What Is a Dry Type Distribution Transformer and How Does It Work?

Confused about which transformer to use for your commercial or industrial project? A dry type distribution transformer offers a safe, oil-free, and low-maintenance solution for indoor and fire-sensitive environments. This guide explains how it works, its advantages, and how to select the right one for your needs.

A dry type distribution transformer is an electrical device that transfers power using air-insulated windings instead of oil. It operates safely in indoor or fire-sensitive environments, offering low maintenance and high reliability. Its cooling relies on natural or forced air, making it ideal for commercial and urban use.

In this comprehensive guide, I’ll walk you through the ins and outs of dry type distribution transformers. Whether you’re a seasoned electrical engineer or a project manager looking to expand your knowledge, this article will provide you with valuable insights to understand and work with these essential power distribution components.

What Is a Dry Type Distribution Transformer? (Definition & Function)

Have you ever wondered how power is safely distributed in buildings without the risk of oil leaks or fires? This is where dry type distribution transformers come into play. But what exactly are they, and how do they differ from their oil-filled counterparts?

A dry type distribution transformer is a power conversion device that uses air or epoxy resin for insulation instead of oil. It’s designed for indoor use, particularly in areas where fire safety is crucial. These transformers typically range from 5 kVA to 15 MVA and are commonly used in commercial buildings, hospitals, and industrial facilities.

Understanding Dry Type Distribution Transformers

Let’s break down the key aspects of these transformers:

- Basic Structure

- Insulation Types

- Cooling Methods

- Voltage and Capacity Range

Basic Structure

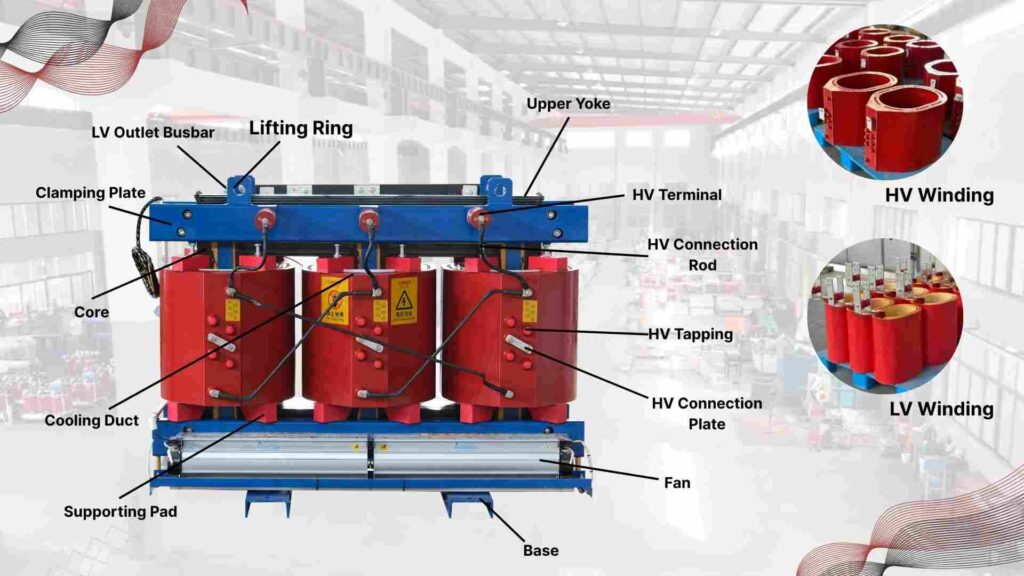

A dry type transformer typically consists of:

- Core (usually made of silicon steel)

- Primary and secondary windings

- Insulation material (air, epoxy resin, or other solid materials)

- Enclosure for protection

I remember my first encounter with a dry type transformer during a hospital renovation project. The compact design and absence of oil made it perfect for the space-constrained, safety-critical environment.

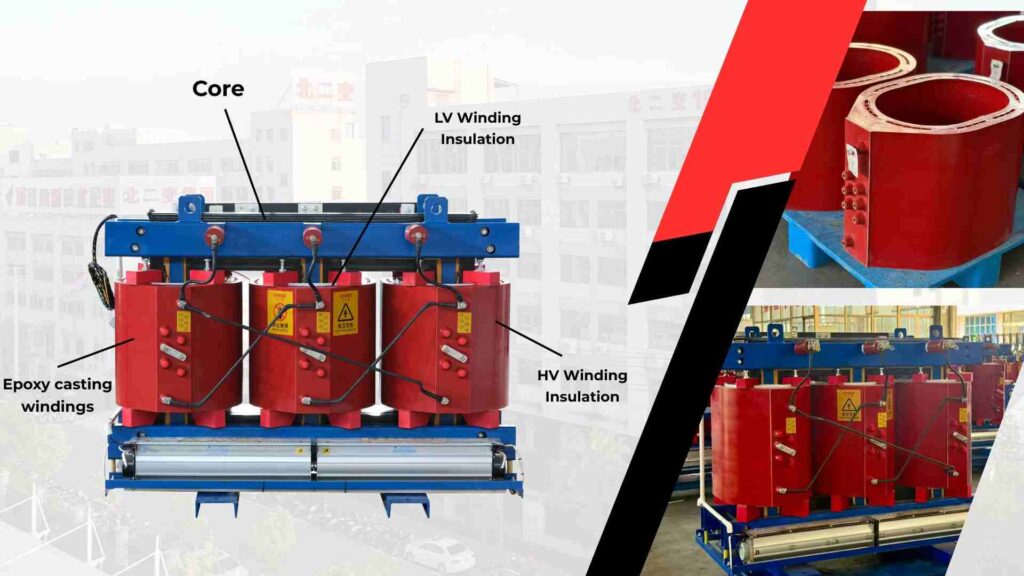

Insulation Types

There are two main types of insulation in dry transformers:

- Open-wound: Air-insulated windings

- Cast resin: Windings encapsulated in epoxy resin

During a recent data center project, we opted for cast resin transformers1. Their superior fire resistance and ability to withstand high humidity were crucial for the facility’s strict safety requirements.

Cooling Methods

Dry type transformers use air for cooling:

- AN (Air Natural): Relies on natural air circulation

- AF (Air Forced): Uses fans for enhanced cooling

Here’s a quick comparison of cooling methods:

| Cooling Method | Advantages | Typical Applications |

|---|---|---|

| AN (Air Natural) | Simple, quiet, low maintenance | Small to medium capacity, indoor use |

| AF (Air Forced) | Higher capacity, better cooling efficiency | Large capacity, industrial settings |

Voltage and Capacity Range

Dry type transformers are versatile:

- Typical voltage range: Up to 35 kV

- Capacity range: 5 kVA to 15 MVA

Key characteristics of dry type distribution transformers:

- Fire-resistant and environmentally friendly (no oil leaks)

- Suitable for indoor installation, close to the load

- Low maintenance requirements

- Good short-circuit strength

- Quieter operation compared to oil-filled transformers

In my experience, understanding these basic characteristics is crucial for proper transformer selection. I’ve seen projects where the choice of a dry type transformer over an oil-filled one significantly simplified installation and reduced long-term maintenance costs.

As we move forward to discuss how these transformers work, keep in mind that their unique design and characteristics make them indispensable in many modern power distribution applications, especially where safety and environmental concerns are paramount.

How Does a Dry Type Transformer Work (Step-by-Step Explanation)

Are you curious about the inner workings of a dry type transformer? Understanding its operation can be crucial for proper application and maintenance. But how exactly does this device transfer power without using oil, and what principles govern its functionality?

A dry type transformer works on the principle of electromagnetic induction2. It transfers electrical energy between circuits through inductively coupled conductors—the transformer’s coils. The primary coil creates a magnetic field when energized, which induces a voltage in the secondary coil. This process allows for voltage transformation while maintaining electrical isolation between circuits.

The Working Principle of Dry Type Transformers

Let’s break down the operation into key steps:

- Electromagnetic Induction

- Voltage Transformation

- Heat Management

- Insulation and Safety

Electromagnetic Induction

The core principle of transformer operation:

- Alternating current in the primary winding creates a changing magnetic field

- This field induces voltage in the secondary winding

- The number of turns in each winding determines the voltage ratio

I once explained this concept to a client using a simple demonstration. By wrapping two wires around a iron rod and connecting one to a battery with a switch, we could see how changing current in one wire induced voltage in the other. This basic principle is at the heart of all transformer operations.

Voltage Transformation

Transformers change voltage levels based on the turn ratio:

- Step-up transformer: Secondary has more turns than primary

- Step-down transformer: Primary has more turns than secondary

Here’s a simple formula to remember:

Voltage Ratio = Primary Turns / Secondary Turns = Secondary Voltage / Primary Voltage

For example, in a step-down transformer:

- Primary: 1000 turns, 11000V

- Secondary: 100 turns

- Secondary Voltage = (100/1000) * 11000V = 1100V

Heat Management

Dry type transformers must manage heat effectively:

- Core losses and copper losses generate heat

- Air circulation (natural or forced) dissipates heat

- Temperature monitoring is crucial for safe operation

During a recent industrial project, we implemented a forced-air cooling system for a large dry type transformer. This allowed us to increase its capacity without compromising on size, crucial for the space-constrained installation area.

Insulation and Safety

Insulation is key to transformer safety and efficiency:

- Air gaps or solid insulation materials separate windings

- Epoxy resin in cast resin transformers provides excellent insulation and protection

Here’s a comparison of insulation methods:

| Insulation Type | Advantages | Considerations |

|---|---|---|

| Air (Open Wound) | Simple, cost-effective | Requires more space, sensitive to environment |

| Cast Resin | Excellent protection, compact | Higher cost, heavier |

Key points to remember about dry type transformer operation:

- The core principle is electromagnetic induction

- Voltage transformation depends on the turn ratio of windings

- Effective heat management is crucial for performance and longevity

- Insulation method affects the transformer’s characteristics and applications

In my experience, a clear understanding of these operational principles is essential for anyone working with dry type transformers. I’ve seen cases where improper application or misunderstanding of heat management led to premature transformer failure, highlighting the importance of this knowledge.

As we move forward to discuss the key features and benefits of dry type transformers, keep in mind how these operational principles contribute to their unique advantages in various applications.

Why Choose a Dry Type Transformer — 5 Key Benefits for Your Project

Are you wondering what makes dry type transformers stand out in the world of power distribution? Their unique features offer significant advantages in many applications. But what exactly are these features, and how do they benefit your projects?

Dry type transformers offer key benefits including enhanced fire safety, environmental friendliness, and low maintenance requirements. They’re ideal for indoor and sensitive environments due to their compact design and absence of oil. These transformers provide high reliability, good overload capacity, and are less susceptible to moisture and contaminants, making them perfect for a wide range of commercial and industrial applications.

Exploring the Advantages of Dry Type Transformers

Let’s delve into the key features and benefits:

- Enhanced Safety

- Environmental Friendliness

- Low Maintenance

- Compact Design

- High Reliability and Performance

Enhanced Safety

Dry type transformers excel in safety:

- No risk of oil fires or explosions

- Self-extinguishing properties in cast resin models

- Suitable for installation near populated areas

I once worked on a hospital renovation project where fire safety was paramount. The choice of dry type transformers significantly simplified compliance with strict safety regulations and gave peace of mind to the facility managers.

Environmental Friendliness

These transformers are eco-friendly:

- No oil means no risk of soil or water contamination

- Reduced environmental impact in case of damage or disposal

- Often made with recyclable materials

During an eco-friendly office complex project, the use of dry type transformers contributed significantly to the building’s green certification, showcasing their environmental benefits.

Low Maintenance

Dry transformers require minimal upkeep:

- No oil to monitor, test, or replace

- Less susceptible to moisture and contaminants

- Longer service intervals compared to oil-filled units

Here’s a comparison of maintenance requirements:

| Aspect | Dry Type Transformer | Oil-Filled Transformer |

|---|---|---|

| Routine Checks | Visual inspection, cleaning | Oil testing, level checks |

| Frequency | Annually or bi-annually | Quarterly or semi-annually |

| Major Maintenance | Rare, mainly electrical tests | Oil filtration, potential oil replacement |

Compact Design

Space efficiency is a key advantage:

- Smaller footprint compared to oil-filled transformers

- Can be installed closer to the load

- Suitable for indoor and confined spaces

I recently worked on a high-rise building project where the compact design of dry type transformers allowed for installation on each floor, optimizing power distribution efficiency.

High Reliability and Performance

Dry transformers offer robust performance:

- Good overload capacity

- Excellent short-circuit strength

- Less affected by harmonics in many designs

Key benefits of dry type transformers:

- Increased safety in fire-sensitive environments

- Reduced environmental risks and easier compliance with regulations

- Lower long-term maintenance costs and efforts

- Flexibility in installation locations, including indoors

- High reliability and consistent performance under various conditions

In my experience, these benefits make dry type transformers an excellent choice for many modern applications. I’ve seen projects where the initial higher cost of dry type transformers was quickly offset by reduced installation complexity, lower maintenance needs, and enhanced safety features.

As we move on to discuss common applications, keep in mind how these features and benefits align with the specific needs of various commercial and industrial projects.

Where Are Dry Type Transformers Used — Top 5 Commercial & Industrial Applications

Are you curious about where dry type transformers are most commonly used? Understanding their applications can help you make informed decisions for your projects. But in which specific commercial and industrial settings do these transformers truly shine?

Dry type transformers are widely used in commercial buildings, industrial facilities, and infrastructure projects. They’re ideal for indoor installations in high-rise buildings, hospitals, data centers, and manufacturing plants. Their safety features make them perfect for areas with high foot traffic or fire risks. In industrial settings, they’re used in petrochemical plants, renewable energy projects, and marine applications.

Exploring Key Applications of Dry Type Transformers

Let’s examine the main areas where dry type transformers are commonly used:

- Commercial Buildings

- Healthcare Facilities

- Industrial and Manufacturing

- Infrastructure and Transportation

- Renewable Energy Projects

Commercial Buildings

Dry transformers are ideal for commercial spaces:

- Office buildings and high-rises

- Shopping malls and retail centers

- Hotels and residential complexes

I recently worked on a smart office building project where dry type transformers were crucial. Their compact size and low noise operation allowed for installation on each floor, providing efficient power distribution without disturbing the work environment.

Healthcare Facilities

Hospitals and medical centers benefit greatly:

- Operating rooms and critical care units

- Diagnostic imaging centers (MRI, CT scan rooms)

- Laboratories and research facilities

During a hospital expansion project, we chose dry type transformers for their reliability and safety. The absence of oil was particularly important near sensitive medical equipment and in areas with oxygen supply.

Industrial and Manufacturing

Many industries rely on dry transformers:

- Automotive manufacturing plants

- Food processing facilities

- Chemical and petrochemical industries

Here’s a comparison of applications in different industrial settings:

| Industry | Application | Key Benefit |

|---|---|---|

| Automotive | Welding lines, paint shops | Reliability in high-dust environments |

| Food Processing | Refrigeration, packaging | Hygiene (no oil contamination risk) |

| Chemical | Process control, pumping stations | Safety in hazardous areas |

Infrastructure and Transportation

Dry transformers play a crucial role in infrastructure:

- Airports and seaports

- Subway and railway systems

- Wastewater treatment plants

I was involved in a major airport expansion where dry type transformers were used extensively. Their fire safety features and ability to handle the variable loads typical of airport operations made them the ideal choice.

Renewable Energy Projects

The renewable sector increasingly uses dry transformers:

- Wind farms (especially offshore)

- Solar power plants

- Hydroelectric facilities

Key reasons for choosing dry type transformers in these applications:

- Enhanced safety in populated or sensitive environments

- Reliability and low maintenance in hard-to-access locations

- Compact design for space-constrained installations

- Environmental friendliness aligning with green energy goals

- Ability to handle variable loads common in renewable energy generation

In my experience, the versatility of dry type transformers makes them suitable for a wide range of projects. I’ve seen them successfully deployed in everything from small urban renovations to large-scale industrial complexes.

For instance, in a recent solar farm project, we used dry type transformers at various points in the power distribution system. Their ability to withstand the harsh outdoor environment and handle the variable output of solar panels was crucial to the project’s success.

As we move on to compare dry type and oil-immersed transformers, consider how these diverse applications showcase the adaptability and benefits of dry type transformers in modern power distribution systems.

Dry Type vs Oil-Immersed Transformer — Which One Is Better for You?

Are you weighing the options between dry type and oil-immersed transformers for your project? This decision can significantly impact your installation’s safety, efficiency, and maintenance needs. But what are the key differences, and how do you choose the right type for your specific requirements?

Dry type transformers excel in safety and environmental friendliness, ideal for indoor and sensitive locations. They require less maintenance but have higher initial costs and lower efficiency in high-capacity applications. Oil-immersed transformers offer better cooling and efficiency for high-capacity needs but require more maintenance and pose environmental risks. The choice depends on factors like installation location, capacity requirements, and environmental considerations.

Analyzing Dry Type vs Oil-Immersed Transformers

Let’s compare these two types of transformers across key aspects:

- Safety and Environmental Impact

- Efficiency and Cooling

- Maintenance and Lifespan

- Installation and Space Requirements

- Cost Considerations

Safety and Environmental Impact

Safety is a crucial factor:

- Dry Type: Higher fire safety, no risk of oil leaks

- Oil-Immersed: Potential fire hazard, risk of environmental contamination

I once consulted on a project where an oil-immersed transformer leak caused significant environmental damage. This incident highlighted the safety advantages of dry type transformers, especially in environmentally sensitive areas.

Efficiency and Cooling

Cooling and efficiency vary between types:

- Dry Type: Less efficient cooling, typically used up to 35 kV

- Oil-Immersed: Superior cooling, efficient for high voltages and capacities

During a large industrial project, we opted for oil-immersed transformers for the main power supply due to their higher efficiency at the required capacity. However, we used dry type units for smaller, localized power distribution within the facility.

Maintenance and Lifespan

Maintenance needs differ significantly:

- Dry Type: Low maintenance, no oil to monitor or replace

- Oil-Immersed: Regular oil testing and potential replacement

Here’s a comparison of maintenance aspects:

| Aspect | Dry Type | Oil-Immersed |

|---|---|---|

| Routine Checks | Visual inspection | Oil testing, level checks |

| Major Maintenance | Rare | Oil filtration/replacement |

| Typical Lifespan | 20-30 years | 30-40 years with proper maintenance |

Installation and Space Requirements

Space considerations can be crucial:- Dry Type: Compact, suitable for indoor installation

- Oil-Immersed: Requires more space, often needs outdoor or specially designed areas

I recently worked on a high-rise office project where space was at a premium. The compact nature of dry type transformers allowed us to install them on each floor, optimizing power distribution without sacrificing valuable real estate.

Cost Considerations

Initial and long-term costs vary:

- Dry Type: Higher initial cost, lower long-term maintenance costs

- Oil-Immersed: Lower initial cost, higher long-term maintenance expenses

Key factors to consider when choosing between dry type and oil-immersed transformers:

- Installation location (indoor vs outdoor, proximity to sensitive areas)

- Capacity and voltage requirements

- Environmental regulations and safety standards

- Long-term maintenance capabilities and costs

- Space availability and installation constraints

In my experience, the choice between dry type and oil-immersed transformers often comes down to a balance of these factors. For instance, in a recent data center project, we chose dry type transformers despite their higher initial cost. The enhanced fire safety and reduced maintenance needs aligned perfectly with the facility’s stringent uptime requirements and safety protocols.

Here’s a summary table to help you compare:

| Factor | Dry Type Transformers | Oil-Immersed Transformers |

|---|---|---|

| Safety | High fire safety | Potential fire risk |

| Environmental Impact | Minimal | Risk of oil leaks |

| Efficiency | Lower at high capacities | Higher, especially at high capacities |

| Maintenance | Low | Higher, regular oil checks required |

| Installation | Flexible, indoor-friendly | Often requires outdoor or special areas |

| Initial Cost | Higher | Lower |

| Long-term Cost | Lower maintenance costs | Higher due to oil maintenance |

| Typical Applications | Commercial buildings, hospitals | Large industrial, utility-scale projects |

As we move forward to discuss top brands offering dry type transformers, keep these comparisons in mind. They’ll help you understand why certain manufacturers might excel in specific applications or markets.

Top Dry Type Transformer Brands 2025 — ABB, Schneider, Siemens, TBEA & SUNTEN

Are you looking for reliable dry type transformer manufacturers but feeling overwhelmed by the options? The market is filled with various brands, each with its strengths. But which companies are leading the pack, and what unique offerings do they bring to the table?

Leading brands in the dry type transformer market include ABB, Schneider Electric, Siemens, TBEA, and SUNTEN. ABB is known for its VPI technology, Schneider for eco-design, Siemens for industrial applications, TBEA for high capacity, and SUNTEN for cost-effective solutions. These companies offer a range of products catering to various needs, from compact designs for urban use to robust models for industrial applications.

Analyzing Top Dry Type Transformer Manufacturers

Let’s explore the offerings of leading brands:

- ABB

- Schneider Electric

- Siemens

- TBEA

- SUNTEN

ABB

ABB is a global leader in power and automation technologies:

- Known for: VPI (Vacuum Pressure Impregnated) dry type transformers

- Key Product: ABB Dry-Type SafeDry 12kV

- Strengths: High short-circuit withstand, Class F insulation

- Market Focus: Global, strong in Middle East and Europe

I recently specified ABB transformers for a major hospital project. Their compact design and excellent fire safety features were crucial for the sensitive healthcare environment.

Schneider Electric

Schneider specializes in energy management and automation solutions:

- Known for: Eco-designed, low-noise transformers

- Key Product: Trihal Cast Resin Transformer

- Strengths: High fire safety, low environmental impact

- Market Focus: Global, particularly strong in commercial and data center applications

During a recent data center project in Southeast Asia, we chose Schneider’s Trihal transformers. Their ability to operate in high humidity environments without compromising performance was a key factor.

Siemens

Siemens is renowned for its industrial and energy technology:

- Known for: GEAFOL cast resin transformers

- Key Product: GEAFOL Neo Dry-Type Transformer

- Strengths: Strong overload capacity, self-extinguishing insulation

- Market Focus: Global, particularly strong in industrial and infrastructure projects

Here’s a quick comparison of these top brands:

| Brand | Key Strength | Typical Applications | Notable Export Regions |

|---|---|---|---|

| ABB | VPI Technology | Hospitals, High-rise buildings | Middle East, Europe |

| Schneider | Eco-design | Data Centers, Commercial | Southeast Asia, Latin America |

| Siemens | Industrial Grade | Factories, Infrastructure | Europe, North America |

| TBEA | High Capacity | Utility, Large Industrial | Middle East, Africa |

| SUNTEN | Cost-effective | Urban Distribution, Telecom | Southeast Asia, Russia |

TBEA

TBEA is a leading Chinese manufacturer with a growing global presence:

- Known for: High capacity dry type transformers

- Key Product: SG Series Dry Type Transformer

- Strengths: Adaptable to harsh environments, high mechanical strength

- Market Focus: Strong in China, expanding in Middle East and Africa

I’ve seen TBEA transformers perform exceptionally well in a recent solar power project in the Middle East. Their ability to withstand high temperatures and dusty conditions was impressive.

SUNTEN

SUNTEN is known for its cost-effective and reliable solutions:

- Known for: Compact, efficient dry type transformers

- Key Product: SC(B)10 Series

- Strengths: Low loss, low noise, high moisture resistance

- Market Focus: Strong in China, growing presence in Southeast Asia and Russia

Key considerations when evaluating these brands:

- Assess their experience in your specific application area

- Consider their local support and after-sales service capabilities

- Evaluate their compliance with relevant standards (IEC, ANSI, etc.)

- Look into their track record in energy efficiency and environmental sustainability

- Consider the total cost of ownership, not just the initial purchase price

In my experience, the choice of brand often comes down to a balance of factors including technical specifications, local support, and project-specific requirements. For instance, in a recent urban redevelopment project, we opted for SUNTEN transformers due to their compact design and cost-effectiveness, which were crucial for the project’s budget constraints and space limitations.

As we move on to discuss how to select the right dry type transformer for your project, keep these brand insights in mind. They’ll help you narrow down your options based on your specific needs and project parameters.

How to Choose the Right Dry Type Transformer (Selection Guide 2025)

Are you feeling overwhelmed by the process of choosing the right dry type transformer for your specific needs? With so many factors to consider, making the right choice can be challenging. But what if you had a clear, step-by-step approach to ensure you select the perfect transformer for your project?

Selecting the right dry type transformer involves assessing your power requirements, considering environmental factors, evaluating space constraints, and understanding safety regulations. Key factors include kVA rating, primary and secondary voltages, insulation class, and cooling method. Also, consider future expansion needs, energy efficiency ratings, and compatibility with existing systems. Proper selection ensures optimal performance and longevity.

Key Steps in Selecting a Dry Type Transformer

Let’s break down the selection process into manageable steps:

- Determine Power Requirements

- Consider Environmental Factors

- Evaluate Space and Installation Constraints

- Assess Safety and Regulatory Compliance

- Factor in Long-Term Considerations

Determine Power Requirements

Start by accurately assessing your power needs:

- Calculate total kVA required for all connected loads

- Determine required primary and secondary voltages

- Consider load factor and future expansion needs

I once worked on a project where underestimating the load led to an undersized transformer. We had to replace it within a year, causing unnecessary downtime and extra costs. Always err on the side of caution when calculating load requirements.

Consider Environmental Factors

The installation environment plays a crucial role:

- Ambient temperature range

- Humidity levels and potential for condensation

- Presence of dust, chemicals, or salt air

- Altitude (affects cooling efficiency)

During a coastal industrial project, we opted for specially designed transformers with enhanced corrosion resistance. This decision significantly extended the transformer’s lifespan in the harsh, salt-laden environment.

Evaluate Space and Installation Constraints

Consider practical aspects of installation:

- Available space and weight limitations

- Ventilation requirements

- Noise level restrictions (especially for indoor installations)

- Accessibility for maintenance and potential replacement

Here’s a quick reference table for space considerations:

| Aspect | Considerations | Impact on Selection |

|---|---|---|

| Available Space | Footprint, height restrictions | May influence kVA capacity choice |

| Ventilation | Air flow, temperature control | Affects cooling method selection |

| Noise Limitations | Proximity to occupied areas | May require special low-noise models |

| Accessibility | Maintenance access, future replacement | Influences size and installation method |

Assess Safety and Regulatory Compliance

Ensure compliance with relevant standards:

- Fire safety regulations (especially for indoor installations)

- Electrical codes and standards (e.g., IEC, ANSI)

- Energy efficiency requirements

- Environmental regulations

I recall a project where we had to switch to a different transformer model late in the planning stage due to overlooked local fire safety regulations. This experience highlighted the importance of thorough regulatory compliance checks early in the selection process.

Factor in Long-Term Considerations

Think beyond immediate needs:

- Energy efficiency ratings and potential energy savings

- Scalability for future expansion

- Reliability and expected lifespan

- Total cost of ownership (including maintenance and energy costs)

Key tips for selecting the right dry type transformer:

- Always include a safety margin in your load calculations

- Consider the total cost of ownership, not just the initial price

- Consult with manufacturers or experts for complex applications

- Review case studies of similar installations

- Consider conducting site visits to see transformers in similar applications

In my experience, successful transformer selection comes down to a balance of technical requirements, practical considerations, and future-proofing. I’ve seen projects succeed when all these factors were carefully weighed, and struggle when even one was overlooked.

Remember, selecting the right transformer is not just about meeting current needs; it’s about ensuring your power distribution system remains efficient, reliable, and adaptable for years to come. By following these steps and considering all relevant factors, you can make an informed decision that will serve your project well into the future.

Dry Type Transformer Buying Guide — Is It the Right Choice for You?

Are you still wondering if a dry type transformer is the best choice for your project? After exploring their features, benefits, and applications, it’s time to synthesize this information and help you make an informed decision. But how do you weigh all these factors to determine if a dry type transformer truly fits your needs?

Dry type transformers are ideal for indoor installations, fire-sensitive areas, and environments where oil leaks pose risks. They excel in commercial buildings, hospitals, and industrial settings with space constraints or high safety requirements. Consider a dry type transformer if you prioritize low maintenance, environmental safety, and flexibility in installation. However, for very high capacity needs or outdoor installations, oil-immersed alternatives might be more suitable.

Making the Final Decision

Let’s recap the key points to consider:

- Safety and Environmental Factors

- Installation and Space Requirements

- Maintenance and Long-Term Costs

- Performance and Efficiency

- Specific Application Needs

Safety and Environmental Factors

Dry type transformers shine in safety-critical environments:

- Ideal for areas with high fire risk or strict safety regulations

- No risk of oil leaks or environmental contamination

- Suitable for installation near sensitive equipment or populated areas

I once recommended dry type transformers for a hospital renovation project. The absence of oil and reduced fire risk were crucial factors in meeting the strict safety standards of healthcare facilities.

Installation and Space Requirements

Consider your installation constraints:

- Dry type transformers are generally more compact

- Suitable for indoor installation, even in confined spaces

- No need for oil containment systems or fire walls

During a recent high-rise office project, the compact nature of dry type transformers allowed for installation on each floor, optimizing power distribution efficiency without sacrificing valuable real estate.

Maintenance and Long-Term Costs

Factor in the total cost of ownership:

- Dry type transformers require less maintenance

- No oil to monitor, test, or replace

- Potentially lower long-term costs despite higher initial investment

Here’s a comparison of long-term considerations:

| Aspect | Dry Type | Oil-Immersed |

|---|---|---|

| Routine Maintenance | Minimal | Regular oil checks and tests |

| Major Servicing | Rare | Periodic oil replacement |

| Environmental Risk | Low | Potential oil leak cleanup costs |

| Lifespan | 20-30 years | 30-40 years with proper maintenance |

Performance and Efficiency

Consider your specific performance needs:

- Dry type transformers are efficient for low to medium capacity needs

- May be less efficient than oil-immersed for very high capacities

- Perform well in variable load conditions common in commercial settings

Specific Application Needs

Align your choice with your application:

- Ideal for commercial buildings, data centers, hospitals

- Well-suited for industrial applications with indoor installation requirements

- Consider alternatives for very high capacity or outdoor utility applications

Key takeaways for deciding on a dry type transformer:

- Prioritize safety and environmental concerns in your decision

- Assess your space constraints and installation location

- Calculate the total cost of ownership, including maintenance

- Evaluate your specific capacity and efficiency requirements

- Consider future expansion needs and flexibility

In my experience, dry type transformers are often the best choice for modern, urban, and safety-conscious applications. However, each project has unique requirements. I’ve seen cases where the initial higher cost of dry type transformers was quickly offset by reduced installation complexity, lower maintenance needs, and enhanced safety features.

For instance, in a recent data center project, we chose dry type transformers despite their slightly lower efficiency compared to oil-immersed alternatives. The decision was driven by the critical need for fire safety, the indoor installation requirement, and the desire for minimal maintenance in a 24/7 operational environment.

Remember, the right choice depends on your specific circumstances. By carefully considering these factors and aligning them with your project’s unique needs, you can make a decision that ensures efficient, safe, and reliable power distribution for years to come.

CHBEB — Reliable Partner for Distribution Transformers

With over 60 years of transformer manufacturing expertise, CHBEB has established itself as one of China’s most trusted and globally recognized suppliers of dry type and oil-immersed distribution transformers. The company operates two factories in Wenzhou, one in Nanjing, and a technical and export office in Beijing, ensuring strong production capacity, engineering flexibility, and responsive customer service.

Why Global Buyers Choose CHBEB

- Certified Quality & Full Testing: Every transformer is manufactured under IEC 60076 / ISO 9001 standards and 100% factory-tested before shipment—no exceptions.

- 100% New Raw Materials: Premium copper, silicon steel, and insulation components; no recycled or downgraded materials.

- Fast-Track Delivery: Standard units ready in as little as 7 days for urgent EPC or retrofit projects.

- Customization & OEM Flexibility: Tailored voltage ratios, enclosure IP ratings, and cooling systems (AN/AF) to meet local grid and safety codes.

- Proven Reliability: Qualified supplier for the State Grid Corporation of China with a zero-accident operational record.

- Global Support: Experienced in export documentation, CE/CB certification, and on-site inspection support for clients in the Middle East, Africa, Southeast Asia, and CIS.

Whether you’re designing a hospital, data center, or renewable energy facility, CHBEB can provide a transformer that reduces installation complexity, minimizes lifetime cost, and ensures compliance with international standards.

👉 Looking for a partner who combines Chinese manufacturing strength with global engineering standards? Contact CHBEB for a tailored technical proposal or download our full catalog today.

Conclusion: Turning Technical Clarity into Strategic Advantage

Dry Type Distribution Transformers (DTDTs) stand as the future-ready solution for modern power systems where fire safety, regulatory compliance, and predictable operation are non-negotiable. They remove oil-handling risks, simplify infrastructure, and deliver steady performance under demanding environmental and urban conditions.

While oil-immersed transformers may appear cheaper at the purchase stage, a full Total Cost of Ownership (TCO) review tells a different story. The hidden costs of fire barriers, oil containment, environmental liability, and intensive maintenance often exceed the initial savings. In contrast, DTDTs combine lower operational risk, shorter installation time, and simplified compliance—a decisive advantage for EPC contractors, developers, and facility owners seeking predictable project outcomes.

Strategic transformer specification now depends on engineering foresight rather than price comparison alone:

- Model the total installed cost: Include auxiliary civil works, energy losses, and maintenance.

- Match insulation to environment: Choose Cast Resin for coastal or humid conditions, VPI for clean indoor sites.

- Verify standard alignment: Ensure thermal design matches the local climate—IEC (20 °C base) vs ANSI (30 °C base).

- Secure reliable testing and certification: Confirm IEC 60076 or IEEE compliance and full type-test reports.

For decision-makers overseeing critical infrastructure, DTDTs provide long-term stability, regulatory assurance, and lifecycle cost efficiency. Choosing the right manufacturer—one with verified engineering depth, certified production, and responsive after-sales support—turns this technology from a compliance measure into a long-term operational advantage.

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group