While effective, it’s not the most environmentally friendly option. New bio-based insulation fluids are changing this.

These natural esters are biodegradable and have a higher flash point. This makes them safer and more environmentally friendly. I’ve seen these materials perform excellently in the field, matching or even surpassing traditional insulation in many aspects.

Solid-State Transformers

Solid-state transformer1s (SSTs) are an exciting development. They use power electronics to convert power, rather than traditional magnetic coupling.

SSTs offer several advantages:

- They’re more compact

- They can handle bi-directional power flow

- They provide better power quality

While still in the early stages, SSTs have the potential to revolutionize power distribution.

| Technology | Benefits | Challenges |

|---|---|---|

| Smart Monitoring Systems | Predictive maintenance, reduced downtime | Initial cost, data security |

| Advanced Cooling Technologies | Improved efficiency, longer lifespan | Complexity, maintenance requirements |

| Eco-Friendly Insulation | Environmentally friendly, safer | Cost, performance in extreme conditions |

| Solid-State Transformers | Compact size, bi-directional power flow | High cost, technology still developing |

These innovations are not just theoretical. They’re being implemented by the top manufacturers we discussed earlier. For example, ABB’s TXpert™ ecosystem incorporates smart monitoring. Siemens’ Sensformer advanced uses IoT technology for real-time monitoring.

As an engineer, I’m excited to see how these technologies will continue to evolve. They’re making our power distribution systems more efficient, reliable, and sustainable.

Efficiency Breakthroughs in Pad Mounted Transformers: How New Designs Are Optimizing Energy Performance

Throughout my career, I’ve seen efficiency become increasingly important in power distribution. The latest designs in pad mounted transformers are taking efficiency to new levels.

New transformer designs are optimizing power distribution through advanced core materials, improved winding techniques, and better load management. These innovations reduce energy losses, improve performance under varying loads, and extend transformer lifespan.

Let’s explore some of these efficiency breakthroughs:

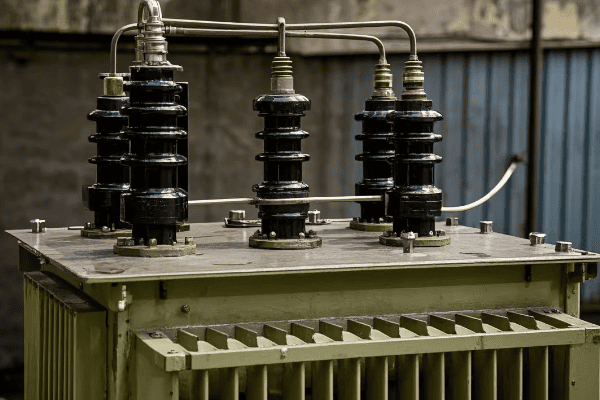

Advanced Core Materials

The core is the heart of a transformer. New materials are making cores more efficient than ever.

Amorphous metal cores are a game-changer. They reduce no-load losses by up to 70% compared to traditional silicon steel cores. I’ve seen these cores in action, and the energy savings are impressive.

Another innovation is the use of grain-oriented electrical steel (GOES). GOES aligns the grain structure of the steel with the magnetic field. This reduces energy loss in the core.

Improved Winding Techniques

Winding design has a big impact on transformer efficiency. New techniques are reducing losses and improving performance.

One innovation is the use of continuously transposed conductors (CTC). CTCs reduce eddy current losses in the windings. This is especially important for large transformers.

Another technique is the use of foil windings. These provide better current distribution and reduce losses. They’re particularly effective in distribution transformers.

Better Load Management

Transformers often operate under varying loads. New designs are optimizing performance across different load conditions.

One approach is the use of on-load tap changers (OLTC). OLTCs adjust the transformer’s voltage ratio while it’s operating. This helps maintain optimal voltage levels under changing loads.

Another innovation is the use of multiple windings. This allows the transformer to operate efficiently under different load conditions.

Thermal Management

Efficient thermal management is crucial for transformer performance and lifespan. New designs are improving heat dissipation.

One approach is the use of nanofluids in transformer oil. These fluids have better thermal properties than traditional transformer oil. They help dissipate heat more effectively, improving efficiency and extending transformer life.

| Efficiency Breakthrough | Benefits | Implementation Challenges |

|---|---|---|

| Amorphous Metal Cores | Up to 70% reduction in no-load losses | Higher initial cost |

| Grain-Oriented Electrical Steel | Reduced core losses | Manufacturing complexity |

| Continuously Transposed Conductors | Reduced eddy current losses | More complex winding process |

| Foil Windings | Better current distribution | Limited to certain transformer types |

| On-Load Tap Changers | Optimal voltage under varying loads | Increased maintenance requirements |

| Multiple Windings | Efficient operation under different loads | More complex design |

| Nanofluid Cooling | Improved heat dissipation | Long-term stability concerns |

These efficiency breakthroughs are not just theoretical. They’re being implemented by leading manufacturers. For example, Siemens uses amorphous metal cores in some of their distribution transformers. ABB has developed advanced OLTCs for their power transformers.

As an engineer, I’m excited about these efficiency improvements. They’re not just saving energy; they’re making our power distribution systems more reliable and cost-effective.

Green Pad Mounted Transformers: Eco-Friendly Innovations Driving Sustainable Power Distribution

In my years in the industry, I’ve seen a growing focus on environmental sustainability. This trend is now shaping pad mounted transformer technology in exciting ways.

Green transformers are using eco-friendly materials, reducing energy losses, and improving recyclability. These innovations include biodegradable insulating fluids, energy-efficient designs, and materials that are easier to recycle at the end of the transformer’s life.

Let’s explore some of these eco-friendly innovations:

Biodegradable Insulating Fluids

Traditional mineral oil insulation is being replaced by more environmentally friendly options. Natural esters, derived from vegetable oils, are leading this change.

I’ve worked with transformers using these biodegradable fluids. They’re not only better for the environment, but they also have some performance advantages:

- Higher flash and fire points, improving safety

- Better moisture tolerance, potentially extending transformer life

- Biodegradability, reducing environmental impact in case of leaks

Energy-Efficient Designs

Green transformers are designed to minimize energy losses. This not only saves energy but also reduces the transformer’s carbon footprint over its lifetime.

Some key design features include:

- Low-loss core materials, like amorphous metals

- Optimized winding designs to reduce copper losses

- Improved cooling systems for better heat dissipation

Recyclable Materials

End-of-life considerations are becoming increasingly important. New transformer designs are focusing on materials that are easier to recycle.

For example, some manufacturers are using:

- Aluminum instead of copper for windings, as it’s easier to recycle

- Cellulose-based insulation materials that are biodegradable

- Modular designs that make it easier to separate different materials for recycling

Compact Designs

Smaller, more compact transformers use fewer materials and take up less space. This reduces their environmental impact in several ways:

- Less raw material used in manufacturing

- Reduced transportation emissions

- Smaller footprint, preserving more land

Smart Features for Energy Management

Green transformers often include smart features that help optimize energy use. These can include:

- Real-time monitoring of energy efficiency

- Automatic voltage regulation to reduce losses

- Load management features to optimize performance

| Eco-Friendly Innovation | Environmental Benefit | Potential Challenges |

|---|---|---|

| Biodegradable Insulating Fluids | Reduced environmental impact, improved safety | Higher cost, performance in extreme conditions |

| Energy-Efficient Designs | Lower energy losses, reduced carbon footprint | Higher initial cost |

| Recyclable Materials | Easier end-of-life recycling | Potential trade-offs in performance or cost |

| Compact Designs | Less material use, smaller footprint | Cooling challenges, limited power capacity |

| Smart Energy Management | Optimized energy use, reduced losses | Complexity, cybersecurity concerns |

These green innovations are being adopted by many of the top manufacturers we discussed earlier. For example, Siemens has developed transformers using biodegradable ester fluids. ABB offers high-efficiency transformers that significantly reduce energy losses.

As an engineer committed to sustainability, I’m excited about these eco-friendly innovations. They’re not just good for the environment; they often bring additional benefits in terms of safety, performance, and long-term cost savings.

Smart Grid-Ready Pad Mounted Transformers: How Digital Connectivity Is Reshaping Power Distribution

In my career, I’ve witnessed the power grid evolve from a simple one-way system to a complex, bidirectional network. Smart grid technology is at the forefront of this evolution, and pad mounted transformers are adapting to play a crucial role.

Smart grid integration2 involves equipping pad mounted transformers with advanced sensors, communication capabilities, and control systems. This allows for real-time monitoring, automated responses to grid conditions, and better integration of renewable energy sources.

Let’s explore how pad mounted transformers are being adapted for the digital age:

Advanced Sensors and Monitoring

Modern pad mounted transformers are equipped with a range of sensors that monitor various parameters:

- Oil temperature and level

- Winding temperature

- Load current and voltage

- Dissolved gas analysis

- Partial discharge detection

These sensors provide real-time data on the transformer’s condition and performance.

Communication Capabilities

Smart transformers can communicate with the grid control center and other grid components. This communication is typically done through:

- Power Line Communication (PLC)

- Cellular networks (4G/5G)

- Fiber optic networks

This allows for real-time data transmission and remote control capabilities.

Automated Voltage Regulation

Smart pad mounted transformers can automatically adjust their voltage output based on grid conditions. This helps maintain stable voltage levels and improve power quality.

Fault Detection and Self-Healing

Advanced algorithms can detect potential faults before they occur. In some cases, the transformer can even take corrective action automatically, improving grid reliability.

Integration with Renewable Energy

Smart transformers can better handle the variable nature of renewable energy sources like solar and wind. They can:

- Manage bidirectional power flow

- Balance load fluctuations

- Optimize power factor

Cybersecurity Features

With increased connectivity comes increased cybersecurity risks. Smart transformers include security features to protect against cyber threats.

Data Analytics and Predictive Maintenance

The data collected by smart transformers can be analyzed to predict maintenance needs, optimize performance, and extend the transformer’s lifespan.

| Smart Grid Feature | Benefits | Challenges |

|---|---|---|

| Advanced Sensors | Real-time condition monitoring | Data management, sensor reliability |

| Communication Capabilities | Remote monitoring and control | Cybersecurity, communication reliability |

| Automated Voltage Regulation | Improved power quality | Complexity, potential for system instability |

| Fault Detection and Self-Healing | Improved grid reliability | Algorithm accuracy, regulatory approval |

| Renewable Energy Integration | Better support for clean energy | Handling variable power flow |

| Cybersecurity Features | Protection against cyber threats | Keeping up with evolving threats |

| Data Analytics | Predictive maintenance, optimized performance | Data privacy, analytical complexity |

Leading manufacturers are at the forefront of these smart grid adaptations. For example, ABB’s TXpert™ ecosystem provides a comprehensive digital solution for transformer management. Siemens’ Sensformer® concept integrates connectivity features into their transformers.

As an engineer working in this rapidly evolving field, I’m excited about the potential of smart grid integration. It’s not just about making transformers smarter; it’s about creating a more efficient, reliable, and sustainable power distribution system for the future.

Safety Innovations in Pad Mounted Transformers: Advanced Protection Systems for 2025 Power Projects

Throughout my career, safety has always been a top priority in transformer design and operation. Modern pad mounted transformers incorporate advanced protection features that significantly enhance their safety profile.

Today’s pad mounted transformers include features like advanced overload protection, arc flash mitigation, and enhanced physical security. These innovations not only protect the transformer itself but also ensure the safety of personnel and surrounding infrastructure.

Transformer Safety Features

Let’s explore some of these advanced safety features:

Overload Protection Systems

Modern pad mounted transformers have sophisticated overload protection systems. These systems monitor the transformer’s load and temperature in real-time.

I’ve seen these systems in action, and they’re impressive. They can:

- Automatically disconnect the transformer if it reaches critical temperature levels

- Adjust cooling systems to manage temperature under heavy loads

- Send alerts to operators before critical conditions are reached

Arc Flash Mitigation

Arc flash events can be catastrophic. New transformer designs include features to prevent and mitigate arc flash incidents:

- Arc-resistant designs that contain the energy released during an arc flash

- Fast-acting protection relays that quickly isolate faults

- Remote racking systems that allow operators to rack circuit breakers from a safe distance

Enhanced Physical Security

Physical security is crucial for pad mounted transformers, especially in urban areas. New designs include:

- Tamper-resistant enclosures

- Advanced locking mechanisms

- Alarm systems that detect unauthorized access attempts

Fire Safety Features

Fire risk is always a concern with transformers. Modern designs incorporate several fire safety features:

- Use of less flammable insulating fluids

- Automatic fire detection and suppression systems

- Fireproof barriers between high-voltage and low-voltage sections

Environmental Protection

Protecting the environment is also a safety concern. New transformers include features like:

- Double-walled tanks to prevent oil leaks

- Oil containment systems to capture any leaks that do occur

- Biodegradable insulating fluids that minimize environmental impact if spilled

Smart Monitoring for Safety

Smart monitoring systems don’t just improve efficiency; they also enhance safety:

- Real-time monitoring of key safety parameters

- Predictive maintenance to prevent safety-critical failures

- Automatic alerts for potential safety issues

Seismic Protection

In earthquake-prone areas, seismic protection is crucial. Modern transformers can include:

- Reinforced tanks and mountings

- Flexible connections that can withstand seismic movement

- Seismic sensors that can disconnect the transformer during an earthquake

| Safety Feature | Benefits | Implementation Challenges |

|---|---|---|

| Overload Protection | Prevents damage from excessive loads | Balancing protection with operational flexibility |

| Arc Flash Mitigation | Reduces risk of catastrophic failures | Cost of implementation, design complexity |

| Enhanced Physical Security | Prevents tampering and vandalism | Balancing security with maintenance access |

| Fire Safety Features | Reduces fire risk and damage | Cost, compatibility with other systems |

| Environmental Protection | Minimizes environmental impact of leaks | Additional space requirements, cost |

| Smart Monitoring | Early detection of safety issues | Data management, cybersecurity |

| Seismic Protection | Improves resilience in earthquake-prone areas | Additional cost, design complexity |

These safety features are being implemented by leading manufacturers. For example, Eaton’s Cooper Power series transformers include advanced overload protection and arc-resistant designs. ABB’s transformers often include smart monitoring systems that enhance safety through predictive maintenance.

As an engineer who has worked on numerous transformer installations, I can’t overstate the importance of these safety features. They not only protect valuable equipment but also ensure the safety of workers and the public. It’s exciting to see how far we’ve come in making pad mounted transformers safer and more reliable.

Renewable-Ready Pad Mounted Transformers: Designed for Solar, Wind, and Energy Storage Integration?

In my years in the industry, I’ve witnessed a significant shift towards renewable energy. This shift has created new challenges and opportunities for transformer design, especially in pad mounted units.

Renewable-ready transformers are designed to handle the unique characteristics of alternative energy sources. They can manage bidirectional power flow, handle voltage fluctuations, and integrate with smart grid systems to optimize renewable energy distribution.

Renewable Energy Transformer

Let’s explore how transformers are being adapted for renewable energy:

Bidirectional Power Flow

Traditional transformers were designed for one-way power flow from the grid to the consumer. Renewable energy sources like solar panels can feed power back into the grid. Modern transformers can handle this bidirectional flow efficiently.

I’ve worked on installations where this bidirectional capability was crucial. It allows homeowners and businesses to contribute excess solar power to the grid.

Voltage Regulation

Renewable energy sources, especially solar and wind, can cause voltage fluctuations. Renewable-ready transformers include advanced voltage regulation features to maintain stable grid voltage.

These can include:

- On-load tap changers that adjust voltage ratios in real-time

- Static VAR compensators to manage reactive power

- Smart inverter integration for improved voltage control

Harmonics Management

Inverters used in solar and wind systems can introduce harmonics into the grid. Modern transformers include features to mitigate these harmonics:

- Special winding designs that reduce harmonic currents

- Built-in harmonic filters

- Smart monitoring systems that detect and respond to harmonic issues

Energy Storage Integration

Some renewable-ready transformers are designed to work seamlessly with energy storage systems. This allows for better management of intermittent renewable sources.

Features can include:

- Interfaces for battery management systems

- Load balancing capabilities to optimize storage and grid power use

- Fast response times to handle rapid changes in power flow

Smart Grid Compatibility

Renewable-ready transformers are designed to be part of smart grid systems. They include communication and control features that allow for:

- Real-time monitoring of power flow and quality

- Remote control and adjustment of transformer settings

- Integration with grid management systems for optimal renewable energy use

Scalability and Flexibility

Renewable energy installations can grow over time. Modern transformers are designed with this in mind:

- Modular designs that allow for easy capacity increases

- Wide operating ranges to handle varying loads

- Plug-and-play compatibility with different renewable sources

Environmental Considerations

Transformers for renewable energy often include eco-friendly features:

- Use of biodegradable insulating fluids

- Designs that minimize energy losses

- Materials chosen for recyclability

| Feature | Benefits | Challenges |

|---|---|---|

| Bidirectional Power Flow | Enables grid feed-in from renewables | Complexity in power management |

| Advanced Voltage Regulation | Maintains grid stability | Cost of advanced control systems |

| Harmonics Management | Improves power quality | Additional components and complexity |

| Energy Storage Integration | Better management of intermittent sources | Coordination with diverse storage systems |

| Smart Grid Compatibility | Optimizes renewable energy use | Cybersecurity, data management |

| Scalability and Flexibility | Adapts to growing renewable installations | Balancing flexibility with efficiency |

| Environmental Considerations | Reduces environmental impact | Potential trade-offs with performance |

Leading manufacturers are at the forefront of these renewable-ready designs. For example, Siemens offers transformers specifically designed for wind farm applications. ABB has developed transformers with advanced voltage regulation features ideal for solar installations.

As an engineer passionate about renewable energy, I’m excited about these developments. These transformers are not just components; they’re enablers of a cleaner, more sustainable energy future. They’re helping to overcome some of the key challenges in integrating renewable sources into our power grids.

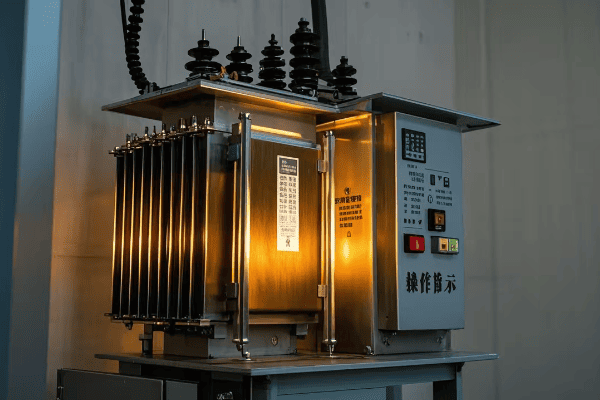

Smart Digital Transformation of Pad Mounted Transformers: How IoT and AI Are Revolutionizing Power Management

Throughout my career, I’ve seen technology transform many aspects of the power industry. The integration of Internet of Things (IoT) and Artificial Intelligence (AI) into pad mounted transformer management is one of the most exciting developments I’ve witnessed.

IoT and AI are revolutionizing pad mounted transformer management. These technologies enable real-time monitoring, predictive maintenance, and automated decision-making. This leads to improved reliability, extended transformer life, and optimized performance.

IoT and AI in Transformer Management

Let’s explore how IoT and AI are changing transformer management:

IoT Sensors and Connectivity

Modern pad mounted transformers are equipped with a variety of IoT sensors. These sensors continuously monitor various parameters:

- Oil temperature and level

- Winding temperature

- Load current and voltage

- Dissolved gas composition

- Vibration levels

These sensors are connected to communication modules that transmit data in real-time to central management systems.

Real-Time Monitoring and Alerts

With IoT connectivity, transformer performance can be monitored in real-time. This allows for:

- Immediate detection of abnormal conditions

- Automated alerts sent to maintenance teams

- Remote diagnostics and troubleshooting

I’ve seen this capability prevent potential failures by catching issues early.

Predictive Maintenance

AI algorithms analyze the data from IoT sensors to predict potential failures before they occur. This predictive maintenance approach:

- Reduces unexpected downtime

- Optimizes maintenance schedules

- Extends transformer lifespan

Load Management and Optimization

AI can analyze historical and real-time data to optimize transformer loading:

- Predicting peak load times

- Balancing loads across multiple transformers

- Adjusting settings for optimal efficiency

Automated Decision Making

AI systems can make automated decisions based on real-time data:

- Adjusting cooling systems based on load and temperature

- Switching to backup systems in case of detected faults

- Optimizing voltage regulation for changing grid conditions

Digital Twin Technology

Some advanced systems use “digital twin” technology. This creates a virtual model of the transformer that:

- Simulates performance under various conditions

- Helps in planning upgrades or modifications

- Aids in training maintenance personnel

Data Analytics for Long-Term Planning

The vast amount of data collected can be analyzed for long-term planning:

- Identifying trends in transformer performance

- Informing future design improvements

- Optimizing asset management strategies

| Feature | Benefits | Challenges |

|---|---|---|

| IoT Sensors and Connectivity | Real-time data collection | Data security, sensor reliability |

| Real-Time Monitoring | Immediate issue detection | Managing large volumes of data |

| Predictive Maintenance | Reduced downtime, extended lifespan | Accuracy of predictive models |

| Load Management | Improved efficiency | Complexity of optimization algorithms |

| Automated Decision Making | Faster response to issues | Ensuring fail-safe operations |

| Digital Twin Technology | Better planning and training | Complexity of modeling |

| Data Analytics | Informed long-term strategies | Data storage and processing requirements |

Leading manufacturers are embracing these digital technologies. For example, ABB’s TXpert™ ecosystem integrates IoT and AI for comprehensive transformer management. Siemens’ Sensformer® concept leverages digital technologies for improved transformer operation.

As an engineer who has worked with traditional and now digital transformer systems, I’m amazed at the potential of these technologies. They’re not just improving how we manage transformers; they’re transforming how we think about power distribution as a whole. The future of pad mounted transformers is smart, connected, and more reliable than ever before.

Built to Last: Durable and Reliable Pad Mounted Transformer Designs for Long-Term Performance

In my years of experience, I’ve seen how crucial durability and reliability are in transformer design. The latest innovations in pad mounted transformers are taking these aspects to new levels.

Modern transformer designs focus on enhancing durability and reliability through advanced materials, improved construction techniques, and intelligent monitoring systems. These innovations lead to longer lifespans, reduced maintenance needs, and improved performance under various conditions.

Durable Transformer Design

Let’s explore the key aspects of these durable and reliable designs:

Advanced Materials

New materials are making transformers more durable than ever:

- Nano-enhanced insulating oils that resist breakdown

- Corrosion-resistant alloys for tank construction

- High-strength, low-loss core materials

I’ve seen these materials significantly extend transformer life in harsh environments.

Robust Construction Techniques

Modern manufacturing processes improve transformer durability:

- Vacuum pressure impregnation for better insulation

- Precision winding techniques for improved mechanical strength

- Seismic-resistant designs for earthquake-prone areas

Enhanced Cooling Systems

Efficient cooling is crucial for longevity. New designs include:

- Advanced oil circulation systems

- Nano-fluid coolants for better heat dissipation

- Smart cooling controls that adjust based on load and ambient temperature

Intelligent Monitoring for Reliability

Smart monitoring systems enhance reliability:

- Real-time tracking of key performance indicators

- Early warning systems for potential issues

- Automated diagnostics to guide maintenance

Moisture and Gas Management

Moisture and gases can degrade transformer performance over time. New designs include:

- Advanced moisture removal systems

- Online dissolved gas analysis

- Automatic pressure regulation systems

Overload Capacity

Modern transformers are designed to handle temporary overloads without compromising longevity:

- Dynamic loading capabilities

- Improved thermal management during peak loads

- Intelligent load management systems

Environmental Resilience

Transformers are built to withstand various environmental challenges:

- UV-resistant external coatings

- Improved sealing against dust and moisture

- Designs that can operate in extreme temperatures

| Feature | Benefits | Challenges |

|---|---|---|

| Advanced Materials | Extended lifespan, improved performance | Higher initial costs |

| Robust Construction | Better resilience to physical stress | Increased manufacturing complexity |

| Enhanced Cooling | Improved efficiency, longer life | Maintenance of advanced cooling systems |

| Intelligent Monitoring | Early problem detection, optimized maintenance | Data management, cybersecurity |

| Moisture and Gas Management | Reduced degradation over time | Complexity of online analysis systems |

| Overload Capacity | Flexibility in load management | Balancing overload capability with long-term reliability |

| Environmental Resilience | Reliable operation in diverse conditions | Designing for multiple environmental factors |

Leading manufacturers are implementing these durability-enhancing features. For example, ABB’s transformers often include advanced monitoring systems for improved reliability. Siemens has developed transformers with enhanced environmental resilience for harsh conditions.

As an engineer who has dealt with transformer maintenance and replacement, I’m impressed by these advancements. They’re not just extending the life of transformers; they’re making them more adaptable and reliable in our ever-changing power distribution landscape. These durable designs are key to building a robust and resilient power infrastructure for the future.

Future Trends in Pad Mounted Transformer Technology (2025–2030): Smart, Sustainable, and AI-Driven Innovations

As someone who has been in the industry for years, I’m always excited to look ahead at emerging trends. The future of pad mounted transformer development is full of promising innovations that could reshape our power distribution systems.

Emerging trends in pad mounted transformer development include the integration of solid-state technology, advanced materials science, AI-driven optimization, and designs focused on sustainability and circular economy principles. These trends promise to make transformers more efficient, flexible, and environmentally friendly.

Future Transformer Technology

Let’s explore some of these exciting future trends:

Solid-State Transformers

Solid-state transformers (SSTs) are an emerging technology that could revolutionize power distribution:

- Use of power electronics instead of traditional magnetic cores

- Ability to handle AC-DC conversion more efficiently

- Compact size and reduced weight

- Better handling of variable loads and power quality issues

While still in early stages, SSTs have the potential to significantly change transformer design.

Advanced Nanomaterials

Nanotechnology is opening up new possibilities in transformer design:

- Nanocomposite core materials for reduced losses

- Nano-enhanced insulating fluids for better cooling and insulation

- Self-healing materials that can repair minor damage automatically

AI-Driven Design and Operation

Artificial Intelligence will play a bigger role in both transformer design and operation:

- AI-optimized designs for specific use cases

- Real-time optimization of transformer performance

- Predictive maintenance systems that learn and improve over time

Sustainability and Circular Economy

Future transformers will be designed with sustainability in mind:

- Fully recyclable components

- Designs that facilitate easy repair and part replacement

- Use of biodegradable materials where possible

- Energy-neutral or energy-positive transformer stations

Integration with Renewable Energy and Storage

Future transformers will be designed to work seamlessly with renewable energy and storage systems:

- Built-in inverters and power management systems

- Direct integration with battery storage

- Adaptive systems that optimize power flow based on renewable energy availability

Modular and Scalable Designs

Flexibility will be key in future transformer designs:

- Modular components that can be easily upgraded or replaced

- Scalable designs that can grow with increasing power needs

- Plug-and-play compatibility with various grid configurations

Quantum Sensing Technology

While still in early research stages, quantum sensing could revolutionize transformer monitoring:

- Ultra-sensitive detection of electromagnetic fields

- Early warning of potential failures at the atomic level

- Improved accuracy in power quality measurements

| Trend | Potential Impact | Current Status |

|---|---|---|

| Solid-State Transformers | Revolutionary change in power conversion | Early commercial trials |

| Advanced Nanomaterials | Significant efficiency improvements | Active research and development |

| AI-Driven Design and Operation | Optimized performance and maintenance | Increasingly being implemented |

| Sustainability and Circular Economy | Reduced environmental impact | Growing focus in design considerations |

| Integration with Renewables and Storage | Enhanced grid flexibility | Ongoing development and implementation |

| Modular and Scalable Designs | Improved adaptability to changing needs | Emerging in some product lines |

| Quantum Sensing Technology | Ultra-precise monitoring capabilities | Early researchLeading manufacturers are already investing in these future technologies. For example, ABB is conducting research into solid-state transformers, while Siemens is exploring AI-driven design optimization. |

As an engineer who has witnessed many technological shifts in the industry, I’m thrilled about these emerging trends. They promise not just incremental improvements, but potentially transformative changes in how we approach power distribution. The future of pad mounted transformers is not just about making better versions of what we have; it’s about reimagining what a transformer can be and do in our evolving energy landscape.

Conclusion

The world of pad mounted transformers is evolving rapidly, driven by technological innovations and changing energy needs. From cutting-edge materials to smart grid integration, from eco-friendly designs to AI-driven management systems, the top manufacturers are pushing the boundaries of what’s possible in power distribution.

As we’ve explored in this article, these innovations are not just improving efficiency and reliability; they’re also making our power systems more sustainable and adaptable to the challenges of the future. The integration of renewable energy sources, the focus on environmental sustainability, and the embrace of digital technologies are all shaping the next generation of pad mounted transformers.

For electrical engineers, utility companies, and anyone involved in power distribution, staying informed about these developments is crucial. The transformers we design and install today will be part of our power infrastructure for decades to come. By choosing innovative, forward-thinking solutions, we can build a more resilient, efficient, and sustainable power grid for the future.

As someone who has spent years in this field, I’m excited to see how these innovations will continue to unfold. The future of pad mounted transformers is bright, and it’s playing a critical role in shaping the future of our energy systems.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group