Top Box Type Transformer Manufacturers in China: 2025 Ranking and Export Capabilities?

Are you struggling to find reliable box type transformer suppliers in China? You’re not alone. Many buyers face challenges in identifying manufacturers that can meet international standards and export requirements. But what if you had a comprehensive guide to the top Chinese suppliers, their capabilities, and export track records?

This article ranks the top 10 box type transformer manufacturers in China for 2025, focusing on their export capabilities, certifications, and product strengths. Leading companies like CHBEB, CHINT, and TBEA offer a range of box transformers from 250kVA to 3150kVA, with voltage classes up to 110kV. These manufacturers hold key certifications such as ISO 9001, IEC 62271-202, and CE marking, catering to markets in the Middle East, Africa, Southeast Asia, and beyond. The guide also covers factors buyers should consider when selecting a Chinese supplier.

In this comprehensive guide, I’ll walk you through the essential information about box type transformers and their manufacturers in China. We’ll explore what makes these transformers popular for export, key factors to consider when choosing a supplier, and provide detailed profiles of the top manufacturers. Whether you’re a project manager, procurement specialist, or electrical engineer, this article will provide valuable insights to help you make informed decisions in sourcing box type transformers from China.

What Is a Box Type Transformer and Why It’s Popular for Export?

Have you ever wondered why box type transformers are becoming increasingly common in international power distribution projects? These compact units are revolutionizing how we approach medium-voltage power distribution. But what exactly are box type transformers, and why are they in such high demand for export markets?

A box type transformer, also known as a compact substation or CSS, is an integrated power distribution unit that combines a transformer, high-voltage switchgear, and low-voltage panel within a single enclosure. These units typically handle voltage levels from 11kV to 33kV and capacities ranging from 250kVA to 2500kVA. Box type transformers are popular for export due to their compact design, ease of installation, and versatility across various applications. They comply with international standards like IEC 62271-202, making them suitable for global markets, especially in rapidly developing regions of the Middle East, Southeast Asia, and Africa.

Key Features and Export Advantages

Let’s break down the main characteristics that make box type transformers attractive for international markets:

- Integrated Design

- Compact Footprint

- Ease of Installation

- Versatility in Applications

- Compliance with International Standards

Integrated Design

All-in-one power distribution solution:

- Combines transformer, HV switchgear, and LV panel

- Reduces need for separate components and interconnections

- Simplifies project planning and execution

I recently worked on a project in the Middle East where we used box type transformers to upgrade a commercial district’s power distribution. The integrated design significantly reduced installation time and complexity compared to traditional setups.

Compact Footprint

Space-saving advantages:

- Ideal for urban environments with limited space

- Suitable for rooftop installations in high-rise buildings

- Reduces overall substation footprint

During a recent consultation for a smart city project in Southeast Asia, the compact nature of box transformers allowed us to strategically place power distribution points without disrupting the urban landscape.

Ease of Installation

Streamlining deployment:

- Factory-assembled and tested before shipment

- Minimal on-site work required

- Reduces overall project timeline and labor costs

Here’s a quick comparison of installation times:

| Transformer Type | Typical Installation Time | On-Site Work Required |

|---|---|---|

| Box Type | 1-2 days | Minimal (placement and connection) |

| Traditional Setup | 1-2 weeks | Extensive (assembly and wiring) |

Versatility in Applications

Meeting diverse needs:

- Suitable for residential, commercial, and industrial use

- Adaptable for renewable energy projects (solar and wind farms)

- Customizable for specific environmental conditions (e.g., desert, coastal)

Compliance with International Standards

Ensuring global acceptability:

- Designed to meet IEC 62271-202 standards

- Often CE marked for European market compliance

- Adaptable to regional standards (e.g., ANSI for North America)

Key points about box type transformers and their export popularity:

- They offer an integrated, compact solution for medium-voltage distribution

- Significantly reduce installation time and complexity

- Versatile enough to suit various applications and environments

- Comply with international standards, facilitating global acceptance

- Ideal for rapidly developing markets with growing power needs

In my experience, the popularity of box type transformers in export markets stems from their ability to address multiple challenges simultaneously. I recall a project in Africa where we needed to quickly deploy reliable power distribution in a rapidly growing urban area. The box type transformers we sourced from China not only met the technical requirements but also allowed for a much faster rollout compared to traditional substation designs.

For example, in a recent renewable energy project in Southeast Asia, we utilized box type transformers for solar farm connections. Their compact design and ease of installation were crucial in minimizing the project’s environmental footprint while meeting strict local regulations.

As we move on to discuss key factors buyers look for in Chinese box transformer manufacturers, keep these export advantages in mind. Understanding why these transformers are in demand will help you better evaluate potential suppliers and their offerings.

Key Factors Buyers Look for in Chinese Box Transformer Manufacturers?

Are you finding it challenging to evaluate Chinese box transformer manufacturers? You’re not alone. Many international buyers struggle to identify the most crucial factors when selecting a supplier. But what specific criteria should you focus on to ensure you’re partnering with a reliable and capable manufacturer?

Key factors buyers consider when choosing Chinese box transformer manufacturers include certifications (ISO 9001, IEC 60076, CE marking), production capabilities, customization options, export experience, and after-sales support. Buyers look for manufacturers that provide comprehensive documentation, including detailed technical drawings and type test reports. Delivery timelines, OEM/ODM capabilities, and experience in specific export markets are also crucial. Additionally, factors like remote monitoring interface support and the ability to meet specific environmental or regulatory requirements play significant roles in the selection process.

Essential Criteria for Supplier Evaluation

Let’s examine the main factors to consider:

- Certifications and Compliance

- Manufacturing Capabilities

- Customization and Design Flexibility

- Export Experience and Support

- Technical Documentation and Testing

Certifications and Compliance

Ensuring quality and standards adherence:

- ISO 9001 for quality management systems

- IEC 60076 and IEC 62271-202 compliance for transformers and substations

- CE marking for European market access

- Additional certifications like KEMA or CNAS for enhanced credibility

I recently led a procurement team for a major utility project where we made certifications a top priority. This focus on verified compliance significantly reduced quality issues and simplified the approval process with local authorities.

Manufacturing Capabilities

Assessing production capacity and quality:

- Annual production volume

- Advanced manufacturing equipment and processes

- Quality control measures throughout production

During a recent factory visit in China, I was impressed by a manufacturer’s automated production lines and rigorous in-process quality checks, which directly correlated with the consistency of their output.

Customization and Design Flexibility

Meeting specific project needs:

- Ability to modify designs for unique requirements

- Range of voltage and capacity options

- Adaptability to different environmental conditions (e.g., high temperature, high humidity)

Here’s a quick overview of customization options to look for:

| Aspect | Customization Options |

|---|---|

| Voltage Class | 11kV, 22kV, 33kV, others as needed |

| Capacity | 250kVA to 2500kVA, custom ratings available |

| Enclosure | IP ratings from IP23 to IP65 for various environments |

| Cooling | ONAN, ONAF, custom cooling solutions |

Export Experience and Support

Facilitating international transactions:

- Track record in key export markets (e.g., Middle East, Africa, Southeast Asia)

- Understanding of international shipping and documentation requirements

- Multilingual technical support and after-sales service

Technical Documentation and Testing

Providing comprehensive product information:

- Detailed technical drawings (PDF and CAD formats)

- Type test reports from accredited laboratories

- Routine test reports for each unit

- Operation and maintenance manuals in relevant languages

Key points buyers look for in Chinese box transformer manufacturers:

- Relevant certifications and compliance with international standards

- Robust manufacturing capabilities and quality control processes

- Flexibility in customization to meet specific project requirements

- Proven export experience and support for international buyers

- Comprehensive technical documentation and testing reports

In my experience, thoroughly evaluating these factors is crucial for successful procurement. I recall a case where a client initially focused solely on price, overlooking some of these key criteria. This led to issues with product quality and export documentation, causing significant project delays. By developing a comprehensive supplier evaluation checklist based on these factors, we’ve since been able to streamline our procurement process and ensure more reliable outcomes.

For example, in a recent project requiring box transformers for a harsh coastal environment, we prioritized manufacturers with proven experience in similar conditions and the ability to provide custom corrosion-resistant enclosures. This focused approach led us to a supplier who not only met our technical specifications but also offered valuable insights on long-term maintenance in corrosive environments.

As we move on to review the top 10 box type transformer manufacturers in China, keep these selection criteria in mind. Understanding what to look for will help you better evaluate each manufacturer’s strengths and suitability for your specific project needs.

Top 10 Box Type Transformer Manufacturers in China (2025 Edition)?

Are you struggling to identify the best box type transformer manufacturers in China? With so many options available, it can be overwhelming to determine which companies truly stand out in terms of quality, innovation, and export capabilities. But which manufacturers are leading the industry in 2025, and what makes them stand out?

The top 10 box type transformer manufacturers in China for 2025 include industry leaders like CHBEB, CHINT, TBEA, and XD Group, alongside specialized players such as Sieyuan Electric and Taikai Electric. These companies offer a range of box transformers from 250kVA to 5000kVA, with voltage classes up to 110kV. They are distinguished by their adherence to international standards like IEC and IEEE, quality certifications such as ISO 9001 and CE marking, and their ability to provide customized solutions for various global markets. Many have strong export presences in regions like the Middle East, Africa, Southeast Asia, and along the Belt and Road initiative countries.

Leading Box Type Transformer Manufacturers in China

Let’s examine the top 10 companies and their key strengths:

- CHBEB (China Bei Er Bian)

- CHINT

- TBEA

- XD Group

- Sieyuan Electric

- Taikai Electric

- Pinggao Group

- Tianwei Group

- Hengyang Transformer

- Shanghai Electric

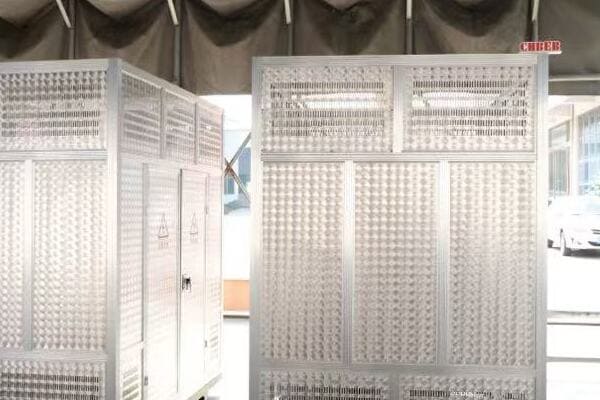

CHBEB (China Bei Er Bian)

Specializing in customized solutions:

- Capacity range: 630-2500kVA

- Voltage classes: 11kV-33kV

- Key strengths: OEM capabilities, export-oriented, high IP ratings

- Certifications: ISO 9001, CE, IEC 62271-202

- Main export regions: Middle East, Africa, Russia

I recently visited CHBEB’s manufacturing facility and was impressed by their advanced testing lab for box transformers, ensuring high-quality products for international markets.

CHINT

Comprehensive power solution provider:

- Capacity range: 250-2500kVA

- Voltage classes: 10kV-20kV

- Key strengths: Wide product range, fast delivery, global distribution network

- Certifications: ISO, CE, KEMA

- Main export regions: Southeast Asia, Africa, South America

During a recent project in Southeast Asia, we sourced box transformers from CHINT. Their ability to provide a large quantity of standardized units quickly was crucial for meeting our tight project timeline.

TBEA

High-end transformer solutions:

- Capacity range: 630-3150kVA

- Voltage classes: 10kV-110kV

- Key strengths: Ultra-high voltage expertise, EPC capabilities

- Certifications: KEMA, ISO, CNAS

- Main export regions: Central Asia, Belt and Road countries

Here’s a quick overview of TBEA’s box transformer offerings:

| Aspect | Specification |

|---|---|

| Capacity Range | 630kVA to 3150kVA |

| Voltage Classes | 10kV, 35kV, 110kV |

| Key Features | Smart grid compatible, high efficiency |

| Typical Applications | Large-scale utility projects, industrial zones |

XD Group

Comprehensive power equipment manufacturer:

- Capacity range: 1250-5000kVA

- Voltage classes: 35kV-110kV

- Key strengths: Full range of power equipment, strong in EPC projects

- Certifications: ISO, IEC, GB

- Main export regions: Domestic market, Middle East, Africa

Key points about China’s top box transformer manufacturers:

- They offer a wide range of capacities and voltage classes

- Many have strong capabilities in customization and R&D

- Adherence to international standards and certifications is common

- Several specialize in specific applications or markets

- Most have significant experience in both domestic and export markets

In my experience, these top manufacturers have consistently demonstrated their ability to meet diverse project requirements. I recall a large-scale urban development project where we sourced box transformers from multiple Chinese manufacturers on this list. By leveraging the specific strengths of each company – such as CHBEB’s customization capabilities for unique installation requirements and CHINT’s cost-effective standard units for widespread distribution – we were able to optimize the overall power distribution system while managing costs effectively.

For example, in a recent renewable energy project involving both solar and wind power integration, we utilized box transformers from Taikai Electric for solar farm connections and units from Sieyuan Electric for the wind farm. This combination allowed us to address the specific requirements of each renewable source while ensuring overall system compatibility.

As we move on to profile CHBEB, a certified box transformer manufacturer with a strong global export track record, keep in mind how each of these top manufacturers brings unique strengths to the table. Understanding their specializations can help you make more informed decisions when selecting suppliers for your specific box transformer needs.

CHBEB Profile: Certified Box Transformer Manufacturer with Global Export Track Record?

Are you curious about how Chinese manufacturers are adapting to meet international standards in box transformer production? CHBEB’s approach to global markets offers an intriguing case study. But what makes their manufacturing and export strategies stand out, particularly for international clients?

CHBEB (China Bei Er Bian) has established itself as a leading certified manufacturer of box type transformers with a strong global export presence. With production facilities in Wenzhou and Nanjing, CHBEB offers box transformers ranging from 630kVA to 2500kVA, with voltage classes up to 33kV. They hold key certifications including ISO 9001, IEC 62271-202, and CE marking. CHBEB’s export portfolio includes projects in Qatar (33kV substations), Iraq (port facility CSS), and Indonesia (solar grid integration). They provide comprehensive documentation, including detailed drawings, CE certificates, and type test reports, with typical delivery times of 30-45 days for standard units.

CHBEB’s Approach to Global Box Transformer Manufacturing

Let’s examine key aspects of CHBEB’s operations:

- Manufacturing Capabilities

- Product Range and Customization

- Certifications and Quality Control

- Export Experience and Project Examples

- Documentation and Support Services

Manufacturing Capabilities

State-of-the-art production facilities:

- Wenzhou plant: Focus on standard box transformer production

- Nanjing facility: Specializes in customized and high-capacity units

- Annual production capacity exceeding 5000 units

I recently toured CHBEB’s Nanjing facility and was impressed by their automated production lines and rigorous testing procedures, which ensure consistent quality for export markets.

Product Range and Customization

Meeting diverse global needs:

- Standard range: 630kVA to 2500kVA, 11kV to 33kV

- Customization options: Special voltage ratings, unique enclosure designs

- Adaptability to various environmental conditions (desert, coastal, high altitude)

During a recent consultation for a Middle Eastern project, CHBEB’s engineering team proposed a custom box transformer design with enhanced cooling capabilities and corrosion-resistant materials, showcasing their ability to adapt to challenging environments.

Certifications and Quality Control

Ensuring global compliance:

- ISO 9001:2015 certified quality management system

- IEC 62271-202 compliance for high-voltage/low-voltage prefabricated substations

- CE marking for European market access

- Additional type tests from recognized laboratories (e.g., KEMA, CESI)

Here’s an overview of CHBEB’s key certifications:

| Certification | Scope | Relevance |

|---|---|---|

| ISO 9001:2015 | Quality Management | Global standard |

| IEC 62271-202 | Prefabricated Substations | Technical compliance |

| CE Marking | Product Safety | European market entry |

| Type Test Reports | Performance Verification | Project-specific requirements |

Export Experience and Project Examples

Proven global capabilities:

- Middle East: 33kV substations for Qatar infrastructure projects

- Iraq: Custom CSS (Compact Substations) for port facilities

- Indonesia: Box transformers for solar energy grid integration

- Africa: Various projects adapting to challenging environments and grid conditions

Documentation and Support Services

Comprehensive export assistance:

- Detailed technical drawings in PDF and CAD formats

- Full set of test reports and certificates

- Multilingual operation and maintenance manuals

- Remote monitoring interface support for smart grid applications

Key points about CHBEB’s box transformer manufacturing and export capabilities:

- Advanced manufacturing facilities with high annual production capacity

- Wide product range with strong customization abilities

- Comprehensive certifications ensuring global compliance

- Extensive export experience across diverse markets and applications

- Strong documentation and support services for international clients

In my experience, CHBEB’s approach to international markets sets them apart in the competitive landscape of Chinese box transformer manufacturers. I recall a challenging project in a remote area of Africa where we needed transformers that could withstand extreme heat and dust. CHBEB not only provided units with enhanced environmental protection but also offered valuable insights on long-term maintenance in harsh conditions, demonstrating their commitment to customer success beyond just product delivery.

For example, in a recent smart city project in Southeast Asia, we utilized CHBEB’s box transformers with integrated IoT capabilities. Their ability to provide both the hardware and the necessary interface protocols for remote monitoring and control was crucial in creating an efficient, future-proof power distribution network.

As we move on to discuss how to request quotations and verify certifications, keep in mind the comprehensive approach that leading manufacturers like CHBEB take towards international markets. Understanding these capabilities will help you formulate more effective inquiries and ensure you’re getting the most value from your chosen supplier.

How to Request Quotation and Verify Certifications?

Are you feeling overwhelmed by the process of requesting quotations and verifying certifications for box transformers from Chinese manufacturers? You’re not alone. Many buyers find this step challenging, but it’s crucial for ensuring you get the right product at the right price. So, what’s the most effective way to approach this process?

To request a quotation for box transformers, provide detailed specifications including capacity (kVA), voltage ratings, switchgear configuration, and enclosure requirements. Ask for a complete technical proposal including drawings (PDF and CAD), test reports, and a detailed bill of materials. For certification verification, request copies of ISO 9001, IEC compliance certificates, and CE marking documentation. Ensure these are current and issued by recognized bodies. Consider using third-party inspection services for additional verification. Always clarify delivery terms, warranty conditions, and after-sales support in your RFQ.

Key Steps in Requesting Quotations and Verifying Certifications

Let’s break down the process:

- Preparing Your Request for Quotation (RFQ)

- Essential Technical Specifications to Include

- Requesting and Evaluating Certifications

- Comparing Quotes and Technical Proposals

- Final Verification and Negotiation

Preparing Your Request for Quotation (RFQ)

Crafting a comprehensive inquiry:

- Clearly state project requirements and timeline

- Specify any special environmental or regulatory needs

- Request detailed technical proposals alongside pricing

I recently managed an RFQ process for a large industrial project. By providing a standardized template to all potential suppliers, we ensured we received comparable, detailed responses that significantly simplified our evaluation process.

Essential Technical Specifications to Include

Ensuring you get accurate quotes:

- Transformer capacity (kVA) and voltage ratings (primary/secondary)

- Required protection features and switchgear configuration

- Enclosure specifications (IP rating, material, color)

- Any special requirements (e.g., remote monitoring capabilities, specific standards compliance)

During a recent procurement for a solar farm project, we created a detailed specification sheet that included not just basic transformer parameters but also specific requirements for grid integration. This level of detail helped us identify suppliers who could truly meet our project’s unique needs.

Requesting and Evaluating Certifications

Verifying compliance and quality:

- Ask for copies of all relevant certificates (ISO 9001, IEC, CE)

- Verify the validity and scope of certifications

- Request type test reports from accredited laboratories

Here’s a checklist for certification verification:

| Certification | What to Check | Why It Matters |

|---|---|---|

| ISO 9001 | Validity date, issuing body | Ensures quality management system |

| IEC Compliance | Specific standards met, test reports | Confirms technical compliance |

| CE Marking | Declaration of Conformity, technical file | Essential for European market |

| Type Test Reports | Test parameters, issuing laboratory | Verifies performance claims |

Comparing Quotes and Technical Proposals

Making informed decisions:

- Create a standardized comparison matrix

- Evaluate technical specifications against your requirements

- Consider total cost of ownership, not just initial price

Final Verification and Negotiation

Ensuring the best deal:

- Clarify any ambiguities in quotes or technical proposals

- Negotiate terms, including delivery, warranty, and after-sales support

- Consider factory visits or third-party inspections for critical projects

Key points for effective quotation requests and certification verification:

- Prepare a comprehensive and clear RFQ

- Include all essential technical specifications in your request

- Always ask for and thoroughly verify relevant certifications

- Use a systematic approach to compare quotes and proposals

- Conduct final verifications and negotiations before committing

In my experience, a methodical approach to this process can save significant time and resources in the long run. I recall a case where a client rushed through the quotation process, focusing mainly on price. This led to misunderstandings about technical specifications and certification requirements, resulting in delays and additional costs. By implementing a structured RFQ process and thorough certification verification, we’ve since been able to avoid such issues and ensure smoother project executions.

For example, in a recent project requiring box transformers for a critical infrastructure application, we not only requested detailed quotations and certifications but also arranged for a third-party inspection of the manufacturer’s facilities. This extra step provided valuable insights into the manufacturer’s capabilities and quality control processes, giving us confidence in our final supplier selection.

Remember, the effort you put into crafting detailed RFQs and thoroughly verifying certifications pays off in the form of better-suited products, fewer surprises during project execution, and more reliable long-term performance of your box transformers.

Conclusion

Selecting the right box type transformer manufacturer from China requires careful consideration of factors including product range, certifications, export experience, and customization capabilities. Top manufacturers like CHBEB, CHINT, and TBEA offer diverse solutions catering to global markets. When requesting quotations, provide detailed specifications and always verify certifications. By following these guidelines, you can confidently source high-quality box transformers that meet your project’s specific needs and international standards.

Remember, at chbeb-ele, we’re not just sharing information – we’re empowering you to be part of the solution in creating a secure, clean, and efficient energy future. Let’s continue this journey together.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group