What is an Autotransformer: The Efficient Power Converter You Need to Know About?

What is an Autotransformer: The Efficient Power Converter You Need to Know About?

Are you tired of bulky transformers eating up space and energy? There’s a smarter solution you might be overlooking.

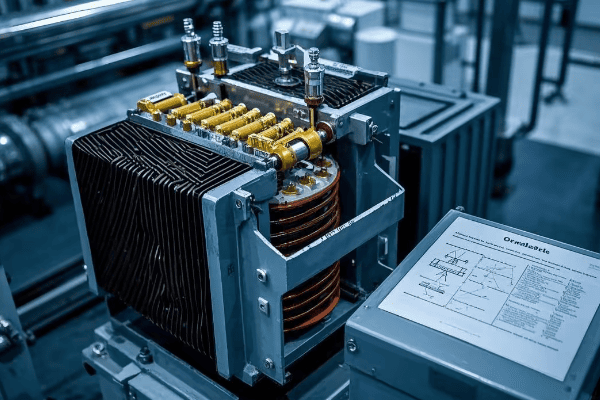

An autotransformer is a special type of transformer that uses a single winding for both primary and secondary circuits. It offers higher efficiency, smaller size, and lower cost compared to traditional transformers, making it ideal for various voltage conversion applications.

As an electrical engineer with years of experience in power systems, I’ve seen firsthand how autotransformers can revolutionize energy conversion. Let’s dive into the world of autotransformers and discover why they might be the solution you’ve been searching for.

How Does an Autotransformer Work: Unveiling the Basics of This Unique Transformer?

Have you ever wondered how a transformer can be more efficient? The secret lies in its unique design.

An autotransformer works by using a single winding as both the primary and secondary coils. It has a common portion shared by both circuits, allowing for direct electrical connection and more efficient power transfer.

I remember the first time I saw an autotransformer in action. Its simplicity and efficiency amazed me. Let’s break down how these clever devices work:

The Basics of Autotransformer Operation

-

Single Winding: Unlike traditional transformers with separate primary and secondary windings, an autotransformer uses a single winding.

-

Tapped Winding: The winding has taps at different points, creating sections for input and output.

-

Common Section: Part of the winding is shared between the input and output circuits.

-

Electrical Connection: There’s a direct electrical connection between the input and output, not just magnetic coupling.

How Voltage Conversion Happens

The voltage conversion in an autotransformer depends on the ratio of turns between the common section and the whole winding. Here’s a simple way to understand it:

| Section | Turns | Voltage |

|---|---|---|

| Whole Winding | N | V |

| Common Section | n | v |

The voltage ratio is proportional to the turns ratio:

V / v = N / n

For example, if you have 1000 turns total and tap at 900 turns, you can convert 1000V to 900V.

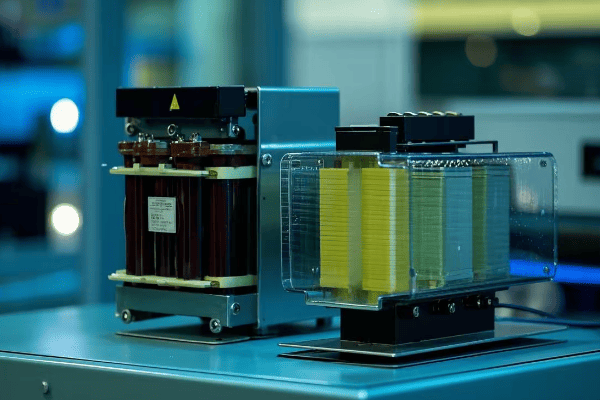

Types of Autotransformers

- Step-Up Autotransformer: Increases voltage

- Step-Down Autotransformer: Decreases voltage

- Variable Autotransformer (Variac): Allows for adjustable output voltage

I once worked on a project where we replaced a traditional transformer with an autotransformer in a power distribution system. The energy savings and reduced space requirements were impressive. The client was thrilled with the results.

Advantages of Autotransformer Design

- Higher Efficiency: Less power loss due to the shared winding

- Smaller Size: Requires less copper and iron core material

- Lower Cost: Fewer materials mean lower production costs

- Better Voltage Regulation: Often provides tighter voltage control

Limitations to Consider

- No Electrical Isolation: Input and output are not electrically isolated

- Limited Voltage Change: Most effective for voltage changes less than 2:1

- Higher Short-Circuit Current: Can be a safety concern in some applications

Understanding how autotransformers work is key to appreciating their benefits and limitations. In my experience, they’re often the best choice for applications requiring small voltage adjustments or where space and efficiency are prime concerns. However, it’s crucial to consider the lack of isolation in safety-critical applications.

Autotransformer vs. Traditional Transformer: Key Differences and Advantages?

Wondering why you should choose an autotransformer over a traditional one? The differences might surprise you.

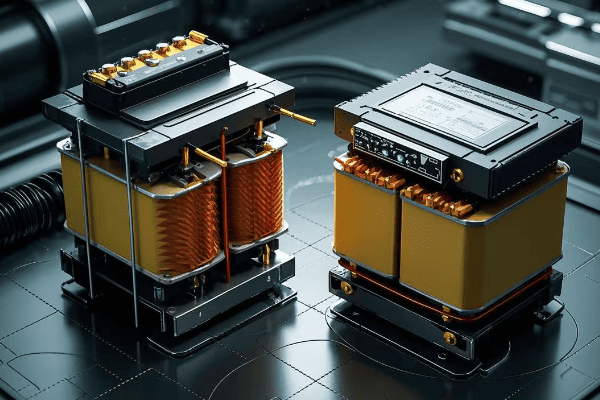

Autotransformers offer higher efficiency, smaller size, and lower cost compared to traditional transformers. However, they lack electrical isolation, making traditional transformers better for applications where safety isolation is crucial.

In my years of working with both types, I’ve seen how choosing the right transformer can make or break a project. Let’s compare these two transformer types:

Key Differences

| Feature | Autotransformer | Traditional Transformer |

|---|---|---|

| Windings | Single, tapped | Two separate |

| Electrical Isolation | No | Yes |

| Size | Smaller | Larger |

| Efficiency | Higher | Lower |

| Cost | Lower | Higher |

| Voltage Ratio | Limited range | Wide range |

Advantages of Autotransformers

-

Higher Efficiency

- Less copper loss due to shared winding

- Typically 98-99% efficient vs. 95-98% for traditional transformers

-

Smaller Size and Weight

- Up to 50% reduction in size for similar ratings

- Ideal for space-constrained applications

-

Lower Cost

- Less material used in construction

- Can be 20-30% cheaper than equivalent traditional transformers

-

Better Voltage Regulation

- Often provides more precise voltage control

- Useful in applications requiring tight voltage tolerances

Advantages of Traditional Transformers

-

Electrical Isolation

- Provides safety barrier between primary and secondary

- Essential in many industrial and medical applications

-

Wide Voltage Range

- Can handle large step-up or step-down ratios

- Suitable for a broader range of applications

-

Fault Isolation

- Prevents fault propagation between primary and secondary

-

Separate Grounding

- Allows for different grounding schemes on primary and secondary sides

I once worked on a project where we initially specified a traditional transformer for a voltage adjustment in a factory. After analyzing the requirements, we realized an autotransformer could do the job more efficiently and at a lower cost. The change saved the client significant money and reduced energy losses.

When to Choose Each Type

Choose an Autotransformer When:

- You need small voltage adjustments (less than 2:1 ratio)

- Space and weight are at a premium

- Efficiency is a top priority

- Electrical isolation is not required

Choose a Traditional Transformer When:

- Electrical isolation is necessary for safety

- You need large voltage step-up or step-down

- Separate grounding schemes are required

- Fault isolation between circuits is crucial

Safety Considerations

It’s important to note that the lack of isolation in autotransformers can be a significant safety concern in some applications. In my experience, this is particularly crucial in:

- Medical equipment

- Sensitive electronic devices

- Applications with potential ground faults

Always consult safety standards and regulations when deciding between autotransformers and traditional transformers.

Understanding these differences is crucial for making the right choice in your power system design. While autotransformers offer significant advantages in efficiency and size, traditional transformers still have their place, especially where safety isolation is paramount. In my career, I’ve found that carefully weighing these factors leads to the most successful and cost-effective solutions.

Applications of Autotransformers: From Home Appliances to Industrial Power Systems?

Ever wondered where those efficient autotransformers are hiding? They’re more common than you might think!

Autotransformers are used in a wide range of applications, from household voltage converters to large-scale power distribution systems. Their efficiency and compact size make them ideal for voltage regulation, motor starting, and power transmission.

Throughout my career, I’ve encountered autotransformers in surprisingly diverse settings. Let’s explore some of the most common and interesting applications:

Home and Office Applications

-

Voltage Converters

- For international travelers to use 110V appliances in 220V countries (and vice versa)

- I once used a small autotransformer to power my laptop during an overseas work trip

-

Dimmer Switches

- Variable autotransformers used in lighting control

- Provide smooth dimming for incandescent and some LED lights

-

Home Theater Systems

- Used in some audio equipment for impedance matching

- Can improve sound quality in high-end systems

Industrial Applications

-

Motor Starting

- Reduce inrush current when starting large motors

- I’ve implemented these in factories to prevent voltage dips during motor start-up

-

Voltage Regulation

- Maintain stable voltage in industrial processes

- Crucial in sensitive manufacturing operations

-

Welding Equipment

- Provide variable voltage control in welding machines

- Allow welders to adjust power output for different materials

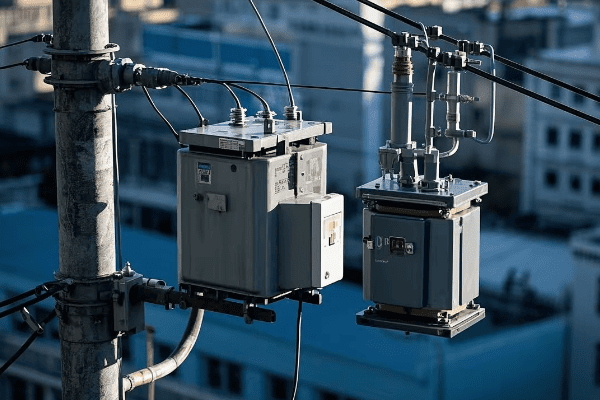

Power Distribution Applications

-

Transmission Line Interconnection

- Connect power grids with slightly different voltages

- I’ve worked on projects linking regional grids using large autotransformers

-

Substation Voltage Control

- Fine-tune voltage levels in power distribution networks

- Help maintain consistent voltage for end-users

-

Renewable Energy Integration

- Adjust voltage levels from wind or solar farms to match grid requirements

- Becoming increasingly important in the green energy transition

| Application | Voltage Range | Key Benefit |

|---|---|---|

| Home Voltage Converters | 110V – 220V | Compact size |

| Motor Starting | Up to 11kV | Reduced inrush current |

| Grid Interconnection | Up to 765kV | Efficient power transfer |

Specialized Applications

-

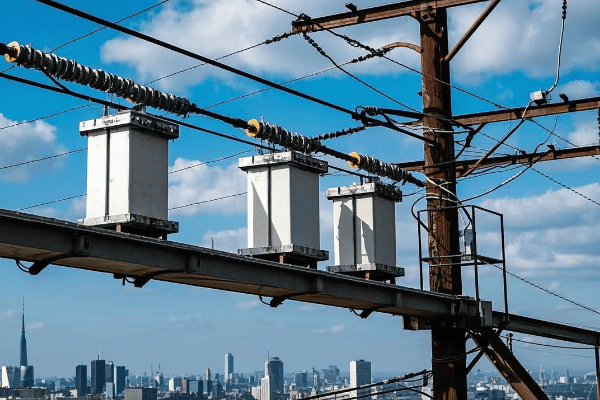

Railway Systems

- Convert grid power to appropriate voltage for electric trains

- I’ve consulted on projects upgrading railway power systems

-

Testing Equipment

- Provide variable voltage in laboratory and testing environments

- Essential in quality control and product development

-

HVDC Converter Stations

- Used in the conversion process between AC and DC in high-voltage transmission

- Play a crucial role in long-distance power transmission

Considerations in Choosing Autotransformers

When selecting autotransformers for specific applications, consider:

- Voltage Range: Ensure it covers the required input and output voltages

- Power Rating: Must handle the maximum expected load

- Efficiency: Important for energy-intensive applications

- Size and Weight: Critical in space-constrained installations

- Cooling Method: Air-cooled or oil-cooled depending on the environment

- Control Features: Manual or automatic voltage adjustment

In my experience, the versatility of autotransformers makes them a go-to solution for many voltage conversion needs. However, it’s crucial to remember their limitations, particularly the lack of electrical isolation. In applications where safety isolation is paramount, traditional transformers remain the better choice.

The wide range of applications for autotransformers demonstrates their importance in our electrical systems. From the small converter in your travel bag to the massive units in power substations, these efficient devices play a vital role in ensuring our electrical systems run smoothly and efficiently.

The Efficiency Factor: Why Autotransformers Are Gaining Popularity?

Wondering why autotransformers are becoming the go-to choice for many engineers? The answer lies in their impressive efficiency.

Autotransformers are gaining popularity due to their high efficiency, often reaching 98-99%. This efficiency comes from their unique design, which reduces copper losses and core losses compared to traditional transformers.

In my years of designing and implementing power systems, I’ve seen a clear trend towards autotransformers in many applications. Let’s dive into why they’re so efficient:

Sources of Efficiency in Autotransformers

-

Reduced Copper Losses

- Single winding design means less copper used

- Lower resistance in the windings

-

Smaller Core

- Less iron needed in the core

- Reduces core losses from hysteresis and eddy currents

-

Direct Electrical Connection

- Part of the power is transferred conductively, not just inductively

- Results in less overall power loss

Efficiency Comparison

| Transformer Type | Typical Efficiency | Losses |

|---|---|---|

| Autotransformer | 98-99% | 1-2% |

| Traditional Transformer | 95-98% | 2-5% |

I once worked on a project upgrading a factory’s power distribution system. By replacing several traditional transformers with autotransformers, we achieved a 2% increase in overall system efficiency. This translated to significant energy savings for the client.

Factors Affecting Autotransformer Efficiency

-

Voltage Ratio

- Most efficient for small voltage changes (less than 2:1)

- Efficiency decreases for larger voltage differences

-

Load Factor

- Operate most efficiently near rated load

- Efficiency can drop at very low or very high loads

-

Core Material

- High-quality silicon steel or amorphous metals improve efficiency

- I’ve seen modern core materials push efficiencies even higher

-

Winding Design

- Optimized winding layouts reduce losses

- Advanced winding techniques can further improve efficiency

Real-World Benefits of High Efficiency

-

Energy Savings

- Lower losses mean less wasted energy

- Can result in significant cost savings over time

-

Reduced Heat Generation

- Less energy lost as heat

- Can simplify cooling requirements

-

Environmental Impact

- Lower energy consumption reduces carbon footprint

- Aligns with green energy initiatives

-

Improved System Performance

- Higher efficiency can mean better voltage regulation

- Reduces stress on other system components

Calculating Efficiency Gains

To understand the impact, let’s look at a simple calculation:

Assume a 1000 kVA transformer operating 24/7:

- Traditional Transformer (97% efficient): 30 kW losses

- Autotransformer (99% efficient): 10 kW losses

Annual Energy Savings: (30 kW – 10 kW) 24 hours 365 days = 175,200 kWh

This can translate to substantial cost savings and reduced environmental impact.

Limitations and Considerations

While efficiency is a major advantage, it’s important to consider other factors:

- Safety: Lack of electrical isolation can be a concern in some applications

- Voltage Range: Less suitable for large voltage transformations

- Initial Cost: While often cheaper, high-efficiency models can have higher upfront costs

In my experience, the efficiency benefits of autotransformers make them an excellent choice for many applications, especially where small voltage adjustments are needed. However, it’s crucial to balance efficiency with other requirements like safety and voltage range when making a selection.

The growing popularity of autotransformers is a testament to the industry’s focus on energy efficiency. As we continue to seek ways to reduce energy consumption and improve system performance, autotransformers will likely play an increasingly important role in our power systems.

Safety Considerations: Understanding the Risks and Precautions of Autotransformers?

Concerned about the safety of autotransformers? You’re right to be cautious – these efficient devices come with unique safety considerations.

Autotransformers lack electrical isolation between input and output, which can lead to higher fault currents and potential shock hazards. Proper installation, grounding, and protective measures are crucial to ensure safe operation.

In my years working with power systems, I’ve learned that understanding and respecting the safety aspects of autotransformers is crucial. Let’s explore the key safety considerations:

Primary Safety Concerns

-

Lack of Electrical Isolation

- Input and output circuits are electrically connected

- Can lead to propagation of faults between circuits

-

Higher Fault Currents

- Short circuits can result in extremely high currents

- Requires robust protection systems

-

Potential for Electric Shock

- Ground faults can energize the entire system

- Increases risk to personnel and equipment

-

Voltage Surge Transmission

- Surges on input side can directly affect output side

- May damage connected equipment

Safety Measures and Precautions

| Safety Measure | Purpose | Implementation |

|---|---|---|

| Proper Grounding | Prevent shock hazards | Connect to earth ground |

| Safety Measure | Purpose | Implementation |

| —————- | ——— | —————– |

| Proper Grounding | Prevent shock hazards | Connect to earth ground |

| Overcurrent Protection | Prevent damage from faults | Install circuit breakers or fuses |

| Insulation | Prevent direct contact | Use appropriate insulation materials |

| Enclosure | Restrict access to live parts | Install in locked cabinets |

| Warning Labels | Inform about hazards | Apply clear, visible warning signs |

I once worked on a project where an improperly grounded autotransformer led to a near-miss incident. It was a stark reminder of the importance of following safety protocols meticulously.

Best Practices for Safe Operation

-

Proper Installation

- Follow manufacturer guidelines and local electrical codes

- Ensure adequate ventilation to prevent overheating

-

Regular Maintenance

- Conduct periodic inspections for signs of wear or damage

- Test insulation resistance regularly

-

Operator Training

- Educate personnel on specific risks associated with autotransformers

- Provide training on emergency procedures

-

Protective Equipment

- Use appropriate personal protective equipment (PPE) when working with autotransformers

- Install protective barriers around high-voltage areas

-

Fault Protection

- Implement fast-acting fault detection and isolation systems

- Use differential protection schemes for larger units

Special Considerations for Different Applications

-

Industrial Settings

- Implement lockout/tagout procedures during maintenance

- Consider the impact of harmonics and power quality

-

Residential Use

- Ensure autotransformers for home use are certified by recognized safety organizations

- Educate users on proper usage and potential risks

-

Power Distribution

- Implement redundant protection schemes

- Consider the impact on system stability during faults

Regulatory Compliance

Adhering to safety standards is crucial. Key regulations include:

- IEEE C57.12.00 for general requirements

- NEMA ST 1 for specialty transformers

- IEC 61558 for safety of transformers and power supplies

In my experience, staying up-to-date with these standards is essential for ensuring the safe design and operation of autotransformer systems.

Emerging Safety Technologies

The field of transformer safety is constantly evolving. Some recent innovations include:

-

Smart Monitoring Systems

- Real-time monitoring of temperature, current, and voltage

- Early detection of potential issues

-

Advanced Protection Relays

- Faster and more accurate fault detection

- Improved discrimination between normal and fault conditions

-

Arc Flash Mitigation

- Techniques to reduce the risk and severity of arc flash incidents

- Critical in high-power applications

While autotransformers offer significant benefits in terms of efficiency and size, their unique design requires a thoughtful approach to safety. By understanding the risks and implementing proper precautions, we can harness the advantages of autotransformers while ensuring the safety of personnel and equipment.

Sizing and Selection: Choosing the Right Autotransformer for Your Needs?

Struggling to find the perfect autotransformer for your application? You’re not alone in this complex decision-making process.

Selecting the right autotransformer involves considering factors like voltage ratio, power rating, efficiency, physical size, and specific application requirements. Proper sizing ensures optimal performance, energy efficiency, and longevity of the system.

Throughout my career, I’ve guided many clients through the autotransformer selection process. Let me share some key insights to help you make an informed decision:

Key Factors in Autotransformer Selection

-

Voltage Ratio

- Determine input and output voltage requirements

- Autotransformers are most efficient for ratios less than 2:1

-

Power Rating

- Calculate the maximum load the autotransformer will handle

- Include a safety margin for potential future load increases

-

Efficiency Requirements

- Consider energy costs over the autotransformer’s lifetime

- Higher efficiency models may have higher upfront costs but lower operating costs

-

Physical Size and Weight

- Ensure the autotransformer fits in the available space

- Consider installation and transportation requirements

-

Environmental Conditions

- Assess temperature, humidity, and altitude at the installation site

- Choose appropriate cooling methods (air-cooled or oil-cooled)

Sizing Calculations

Here’s a simple approach to sizing:

- Determine load power: P (Watts)

- Calculate input current: I = P / V_in

- Determine voltage ratio: K = V_out / V_in

- Calculate autotransformer rating: S = P * (1 – K)

For example, for a 10 kW load, 240V input, 208V output:

K = 208/240 = 0.867

S = 10,000 * (1 – 0.867) = 1,330 VA

Selection Table

| Application | Typical Voltage Ratio | Power Range | Key Considerations |

|---|---|---|---|

| Home Voltage Conversion | 2:1 or 1.5:1 | 100VA – 5kVA | Portability, safety |

| Industrial Motor Starting | 1.1:1 to 1.5:1 | 10kVA – 1MVA | Inrush current handling |

| Grid Voltage Regulation | 1.1:1 to 1.2:1 | 1MVA – 100MVA | Efficiency, tap changing |

I once worked on a project where a client initially undersized their autotransformer for a motor starting application. The result was frequent tripping and potential motor damage. We rectified the issue by properly sizing the autotransformer to handle the inrush current, which solved the problem and improved overall system reliability.

Application-Specific Considerations

-

Motor Starting

- Size for inrush current (typically 5-7 times full load current)

- Consider duty cycle and starting frequency

-

Voltage Regulation

- Evaluate required voltage adjustment range

- Consider tap changing mechanisms for variable output

-

Power Distribution

- Assess load growth projections

- Consider redundancy requirements

-

Renewable Energy Integration

- Evaluate variability of input voltage from renewable sources

- Consider harmonics and power quality issues

Advanced Selection Criteria

-

Harmonic Handling

- For non-linear loads, consider K-factor rated autotransformers

- Evaluate total harmonic distortion (THD) in the system

-

Short Circuit Impedance

- Important for fault current limitation

- Typically ranges from 2% to 5% for autotransformers

-

Noise Level

- Critical for installations near occupied areas

- Measured in decibels (dB), lower is better for noise-sensitive environments

-

Overload Capacity

- Determine if short-term overloads are expected

- Some autotransformers can handle 20-30% overloads for short periods

Tools and Resources for Selection

-

Manufacturer Selection Guides

- Most reputable manufacturers provide detailed selection tools

- Often include software for precise sizing calculations

-

Industry Standards

- Refer to IEEE, IEC, and NEMA standards for guidance

- Ensure compliance with relevant local codes

-

Simulation Software

- Use power system simulation tools for complex applications

- Helps in analyzing system-wide impacts of autotransformer selection

Choosing the right autotransformer is crucial for the success of your project. It’s not just about meeting current needs but also anticipating future requirements. In my experience, taking the time to thoroughly analyze your needs and consult with experts can save significant costs and headaches down the line.

Remember, the cheapest option is not always the most cost-effective in the long run. Consider the total cost of ownership, including energy costs and maintenance, when making your selection. With careful consideration of these factors, you can select an autotransformer that will serve your needs efficiently and reliably for years to come.

Conclusion

Autotransformers offer efficient, compact, and cost-effective solutions for voltage conversion in various applications. Understanding their operation, advantages, and safety considerations is crucial for optimal selection and use. As technology advances, autotransformers will continue to play a vital role in power systems.

🚀Next steps, you can:

A. Assess your specific voltage conversion needs

B. Consult with an electrical engineer for personalized advice

C. Explore energy efficiency improvements in your power systems

D. Learn about safety protocols for working with autotransformers

E. Stay updated on the latest developments in transformer technology

F. Consider the role of autotransformers in renewable energy integration

Free CHBEB Transformer Catalog Download

Get the full range of CHBEB transformers in one catalog.

Includes oil-immersed, dry-type, pad-mounted, and custom solutions.

Quick Message

Request A free quote

- +86 15558785111

- [email protected]

- +86 15558785111

CHINA BEI ER BIAN (CHBEB) GROUP, with 218 million in registered capital, originated from Beijing Beierbian Transformer Group. Headquartered in Beijing for R&D, it operates major production bases in Nanjing and Yueqing, producing high-quality products.

No 3,RongJing East Road,BeiJing Economic Technological Development Area,BeiJing,China

No 7️Xiangfeng Road,Jiangning,NanJing,JiangSu,China

No.211, Wei 16 Road, Industrial Zone, Yueqing, Wenzhou, Zhejiang, China.

XiangYang Industrial Zone ,YueQing,WenZhou,ZheJiang,China

- [email protected]

- +86 13057780111

- +86 13057780111

- +86 15558785111

Copyright © Bei Er Bian Group